shaw resilient flooring

1/10

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

11 Terms

8 factors of performance

Topcoat- protect the flooring against scratches, stains, and scuffing

Gloss - impacts perception of scratches (higher the gloss, show more scratches)

Emboss- applied to the surface of the flooring product

Wear layer- protective layer above the print film that can come in different thicknesses

Print film- is the layer the visual is printed on, through rotogravure or digital

Color- hide scratches but show more soil, dark colors hide scuffing but show scratches, usage of the space

Core construction - give the platform more thickness, add height, provides dimensional stability

Installation and maintenance - check before install

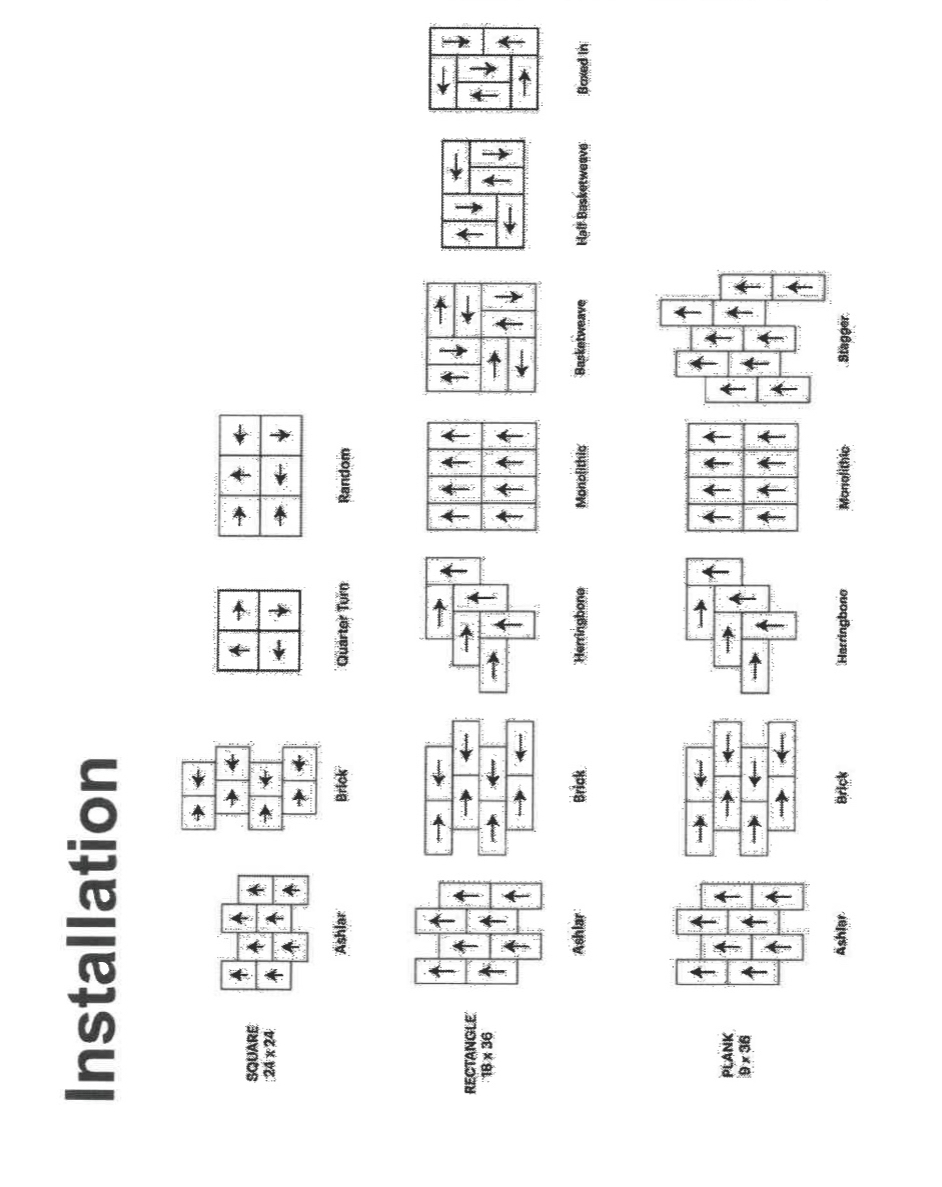

Installation, keys, drawings

Before product

checking the slab for moisture conditions can prevent lifting of planks and adhesive failure

Uneven subfloor can telegraph through some product

Sephora really needs to be completlymlevel

Installing on top of old products can also cause imperfections to show through the new resilient products

Before installation

proper transition or minimizing transition can affect the user experience, and can minimize the risk of trip and fall

Keys

include any installation, diagrams, or key for subtracter to install is complicated

Ensure the design is installed, how it is supposed to be

More efficient

Factors to consider on a project

scope

Budget

Usage

Aesthetic

Timeline

Sustainability

Maintenance - how often will product be cleaned, what’s the clients current space?, our employees eating or drinking in the space, important to manage the clients expectations

Important to the end user

Same answer for the other slide

Benefits of resilient flooring

Durable

Cost effective

Easy to maintain and install

Aesthetic

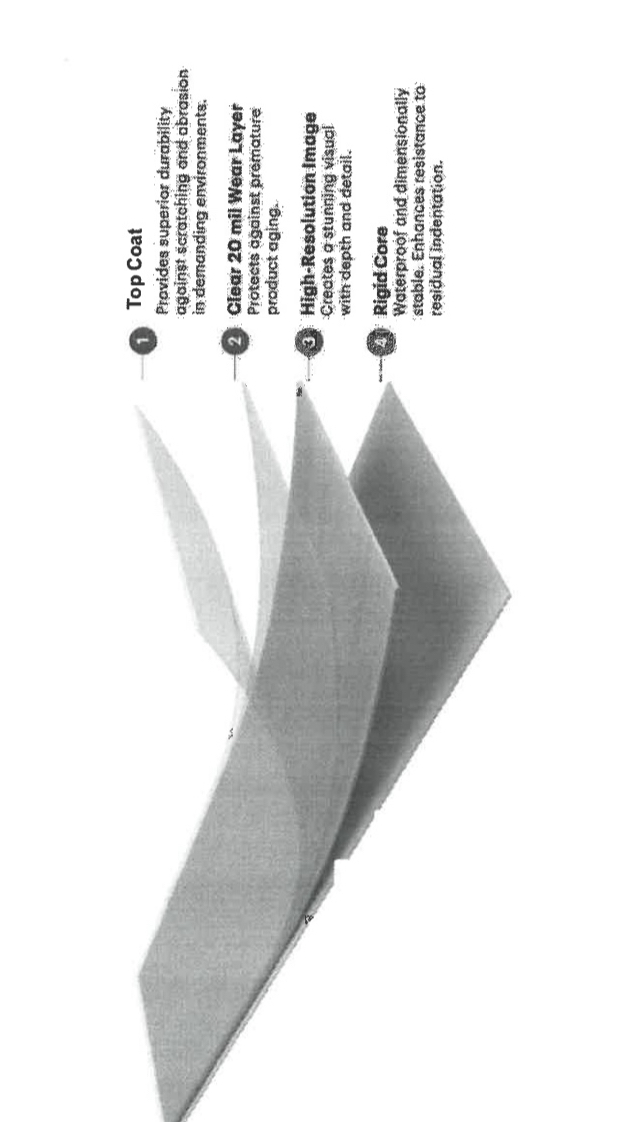

LVT

Luxury vinyl tile

Top 8 layers

rigid core

Types

Spec/xrc (solid polymer composite)

Mineral core (mineral composition)

Benefits

helps uneven, subfloors, and telegraphing

Performs with high static and rolling loads when glued down

Water resistant from top to down

Does not have to acclimate

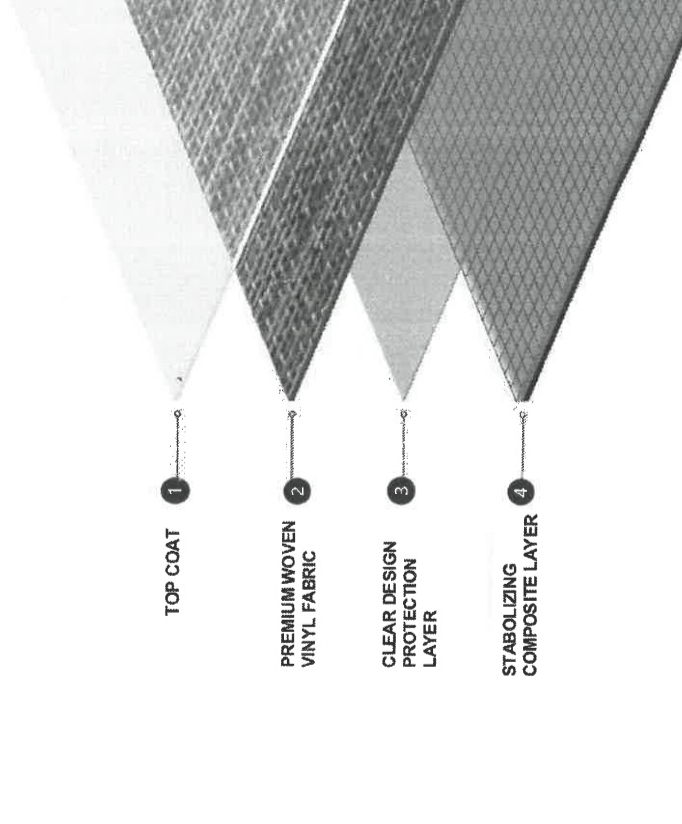

Woven resilience

performance of an LVT, with a visual of a textile

Performs in environments with heavy static and heavy, rolling loads

Some manufacturers add a topcoat to seal the woven and keep dirt out

Direct glue insulation

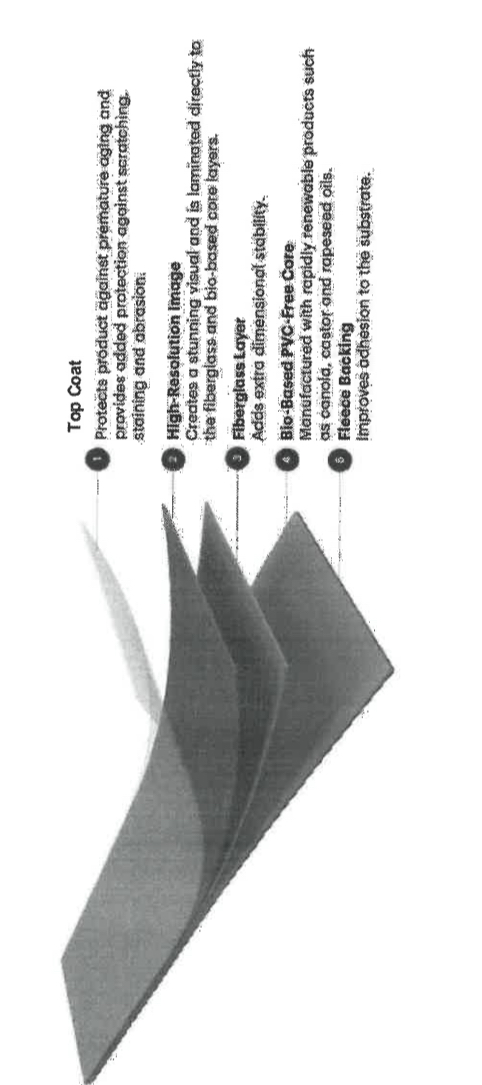

Bio-based

cost more than traditional LVT

Cannot be polished

Manufactured wood rapidly, renewable products, such as canola, castor, and rapeseed oils

Available in sheet or plank

Heterogeneous construction

Sheet goods

Homogenous

uniformed structure- through body

6’7” wide

95% is heat welded

Can be cover to create barrier against moisture and fluids

Most durable type of resilient for punctures in cuts

Heterogeneous

made up layer

Can be covered

Lots of options

Heated welding

Welding chemical

also called cold welding

Uses a solvent to merge two pieces of resilient sheet goods together

Does not create as much as a full seal as

Heat welding

continuous flooring surface is created by a mechanical bond in the seam

Uses he in bed rods made of the same material as a sheet to bond to seams

Welded floors are the most aspect in the only impervious floors

Flash cove

she good is extend it to go up the bottom of the wall

Create a more sternal environment, perfect for spaces where clean this is critical

Other resilient flooring: VCT, Linoleum, Rubber flooring

VCT (vinyl composite tile)

limited visual + product sizes

Maintenance intensive

Homogeneous product with a true true pattern

PVC chips, limestone, and other fillers

Linoleum

PVC free

Limited visuals

Sensitive to UV exposure

Poor stain resistance

Cleaning choices are limited

Rubber

PVC free

Durable and has good slippers resistance

Limited visual

Made from synthetic rubber (not a renewable material)

Subject to fading and colorfast issues