Business 212: Business Statistics Ch 16. Using Control Charts in Business

1/44

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

45 Terms

statistical process control

a way to apply statistics to identify and fix problem in quality control

common cause

comes from a stable system

special cause

comes from a specific issue or event

PCDA

plan, do, check, act

The design of a product is causing quality control issues. This is an example of a which type of cause?

Special

Common

Specific

Uncommon

Common

A cause of variation that comes from a specific event or issue is what type of cause?

Uncommon

Common

Specific

Special

Special

After figuring out whether a change reduces variation, the PDSA method requires that the company do which of the following?

Plan

Study

Do

Act

Act

Implementing a change in the process is part of which step of PDSA?

Study

Do

Act

Plan

Do

How does the Act step relate to the Planning step of PDSA?

The process is random so Act and Planning may be the same

The process is hierarchical with Act coming first

The process is terminal so Act is the last step

The process is cyclic so Act leads to Planning

The process is cyclic so Act leads to Planning

Process control

the mechanism by which a company ensures that its processes are standardized to the point that variance is minimal and there is high reliability in the outputs of the process

Rational sub-grouping

instead of comparing data points over time, the sub-grouping actually examines the results of production that occurred under substantially similar conditions

Process sampling

occurs when the output or result of process, usually selected at random, is evaluated

A process that, when followed strictly, still produces a poor output is a process that _____.

automates error

reduces costs

controls a sub-group

improves output statistics

automates error

ABC Widgets has a manufacturing plant that produces 100,000 units per day. Every unit produced on any given day should have virtually no variances between units. The term _____ describes the act of scrutinizing a part of the process for the purpose of evaluating whether the process is proceeding as expected.

process sampling

root cause analysis

variance evaluation

process observation

process sampling

Which of the following would NOT qualify as a rational subgroup for a sampled process?

All widgets made from 1 of 12 machines in the same factory.

All widgets produced by the overnight shift.

Widgets produced in 1 of 21 nationwide factories.

Widgets produced over a 10-year period.

Widgets produced over a 10-year period.

The now defunct automaker Saturn experimented with a rational sub-group process control mechanism by which any employee at the company could:

Immediately and unilaterally stop the entire assembly line if they noticed a process problem that could impact quality or safety.

Select any car from the assembly line for immediate quality inspection.

Anonymously communicate the trade secrets of its competitors.

Report a violation of the collective bargaining agreement (CBA) without leaving their post.

Immediately and unilaterally stop the entire assembly line if they noticed a process problem that could impact quality or safety.

Jamestown Steel produces beams for building construction. Which scenario is the BEST example of a rational subgroup?

Line workers are permitted by the company to stop production if any beam appears to be too long.

The company creates one test batch for every 50 beams produced.

The company sorts beams by length and double-checks every beam prior to shipping.

The company randomly chooses a few beams from every batch to make sure they are substantially similar in specification and quality.

The company randomly chooses a few beams from every batch to make sure they are substantially similar in specification and quality.

attribute data

non-continuous data

control chart

a graph that shows how something changes across the time

Np chart

how often something occurs with a fixed sample size when the choices are yes/no

the sample size is fixed

p chart

how often something occurs with varying sample sizes when the choices are yes/no

c chart

how often something occurs with a fixed sample size when there are more than two choices

u chart

how often something occurs with varying sample sizes when there are more than two choices

If a sample size is fixed and there are only two choices (yes or no) for whether something has occurred, it is best to use a(n) _____ chart.

p

Np

c

u

Np

A business owner is collecting data about how many products they sell in each of three sizes: small, medium, and large. The data the owner is collecting is _____ data.

continuous

controlled

attribute

continuum

attribute

If a sample size varies and there are only two choices (yes or no), the data is best arranged in a(n) _____ chart.

p

Np

u

c

p

Which type of data is on a continuum?

attribute

categorical

controlled

continuous

continuous

A manager has collected data that looks at how many bugs are in the programs his company produces each day. The company produces different numbers of programs each day, and some programs have several bugs. The best choice is for the manager to use a(n) _____ chart.

u

Np

p

c

u

variables

things that change value

control chart

visual representation of information across time

Khalil wants to see how much variation there is in the cost of manufacturing his company's products. He is likely going to use a control chart to see the _____ data.

distribution of

monitored stability in

trends in

implemented changes of

distribution of

Visual representations of information across time are called _____.

distributive curves

control charts

monitored charts

attribute curves

control charts

Which of the following is a variable in business?

cost to manufacture a product

All answers are correct.

durability of a product

profit and loss

All answers are correct.

Leslie's boss gives her a control chart showing her how much time the sales reps in her department have spent with customers over the past month. This allows Leslie to see if the time spent with customers is increasing, decreasing, or staying the same over time. This is an example of using control charts to _____.

monitor a situation

determine whether implemented changes are working as expected

follow trends in the industry

understand when to take action and what action to take

monitor a situation

Using control charts to decide whether to increase spending on professional development for employees is an example of using control charts to _____.

follow trends in the industry

determine whether implemented changes are working as expected

understand when to take action and what action to take

monitor a situation

understand when to take action and what action to take

control chart

graph that shows variations in quality of manufacturing over time

systematic cycle

a regular up and down pattern

trend

data that goes up and down over time

sudden change

indicates something major occurred once to shift manufacturing

gradual change

indicates that something is happening on a continuous basis or something that has happened is gaining steam

Clarence is looking at a control chart for his company. It shows that they are very productive for three weeks, and then they have a week where they are not productive, followed by three more weeks of high production. Which type of pattern is Clarence noticing?

systematic trend

systematic cycle

sudden change trend

gradual change trend

systematic cycle

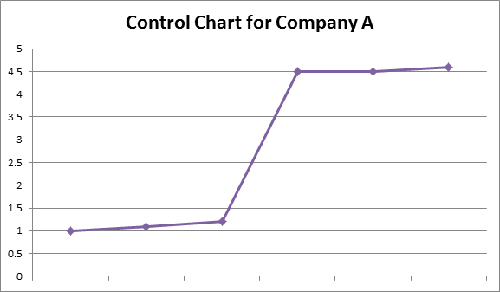

What is most likely to have caused the change in this control chart?

an initiative that is gaining steam

a sudden, one-time occurrence

a continuous process initiative

a regular occurrence that impacts production

a sudden, one-time occurrence

Regular maintenance of equipment, training of employees, and other ongoing initiatives can help companies improve their production. Which pattern on a control chart will most likely represent these types of changes?

sudden change trend

systematic cycle

systematic trend

gradual change trend

gradual change trend

Clarence is looking at a control chart for his company. It shows that they are very productive for three weeks, and then they have a week where they are not productive, followed by three more weeks of high production. Clarence's company's changes are likely due to:

something major that occurred once to shift production

something that is gaining steam and shifts production

something that is happening on a continuous basis to shift production

something that regularly influences production

something that regularly influences production

Juliana examines a control chart that shows that her company's manufacturing plant suddenly began making more faulty items after they installed a new machine. Which type of pattern is Juliana observing?

sudden change trend

gradual change trend

systematic cycle

systematic trend

sudden change trend