Orgo Lab 2 Quiz 6: Reversible Reactions

1/16

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

17 Terms

This week's Inquiry: Part 1

- How can we obtain the best possible yield from reversible reactions?

→ Reversible: Keq ~ 1 (both reactants and products are abundant at equilibrium)

Examples of common esters (5)

- Ethyl pentanoate: used in apple-scented products

- Isoamyl acetate: used in banana-scented products

- Bornyl acetate: component of synthetic pine-needle scent

- Ethyl acetate: produced by spoiled wine (smells bad)

- Jojoba oil: used in anti-acne skincare products

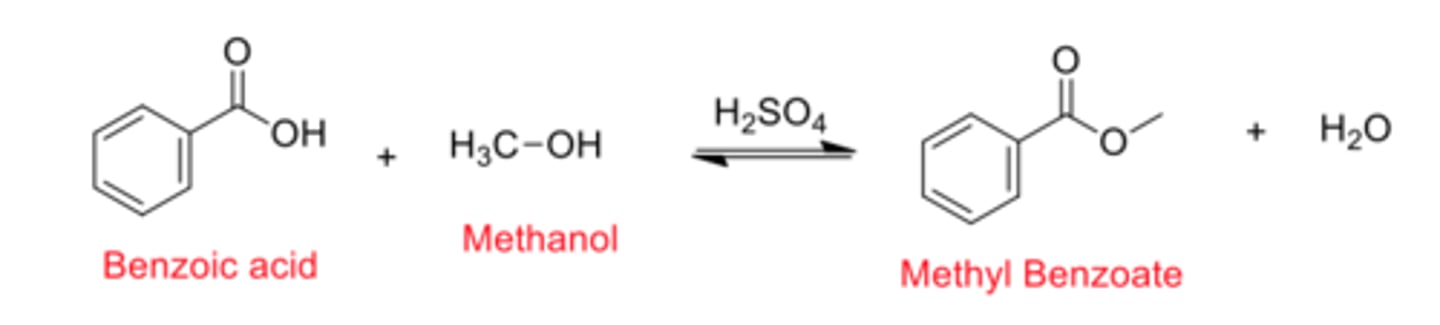

Fischer Esterification: Purpose and Mechanism

- Common method used to synthesize esters

→ Uses an acid catalyst to convert a carboxylic acid + alcohol to an ester + H₂O

Mechanism:

1. Acid catalyst protonates the carbonyl group of a carboxylic acid, making it more electrophilic

2. An alcohol (ROH) adds to the carbonyl carbon to produce a tetrahedral intermediate, which does a proton transfer, then expels H₂O

3. Net result: carbocylic acid + alcohol → ester + H₂O

What 2 reactions will we be performing? What is the goal?

PART 1:

Benzoic acid + methanol → (H₂SO₄ catalyst) → methyl benzoate + H₂O

PART 2:

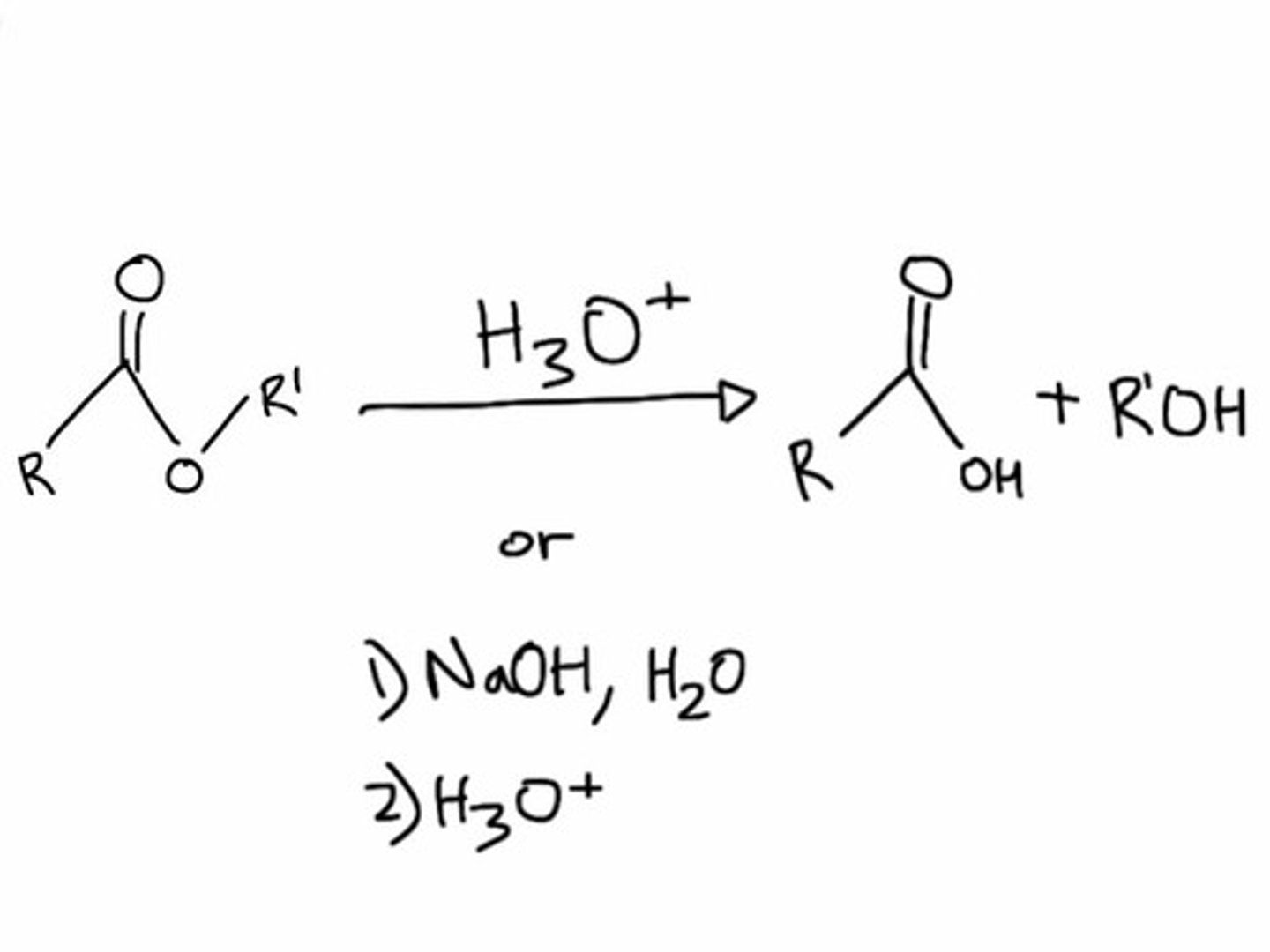

Methyl benzoate + (1) 3 NaOH (2) H₃O⁺→ benzoic acid + methanol

GOAL:

- Analyze each product to see whether we achieved a high yield in both directions

What is the problem with Fischer esterification for synthesis? What is our solution?

- In Fischer esterification, all steps are REVERSIBLE, so the reaction will not naturally run to completion

- For our reaction (benzoic acid and methanol), Keq = 4.0 → this corresponds to an expected (NOT "theoretical") yield of ~67%

- Our solution: increase the concentration of a reactant (by using methanol as the solvent) to drive the reaction forward!

→ This will make the [ ] of methanol ~24.7 mol/L and will increase expected yield to ~99.7%

Why can't we use distillation to drive the esterification (methanol + benzoic acid) forward?

- The most-volatile component of our reaction mixture is methanol (BP ~ 65°C), so methanol will be preferentially removed by a fractional still

- Since methanol is a reactant, distillation would drive the reaction in reverse and DECREASE the yield of products

Our Experimental Procedure: Esterification of Benzoic Acid (Part 1)

1. Convert 5g benzoic acid to methyl benzoate using Fischer esterification

→ Combine 5.0 g benzoic acid, 25 mL methanol, and 1.5 mL H₂SO₄

2. Purify the ester product by liquid-liquid extraction with 25 mL water and 25 mL diethyl ether, then wash with 10% sodium bicarbonate and dry with anhydrous magnesium sulfate

→ Rotary evaporate to remove ether

3. Analyze the neat liquid product by FT-IR spectroscopy (to determine whether we successfully produced an ester) and ¹H NMR spectroscopy (to confirm that our product was methyl benzoate

→ Solvent: deuterated chloroform

4. Store the product in a sealed vessel for use in part 2

Chemical Waste Plan: Part 1

- All organic materials produced are NON-HALOGENATED ORGANICS

- Aqueous washings (from liquid-liquid extraction?) can be acidic or basic, so test pH using alkacid paper, then place in AQUEOUS OR BASIC ACIDIC container as appropriate

- Transfer pipettes = BROKEN GLASS

- Filter paper should be dried in the hood, then placed in SOLID WASTE

This week's Inquiry: Part 2

- How can we make benzoic acid from methyl benzoate?

→ We are converting last lab's product back into the original reactants via saponification

What are 2 pathways for the hydrolysis of esters?

1. Acid-catalyzed hydrolysis

- Yields a CARBOCYLIC ACID and an ALCOHOL

- Basically the reverse of the Fischer esterification process (and, thus, establishes an *equilibrium*)

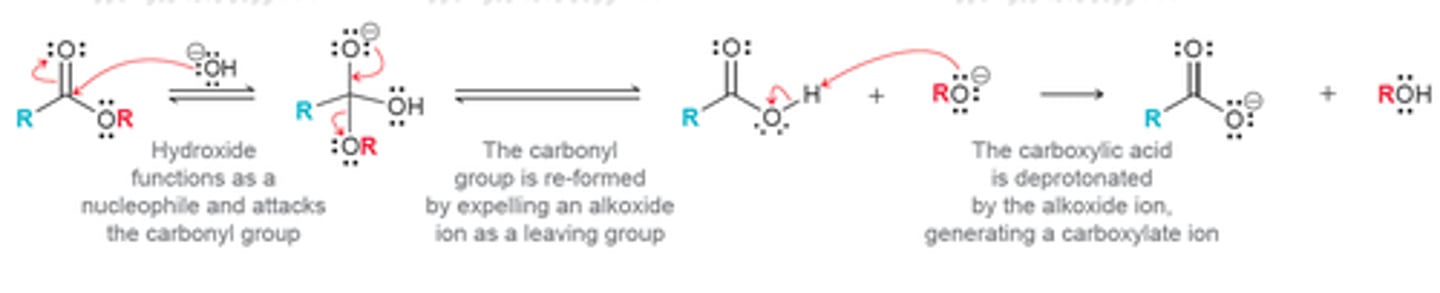

2. Hydrolysis under basic conditions ("saponification")

- Yields a CARBOXYLATE (deprotonated carboxylic acid) and an ALCOHOL

- Once the OH⁻ adds and is deprotonated, the reaction is *NOT reversible* (because nucleophiles will not attack the anionic carboxylate)

- This means that the reaction should proceed to completion!

Saponification: definition and process

- The clevage of an ester into an alcohol + carboxylate anion using H₂O and BASE

- Note: NaOH (the base) is CONSUMED in this reaction (adds to the carbonyl carbon) → it is not acting as a catalyst

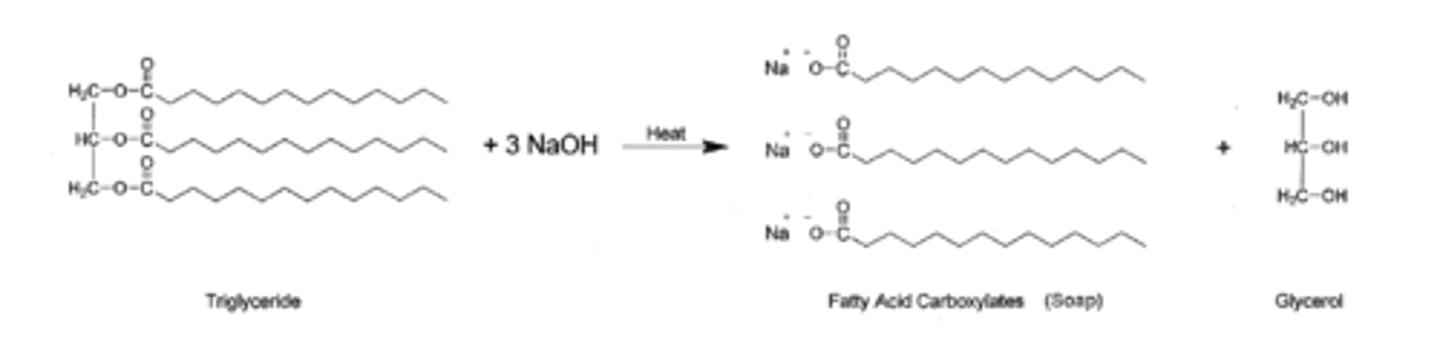

Modern uses of saponification

- The fatty acids produced by hydrolysis of triglycerides (esters!) are common ingredients in detergents and soaps

Fat (solid lipid) or oil (liquid lipid) + 3 equivalents NaOH → glycerine/glycerol + 3 fatty acid salts (carboxylic acid compounds)

How was saponification/soap discovered (according to the Fight Club dude?)

- Wood ashes + water = lye (basic)

- Lye + fat (from burnt bodies) = soap

- Also: glycerine (byproduct of triglyceride saponification) + HNO₃ = nitroglycerine (explosives)

*In case prof Davis asks, this guy's name is Tyler Durden

Safety notes: silica glasswear

- Silica (in glass) is slightly soluble in bases—when refluxing a very basic solution, you may prioduce NaSiO₃ (a component of cement), which can "cement" your glasswear together

- Solution: use extra vacuum grease

What should we look for in the IR when analyzing our products?

- Part 1: if we converted benzoic acid into methyl benzoate, the broad carboxylic acid O-H absorption should disappear

- Part 2: if we re-produced benzoic acid, the O-H should be present

Our experimental procedure: part 2

1. Convert 5.7 g of methylbenzoate into benzoic acid using a saponification reaction

→ Combine 5.7 g methylbenzoate and 40 mL of 3M NaOH, and reflux for 45 minutes

2. Precipitate the benzoic acid product by acidifying the reaction mixture with HCl

→ Produces benzoic acid from benzoate ions)

3. Recrystalize the precipitate from deionized water

4. Analyze the product by FT-IR and ¹H NMR spectroscopy

Chemical Waste Plan: Part 2

- All organic materials are NON-HALOGENATED ORGANICS

- Aqueous solutions = AQUEOUS ACIDIC

- Filter paper (dried in fume hood) = SOLID WASTE

- Transfer pipettes = BROKEN GLASS WASTE