turbine 1

1/70

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

71 Terms

PT6 is divided into # separate rotating sections

gas section, power section

gas section

supplies hot high velocity gas to power section

powered by starter

gas generation drives the accessories

power section

uses high velocity gases to drive the prop through a reduction gearbox

PT6 is a ____ flow engine

reverse flow engine

inlet is at rear

exhaust is at front

jet propulsion is based on what

newtons 3rd law

types of reaction engine

rocket jet, ram jet, pulse jet

types of gas turbine engine

Turbo jet

Turbo fan

Prop fan

Turbo prop

Turbo shaft

rocket jet

operate outside Earth’s atmosphere because it carries its own source of oxygen and fuel

combustion starts and finishes until all fuel is burned

fuel is solid or liquid

ram jet

requires forward velocity to compress the air to support combustion

changes velocity to static pressure for combustion

pulse jet

similar to ram jet but has air inlet check valves

check valves open for intake and close for combustion

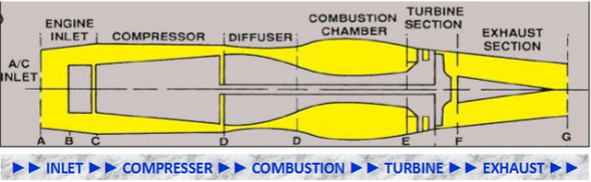

turbojet

1 airflow path through the engine

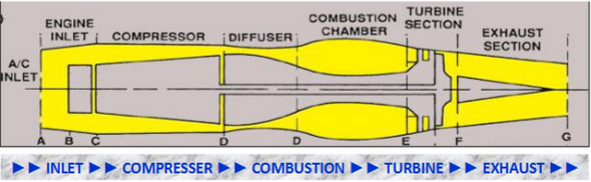

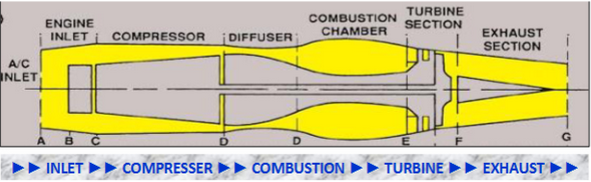

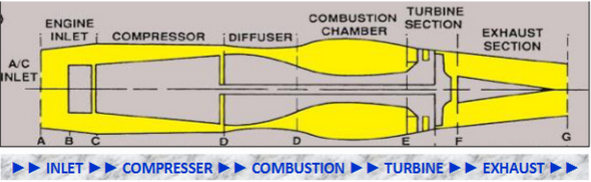

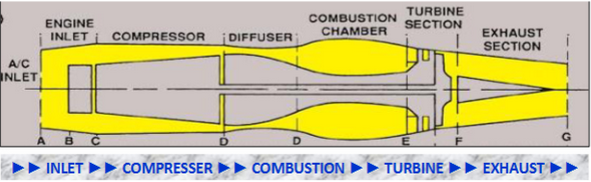

5 fundamental sections - inlet, compressor, combustion, turbine, exhaust

air inlet

divergent duct - air velocity decrease and static pressure increase

compressor

compresses air

increase static pressure and decrease air velocity

diffuser

divergent duct - increase static pressure and decrease air velocity

maximum potential energy

combustion

potential energy converts to kinetic energy

fuel mixed with high pressure air and ignited > BOOM

high energy and velocity air exiting combustion chamber flows rearward to power turbines

turbine

kinetic energy converts to mechanical energy

high energy and velocity air rotates compressor

exhaust

convergent duct - static pressure decrease and velocity increase for thrust

high velocity and temperature for thrust

spool

single shaft with a compressor at the front and turbine at the back

compressor, shaft and turbine rotate at same rpm

turbofan

uses large fan assembly that increases mass airflow to create thrust

cruise at subsonic speeds with short field takeoff capabilities

turbofan inlet air is divided into

2 airflow - primary (core) and secondary (bypass)

what generates thrust in turbofan

secondary (bypass) airflow

thrust ratio

thrust of the fan vs thrust of the core

bypass ratio (BPR)

ratio of bypass airflow vs core airflow

fan pressure ratio

ratio of air pressure entering vs exiting the fan

aspect ratio

ratio of blades length vs width

turboprop

basic gas turbine engine to power a propeller through a reduction gearbox by fixed or free turbine

fixed turbine engine

prop is connected directly to the compressor section through the reduction gearbox

free turbine engine

engine is divided into gas generation section and power section

gas generator section powers an independent free-wheeling turbine that drives the propeller through the reduction gearbox

advantages of free power engine

Reduced noise levels

Improved fuel consumption

Environmentally cleaner

disadvantages of free power engine

Rapidly loses power due to increased drag at high speeds

Slower airspeed

free power vs fixed

Reduced noise and blade erosion > propeller is low rpm

Engine is easier to start, especially in cold weather

Lower vibration due to independent operation from gas generator section

Can apply brake to prop during aircraft loading without shutting down engine

turboshaft

uses gas turbine engine to turn drive shaft output

same as free turbine turboprop

helicopter, APU

propfan

consists of 2 contra-rotating unducted fans mounted aft of engine

high density air

low temperature, low altitude, low humidity

greater thrust and improved engine performance

low density air

high temperature, high altitude, high humidity

degrades engine performance

force

tendency to produce work

force = pressure x area

work

force acting on a body causing it to move

work = force x distance

power

rate of doing work

power = work/time

velocity

how far an object moves and how long and direction

velocity = distance/time

acceleration

change in velocity with respect to time

acceleration = change in velocity/time

mass

amount of matter in an object

momentum

product of mass and velocity

potential energy

stored energy

kinetic energy

release of stored energy

brayton cycle

constant-pressure thermodynamic cycle where fuel energy transformation occurs in gas turbine engine

intake pressure vs exhaust pressure > constant

pressure is inversely proportional to volume

temperature is proportional to pressure

brayton cycle concept in engine

fuel (chemical energy) > heat energy > gas pressure increase > kinetic energy in the form of high velocity airflow > mechanical energy as gas rotates turbines

gross thrust

total thrust produced without deduction of drag caused by the momentum of incoming air (ram drag)

net thrust

gross thrust - intake ram drag

how is thrust increased

increase mass airflow through the engine

increase jet velocity

ram drag

loss of thrust caused by increasing the velocity of air entering the engine (negative thrust)

ram effect (ram recovery)

ram drag is recovered by using a divergent inlet duct and high aircraft speed to increase mass airflow and jet velocity

Factors that affect thrust

Propulsive efficiency - through design

Thermal efficiency - through design

Inlet density - through atmospheric conditions

Selected compressor rpm - through operating conditions

propulsive efficiency

measure of effectiveness when engine converts kinetic energy into useful work

engine exhaust velocity vs aircraft speed

thermal efficiency

Ratio of the total work produced by the engine to the fuel (chemical) energy input

factors affecting thermal efficiency

Turbine inlet temperature

Compression ratio

Compressor & turbine efficiencies

Compressor inlet temperature

Burner efficiencies

inlet density

thrust is proportional to inlet air density

high density = high mass airflow = high thrust

factors that influence inlet density

Altitude

Temperature

Airspeed

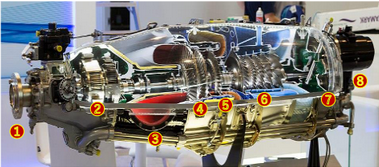

propeller mount

prop reduction gearbox

exhaust

2 stage free power turbine

1 stage gas generator turbine surrounded by the combustion chamber

1 centrifugal and 4 axial compressor stage

air intake

accessories

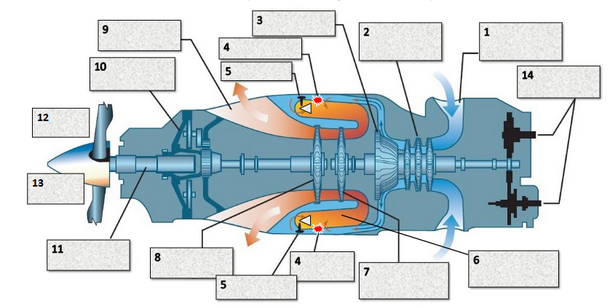

Air inlet

3 stage axial flow compressor

1 stage centrifugal compressor

Igniter

Fuel nozzle

Combustion chamber

Compressor turbine (gas producer)

Free power turbine

Exhaust outlet

Reduction gearbox

Propeller drive shaft

Propeller

Prop spinner

Accessory gearbox

hero’s aeolipile

converted steam pressure into mechanical power

sphere filled with water > heated > steam escapes through nozzle > sphere spins > reaction principle

chinese rocket

Solid fuel rocket using black powder, charcoal, sulfur and saltpeter (potassium nitrate)

first chemical reaction rocket

da vinci’s chimney jack

Used heat to drive a reaction type turbine to power a rotating skewer (rotisserie)

branca’s turbine device

Used steam-driven turbine (impulse wheel) to operate reduction gears

newton’s horseless carriage

Used reaction principle to propel a carriage

Frank Whittle

patented first turbojet aircraft engine

patented first turbofan aircraft engine

Hans Von Ohain

developed first axial flow engine

ultra low bypass

< 1:1 BPR

low bypass

<2:1 BPR

medium bypass

2:1 - 4:1 BPR

high bypass

4:1 - 9:1 BPR

ultra high bypass

> 10:1 BPR