Flexible Structures Final

1/97

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

98 Terms

Tufting

Sewing (stitching) of surface yarns onto a primary backing

Tufted Carpet Structure

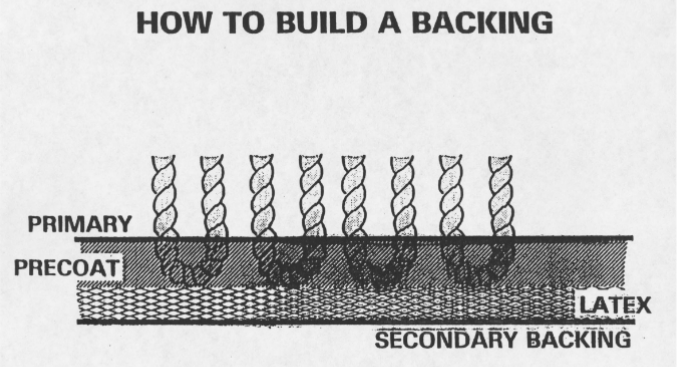

Surface yarns (nylon, polyester, cotton), primary backing (usually woven or split film polypropylene yarns), coating (latex), and secondary backing (either spun jute or fibrillated polypropylene yarns).

Needle Gauge

Number of needles per unit width

Stitches per minute

the rate of reciprocal up and down motions by the needle bar (it is also equal to the speed of the needle bar in revolutions per minute, rpm)

Stitches per inch

spacing of the needle bar stitches along the machine (or vertical) direction of the fabric

Pile height

the distance of the loops below the primary fabric

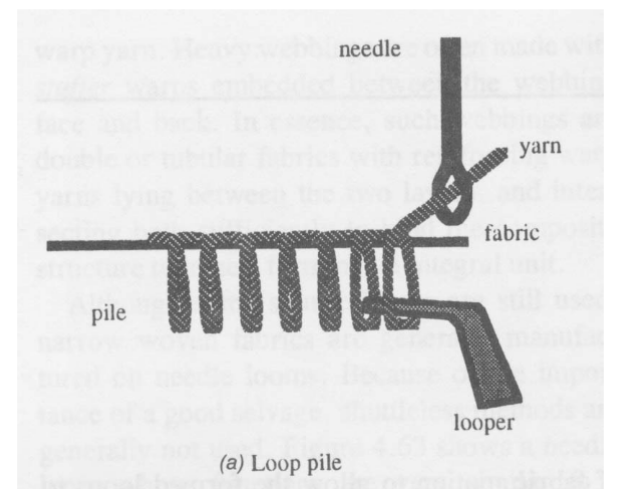

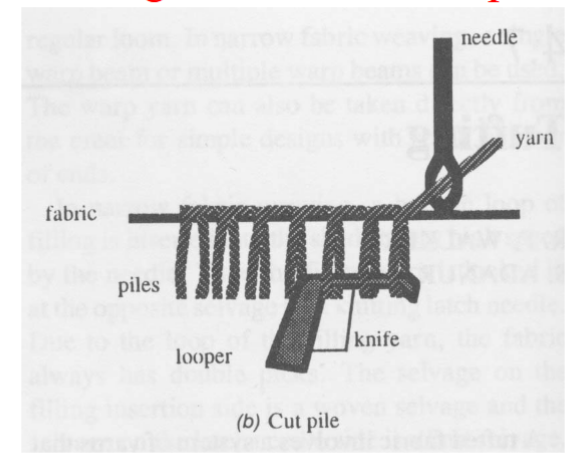

Tufting elements for loop pile

Various Surface Elements

By using different types of loopers, knives and yarn feed control, the following effects can occur:

Level loops

Multi Level Loops

Level cut loops

Multi Level cut and uncut loops

Level cut and uncut loops

Tufting Elements for cut pile

How to build a backing

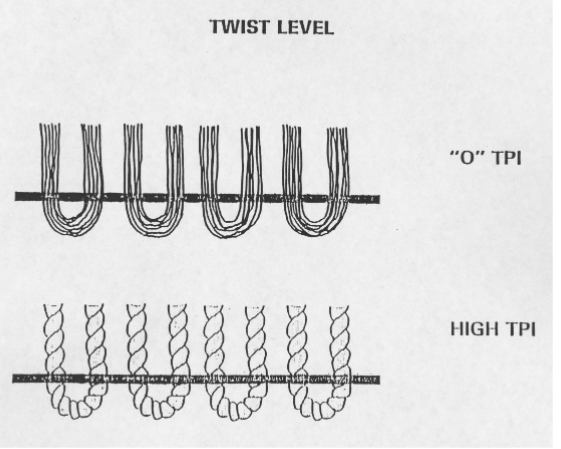

Twist Level

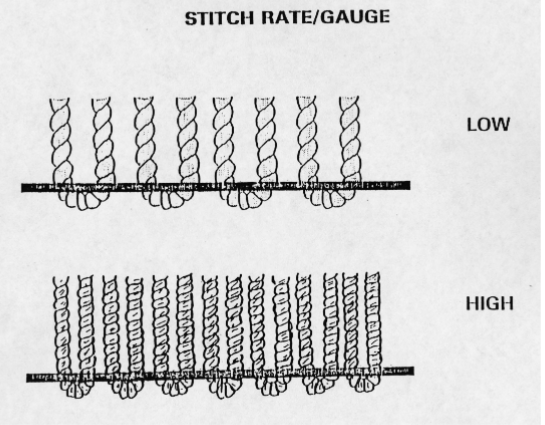

Stitch rate/gauge

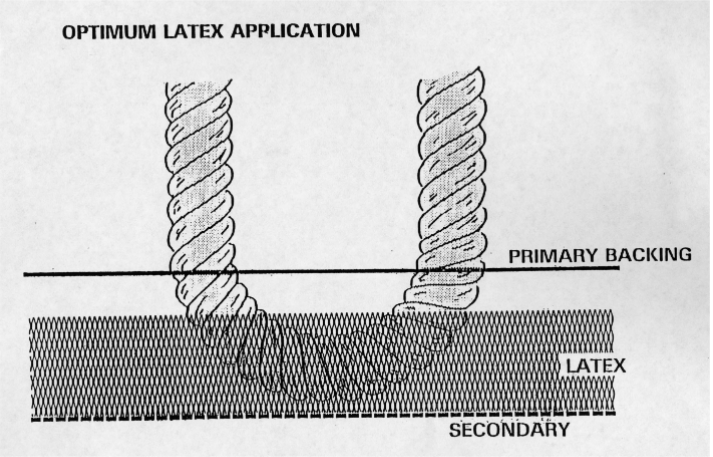

Optimum Latex application

Saxony Carpet

Cut-pile carpet

Highly twisted yarn

Evenly sheared

Medium length pile yarns

Plush Carpet

Cut-pile carpet

Pile yarns are slightly twisted, dense and very evenly sheared

Has the look of a solid, flat velvet surface

Shag Carpet

Loosely tufted carpet construction

Cut pile of 1-5 inches

Greater than normal spacing between tufts

Markets for Carpet

Homes (consumer)

Business institutions

Indoor

Outdoor

Factors for Carpet Selection

Location and traffic pattern

Frequency and kind of cleaning

Flammability

Nature of the environment

Static control

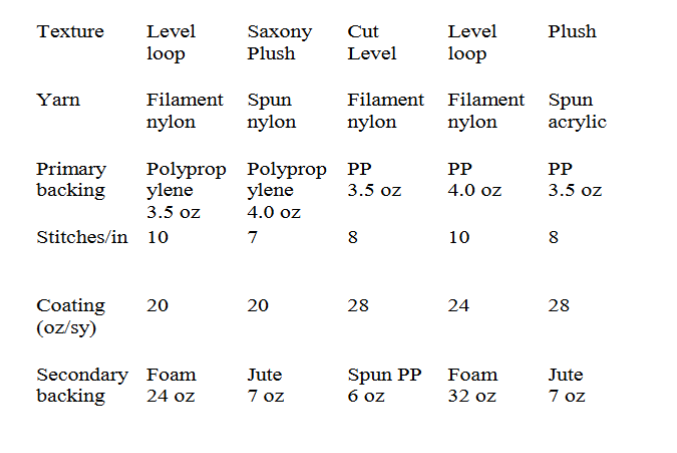

Typical Carpet Styles

Primary Backing

Jute (8-10 oz/sy)

Split film woven polypropylene (3-4 oz)

Polypropylene film sheet

Cotton duck

The secondary backing is added to provide…

Increased thickness (resilience, hand, insulation)

Dimensional stability

Improvement in locking tufts

Resistance to fraying

Skid resistance

The secondary backing fabric must…

Be dimensionally stable

Stick to the adhesive which binds it to the carpet

Resist environmental degradation

Tufted Fabric Control

Secondary Backing (type, composition construction)

Primary backing (type, composition construction)

Surface fiber (material, characteristics i.e: type, length, denier)

Yarn

Fabric

Coloration

Finish (shearing, brushing, final inspection)

Braiding

Simplest form of fabric formation: diagonal intersection of yarns

Braiding Industrial Applications

Electrical wires and cables

Harnesses

Hoses and belts

Surgical sutures

Composite reinforcements

Reinforcement structure of sporting goods

Braiding Manufacturing

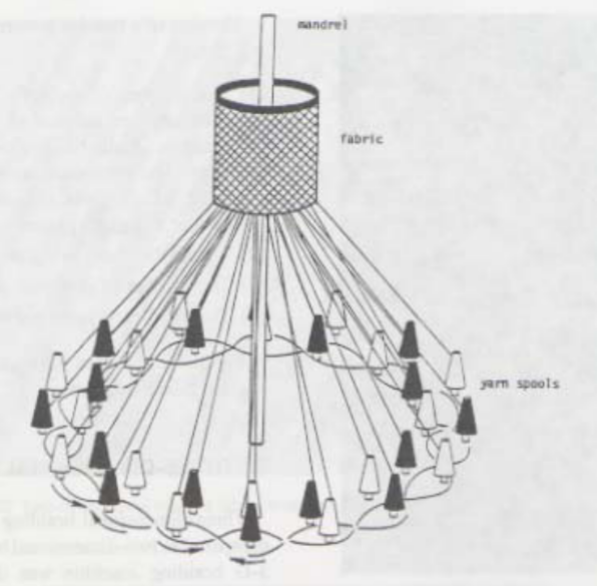

Geometry directly related to the machine that forms the fabric

2D Brading

Circular Braiding (Maypole and rotary)

3D Braiding

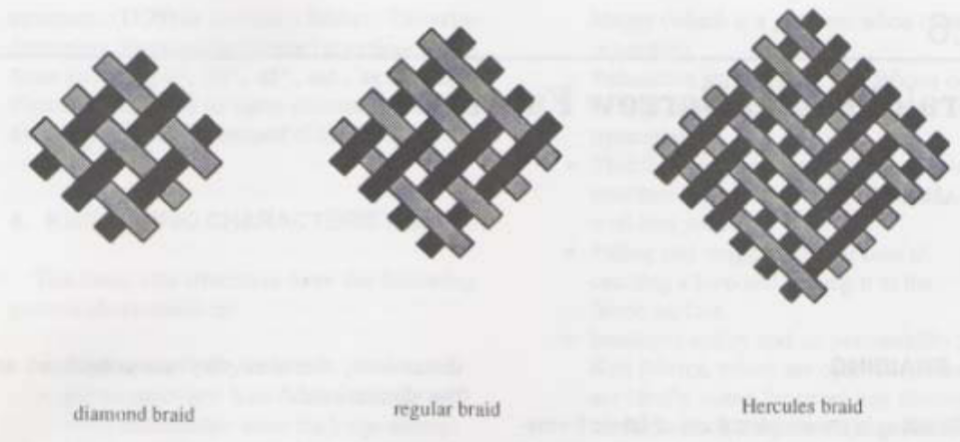

Common 2D Braiding Patterns

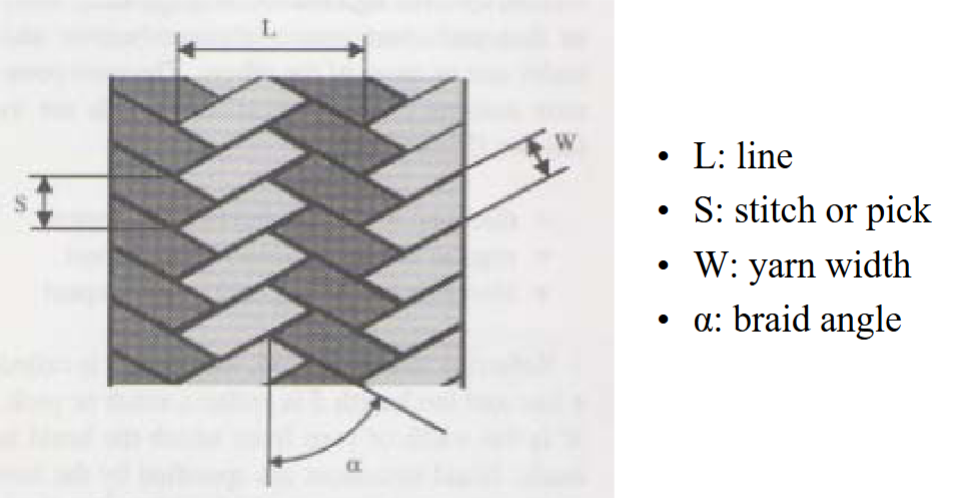

Braiding Fabric Parameters

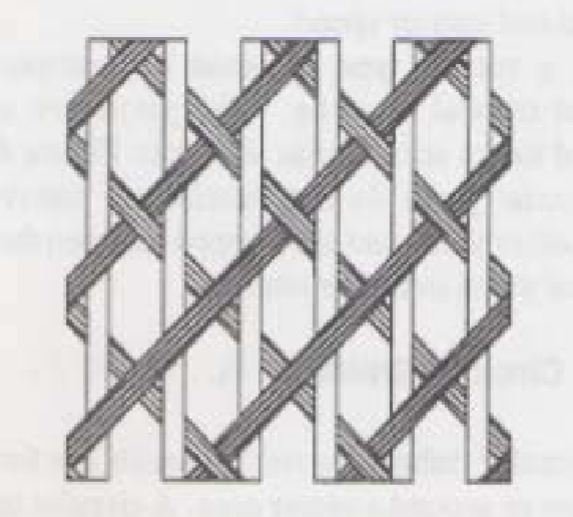

Triaxial Braid

Schematic of Maypole Braiding

Size of Braid is governed by…

The number of carriers

Tubular braids: even number of carriers

Flat braids: odd number of carriers

Diameter of the yarns

Number of yarn ends per carrier

Number of yarns per unit length

Narrow Fabrics

Less than 12 inches (30 cm) in width

Woven selvage

Examples are Ribbons, Tapes, and Webbings

Narrow Fabrics Manufacturing

Several sets of warp yarns may be beamed to make several narrow fabrics, side-by-side on the same loom

A full width thermoplastic fabric can be cut into strips; edges are sealed, forming ribbons

Elastic webbing or tape is made by using bare or wrapped rubber warp yarn

Heavy webbings are made with stuffer warps

Single warp beam or multiple beams

Warp yarn can be taken from the creel directly

Needle inserts a loop of filling yarn into the shed at a high speed

Essential Fiber Properties for Architecture and Construction

Synthetic Fibers

Good strength

Hydrophobicity

Rot and fungi resistant

UV resistant

Temperature resistant

Biological resistance

Weather resistant

Advantages of Fibers in Construction

Weight

1/30th of the conventional weight of bricks and steel

Large, obstruction-free spans

Shorter erection time of the fabric envelope

Mechanical damage due to wear is restricted to a small area by the fabric structure

Damage can be easily repaired

Resistance to Earthquakes

Freedom to design various shapes and appearances

Film Membrane Structure

Transparent polymers in sheet form without coating or lamination

Clear vinyl, polyester or polyethylene

Less expensive and durable

Mesh Membrane Structure

Porous fabrics that are lightly coated with vinyl

Knitted meshes

High density polyethylene, polypropylene or acrylic yarns

Used as shelters from wind and sun

Not as much rain protection

Fabric Structures

The most widely used membrane structures

Coated or laminated to improve strength and environmental resistance

Coated Fabrics

“Envelope” of large building constructions

Airports, stadiums, sports halls

Schematic of a Laminate

Typical requirements for fabrics in construction

Resistance to deformation and extension under tension

Waterproof

Impermeable to air and wind

Resistant to abrasion and mechanical damage

Resistance to sunlight and acid rain

Base Fibers

Made of synthetic fibers

Carrier layer

Provides the necessary strength to the structure

High tenacity polyester

Fiberglass

Nylon

Continuous filament yarns

Inherent strength

Elongation resistance

Low yarn twist to carry higher tensile loads

Hydrophobic materials

Base Fabrics Manufacturing

Woven (plain, low-harness twill)

Warp tension not to exceed 9 N/tex during weaving

Rapier, projectile, air-jet and water-jet

Width up to 5m

Knit (warp-knit)

Nonwoven stitch bonded

Heat-setting usually not required

Coating and Laminating

Provides waterproofness

Protects base fabric from sunlight and weathering degradation

Polyester Fabrics

Usually coated or laminated with PVC films

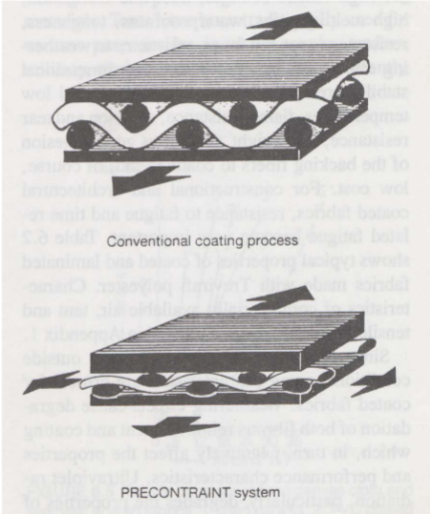

Precontraint process used to improve dimensional stability

Fiberglass Fabrics

Usually coated with PTFE for durability

PTFE coated fiberglass is the only material that meets the US model building codes definition of non-combustible materials

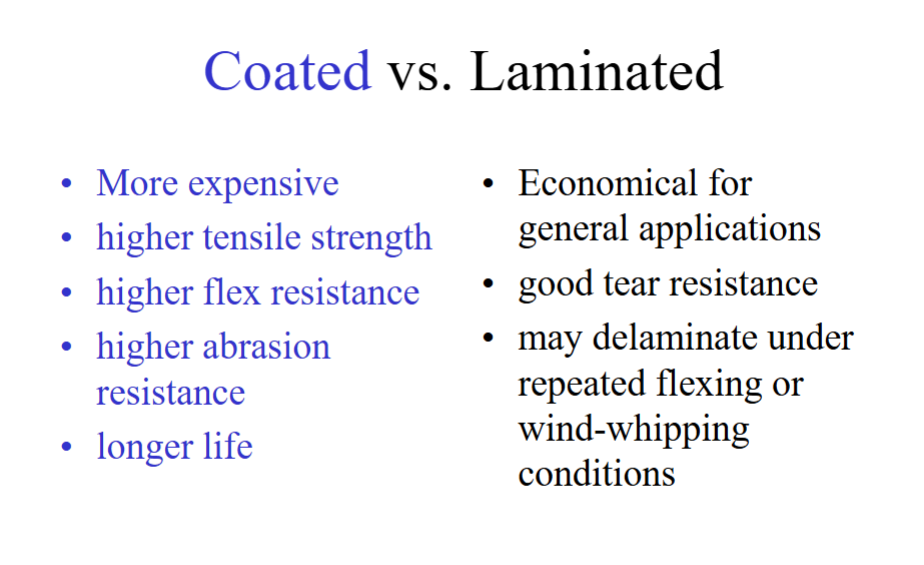

Coated vs. Laminated

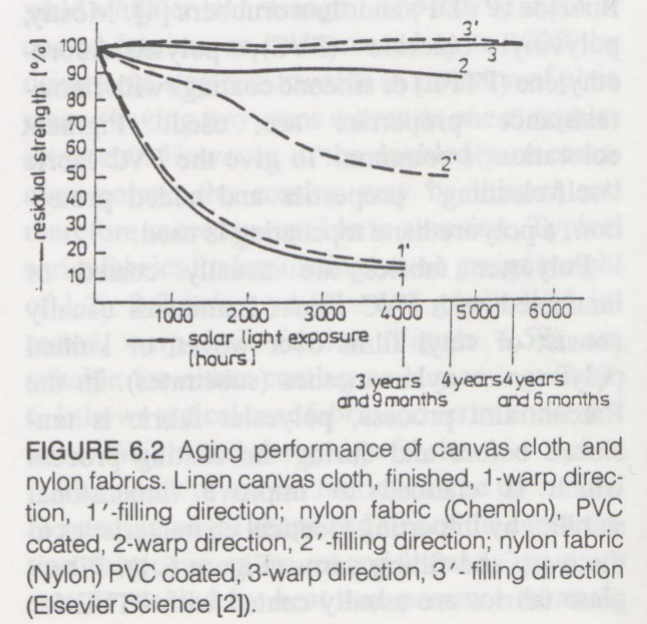

Aging of Fabrics

Weather effects and Residual strength

Application of Coated Fabrics in Building Structures

Membrane structures

Tents

Clear-span structures

Air structures

Tensile structures

Most widely used structures

PVC coated polyester

PTFE coated woven fiberglass

Silicone coated fiberglass

Tents

Probably the first constructions

Used by nomadic people, traders, military, explorers and campers

New tents for building construction, businesses, exhibits, leisure and recreation

Typical materials for tent walls include polyesters, nylon and vinyls

Pole Tents

Fabric is draped or hung

Mass produced

Tension tent

Fall between tents and tensile structures

Provides clear span

Does not require ropes or cords

Mass produced

Clear-Span Structures

Provides clear space beneath the fabric

Free of poles and other supporting elements

Fabric is pulled taut through channels in the frame’s ribs

More permanent than tents and less permanent than air or tensile structures

Can accommodate doors, flooring, insulation and HVAC

PVC coated polyester

Tension Structures

Metal bars, tensioning cables, wooden or metal frameworks

Fabric carries most of the load

Curvilinear structures

Fabric is highly tensioned

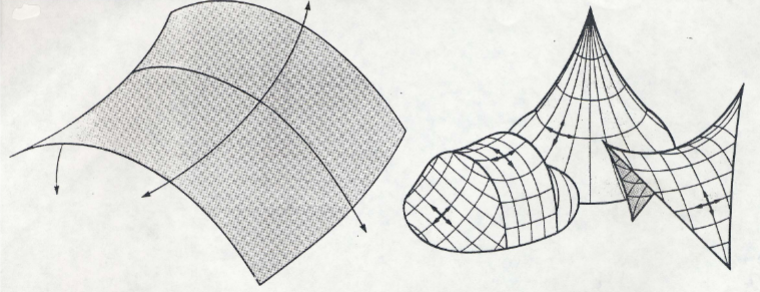

Schematic of Tension Structures

Basic building block shapes

Hyperbolic paraboloid

Hyperboloid

Fabric is double curved

Curvatures opposing each other from a single intersecting point

Crossed arc appears parabolic in cross section and as an “X” from above

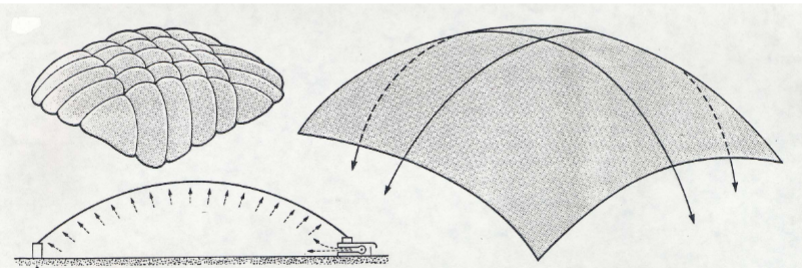

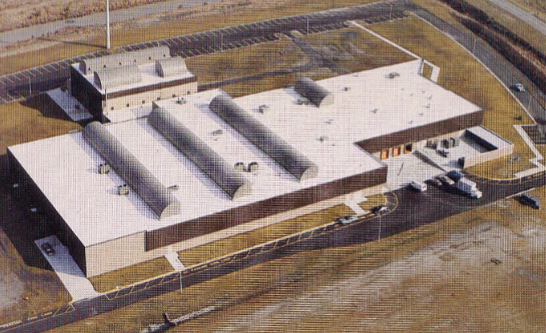

Air Structures

Air Supported System

Air pressure inside the envelope

Provides tensioning

Maintains required configuration and stability

Main components

Envelope (fabric)

Inflation system (fans)

Anchorage systems (cables and foundation)

Doors and access equipment

Pressure 0.3% above the ambient pressure

PVC coated polyester is the most used

Pressurized air-supported structure

History of Air Pressurized Structures

Collapse of some large-scale stadium domes in the early 80s

Well-built air structures are stable and strong

Modular buildings

Can be designed for nearly any shape

Surfaces are curved

Air Inflated Ribs (Air Beams)

Pressurized air-inflated support tubes

Wide diameter (42 inches)

Low pressure (4-10 psi)

Narrow diameter (4-18 inches)

High pressure (30-100 psi)

Mostly for lightweight, easy to transport military structures

Polyester and nylon

Safety tarpaulins for cold weather construction

Waterproof. flame retardant tarpaulins

Cold weather construction

Usually polyester fabrics (6-8 ounces)

Designing with Coated Fabrics

Three types of stresses

Stresses due to applied load tension in the fabric

Weight of suspended fabric

Stresses induced by natural forces die to wind, rain and snow

Textiles as Roofing Materials

Single-ply and multi-ply materials

Traditional built-up roofing (BUR)

Alternating plies of felts, fabrics and mats are bonded together with asphalt or coal tar

Single ply roofing

Introduced in the 1960s in the US

Used mostly in commercial applications

Single Ply Roofing

Made of single layer, watertight, weatherable membrane

Sealed at the seams and edges

Three types of membranes

Elastomers and thermosets (rubber)

Thermoplastics

Modified bitumens

Elastomer Membranes

EDPM (ethylene propylene diene monomer): most commonly used single ply elastomer

Neoprene (chloroprene rubber)

Chlorosulfonated polyethylene (CSPE)

Chlorinated polyethylene (CPE)

Polyisobutylene (PIB)

Properties Required in Roof Materials

Toughness, non-wicking, delamination resistance, chemical resistance, UV resistance, flame resistance and fungus resistance

Textiles for Acoustic and Heat Insulation

Two types of noises and buildings

Airborne noise

Impact noise

Three acoustical properties

To improve audibility

Preserve the natural quality of sound

Prevent the transmission of undesired sound

Reverberation Time

Time it takes a sound to die away in a budling

Absorbent materials to reduce the time

Carpet

Textile wall coverings

Curtains

Factors affecting sound absorption

Cut pile is better than a loop pile

In cut pile construction, pile height and density increase absorption

In loop pile, pile height is more important than density

Acoustic performance is independent of the pile fiber type

Filtration

Process of separation (separation of one material from another)

Purpose is to improve the purity of the filtered material and recover solid particles

Why textiles are suitable?

• Complicated structure

• Considerable thickness

• 3D network of fibers

• Small pockets of void volume

• “tortuous” path around textile fibers

• High filtration efficiency (25%-99.9%)

• Reasonable filter life before plugging

• Woven and nonwoven fabrics

Principles of Filtration

Main objective of the filter medium:

Maximize the possibility of collision

Subsequent retention of the suspended particles in the fluid

Minimize the energy lost

Fabric Structure

• Porosity: air volume/total volume

• The amount and distribution of air space influences the efficiency of filtration

• Air permeability: capacity of a porous medium to transmit fluids

• As the porosity increases, the pressure drop decreases

• Pressure drop should be minimized

Process of Separation

• Particle filtration

• Microfiltration

• Ultrafiltration

• Nanofiltration

• Reverse osmosis (hyperfiltration)

Filtration Equipment

• Filters for Dry Filtration

• Filters for Liquid Filtration

• Drum, disk, plate, frame, belt, vessel, ...filters

Liquid Filter Bags

• petroleum derivatives

• chemicals

• cutting oil

• cleaning fluid

• paints

• pharmaceuticals

• food processing

• beverages

• cosmetics

• semiconductors

Rotary Drum Filters

For slurry filtration

Large drum (20 ft in diameter, 20 ft long)

Vacuum type (rotary drum vacuum filters)

Drum rotates continuously and slowly

Lower part is dipped in the slurry

Vacuum is applied inside the drum to suck the fluid leaving a layer of solid on the outside of the fabric

As the drum rotates, solid is lifted and separated by the fabric by knife

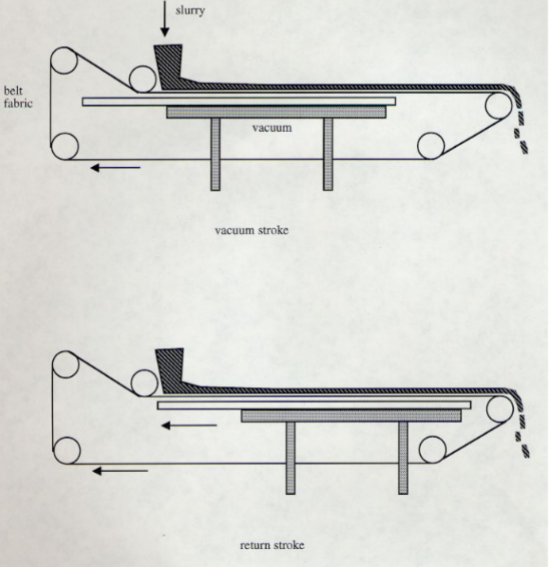

Belt Filter

Suction tray supports a rotating filter cloth

Continuous cycle of vacuum stroke/return stroke

Bag Filters

• Used for dust removal in industrial atmosphere

• Dust can be captured on the internal or external surface of the bag

• Large numbers of woven or nonwoven fabric tubes or bags used

• Suction created by a fan pulls the dusty air through the bags, collecting the dust on the fabric surface

• Filtration efficiency: 99.9% for fine dust collection

• Collected dust must be removed from the fabric surface periodically for efficient filtration

• Dust is collected in a container below the bags and removed periodically

Textiles in Dry Filtration

• mining, chemical, iron and steel industry

• cement, lime, clay, kaolin and ceramic works

• utilities

• feed, grain and food industry

• woodworking and furniture industry

• paper related industry

• textile plants

Polyester in Filtration

Advantages

Strength

Relatively high temperature resistance

low cost

Disadvantages

Low resistance to alkalis, acids and steams

Nonwoven Fabrics in Filtration

Filtration of gases

Needle punched fabrics

Good dimensional stability

Excellent particle retention

Freedom from plugging

Geosynthetics

Geo refers to earth

Synthetics is manmade materials

Manufacturing: Polymer and Fiber Engineering

Application: Civil Engineering

Heavy construction

Building construction

Hydrogeology

Environmental engineering

Soil, rock and ground related activities

Geosynthetic Functions

Separation of soils

Reinforcing poor soils

Soil filtration

Water drainage

Leak proof barrier for preventing liquid movement

Advantages of Geosynthetics

Performance (no deterioration of material or excessive leakage)

Economics (lower initial costs and long life)

Geotextiles

Largest group of geosynthetics

Traditional textile structures

Tremendous growth last 40 years

Biodegradation is not a problem

Flexible, porous fabric structures

Woven, nonwoven, warp knit

80 specific applications for geotextiles

Geogrids

• Small but rapidly growing segment of geosynthetics

• not textile-like structures

• plastics formed into a very open, gridlike configuration with large apertures

• at least 25 application areas

• two functions (reinforcement and seperation)

Geonets

• Manufactured by continuous extrusion of polymeric ribs at acute angles to one another

• large apertures in a netlike configuration

• function: drainage (to convey fluids)

Geomembranes

• Second largest group of geosynthetics

• Impervious thin sheets of rubber or plastic materials

• Used for linings and covers of liquid or solid storage facilities

• Primary function: liquid or solid barrier

• At least 30 individual applications

Geocomposites

Combination of the other geostructures

Major functions include separation, reinforcement, filtration, drainage, and moisture barrier

Geosynthetic Clay Liners (GCL)

• Newest member of the family

• Rolls of thin layers of clay sandwiched between two geotextiles or bonded to a geomembrane

• Needle punched, stitched or adhesive bonded

• Used as primary or secondary liners or beneath a geomembrane

Geo-others

• Threaded soil masses

• Polymeric anchors

• Encapsulated soil cells

• Any of the five major functions of geosynthetics

Designing with Geotextiles

Design by cost and availability

Design by specification

Using standard tables

Designed by function

Factor of safety (FS)

Design by Function

FS = Allowable property/required property

Allowable property (value based on a lab test that models the actual situation)

Required property (value based on design method that models the actual situation)

Geotextile Properties and Test Methods

• Physical Properties

• Mechanical Properties

• Hydraulic Properties

• Endurance Properties

• Degradation Properties

Application areas of medical textiles

Protective medical apparel

Implants

Blood filters

Surgical dressings

Biomaterials

Materials used in contact with tissue, blood, cells, protein and any other living substance