1.4 Addition/fabrication processes

1/6

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

7 Terms

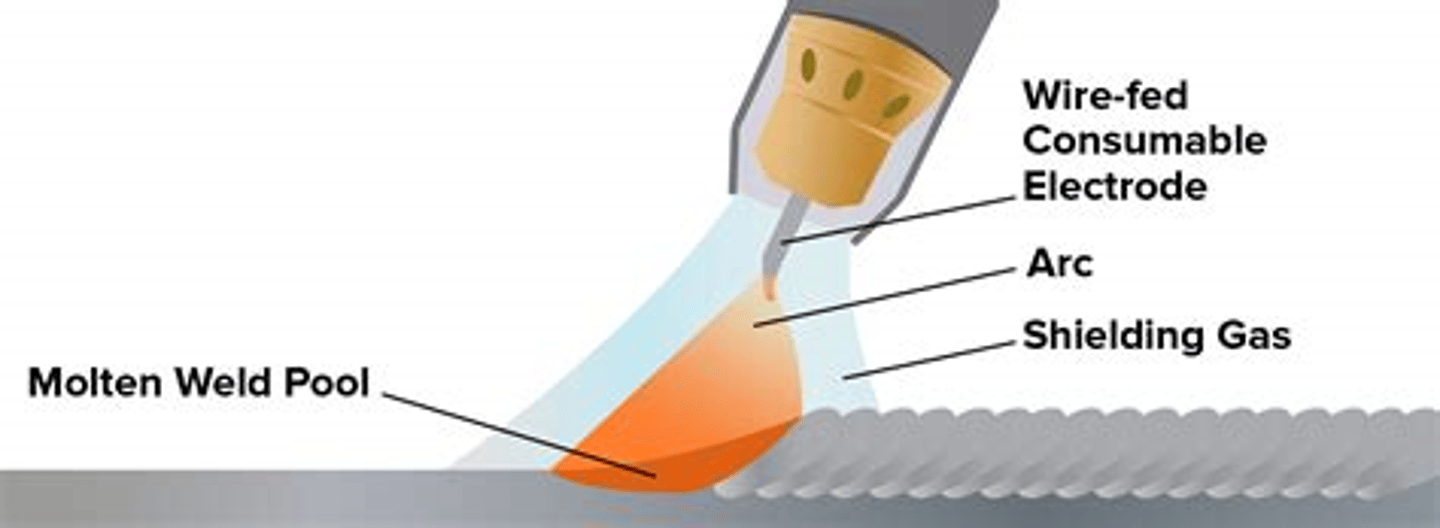

MIG welding (metal inert gas)

A form of resistance welding using an inert gas to provide a protective cloud around the joint area as it is being joined.

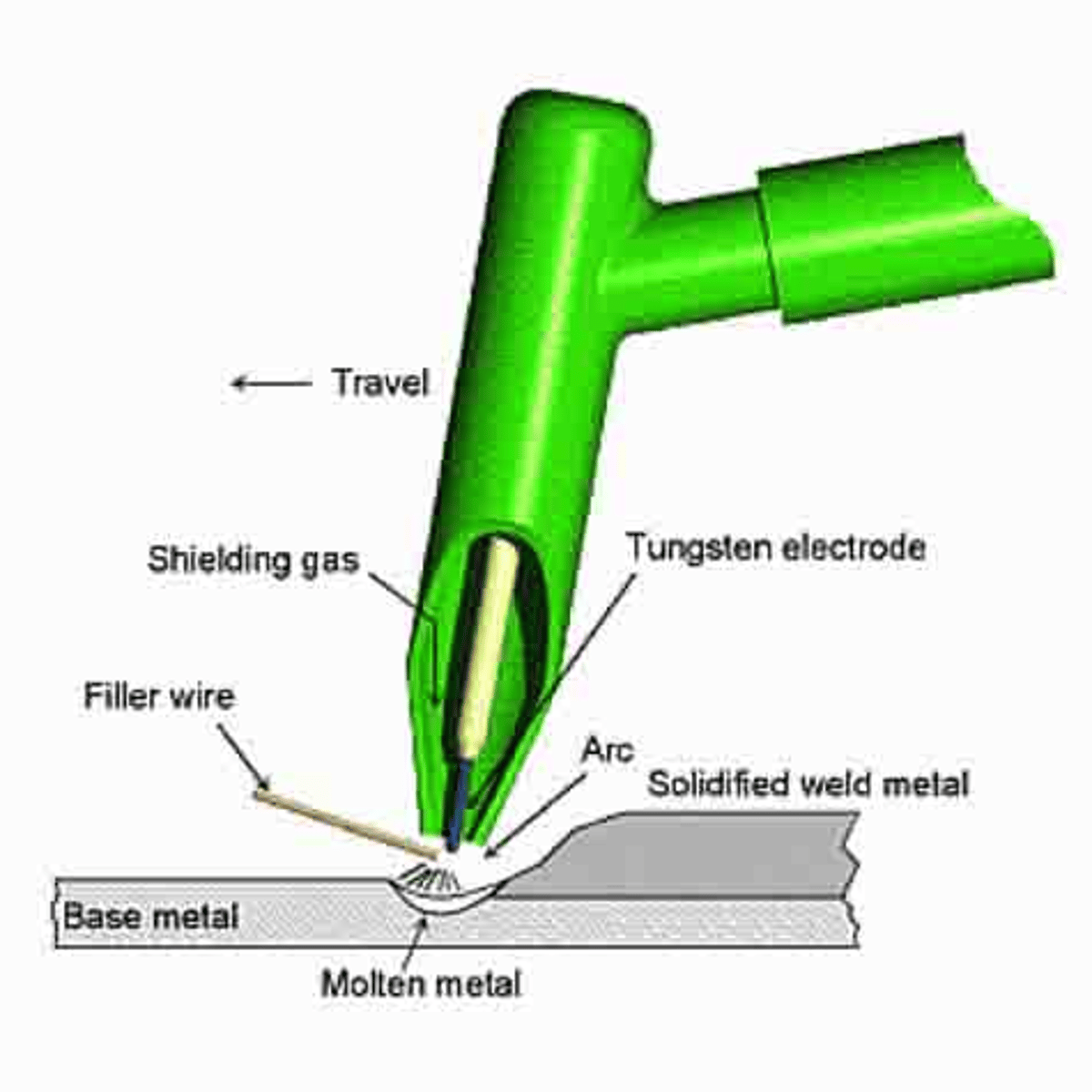

TIG welding (tungsten inert gas)

A form of electric arc welding using a tungsten electrode, the arc from which is surrounded by an inert gas such as argon to prevent oxidation during welding. Used for stainless steel and other non-ferrous metals like aluminium and copper or magnesium alloys.

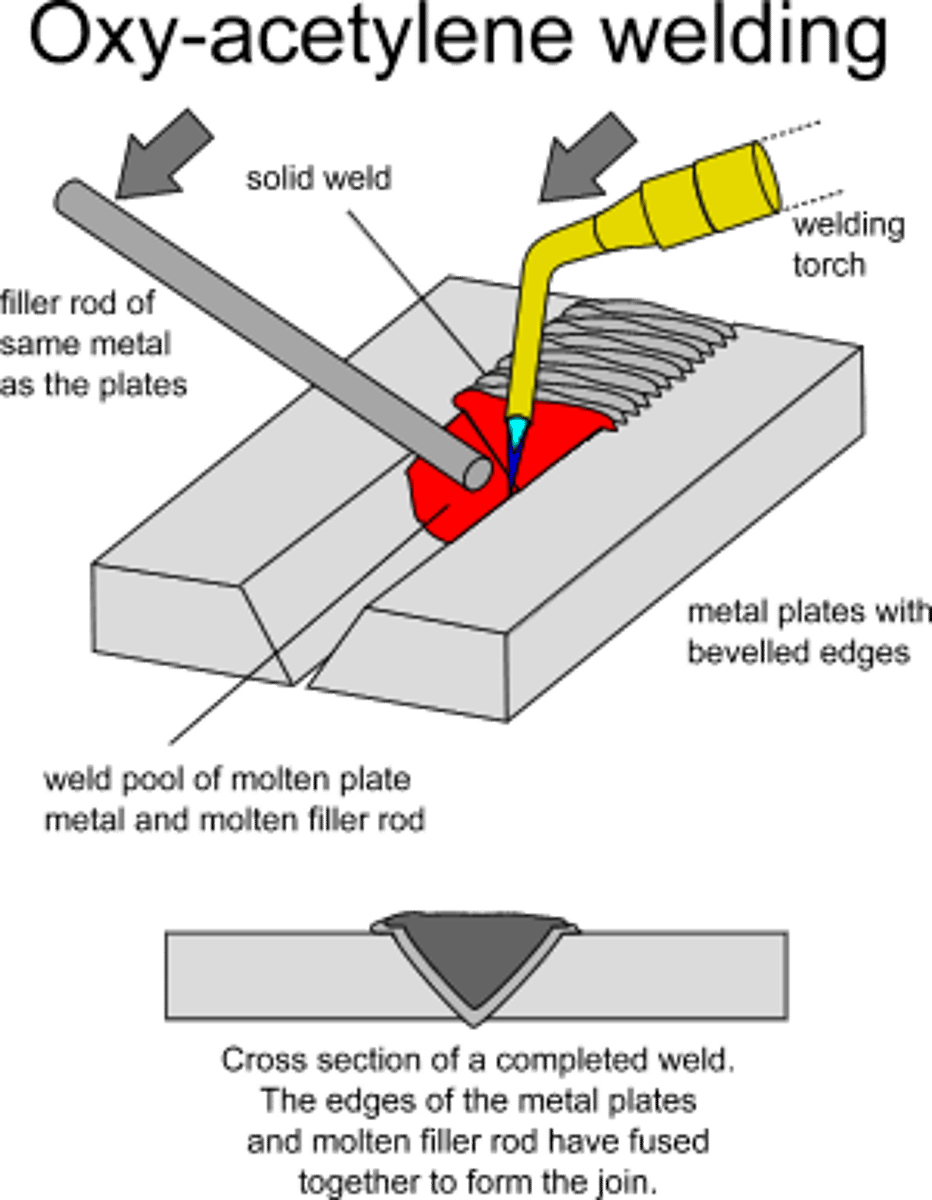

Oxy-acetylene welding

1. The metal is prepared by grinding an angle on the edges of the two pieces to be joined to form a v shape. this is done to ensure that the weld runs through the entire thickness of the metal

2. the joint area is heated to form a melt pool and at the same time, steel filler rod is introduced to the joint area. The melt pool is extended to form a continuous bead along the length of the joint. the molten metal will flow to the hottest part of the metal, therefore by moving the torch along the joint line, a continuous seam is formed

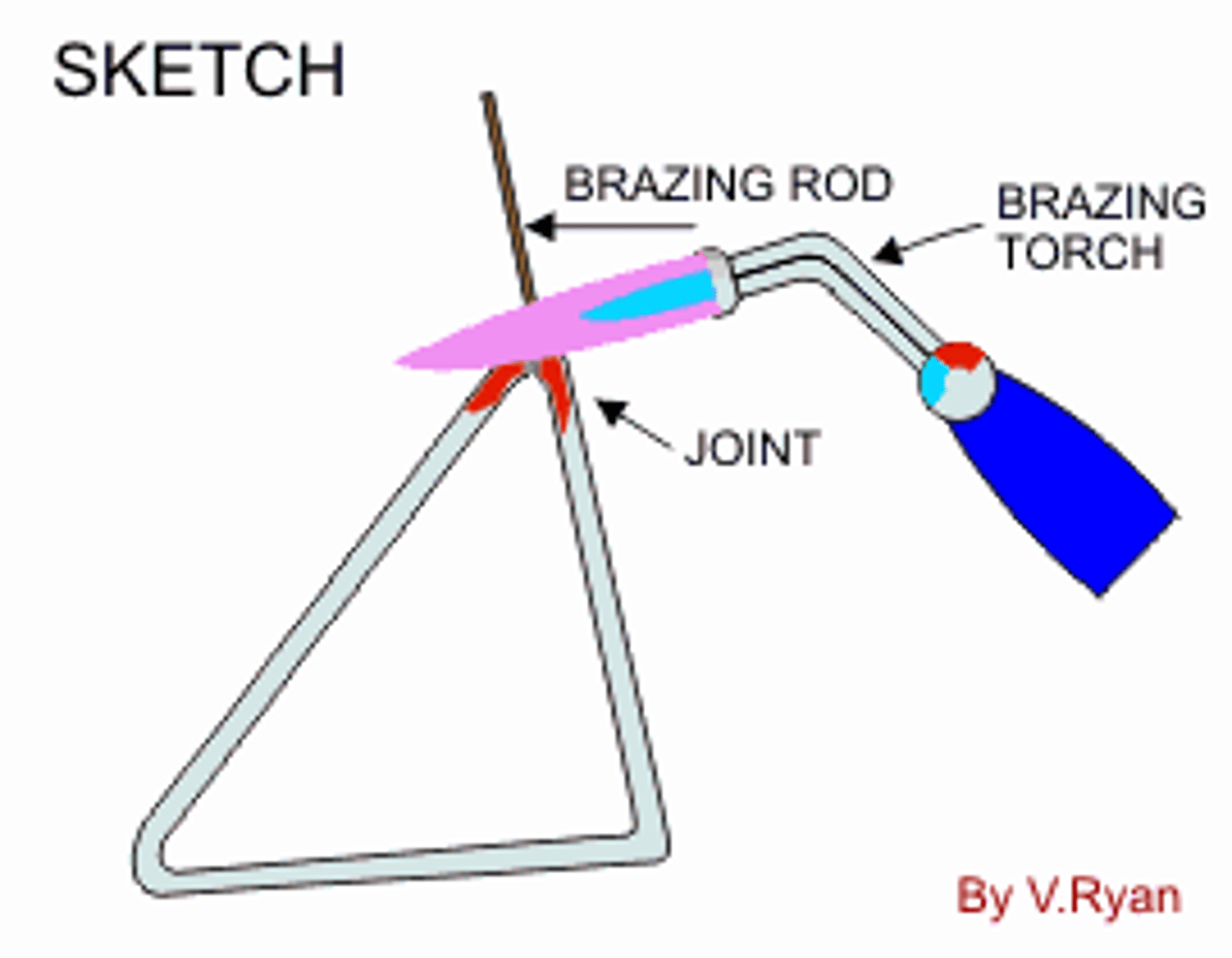

Brazing

1. The material to be joined is cleaned and degreased

2. The two pieces are clamped together

3. A flux is applied ( helps prevent the joint from oxidising )

4. The joint is heated using an oxy-acetylene or gas/air torch to a temperature of approximately 850 degrees

5. The brazing rod is applied to the joint area. The brazing spelter will flow along the joint by capillary action to the hottest part, so it can be made to follow the joint line by manipulating the torch

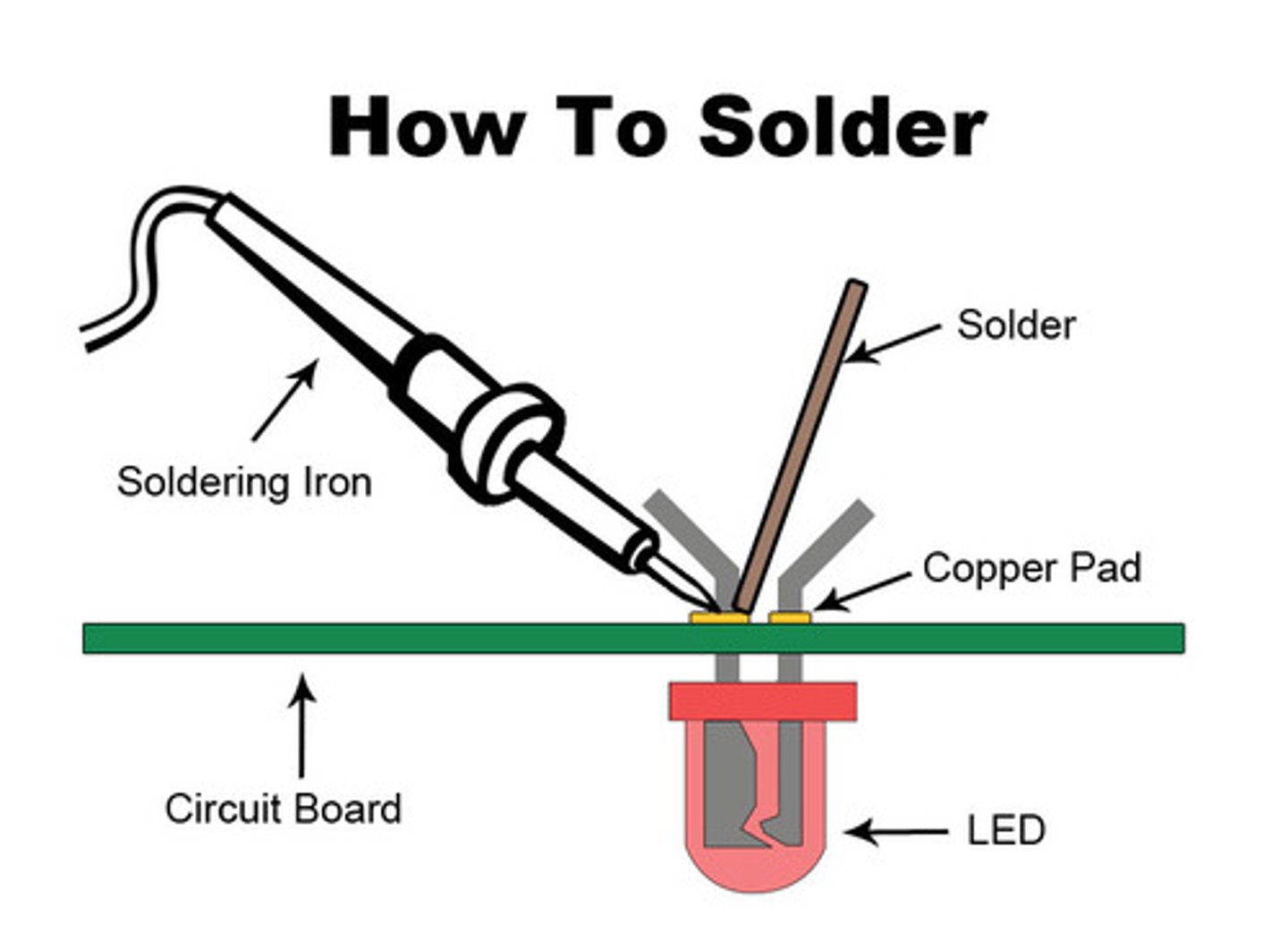

Soldering

1. The metal is cleaned and degreased

2. The joint area is wired up or clamped

3. The metal is heated up to the melting point of the solder

4. The solder is added to the metal. The solder will flow along the joint using capillary action

5. the metal is cleaned to move any flex residue

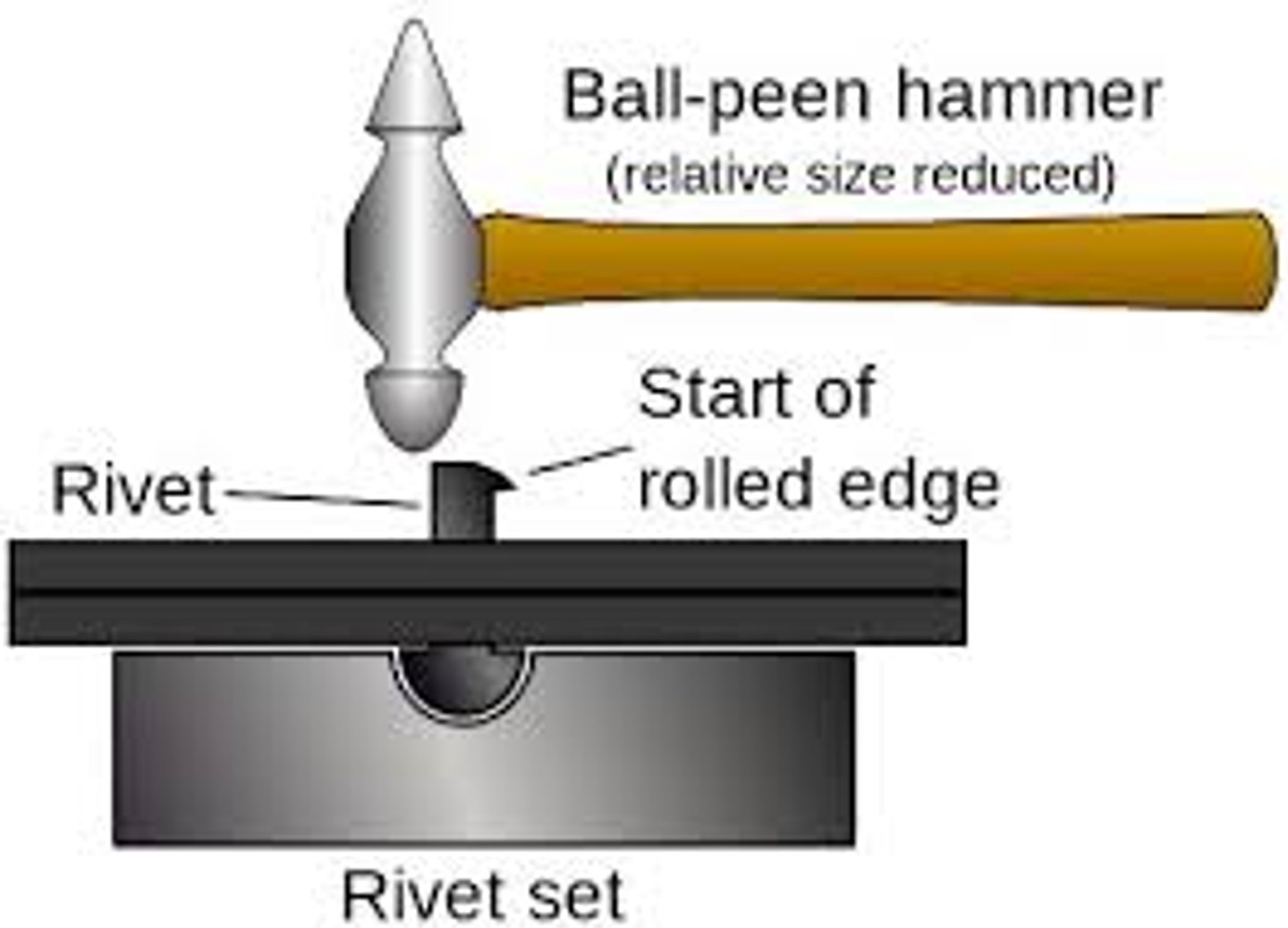

Riveting

Riveting is a permanent joining method usually used to join sheet metal or plate. Rivets are metal fasteners that have a head at one end and a shaft or tail at the other end.

Pop riveting

Is a technique that is used to join thin pieces of sheet metal and it can also be used to join plastic sheet