Topic 5- Transition metals,alloys and corrison

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

what type of metal are most metals

transition metals

what are the properties of transition metals

High melting point

High density

Formation of coloured compounds

Catalytic activity of metals and their compounds

As exemplified by iron

what does the oxidation of metals result in

corrosion

what is corrosion

Breaking down of metals due to chemical reactions , usually with oxygen

what is rusting

rusting is specifically the corrosion of iron (only metal that rusts, others corrode) in the presence of oxygen and water

what is rust

hydrated iron (III)

What is the formation of rust

iron + water + oxygen → hydrated iron (III) oxide

Explain how rusting of iron can be prevented by:

a exclusion of oxygen

Using a physical barrier:

Coating the iron with oil or paint

Both provide physical barrier between the iron, oxygen and water

Prevents iron from reacting with oxygen

Explain how rusting of iron can be prevented by:

b exclusion of water

Using a dessicant

A substance that absorbs the water vapour so it keeps the iron dry

Explain how rusting of iron can be prevented by:

c sacrificial protection

Involves attaching big blocks of magnesium or zinc to the iron

Because magnesium is more reactive than iron it will corrode first leaving the iron intact

Magnesium blocks replaced because they have been corroded immediately

Mg → Mg2+ + 2e-

how can electroplating be used to improve the appearance and / or the resistance to corrosion of metal object?

electroplating coats the surface of one metals with a thin layer of another. to improve appearance, expensive metals such as silver and gold can be used. to improve a metal's ability to resist corrosion, chromium is often used because it stops air and water reaching the steel below, preventing it from rusting. electronic equipment and expensive hi-fi cable may use gold-plated connectors because gold is the third-best electrical conductor, and does not tarnish.

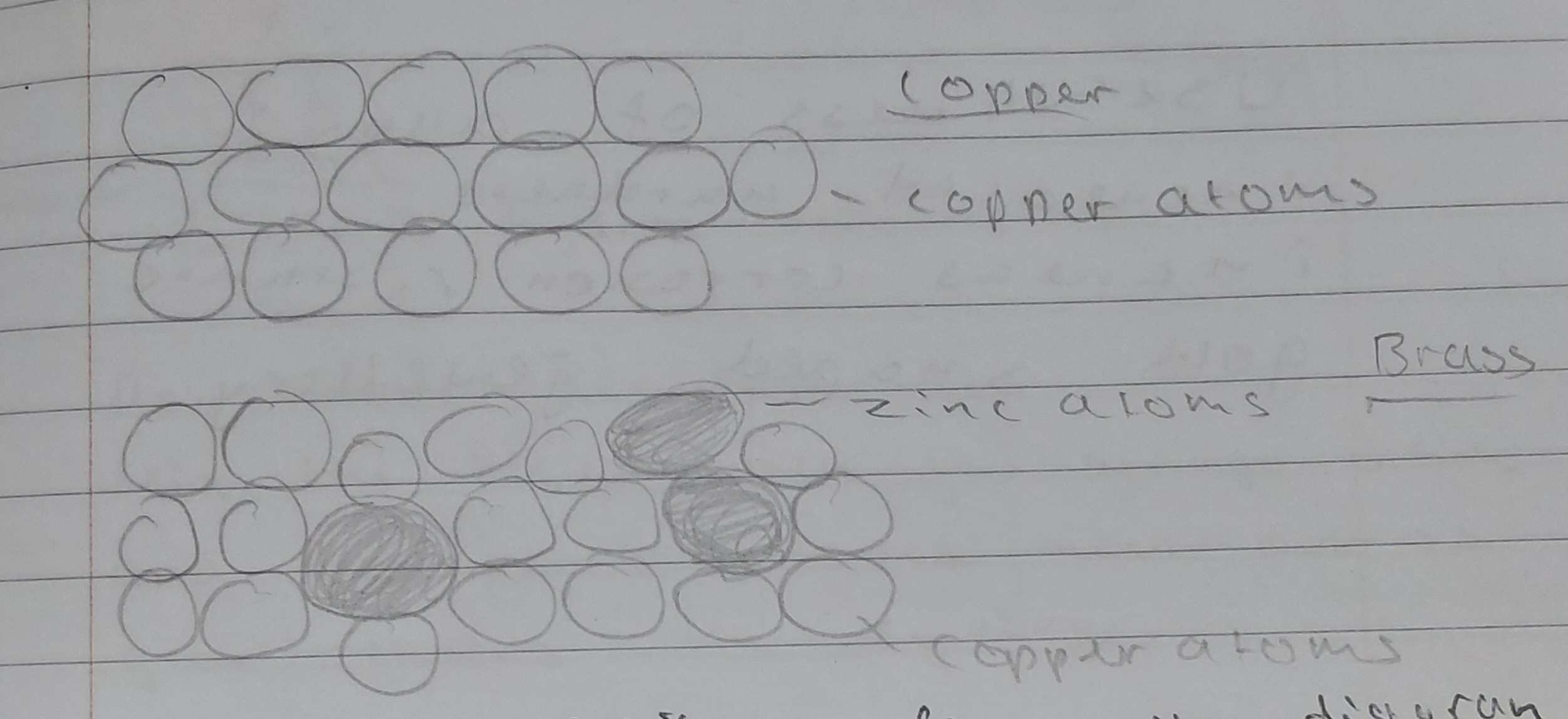

Explain, using models, why converting pure metals into alloys

often increases the strength of the product

an alloy is formed when a small amount of another metal is added to an otherwise pure metal

It alters the regular arrangement of the atoms

So the layers no longer slide easily past one another

Making the alloy harder than the pure metal

why is iron alloyed with other metals to produce alloy steels?

pure iron is too soft for everyday use, but wrought iron is stronger, even though it only contains a small amount of other elements. alloy steels are even stronger than wrought iron.

what are the properties of aluminium, and what is it used for?

aluminium resists corrosion, but it does not conduct electricity as well as copper. however, it is stronger, cheaper, and less dense, so it is used for overhead electrical cables.

what are the properties of gold, and what is it used for?

golds resists corrosion, and is also malleable, ductile, and a very good conductor of electricity. however, it is very expensive, so instead of using it for most electrical wiring, it is used in tiny amounts to connect microprocessors and memory chips. jewellery

what are the properties of copper, and what is it used for?

copper resists corrosion. it is also malleable, ductile, and a very good conductor of electricity. it is not as good as gold, but is thousands of times cheaper, so it is chosen for most electrical wiring.

what are the properties of magnalium, and what is it used for?

magnalium is less dense and almost four times stronger than aluminium alone, and although it is denser than magnesium, it is twice as strong, and has better resistance to corrosion. these properties allow the manufacture of strong but lightweight metal parts used for aircraft parts and scientific instruments.

what are the properties of brass, and what is it used for?

brass is resistant to corrosion, and I stronger than copper, although it is not as good a conductor of electricity. this makes it more suitable than copper alone for making electrical plug pins.