[FC] TOPIC 5: Hazards Analysis Methods

1/20

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

21 Terms

HAZOP stands for?

HAZ — Hazard || OP — Operability

Hazard — any deviation in operation that can cause:

a release of toxic, flammable or explosive chemicals, or

any action that could result in injury to personnel

Operability — any deviation in operation within the design envelope that will cause:

a shutdown or

lead to a violation of environmental, health or safety regulations, or

negatively impact profitability

What is HAZOP?

A systematic process hazard analysis technique to IDENTIFY potential hazard & operating problems

Conducted by a multi-disciplinary team using qualitative technique based on "guidewords" to uncover deviations

Guidewords help to detect how deviations can lead to hazardous situations or operability problems

Purpose of HAZOP

Identify deviations from design/normal operations and uncover associated hazards and operability problems

Generate corrective actions to eliminate risks of these deviations that result in hazardous consequences or operability problems or reduce them to acceptable levels

When to conduct HAZOP and follow-ups?

Design Phase — When P&IDs reach ‘Approved for Design’ stage

Construction Site Inspections — Verify HAZOP recommendations are implemented

Pre-Commissioning — Conduct safety reviews plant procedures & safety audits

Operational Phase — Regular reviews (every 5 years) and after modifications to ensure continued safety

HAZOP study team

HAZOP study team should consist of:

Typically consists of 5-8 people with a range of relevant skills

Independent leader (not from the plant being studied)

Project engineer

Operations representative

Discipline engineers

Process

Instrument/ electrical

Mechanical/ maintenance

HAZOP minute recorder

One of the above

What information does HAZOP require?

HAZOP requires the following information:

P&IDs

Process flow diagrams

Heat and material balances

Layouts

Interlock logic diagrams

Equipment data sheets

Safety data sheets

Hazardous area layouts

What modes of operation does HAZOP consider?

Modes of operation to be considered during HAZOP study:

Normal operation

Reduced throughput operation

Routine start-up

Routine shut-down

Emergency shutdown

Commissioning

Special operating modes

Principle of HAZOP — flow

Preventive Actions | Mitigation Actions | |

↑ | ↑ | |

Identify Causes | ← PARAMETER → | Identify Consequences |

Principle of HAZOP — Guidewords, meanings and examples

GUIDEWORDS | MEANING | EXAMPLES / DEVIATION |

No (not, none) | None of the design intent is achieved | No flow when production is expected |

More (more of, higher) | Quantitative increase in a parameter | Higher temperature than desired |

Less (less of, lower) | Quantitative decrease in a parameter | Lower pressure than normal |

As well as (more than) | An additional activity occurs | Other valves closed at the same time (logic fault or human error) |

Part of | Only some of the design intention is achieved | Only part of the system is shut down |

Reverse | Opposite of the design intention occurs | Back-flow when the system shuts down |

Other than (other) | Complete substitution as another activity takes place | Liquids in the gas piping |

Early / late | The timing is different from the intention | - |

Before / after | The step (or part of it) is effected out of sequence | - |

Faster / slower | The step is done/not done with the right timing | - |

Where else | Applicable for flows, transfer, sources and destinations | - |

Principle of HAZOP — Examples of parameters

|

|

|

Principle of HAZOP — Examples of guidewords + parameter + eg. causes

Examples of Guidewords + Parameters + (eg. causes)

No Flow (eg. wrong flow path, blockage, incorrect blind plate, incorrectly fitted check valve, burst pipe, large leak, equipment failure, incorrect pressure differential, isolation in error)

More Flow (eg. increased pumping capacity, increased suction pressure, reduced delivery head, greater fluid density, exchanger tube leaks, cross connection of systems, control faults)

More Temperature (eg. ambient conditions, failed exchanger tubes, fire situation, cooling water failure, defective control, internal fires)

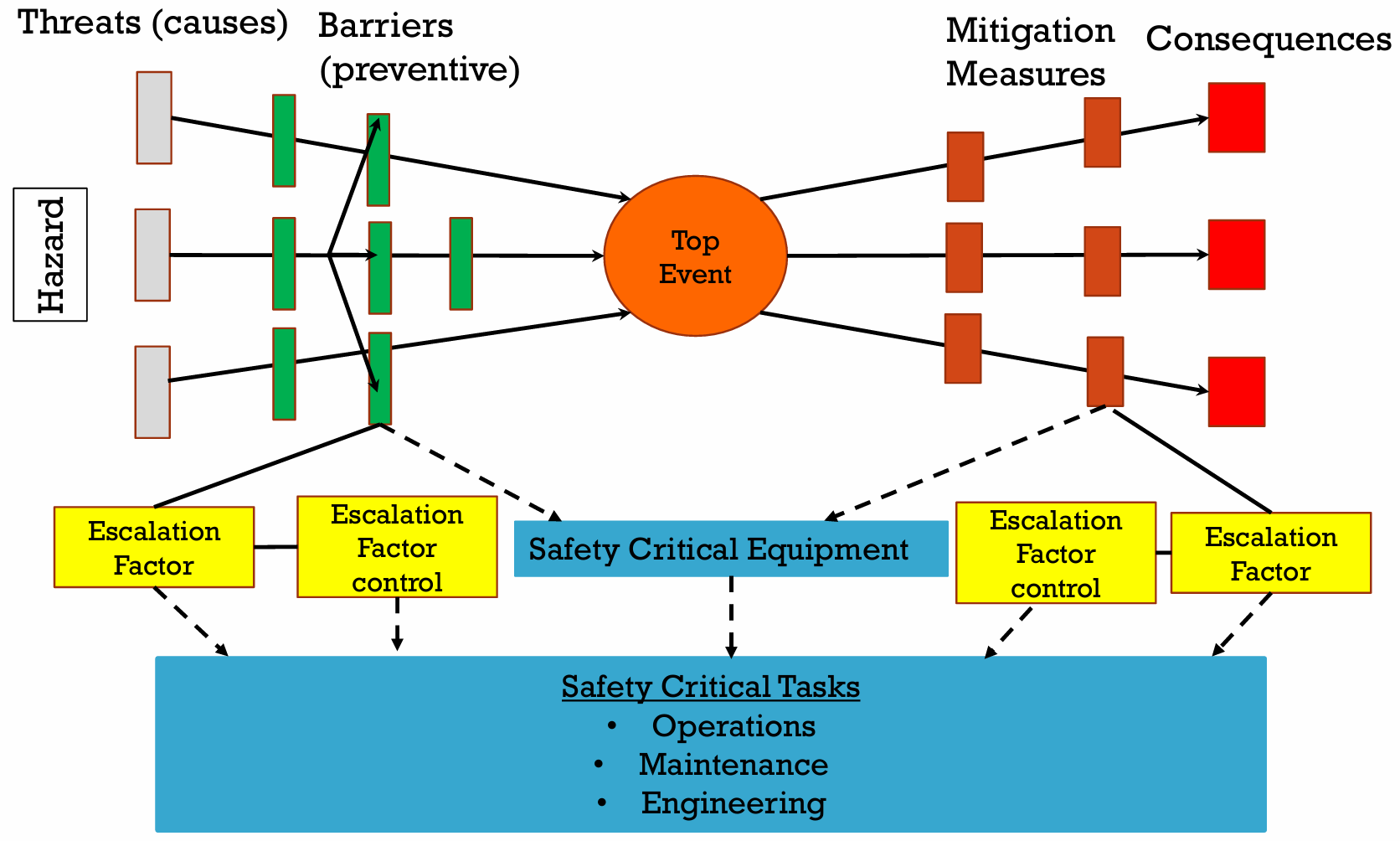

What is Bow-Tie Analysis?

Links Hazards & Consequences to an ‘Event’ which enables development of Causes & Threats and Preventive & Recovery measures

Effective visualisation & better communication of hazards

What are the steps for Bow-Tie Analysis?

(1. Hazard)

2. Top Event

3. Consequence

4. Threat

5. Barriers

6. Recovery Measures

7. Escalation Factors & Controls

8. Critical Tasks

Bow-Tie Analysis — Hazard

1. Hazard — Anything, any source or any situation with the potential to cause:

Bodily injury, ill-health or death

Damage to equipment or properties

Delay to operations or work schedules

Bow-Tie Analysis — Top Event

2. Top Event — The incident that occurs as a result of a hazard being released

eg. Loss of containment

Electrical shock

Fall from height

Exposure to toxic material

Exposure to radioactive material

Effluent discharge into waterways

Emission of toxic gases

Bow-Tie Analysis — Consequence

3. Consequence — An event or chain of events that results from the hazard being released

eg. Serious injury

Death

Latent illness or disease which has long gestation period (Chronic illnesses)

Property damage (ie. own or public)

Environmental damage

Loss of reputation leading to loss in current & prospective business

Loss of revenue - paying for compensation, medical expenses, production loss or deferment

Bow-Tie Analysis — Threat

4. Threat — A possible cause that will release the hazard to become a top event

eg. Threat → Top Event

Corrosion/erosion of pipes → Loss of containment

Loose electrical wiring → Electrical shock/fire

Over-pressurisation of a vessel → Explosion

Incorrect valve positioning → Toxic gas release

Fatigue/lack of training → Incorrect operation of equipment

Extreme weather (eg. lightning) → Power surge/fire

Bow-Tie Analysis — Barriers

5. Barriers — Measures put in to prevent the release of a hazard or to prevent the occurrence of a top event once the hazard is released

eg. Guards or protective shields e.g. protective coatings, corrosion inhibitors, machine guards, fencing etc.

Pressure / safety relief valves

High temperature cut-off switches

Correct / valid / updated operating procedures

Safety interlocks in processes

Lowering speeds of equipment

Carry out maintenance when it is due

Reducing congestion in operating areas

Bow-Tie Analysis — Recovery Measures

6. Recovery Measures — All technical, operational, & organizational measures to reduce the impact of the Consequences due to the occurrence of the Top Event

eg. Gas, fire & smoke alarms

Emergency Shutdown systems

Firewater deluge systems

Fire and blast walls

Emergency Response plans, training & drills

Business Resumption Plans

Bow-Tie Analysis — Escalation Factors & Controls

7. Escalation Factors & Controls — Conditions that lead to increased risk due to loss of barriers or loss of recovery measures especially life saving or mitigating capabilities. Escalation Controls can then be identified for Escalation Factors.

eg. Abnormal operating condition (such as critical standby equipment is under maintenance during an emergency)

Plant operating outside the design envelope

Extreme environmental conditions - may not allow the activation of planned recovery measures

Incorrect operation of the plant due to unavailability of updated operating procedures

Human error due to lack of competence or ineffective training

Bow-Tie Analysis — Critical Tasks

8. Critical Tasks — Activities that need to be carried out to ensure the effectiveness and correct operation of Barriers and Recovery Measures