COPMAN WK 1: Introduction to Operations Management

1/44

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

45 Terms

Operations

Operations refer to the part of an organization that is responsible for producing goods and/or services.

Goods

are physical items inclusive of raw materials, parts and subassemblies such as engine system used in a car, and final products such as computers and machineries.

Services

are activities that provide a combination of time, location, form and psychological value.

Operations Management

The business function responsible for planning, coordinating, and controlling the resources needed to produce products and services for a company.

Finance

Responsible for securing financial resources at favorable prices and allocating those resources throughout the organization, as well as budgeting, analyzing investment proposals, and providing funds for operations.

Marketing

Responsible for assessing consumers' needs and wants, and selling and promoting the organization's goods and services.

Operation

Is responsible for producing goods and or providing services offered by the organization

Operations Management (OM)

transforms inputs to outputs.

Inputs

Resources such as People, Material, and Money.

Outputs

Goods and services produced by the organization.

Value Added

The difference between the cost of inputs and the value or price of output.

Efficiency

means performing activities well for least possible cost

Manufacturers

Organizations that produce tangible products that can be inventoried.

Service Organizations

Organizations that provide intangible products that cannot be inventoried.

Operations Function

Includes many interrelated activities such as forecasting, capacity planning, scheduling, managing inventories, assuring quality, motivating employees, and locating facilities.

System Design

Involves decisions related to system capacity, geographic location, facilities arrangement, placement of equipment, product and service planning, and acquisition of equipment, typically requiring long-term commitments.

System Operation

Involves management of personnel, inventory planning and control, scheduling, project management, and quality assurance, generally involving tactical and operational decisions.

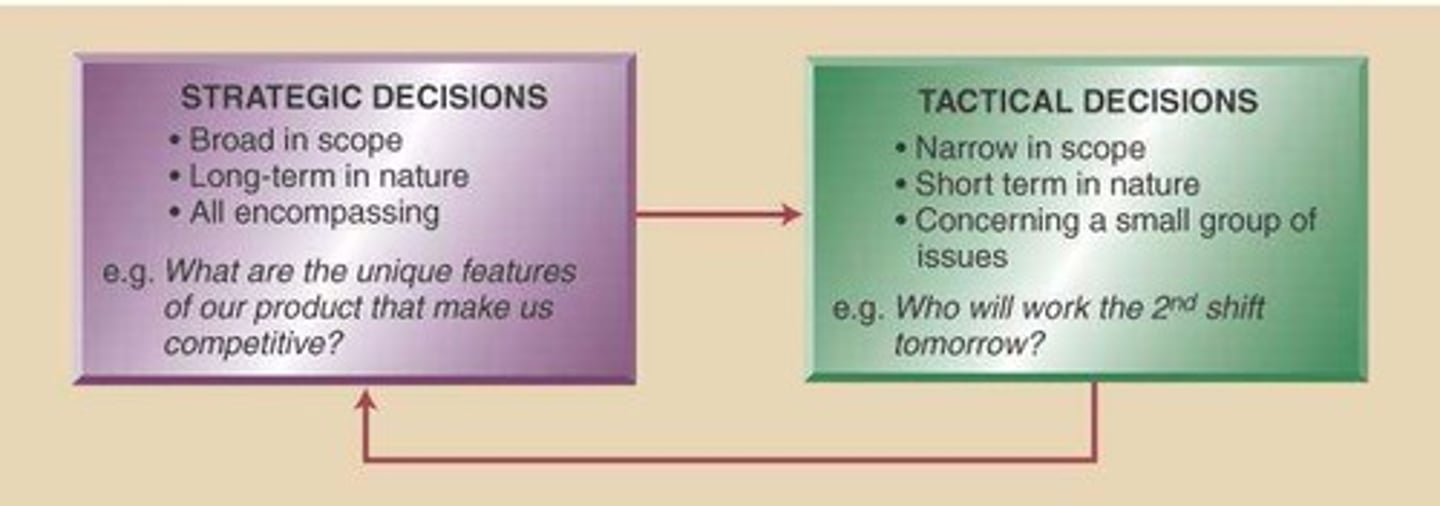

Strategic Decision Making

The process of charting a course based on long-term goals and long-term vision.

Tactical Decisions

Medium-term, less complex decisions made by middle managers focusing on specific day-to-day issues like resource needs, schedules, and quantities to produce an output.

Models

An abstraction of reality, a simplified representation of something, used as a key tool by all decision makers.

Physical Models

One classification of models that represent physical objects.

Schematic Models

One classification of models that represent concepts or systems in a diagrammatic form.

Mathematical Models

One classification of models that use mathematical expressions to represent relationships.

Quantitative Approach

A problem-solving method that often attempts to obtain mathematically optimal solutions to managerial problems.

Performance Metrics

Metrics used to manage and control the operation.

Analysis of Trade Offs

Decisions that involve considering the trade off between increased customer service and the increased cost of inventory.

System Approach

Emphasizes interrelationship among subsystems such as Marketing, Finance, and Operation.

System

A set of interrelated parts that must work together

Ethics

mangers must consider how their decisions affect the stakeholders of the organization

Industrial Revolution

Began in the 1770s in England and spread to Europe and the United States during the 19th century.

Craft Production

Early manufacturing method where highly skilled workers used simple and flexible tools to produce goods according to customer specifications.

Scientific Management

Began in 1900, based on observation, measurement, analysis, and improvement of work methods and economic incentives.

Frederick Winslow Taylor

Known as the Father of Scientific Management, emphasized maximizing output.

Frank Gilbreth

Industrial engineer who developed principles of motion economy applied to small portions of tasks.

Henry Gantt

Recognized the value of non-monetary rewards to motivate workers and developed the Gantt Chart for scheduling.

Harrington Emerson

Applied Taylor's ideas to organizational structure and encouraged the use of experts to improve efficiency.

Henry Ford

Industrialist who employed scientific management techniques in his factories.

Mass Production

Production method where low-skilled workers use specialized machinery to produce high volumes of standardized goods.

Interchangeable Parts

Parts made to such precision that they do not have to be custom fitted.

Division of Labour

Breaking up of a production process into small tasks, allowing each worker to perform a small portion of the overall job.

Human Relation Movement

Began in the 1930s, emphasizing the importance of the human element in job design.

Lilian Gilbreth

Psychologist who focused on the human factor in work alongside her husband Frank Gilbreth.

F. W. Harris

Developed one of the first mathematical models for inventory management in 1915.

Japanese Manufacturers

Developed management practices that increased productivity and quality, emphasizing quality, continual improvement, worker teams, and customer satisfaction.

Supply Chain

A system that encompasses the flow of goods and services from origin to consumer.