Metals

1/48

Earn XP

Description and Tags

MEC207 Materials Processing, metals section of the course

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

49 Terms

How does casting work?

molten metal

introduced into a mould cavity

solidification into the shape of the mould

finishing processes

how can heat transfer affect solidification?

most metals contract when solidifying

cooling too quickly can cause defects

What are the 3 types of casting? What are they good for?

sand casting - larger, one off objects

investment casting - small components

permanent mould casting - small, mass production

how do solid state deformation processes work?

they change the shape of the metal by plastic deformation using force

what is rolling?

the process of reducing the thickness (or cross section) by compressive forces applied by a set of rolls

why are backup rolls needed in a cluster mill?

to provide rigidity and prevent deflection

this is needed as the metals being rolled are at room temp. and so very strong

what unique thing does a steckel mill do? why is this good?

it pulls the metal whilst it is being rolled

this increases surface quality

and reduces energy requirements of the mill

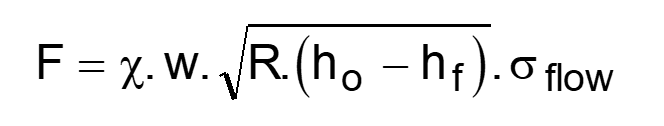

what is the rolling force equation?

F - rolling load/force

X - friction factor

w - width of the material being rolled

R - radius of the rolls

ho - initial gauge thickness

hf - final gauge thickness

σflow - flow stress of the material

What should one do if the rolling load is greater than the capacity of the rolling mill?

get a better machine

raise the temperature in order to decrease the strength of metal

decrease the amount of rolling reduction per pass

What are 4 types of defects that can happen in rolling?

flatness

porosity

edges cracking

crocodile defect

How does extrusion work?

a round billet is placed into a chamber and forced through a die opening by a ram

it is normally carried out at elevated temperatures

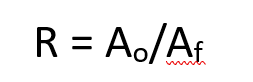

what is the extrusion ratio equation?

R is the extrusion ratio

Ao is the initial cross sectional area of the billet

Af is the final cross sectional area of the extrusion

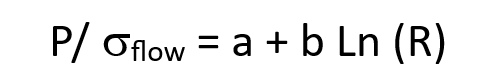

what is the extrusion pressure equation?

P is the extrusion pressure

σflow is the flow stress of the material

a and b are extrusion constants

R is extrusion ratio

Ln is the natural log

how does forging work?

heat the metal up that smack it into desired shape w

what is forgeability?

the capability of a metal to undergo deformation without severe surface cracking

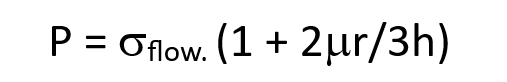

what is the upsetting force equation?

σflow is the flow stress of the material

mu is the friction factor

r is the effective radius of the workpiece

h is the height of the workpiece

What is isothermal forging?

A type of forging where the dies are heated to the same temperature as the workpiece

It is good when you want more control over the mechanical properties though it is expensive

What is anistropy? How can it be resolved?

when the grains are aligned in the direction of deformation

change the direction of deformation every 90°

Why might powder metallurgy processes be used over traditional processing routes?

To avoid high scrap rate

Less steps

Alloys used are high cost and high performance

Can be difficult to machine

How does additive layer manufacturing work?

Layer upon layer addition of material to build up a final component

Advantages of ALM

near-net shape or net-shape

reduced buy-to-fly ratio

low amount of scrap

design iteration friendly - immense freedom of design

allows for complex geometries

What processes are used to turn metals into powders? Describe them.

Water and gas atomisation

The metal is melted then water/gas is blasted at it which turns it into a powder

Name and describe 2 types of ALM

Powder Bed - Laser beam is used to melt layers of powder. High risk of mess up.

Blown Powder - Powder is blown through nozzles and melted as it comes out

What are some issues with laser systems?

bog

Name an alternative to using a laser beam. Why?

electron beam

Disadvantages of ALM

certain powders are expensive to produce

high energy footprint in powder manufacture

still problems w mechanical properties and surface quality

some metal systems cannot easily be used

How does metal injection moulding work?

metal and binder mixed then granulated and put into injection mould

injection moulded into green compact that is around 65-70% dense

remove binder through heating to form brown compact

sintered to increase density then final product is virtually 100%

Name some considerations for MIM

quality of powder - fine and spherical is best

binder

injection

debinding - careful handling needed

sintering

What happens to the part’s volume due to sintering?

It decreases

Advantages and disadvantages of MIM

advs

good for very small parts

offers large flexibility on chemistry and geometry

lower energy footprint per part than casting

disadvs

carbon pickup

powders are expensive

high cost and energy footprint of powder involved

potential problems with mechanical properties because of porosity and poor surface finish

limitations on size and dimensions of component that can be built

Not all alloy systems suitable for MIM

How does hot isostatic pressing work?

Put powder in a paint can and squeeze it at high temperature to squeeze out all porosity

produces something fully dense

Name some considerations for HIP

capsule manufacture

design

HIP cycle

mould removal

Advantages and disadvantages of HIP

Advs

unparalleled shape complexity and surface quality

trusted process

only way to make some metal matrix composites

Disadvs

costly

complex

low volume

How does spark plasma sintering work?

Put powder in a mould and pulse a DC current through it for very short periods of time (10ms)

The spaces between particles get highly charges and pores close under high pressures

Name the different types of bonding

Primary - strong

ionic

covalent

metallic

Secondary - relatively weak

van der waals

hydrogen

Which 3 properties does bond energy affect?

melting temperature

elastic modulus (stiffness)

thermal expansion coefficient

how does bonding energy affect melting point?

higher bonding energy means higher melting point

what is thermal expansion?

when the temperature of an object increases and causes the amplitude to increase making the overall object to expand

how does bonding energy affect the coefficient of thermal expansion?

as bonding energy increases, the coefficient of thermal expansion decreases

what are the 3 main types of crystallographic structure?

face centred cubic (FCC)

body centred cubic (BCC)

hexagonal close packed (HCP)

Describe FCC

atoms touch each other along face diagonals

Describe HCP

hexagonal layers stacked on top of each other

Describe BCC

not a close packed structure

atoms on the edges of a middle one

touch on diagonals

why is atomic arrangement important?

determines microstructure and properties of a material

controls a large number of properties

similar behaviour is shown in materials with the same arrangement

can cause anisotropy

what is polymorphism?

when a material shows more than one crystal structure

what is allotropy?

when a change in structure is reversible

Describe iron’s polymorphism journey

low temp iron is BCC (alpha)

changes to FCC at 912°C (gamma)

reverts to BCC at 1394°C (delta)

upon cooling, the reverse occurs

How can one physically see iron’s structure changes?

a iron wire changes in length due to changes in density

as it changes from BCC to FCC, it undergoes a contraction as FCC is close packed while BCC is not. it expands suddenly when it gets to BCC again

What happens to Tin when it cools?

she be exploding because her structure changes which causes her volume to decrease by like 27%