Extraction and uses of metals — TRIPLE CONTENT

1/26

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

27 Terms

Mineral

Found in the Earth’s crust and are rich in a metal (or metal ions)

Is a specific metal compound

Ore

Is a rock with a high amount of the mineral/rich in the metal compound

It has to be rich enough in the mineral to be worth extracting to be considered ores

All ores are minerals but not all minerals are ores. Ores are specific minerals that contain high concentrations of valuable elements like metals, making them economically viable to extract and use

Where are most metals found?

What about the other type of metals + which are in which category?

Most metals are found in the Earth’s crust combined with other elements in ores (a rock)

A very few unreactive metals like gold are found native/in the Earth’s crust as the uncombined element

What does the extraction of a metal typically involve? Explain how the method of extraction of a metal is related to its position in the reactivity series

Usually removing oxygen from the metal oxides.

If the ore contains a metal which is below carbon in the reactivity series, then the metal is extracted by heating with a reducing agent like carbon (cheap) in a displacement reaction/redox.

Because carbon is more reactive, it will displace the metal from its oxide/carbon is reducing agent so it reduces (gains oxygen) Fe2O3.

Is the ore contains a metal which is above carbon in the reactivity series, then electrolysis is used to extract the metal.

Large amounts of electricity needed = expensive

what are the two main economic factors to take into account for the methods of extraction of metals?

Cost of energy

Cost of the reducing agent

Extraction of metals above carbon: aluminium

What is the name of its ore? How will we extract aluminium?

Aluminium ore Bauxite is the most abundant in the Earth’s crust

Rocky impurities are removed leaving the compound aluminium oxide (Al2O3)

Molten bauxite is dissolved in molten cryolite so Al³+ ions and O²- ions are free to move

Electrolysis is used to separate aluminium from oxygen as Al is more reactive than carbon, so carbon wouldn’t be able to displace aluminium from its compound

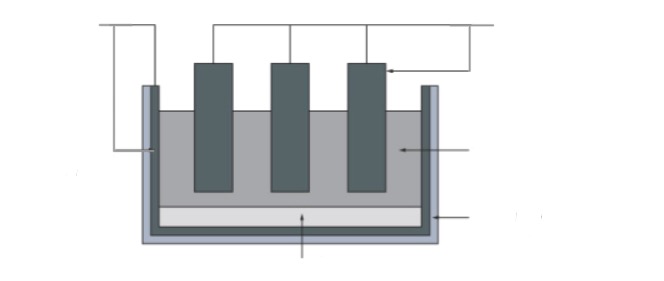

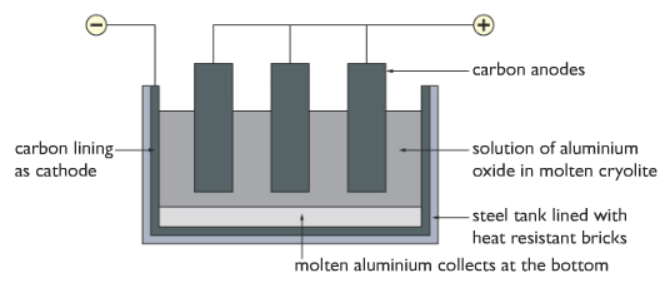

During electrolysis to extract aluminium, what happens at the cathode (negative electrode)?

Electrolysis

Negative cathode: positive aluminium ions (Al³+) are attracted to the cathode. Ions gain electrons (reduction) to become aluminium atoms

Al³ + 3e- → Al Reduction

During electrolysis to extract aluminium, what happens at the anode (positive electrode)?

Positive anode: negative oxygen ions (O²-) are attracted to the anode. Ions lose electrons (oxidation) to become oxygen atoms. The atoms join together to form O2 molecules

2O² → O2 + 4e- Oxidation

During extraction of aluminium by electrolysis why is the negative cathode at the base?

To collect the molten aluminium.

Positive Al³+ ions are attracted to the negative cathode, gain electrons and become neutral aluminium atoms, which then melt and sink to the bottom to the cathode. We turn circuit off and drain molten Al.

What is the problem of using electrolysis to extract metals? What solution is there?

It is very expensive as it uses a lot of energy to reach the temperature needed.

Aluminium oxide has a very high melting point (melts at 2050°C). We could add a compound called cryolite to lower the melting point to 850°C. This is bc it would give us an impure substance (a mixture) so it melts over a range of temperatures

Why do anodes need replacing? (2)

Graphite (carbon) is quite inert so it is used in anodes but:

the graphite (carbon) anodes/(positive) electrode may react

with the oxygen formed at the anode from electrolysis (REJECT “from air” IGNORE “from aluminium oxide”) forming carbon dioxide

Carbon + oxygen → carbon dioxide

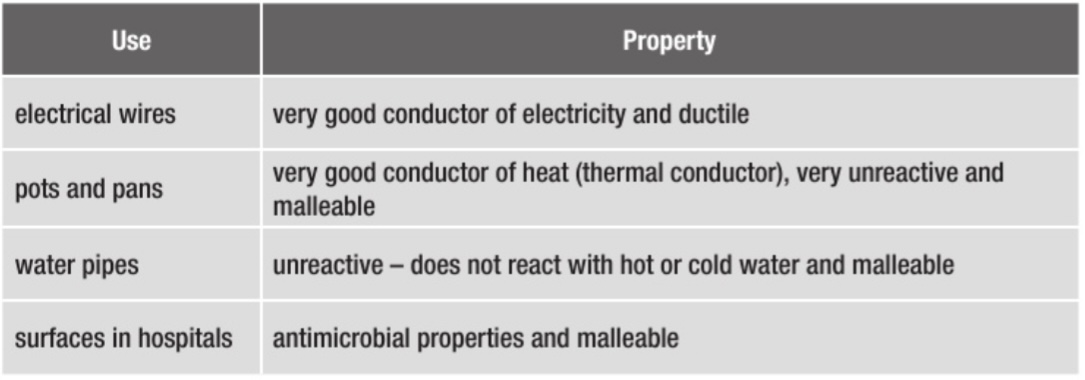

The uses of aluminium depend on…

Pure aluminium is not very strong. It can be strengthened by adding other elements like silicon, copper or magnesium. Uses of Al depend on:

Low density and strength (when alloyed)

Conducts heat and electricity

Can resist corrosion/ it is non-toxic

Malleable (because it is a metal — metallic bonding)

Why does aluminium resist corrosion? Uses of aluminium alloys + give reasons why aluminium is used for each

Aluminium resists corrosion because it has a very thin but very strong layer of aluminium oxide in the surface. This prevents anything else reaching the surface and reacting with it.

Uses include (exam board is obsessed with these)

Pans = conducts heat, resists corrosion

Overhead power cables = conducts electricity, low density, resists corrosion

Aeroplanes = low density, not flamamable

Extraction of zinc + equation

Zinc is often found as ore zinc sulfide (ZnS). To extract it, first it needs roasting (react with O2) to produce zinc oxide — is easier

Equation: 2ZnS (s) + 3O2 (g) → 2ZnO (s) + SO2 (g)

Extraction of metals below carbon: e.g copper + colours

Thermal decomposition (heated) to form copper oxide — copper oxide is more easily reduced by carbon than copper carbonate a common and inexpensive reducing agent

Ore of copper is malachite (CuCO3)

CuCO3 (green) → CuO (black) + CO2

Extraction/redox/displacement

2CuO (s) + C (s) → 2Cu (s) + CO2 (g)

Cu is orange-brown or pink-brown

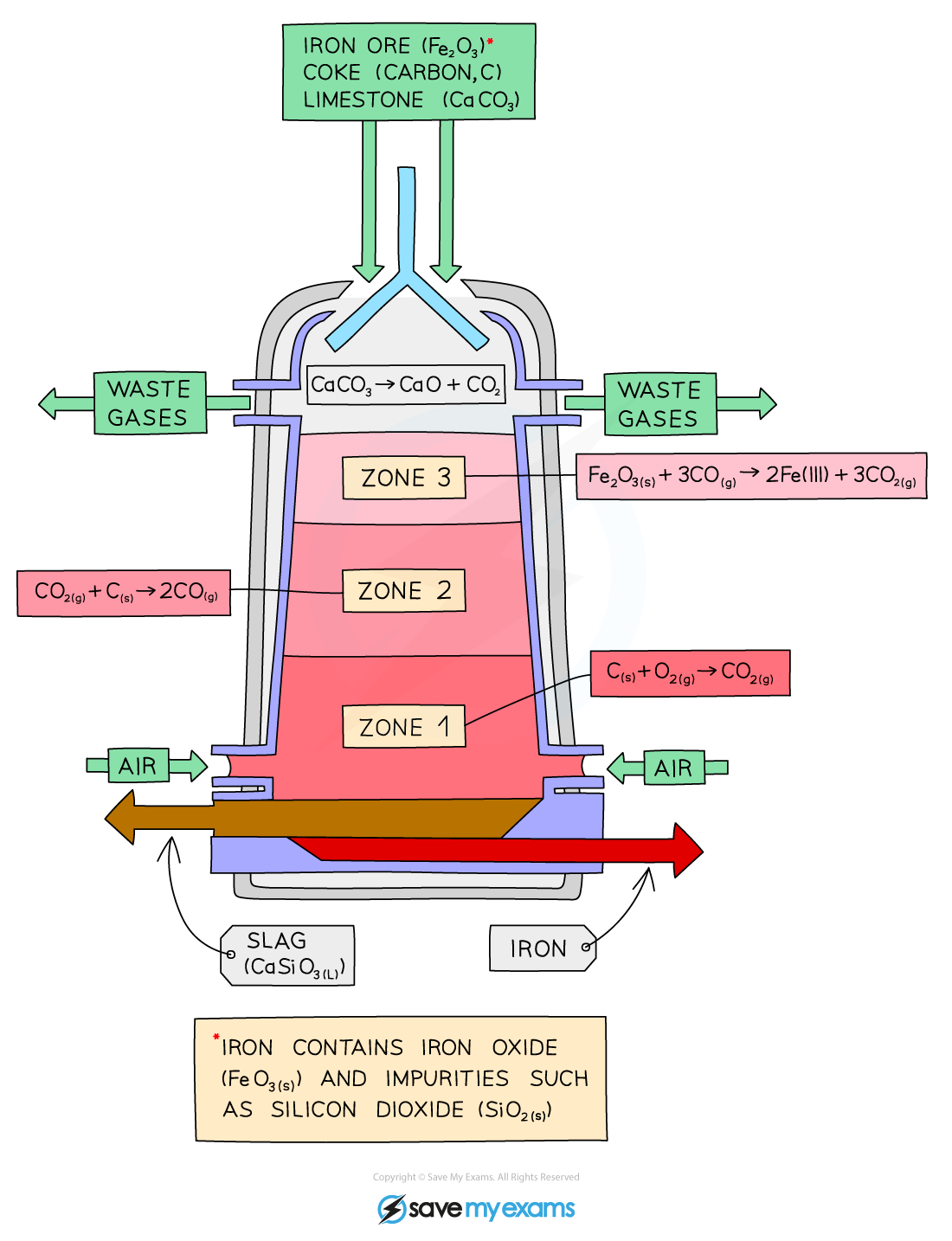

What is the process of extraction of iron? + equations

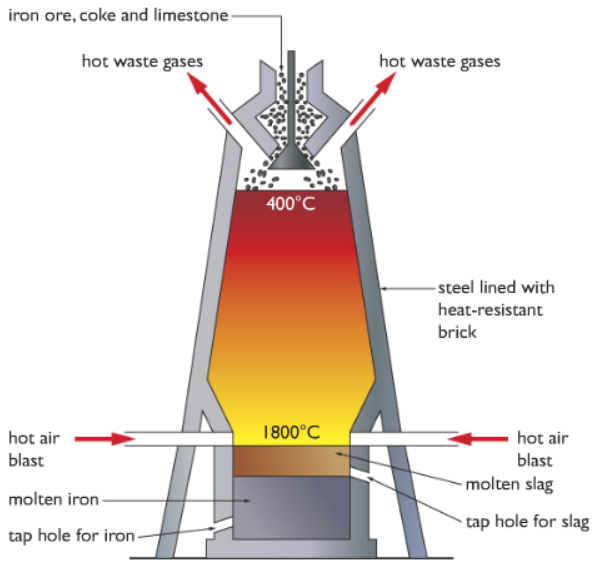

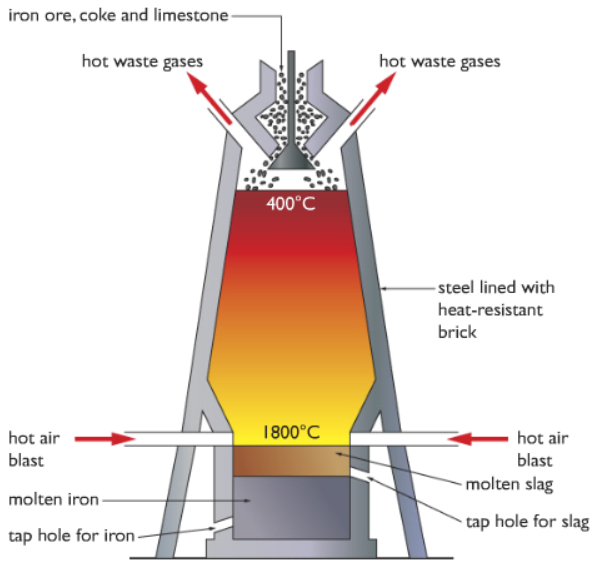

This is a continuous process with new raw materials added and products removed all the time due to the time and cost associated with getting the furnace up to temperature

Raw materials: iron ore (hematite), coke (impure form of carbon) and limestone are added into the top of the blast furnace

Raw materials are added from the top of blast furnace

Hot air is blown into the bottom to heat up the inside of the blast furnace. This heat causes the oxygen in the hot air to react with the carbon in coke.

C + O2 → CO2

The reaction between carbon and oxygen is exothermic. This releases more heat inside furnace so this reaction is mainly used to generate heat.

This heat energy released from the above reaction mantains the temperature inside the blast furnace. This high temperature causes carbon dioxide to react with oxygen in the air to produce carbon monoxide. Carbon dioxide has been reduced to carbon monoxide

CO2 + C → 2CO

CO is a powerful reducing agent so it reduces the iron(II)oxide to iron metal. This will melt and collect at the bottom of the furnace.

Fe2O3(s) + 3CO(g) → 2Fe(l) + 3CO2

We use the blast furnace for the redox reaction (carbon will take oxygen away)/also a displacement reaction because carbon is more reactive so will displace iron from its Fe2O3 compound

Iron (III) oxide

By heating with carbon, the reducing agent = Fe2O3 (s) + 3C (s) → 2Fe(l) + 3CO(g)

Other reactions also occur and the main reducing agent is actually carbon monoxide = Fe2O3(s) + 3CO(g) → 2Fe(l) + 3CO2(g)

How can we ensure that a minimum amount of heat is lost?

The body of the blast furnace is covered with heat-resistant bricks (insulation)

What is the function of limestone?

Limestone (calcium carbonate, CaCO3) removes the acidic impurities in the ore.

Under the heat of the blast furnace, limestone thermally decomposes to form calcium oxide (and carbon dioxide)

CaCO3 (s) → CaO (s) + CO2 (g)

Calcium oxide then reacts with silicon dioxide to form calcium silicate by neutralisation.

CaO (s) + SiO2 (s) → CaSiO3 (l)

It melts and collects as a molten slag floating above the molten iron, which is recollected separately.

Uses of iron alloys: mild steel

Mild steel

Contains up to 0.25% carbon

Malleable, ductile so can be used in nails, car bodies, ship building, girders and bridges

However, disadvantage of mild steel is that it rusts + denser than aluminium

Some car bodies are made from Al → lighter so less fuel and won’t rust

Uses of iron alloys: high-carbon steel

High carbon steel

Contain about 0.6-1.2% carbon

Harder and more resistant to wear than mild steel but more brittle (not as malleable or ductile)

Used for cutting tools, masonry nails

This alloy also usually contains small amounts of manganese

Uses of iron alloys: stainless steel

Stainless steel

Contains chromium (and often nickel)

Chromium forms a strong oxide layer, protecting the iron. Stainless steel is therefore resistance to corrosion

Uses include kitchen sinks, saucepans, cutlery, gardening tools. Also in brewing (making beer), dairy and chemical industries → corrosion-resistant vessels needed.

What is an alloy?

Is a mixture of a metal with, usually, other metals or carbon.

Why are alloy usually harder than the individual pure metals from which they are made?

In an alloy, different metals/elements have slightly differently sized atoms

This disrupts the regular lattice arrangement of the layers of metal ions

Therefore it makes it more difficult for the layers of ions to slide over each other.

Suggest how increasing the carbon content of steel increases the strength of the steel (2)

- In alloys the regular lattice arrangement of the layers of metal ions is disrupted by carbon atoms

- Therefore it is harder for the layers to slide over each other.

Supongo que the more carbon atoms the harder.

Uses of copper and its alloys + reasons