11 pt.1 : Metal Alloys & Metal Framework Fabrication

1/67

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

68 Terms

what type of metal alloys are used in the fabrication of RPD framework?

noble metal

base metal

what metals are included in the noble metal group

what are the base metals?

what is the most popular metal used for an RPD?

cobalt-chromium

when considering the combination of metals used for an RPD, how do you tell which metal is in the highest concentration?

the firs metal listed is in the highest concentration

what are the principal material used in the fabrication of RPD?

chromium type alloys

why are chromium type alloys the principal materials used in the fabrication or RPD

prevents rusting, corrosion, tarnish

known as passivation

How does the addition of vitallium affect metal framework of RPD?

allows more elongation and makes it less brittle

the addition of chromium to prevent corrosion and tarnish (Cr2O3) is known as?

passivation

a process that enhances a material's corrosion resistance by removing impurities from its surface, most commonly through chemical treatment

chromium alone allows how much elongation when compared to chromium in addition to vitallium?

chromium allows 2-3% elongation and is quite brittle while vitalloum allows more elongation and is not as brittle

what are the major constituents of most available materials for the metal framework of an RPD?

cobalt (60%)

chromium (25-30%)

what is the purpose of cobalt in a cobalt-chromium metal framework?

hardness

what is the purpose of chromium in a cobalt-chromium metal framework?

corrosion resistance

what is the purpose of molybdenum, tungsten and carbon in metal framework?

hardening and strengthening

what is the purpose of manganese and silicon in metal framework?

fluuidity

in a cobalt-chromium-nickel metal framework, how do you expect the molybdenum and carbon levels to differ from metal frameworks that are only cobalt-chromium.

there will be less molybdenum and carbon in a metal framework that includes nickel in addition to cobalt and chromium

having less of these makes Co-Cr-Ni have more elongation (10%)

what is the purpose of beryllium in a nickel-chromium metal framework?

lower the melting temperature

enhances fluidity

improves grain structure

you will find beryllium added to which metal framework combination for lower melting temp, enhanced fluidity and improved grain structure?

a nickel-chromium metal framework

compare titanium and chrome

titanium is lighter than chromium but just as strong

compare the melting temp of base metal RPD allows to that of gold alloys

higher melting temp of base metal RPD alloys

fusion temp range of gold alloys?

1,399 to 1,454 celcius

compare weight of chromium allows and gold alloys

chromium alloys are lighter than gold

in which alloy will you expect relatively high linear casting shrinkage (2.05 - 2.33%)?

gold alloy

when is the use of lighter materials especially important in an RPD?

large and bulky maxillary removable appliances

chromium is ___% harder than type 4 gold alloys

30%

ultimate tensile strength makes it fracture resistant

high yield strength to resist permanent deformation

compare the modulus of elasticity (stiffness) of cast based metal alloys to that of gold

cast based metal alloy stiffness is approximately 2x that of gold alloys

which metal frameworks can be altered by high temp heat treatments?

Ni-Cr can be made stronger using heat

Co-Cr CANNOT

how much Cr, Co and Ni by weight is necessary for an alloy to exhibit a reasonable degree of intraoral corrosion resistance

more than 85% by weight

surfaces are made passive in the air to resist corrosion by…

the spontaneous development of a thin, transparent and contiguous Cr2O3 film

known as passivation

what reduces Cr release levels in artificial saliva, leading to better corrosion resistance?

chemical coating with zirconium oxide (ZrO2)

when repairing or modifying a Co-Cr-Mo RPD framework, how do you avoid galvanic corrosion?

by repairing or modifying with the same allow combination

Cr-type alloys are attacked by what substance?

chlorine

is it okay to use house bleaches to clean applicants made from Cr allloys?

NO

chlorine attacks Cr-type alloys

what are lab considerations when manipulating a metal framework?

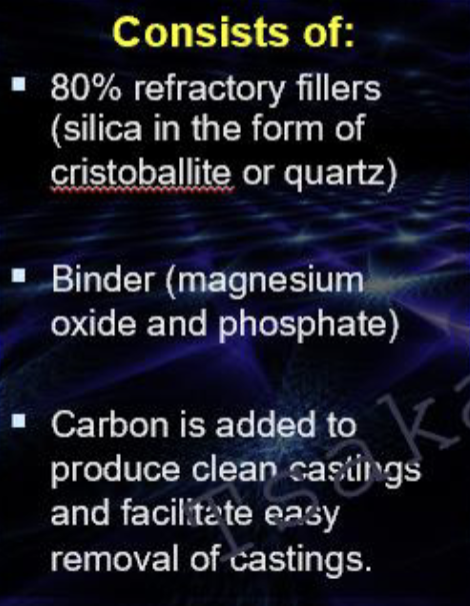

phosphate bonded or ethyl silicate investment materials

compensate for the high linear casting shrinkage or Co-Cr alloys

entrapped gases can produce voids in a large casting

advantages of phosphate-bonded investments

high strength

easily withstand temps that reach 1650 F

used with high-fusing cream-metal alloys

what does this describe?

phosphate-bonded investments

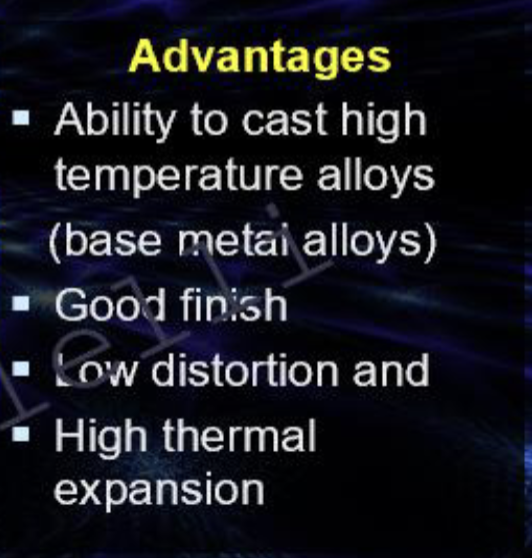

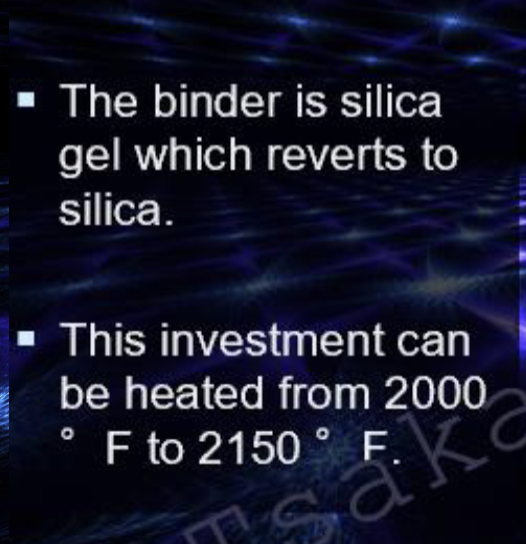

advantages of ethyl-silicate bonded materials?

these are characteristics of what investment?

ethyl-silicate

what affects the microstructure and mechanical properties of Cr-Co alloys?

casting temperature

what is used to adjust the alloy due to harness and strength?

high speed laboratory equipment

what is the most common allergic metal known with a 10-20% incidence?

nickel allergy

what is more common in women na d in chronic exposure through jewelry and can be quite severe?

nickel allergy

T or F: nickel ions (Ni+2) are documented to be mutagens in humans and can be carcinogenic intraorally

FALSE

there is NO evidence that nickel is carcinogenic intraorally

T or F: various Ni compounds may contribute to the development of nasal and lung cancers

TRUE

what enhances beryllium release from Ni-Cr alloys?

acidic environment

an analysis of experimental and occupational data indicates that ____ may increase the risk of lung cancer and tumors in max

beryllium

base metal alloys containing _______ revealed a very high leakage which may pose a health risk

both Be and Ni

what is a chronic allergic-type lung response and chronic lung disease caused by exposure, is an occupational lung disease that only occurs in those with a hypersensitivity and is incurable with treatable symptoms?

berylliosis

steps for fabrication of a metal framework

survey master cast, outline partial design

beading

blockout and relief

duplication

refractory cast

waxing

what are the dimensions required for beading?

0.5 mm deep and wide

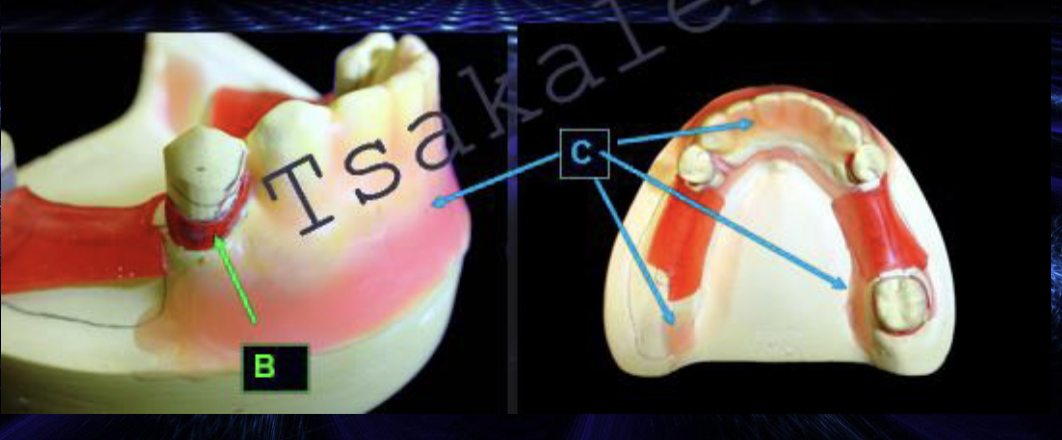

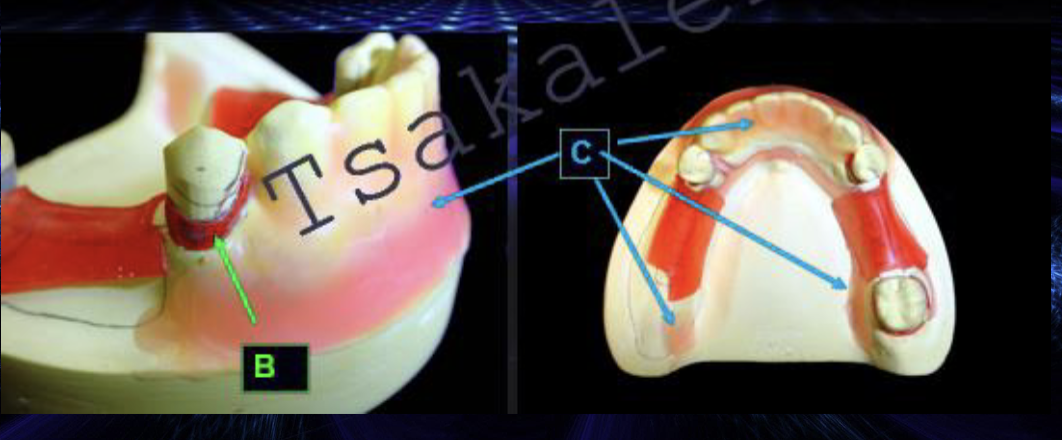

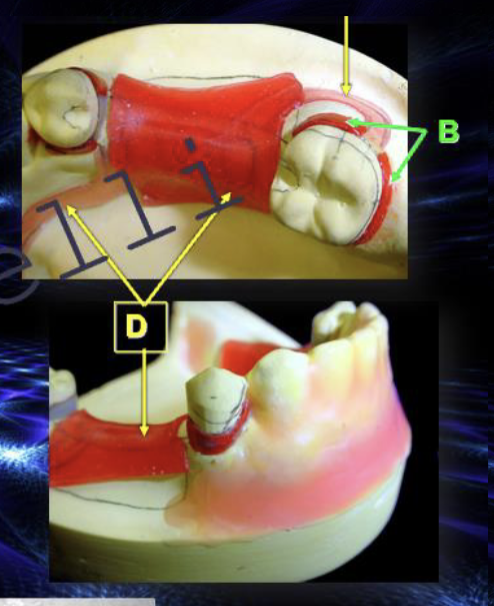

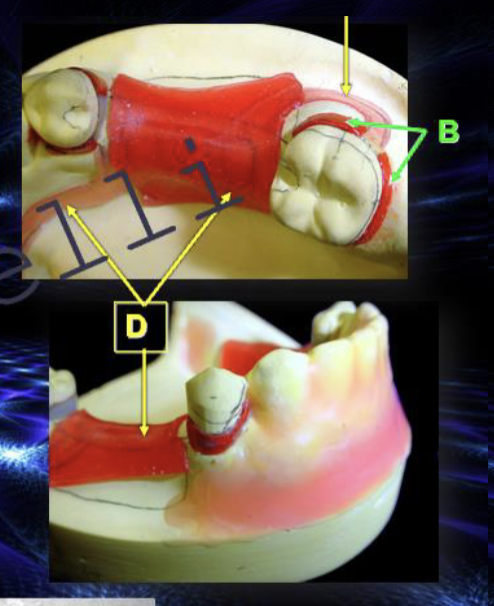

what type of blockout is C

arbitrary

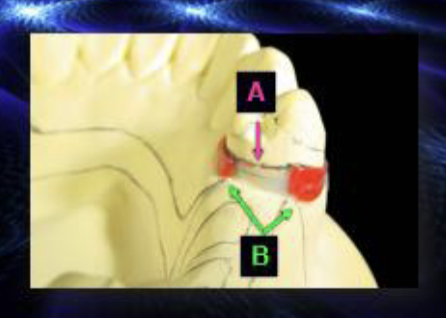

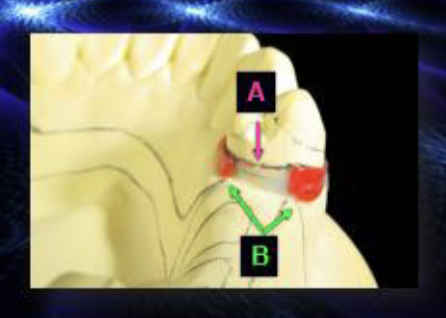

what type of blockout is B

shaped

what type of blockout is B

shaped

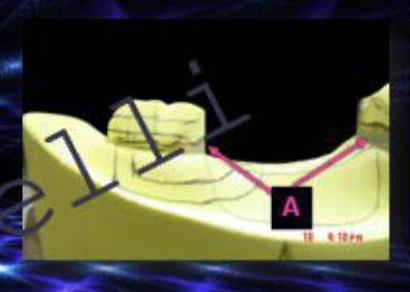

what type of blackout is A

parallel

what type of blockout is A?

parallel

what type of blockout is B?

shaped

D

relief

B

shaped blockout

the refractory cast is treated with…

model spray of bees wax

which clasps are cast as part of the framework?

cast alloy clasps

which clasps should be soldered to the framework?

wrought wire

why should excessive heating of the WW clasp be avoided during casting or soldering?

it will cause recrystallization compromising the wire’s mechanical properties

reduced flexibility

WW clasps should be soldered to the framework at some distance from the _____ ______ reducing the likelihood of overheating during the soldering procedure

retentive terminal

how to avoid overheating the WW clasp during soldering?

WW clasps should be soldered to the framework at some distance from the retentive terminal

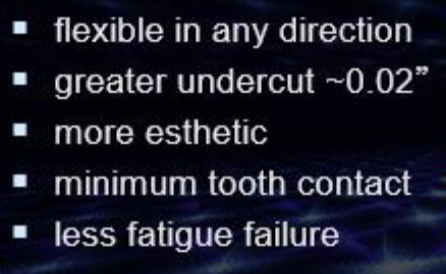

advantages to WW clasp

disadvantages to wrought wire

you should examine the metal framework extra orally for what?

presence of defects )bubble, voids, porosities, nodules

continuity

thickness of components

finish lines

polish

location of components

fit

you should examine the metal framework intraorally for what?

complete and stable seating

adaptation

occlusion