1. polymers

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

32 Terms

dental applications for polymers

Adhesive system

Direct restorative material

Indirect restorative material

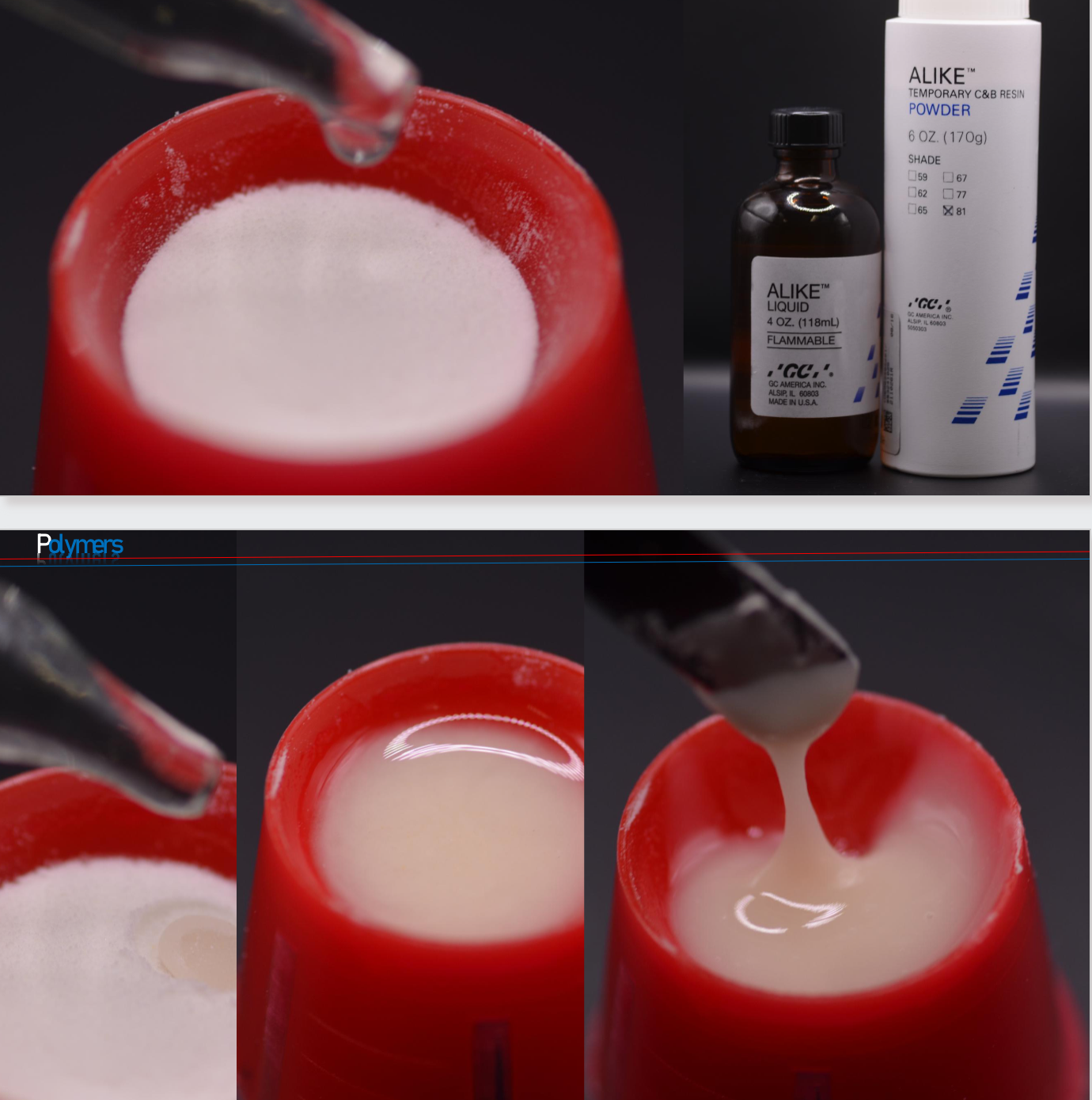

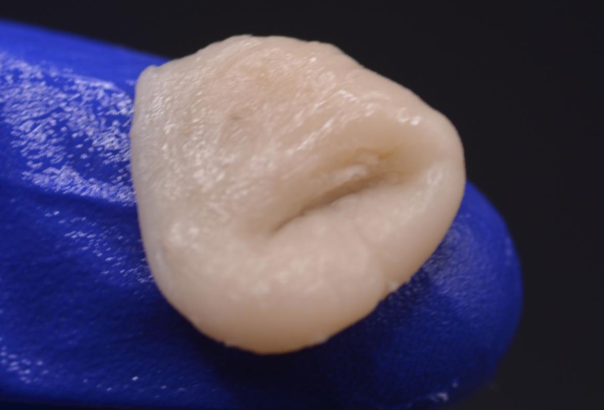

Temporary restorative material

Resin cement

Core and fiber post

Pit and fissure sealant

Cavity liner

bonding

Cavity varnish

Pigment and stain

Custom tray

Impression material

Denture base

Denture teeth

Soft resin

Orthodontic device

Bite registration

Occlusal device

Endodontic filling

Rubber dam

Dental instrument

3D printing

Monomer

Chemical compound that is capable of reacting to form a polymer

-mers suffix meaning

The term used to designate the repeating unit or units in a polymer chain

thus, mers are the “links” in the chain

poly- prefix meaning

Chemical compound consisting of a large molecule formed by the union of many smaller repeating units (mers)

Poly(methylmethacrylate)

acrylic resin

a commonly used acrylic thermoplastic dental material

derived by polymerization of the monomer, methylmethacrylate (MMA)

curing

the process of hardening or setting a material, typically a resin or a composite, into its final form

a chemical reaction in which low-molecular-weight monomers (or small

polymers) are converted into higher-molecular-weight materials to attain

desired properties

Polymerization

Chemical reaction in which monomers of a low molecular weight are converted into chains of polymers with a high molecular weight

Free-radical

An atom or group of atoms (R) with an unpaired electron (•).

R• produces reactions that initiate and propagate polymerization and eventually lead to a final set

steps of polymerization: Induction

Activation of free radicals, which in turn initiates growing polymer chains.

steps of polymerization: Propagation

Stage of polymerization during which polymer chains continue to grow to high-molecular weights.

steps of polymerization: Termination

Stage of polymerization during which polymer chains no longer grow

Degree of conversion/ degree of cure/ degree of monomer-to-polymer conversion

Percentage of carbon-carbon double bonds (-C=C) converted to single bonds (-C-C-) during curing to form a polymeric resin.

Polymerization shrinkage

Arises as the monomer is converted to polymer and the free space it occupies reduces.

Polymerization stress that is resulted from volumetric shrinkage can be affected by:

[1] total volume of material

[2] monomeric composition

[3] filler particle amount

[4] polymerization speed

[5] c-factor

trends for these molecules

size increases going down

molecular weight increases going down = less shrink with packable bc more viscous + bigger molecules

viscosity increases going down

flowable will shrink more bc its lighter

Activation

Process by which sufficient energy is provided to induce an initiator to

generate free radicals and cause polymerization to begin

Activator

Source of energy used to activate an initiator and produce free radicals.

1.Chemical;

2.Physical (light or heat)

Activation Mode: light cured

Best control over setting time

Higher color stability over time

Pre-heated composite*

Cure depends exclusively on the light

Does not require mixing

Basically, a flowable composite

Pre-heated composite

Activation Mode: self cured

Cure depends exclusively on a chemical reaction

Requires mixing

No control over setting time

Lower color stability over time

Activation Mode: dual cured

Cure depends on chemical reaction AND light-curing (light is required*

Requires mixing

Medium control over setting time

Lower color stability over time

Best of “both worlds”

Initiator

A free radical-forming chemical used to start the polymerization reaction.

inhibitor

A chemical added to resin systems to provide increased working time and

extended storage life by minimizing spontaneous polymerization

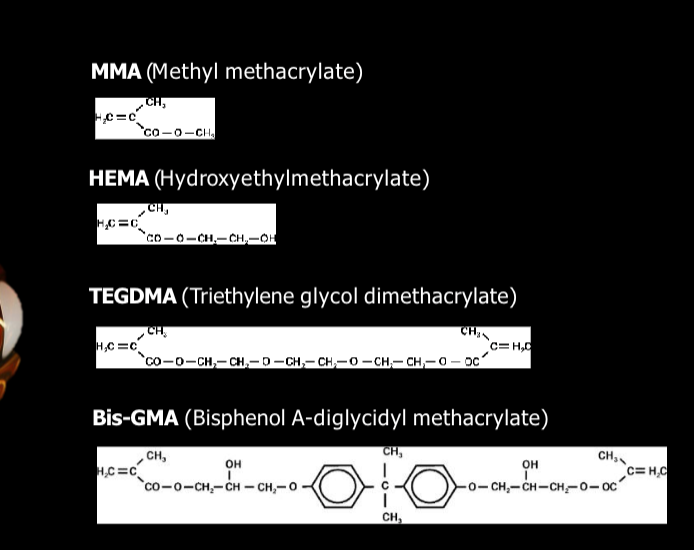

acrylic resin composition liquid

Methyl Methacrylate (MMA)

Tertiary amine

Inhibitor

Dimethacrylate (cross linking agent)

acrylic resin composition powder

Poly(methyl methacrylate) (PMMA)

Benzoyl peroxide

Pigments and opacifiers

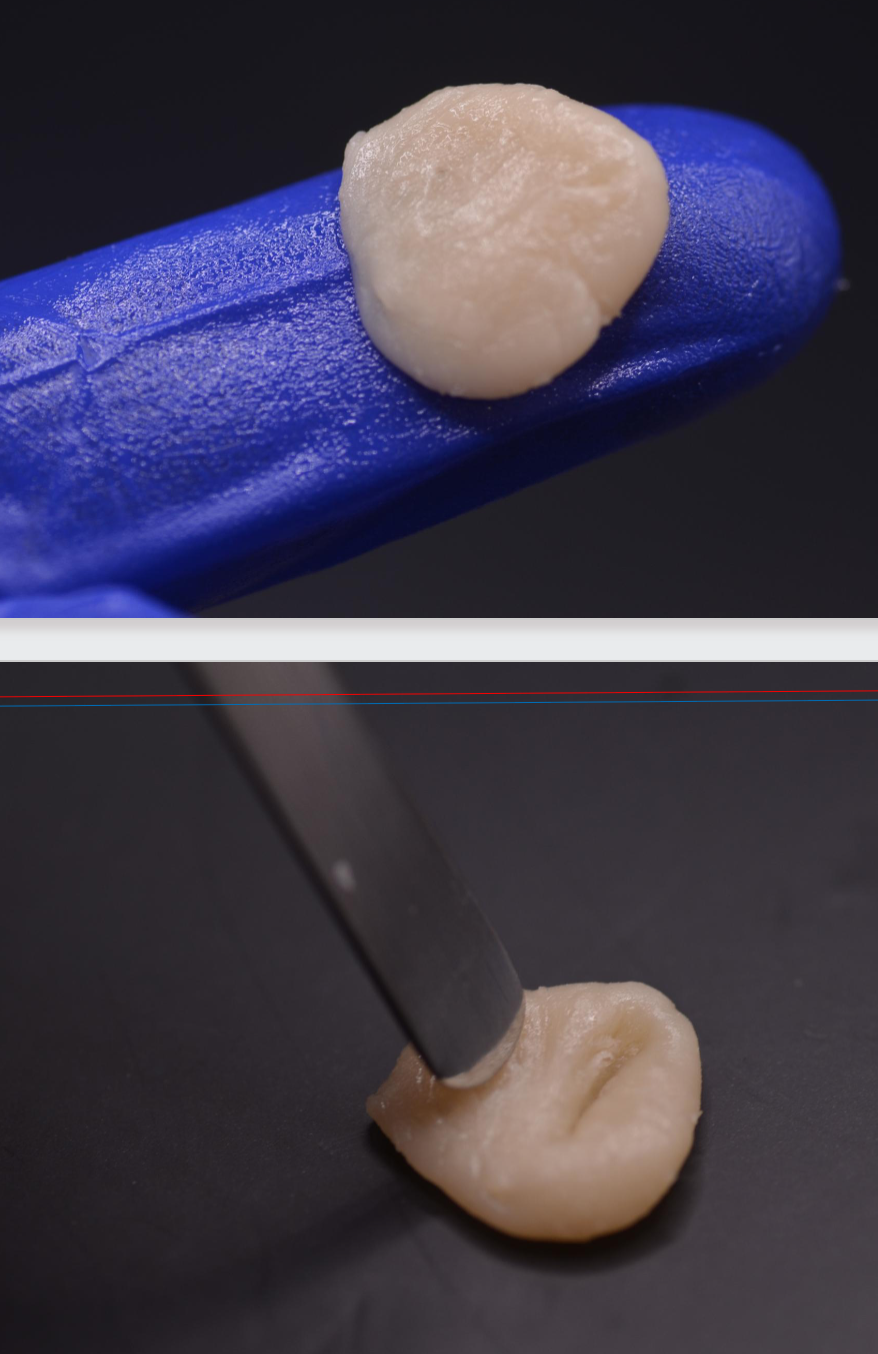

Stages of polymerization

When monomer and polymer are mixed in the proper proportions, a workable mass is produced.

Resultant mass passes through five distinct stages:

sandy

stringy

dough-like

rubber

stiff

Sandy phase

Little or no interaction occurs on a molecular level.

Polymer beads remain unaltered, and the consistency of the mixture an be

described as “grainy”

Stringy (fibrilar) phase

Monomer attacks the surfaces of individual polymer beads and is absorbed

into the beads.

Some polymer chains are formed, increasing the viscosity of the mixture

Doughlike (plastic) phase

An increased number of polymer chains enter the solution.

Clinically, mass behaves as a pliable dough (no longer sticks to the surface of

instruments)

Ideal stage for compression molding

rubbery phase

Monomer is dissipated by evaporation and by further penetration into remaining polymer beads.

Mass rebounds when compressed or stretched (elastic), it cannot be used to copy structures

stiff (dense) phase

Continued evaporation of unreacted monomers, mixture becomes stiff.

Clinically, mixture appears dry and resistant to mechanical deformation

Denture base

The part of the denture that rests on the soft tissues overlying the maxillary and mandibular jawbone and that anchors the artificial teeth.’

Heat-cured.

Elastomers

In general, polymers are hydrophobic.