machine elements quiz 1

1/68

Earn XP

Description and Tags

aa

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

69 Terms

Machine Elements

are the fundamental building blocks of any mechanical system. They are standardized components designed to perform specific functions within a machine. These parts, also known as machine components, are crucial for the machine's overall operation and integrity

Shafts

Rotating members that transmit power/torque between components.

Bearings (rolling-element)

Support a shaft and reduce friction via balls/rollers between inner/outer races.

Gears

Toothed wheels that transmit motion and change speed/torque by meshing.

Belts and Pulleys

Flexible drive using a belt around pulleys to transmit power between shafts.

Couplings (rigid, flexible, fluid)

Connect two shafts to transmit power while accommodating misalignment or damping vibration.

Flywheels

Rotating masses that store kinetic energy and smooth speed fluctuations.

Chains & Sprockets

Positive (no slip) flexible drive using a roller chain over toothed wheels.

Cams & Followers

Convert rotary to prescribed reciprocating motion via a profiled cam and follower.

Linkages

Assemblies of links/joints that generate desired motion paths and force transmission.

Levers

Simple machine elements that amplify force or motion about a fulcrum.

Linear guides / Ways

Precisely finished guide surfaces or rails that provide accurate linear motion.

Springs (coil, leaf, torsion)

Store and release energy, provide force, or absorb shock/deflection

Keys & Keyways / Splines

Positive drive features that lock hubs to shafts to transmit torque without slip.

Fasteners (bolts, screws, nuts, rivets)

Detachable or permanent joints that hold components together.

Welds & Pins

Permanent or semi-permanent structural joining of parts.

Clutches & Brakes

Engage/disengage power flow (clutch) or dissipate energy to stop/hold (brake).

Seals (mechanical seals, lip seals) & Gaskets

Contain fluids and exclude contaminants at rotating or static interfaces

Lubrication elements

Oils/greases and channels that reduce wear & heat in contacts like bearings/gears.

Housings/Frames

Structural supports that hold elements in alignment and carry loads.

Importance of Machine Elements

Every machine is an assembly of these elements

Every machine is an assembly of these elements

WHY ARE MACHINE ELEMENTS IMPORTANT? 1

Proper design ensures reliability, efficiency, and safety

WHY ARE MACHINE ELEMENTS IMPORTANT? 2

Foundation for understanding complex mechanical systems

WHY ARE MACHINE ELEMENTS IMPORTANT? 3

position, velocity, and acceleration of a particle as it moves along a curved line in two or three dimensions

the ____ of an object is the rate of change of its position with respect to a frame of reference

a vector quantity that is defined as the rate at which an object changes its velocity

is a rigid body having two or more paring elements which connect it to other bodies for the purpose of transmitting force or motion

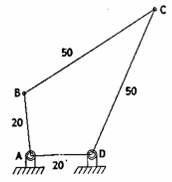

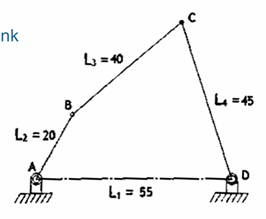

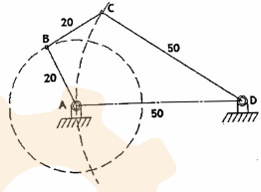

Four Bar Chain

are mechanisms composed only of lower pairs

Four Bar Chain

these mechanisms are popular because of its simplicity and flexibility

frame

every mechanism has a fixed link called the ___

grashof’s criterion

is useful in determining if one link in a four bar mechanism can complete one revolution

Grashof’s Law

states that for a planar four-bar linkage, if the sum of the shortest and longest links is not greater than the sum of the remaining two links, at least one of them will be revolving

grashof’s chain

a four bar mechanism is considered ____ if it satisfies:

Lmin + Lmax < L’ + L”

kinematic inversion

is the process of fixing one link in a kinematic chain and allowing other links to move relative about the fixed linkThis method results in different mechanisms depending on which link is chosen as fixed. c

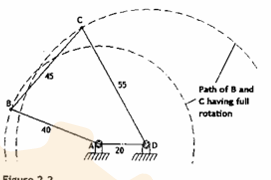

crank and rocker mechanism

the shortest link AB is adjacent with the frame can complete full rotation and link CD will oscillates less than 180 degrees

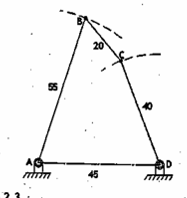

double crank mechanism

if the shortest link AD is held fix then links AB and DC will have complete rotation

double rocker mechanism

if the shortest link BC is the coupler or assigned to be the floating link then both other links AB and DC will oscillate. in this assembly, the shortest link BC can still make a full roation

non-grashof’s chain

a four-bar mechanism is considered as a non-grashof’s chain if it satisfies

Lmin + Lmax > L’ + L”

in a _____, there is no link capable of rotating in full rotation, therefore it is not useful for motor driven application

inversion of non-grashof’s chain

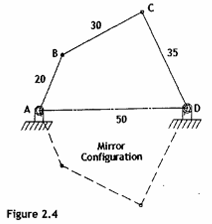

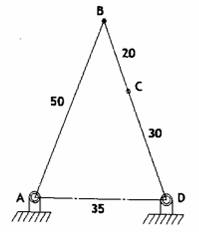

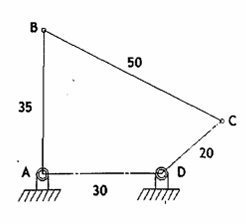

depends on the location of the longest link in the mechanism. all inversions are double rocker mechanism which means two links can oscillate more than 180 degrees and cross the frame line to make a mirror image configuration

inward inward mechanism

the longest link AD is held fix or assigned to be the frame, then link AB and link DC will cross the fram line AD both in inward oscillation, respectively

inward outward mechanism

the longest link AB is adjacent to the frame, then link AB and link DC will cross the frame line AD in inward and outward oscillation, respectively.

outward outward mechanism

the longest link BC is coupler, all other links can cross the frame line AD both oscillating in outward manner

transition chain

Lmin + Lmax = L’ + L”

uncertainty configuration

a transition chain is similar with grashof’s chain, except that in some configurations all links become collinear. this particular form is known as

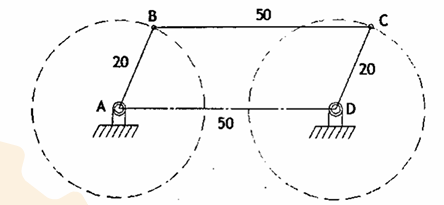

parallelogram mechanism

both link AB and CD moves in the same direction

deltoid or kite mechanism

when the equal lengths of the links are adjacent to each other and the longer link length is held fix. the resulting linkage is a crank and rocker mechanism as shown below. similarly, this type of mechanism also has uncertainty configurations

rhombus mechanism

when equal lengths of the links are adjacent to each other and the shortest link length is held fix, the resulting linkage is a double crank mechanism as shown below. again this type of mechanism also has uncertainty configurations