MODULE 2.4: INTRO TO WATER TREATMENT

1/25

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

26 Terms

Unit Operations

Removal of contaminants is achieved by physical forces such a s gravity and screening (e.g. sedimentation and filtration)

Unit Processes

Removal is achieved by chemical and biological reactions (e.g. flocculation, precipitation, disinfection)

Preliminary Treatment

Process selection normally is based upon the expected characteristics of the influent flow.

Preliminary Treatment

protects downstream plant equipment by removing trash, which could cause clogs, jams, or excessive wear in plant machinery.

Screening

removes large solids, such as rags, cans, rocks, branches, leaves, and roots, from the flow before the flow moves on to downstream processes

Grit Removal

Purpose: to remove inorganic solids (sand, gravel, clay, egg shells, metal fillings, etc.) that could cause excessive mechanical wear

2 ft/s

optimum velocity in sewers is approximately____ at peak flow,

1 ft/s

however, when the flow reaches the grit channel, the velocity should decrease to about ____ to permit the heavy inorganic solids to settle

Primary Treatment

should remove both settleable organic and floatable solids. Poor solids removal during this step of treatment may cause organic overloading of the biological treatment processes following primary treatment.

90 to 95%

40 to 60%

25 to 35%

Normally, each primary clarification unit can be expected to remove

–____ of settleable solids,

–____ of the total suspended solids, and

–____ of biological oxygen demand (BOD).

Surface Loading Rate

the number of gallons of wastewater passing over 1 square foot of tank per day

Weir

a device used to measure wastewater flow

Weir overflow rate (or weir loading rate)

is the amount of water leaving the settling tank per linear foot of water.

Biosolids Pumping

the quantity of solids and volatile solids removed from the sedimentation tank

Trickling Filter Process

Consists of a fixed bed of rocks, gravel, slag, polyurethanefoam, sphagnum peat moss, ceramic, or plastic media over which sewage or other wastewater flows downward and causes a layer of microbial slime (biofilm) to grow, covering the bed of media

Trickling Filter Process

Has advantages over other unit processes. For example, because it is capable of withstanding periodic shock loading, process energy demands are low because aeration is a natural process.

Trickling Filter Process

One of the oldest forms of dependable biological treatment for wastewater.

Hydraulic Loading Rate

is calculated based on filter surface area.

Organic Loading Rate

expressed as a certain amount of BOD applied to a certain volume of media

Organic Loading

is defined as the pounds of BOD or chemical oxygen demand (COD) applied per day per 1000 cubic feet of media — a measure of the amount of food being applied to the filter slime.

Recirculation

in trickling filters involves the return of filter effluent back to the head of the trickling filter.

Trickling Filter Recirculation Ratio

the ratio of the recirculated trickling filter flow to the primary effluent flow.

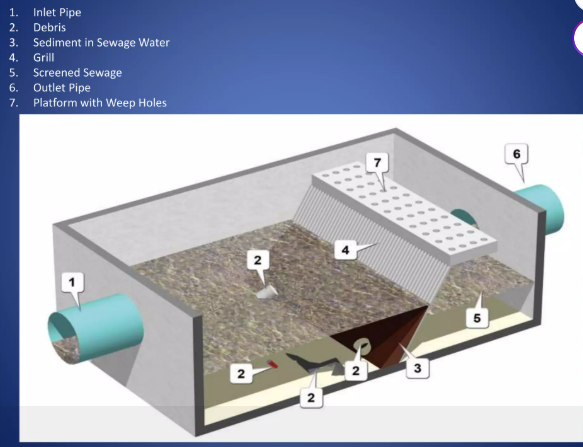

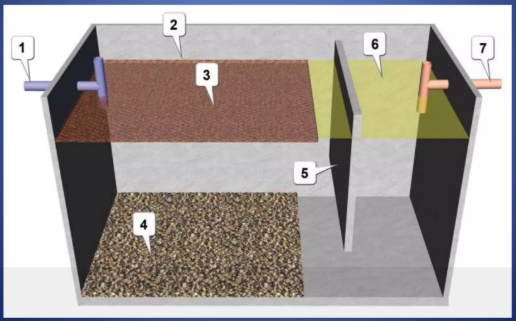

Identify the parts of the Bar Screen Chamber shown

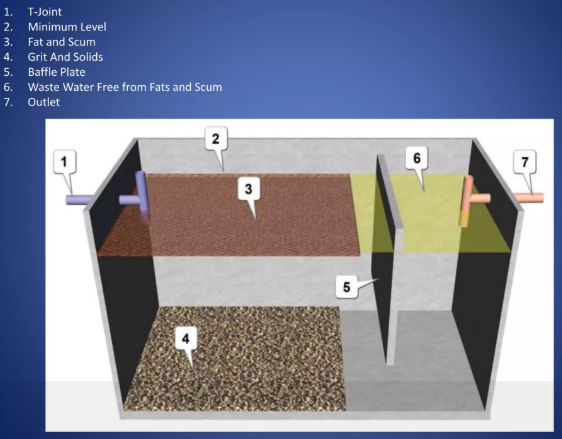

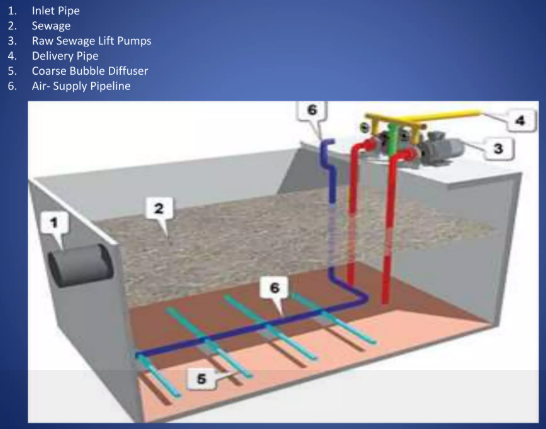

Identify the parts of the Oil & Grease/Grit Trap shown

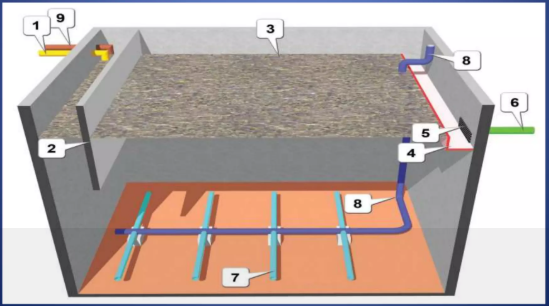

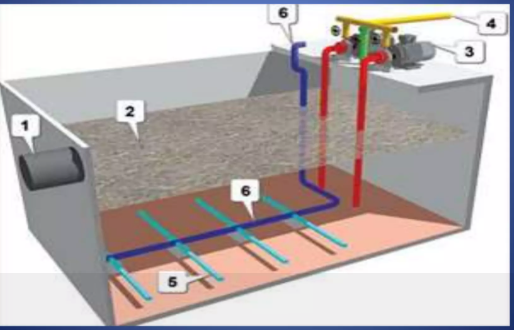

Identify the parts of the Equalization Tank shown

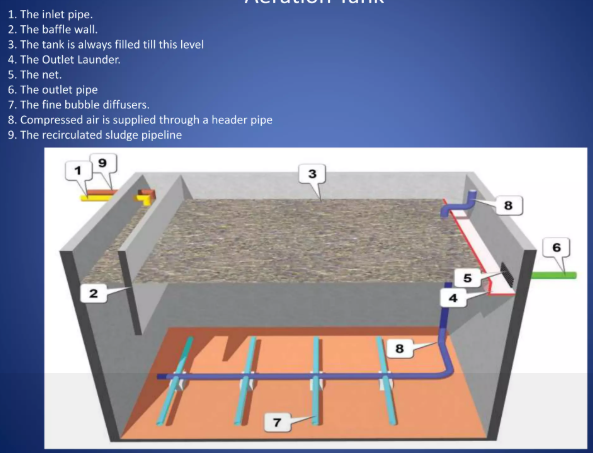

Identify the parts of the Aeration Tank shown