DDS Lecture 14 Content

1/49

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

50 Terms

General Manufacturing Process

Procurement and selection of components and containers

Product preparation: in sterile environment (aseptic)

Quality assurance (stability testing, pyrogen testing)

packaging and labeling

Components of Parenterals

vehicles

solutes

Parenteral Vehicle

non-irritating

non-toxic

no pharmacologic activity

no effect on active ingredient

physical properties: stability at various pH, temperatures, viscosity, miscibility with body fluid

Aqueous Vehicles

isotonic

drugs may be added

0.9% Sodium Chloride injection

Dextrose

Lactated Ringers

Water-Miscible Vehicles

used to affect solubility and reduce hydrolysis

propylene glycol (phenytoin)

Non-aqueous vehicles

fixed oils of vegetable origins

ex. soybean oil (used for propofol), amphotericin B liposomal

Parenteral solutes

antimicrobial agents: thimerosal 0.01%, benzethonium chloride 0.01%

buffers: citrates, acetates, phosphates

antioxidants: sodium bisulfite 0.1%

other added substances: sodium benzoate

Parenteral containers

no container is totally insoluble

should avoid

leaching

permeation

adsorption

selection of containers:

glass

plastic polymers: polyethylene, polypropylene, polyvinyl chloride (PVC)

rubber polymers- butyl, silicone, natural rubber

Plastic containers

Do not break

weight reduction (very light)

flexible (dropper)

risk of permeation, leaching, adsorption: must carefully select drugs

not clear: difficult to inspect contents

melts under thermal sterilization

Glass container

glass composition: silicon dioxide and other oxides

oxides loosely bound to silicon oxide tetrahedron

4 main types, 3 used in containers

Type I Glass

silicon dioxide and boric acid

neutral glass

preferred

low levels of migratory oxides, low leaching

suitable for all products

more expensive

Type II Glass

sodium oxide and calcium oxide

soda-lime glass with high hydrolytic resistance

melt at lower temperatures

lower concentration of migratory oxides than type III

treated with sulfur dioxide to dealkalize interior surface of glass

best used for solutions with pH < 7 or is buffered

Type III glass

sodium oxide and calcium oxide

soda-lime glass with moderate hydrolytic resistance

highest concentration of migratory oxides

best used for dry substances, non-aqeous preparations

Industrial Preparation of Parenteral Products

Compounding

Filtration

Filling/Sealing

Sterilizing

Methods of Sterilization

steam

dry heat

filtration

gas

ionizing radiation

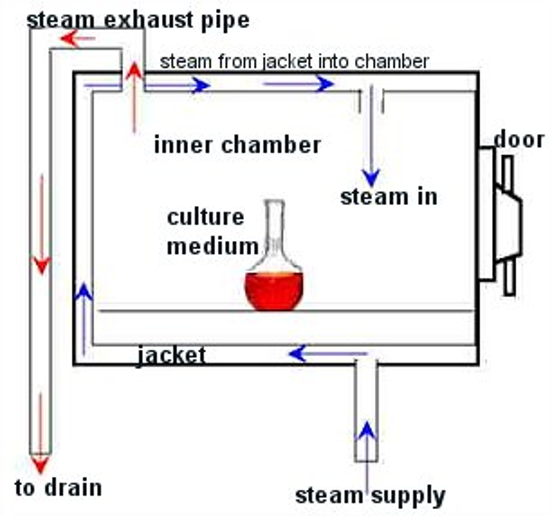

Steam Sterilization

equipment used: autoclave

with moisture, bacteria coagulate and are destroyed at lower temperature (vs. without moisture)

bacterial cells with large % of water killed more easily (spores difficult)

mech of action: denaturing and coagulation of bacteria’s essential protein

ideal for preparations that can withstand required temperatures, but not affected by moisture

usually method of choice is feasible

widely used settings: 15 lbs pressure, 121.5 C (250 F), 20 minutes

used for solutions sealed in ampules or vials, surgical instruments, bulk solutions

Dry Heat

electric or gas “ovens”

dry heat is less effective in killing than moist heat

mechanism of destruction is dehydration

conducted at 150-170 C (302-338 F) for 2-4 hours

higher temp, longer than steam

effective for substances not effectively sterilized by moist heat

ex.

fixed oils

glycerin

mineral oil

paraffin and zinc oxide

thermostable powders

glassware, surgical instruments

Filtration

removal of microbes by adsorption via filter medium

filters produced according to pore size

millpore 14 - 0.025 mcm, smallest bacteria is 0.2 mcm

electric charge of microbes, pH of solution, temperature

best used for heat sensitive solutions (thermolabile), low viscosity solutions

Types of Filters

Candle

Asbestos

Sintered Glass

Membrane (MOST COMMON)

Membrane filter

Bubble Point Test

tests filter integrity

minimum pressure required to force liquid out of the capillary space in the membrane

smaller the pore size, the high the bubble point pressure

manufacturer gives standards for filter

will give certain threshold for pressure

should not get pressure lower than standard (means filter is broken)

Gas Sterilization

use of ethylene oxide or propylene oxide gas

thought to inhibit bacterial cell wall formation

extremely flammable when mixed with air

sterilization with ethylene oxide

~4-16 hours

con: greater precautions required because variability of time, temperature, gas concentration, and humidity

also flammability

pros:

great penetrating qualities useful for powders and heat labile enzyme preparations

antibacterials

ophthalmic prep

vaginal inserts

plastic syringes and tubes

Ionizing Radiation

sterilization via gamma (Cobalt-60), cathode rays, UV lamp

application limited due to highly specialized equipment and effects of radiation

thought to destroy vital chemicals and/or structures (ex. chromosomal nucleoproteins)

used for antibiotics, hormones, sutures, prepackaged, disposable items

Pyrogens

lipopolysaccharide metabolic products from outer cell walls of gram-negative organisms

water soluble and thermostable

may remain after steam and filtration sterilization

bacterial endotoxin unit limit (USP)

5 EU/kg/hour for most drugs

Intrathecals: 0.2 EU/kg

EU = endotoxin units

Pyrogen Testins

Rabbit Test

LAL test

Rabbit Testing

Instruments heated to 250 C > 30 min

heat product to be tested to 37 C ± 2

inject product into vein of 3 rabbit’s ears 10 ml/kg and record temperature for 3 hours

If no rabbit shows increase in temperature >0.5 C OR sum of 3 rabbits is less than 1.4 C, meets USP standards

If one rabbit shows increase in temp more than 0.5 C, repeat test on 5 more rabbits

If not more than 3/8 show rise in temperature or 0.5 C, or sum of 8 rabbits is less than 3.3 C, meets USP standards

LAL test

Limulus Amebocye Lysate Test

extract blood cells of horseshoe crab (Limulus polyphemus) contains enzyme and proteins that coagulate in presence of low levels of lipopolysaccharides

aka Gel clot test, photometric test

Used by USP

5-50x more sensitive to endotoxin than rabbit test

some drugs interfere with test: meperidine, promethazine, oxacillin, vancomycin

Sterility Testing

USP 71: Must confirm sterility of each sterilized batch by either direct innoculation or filtration

use culture medium trypticase soy broth (TSB) and fluid thioglycollate medium (FTM)

medium incubated for 14 days

does require validation before product shipped

direct innoculation or membrane filtration test

Direct inoculation sterility test

the product/medical device will be in direct contact with the test media throughout the incubation period

Membrane Filtration Sterility Test

Test sample effluent is transferred to a cellulose nitrate or cellulose acetate membrane filter capable of retaining microbe

filter is then transferred to two specific nutrient test mediums and incubation for 14 days

Biological Indiactor

biological marker

provides information on whether necessary conditions were met to kill a specific number of microbes for a given sterilization process, providing a level of confidence in the process

endospores or bacterial spores primarily used in biological indicator

microbes considered some of toughest to kill

Steam biological marker

Bacillus stearothermophilus

Gas biological indicator

Bacillus stearothermophilus

Dry Heat Biological Marker

Bacillus subtilis

Ionizing Radiation Biological Marker

bacillus pumulis

bacillus stearothermophilus

bacillus subtilis

USP 797

USP has 2000 chapters

797: minimum practice and quality standards to which sterile preparations should be compounded

applicable for all settings and all personnel that compound sterile preparations

ANY healthcare setting, not just pharmacy

enforced by state boards of pharmacy and FDA

was made official in June 2008

Sterile Preparations

injections (IV, TPN, IM, SC, epidural, IT)

ophthalmic drops and ointments (ex.

aqueous pulmonary inhalations

baths and soaks

irrigations for internal body cavities

implants

Class 5 Environment

class 100

no more than 100 particles per cubic foot

inside hood

Class 7 Environment

class 10,000

no more than 10,000 particles per cubic foot

clean/buffer room

Class 8 Environment

Categories of Compounding sterile preparations

4 main categories:

Immediate use

category 1

category 2

category 3

classifications based on potential for microbial, physical, or chemical contamination during compounding

determined by where the compounded sterile preparation is made and the time period within which it must be used

if the compounding personnel are unsure, they should go with the more stringent category to ensure safety

Immediate Use CSP

ISO Class 5 Environment not required

7 requirements:

Aseptic standard operating procedures and process must be in place

Personnel trained and demonstrate facility-specific competency in aseptic technique

preparation performed per FDA-approved labeling or evidence-based information

preparation limited to 3 different sterile products

any unused medication from a single dose vial is discarded

administration begins within 4 hours of preparation

BUD: 4 hours

CSP must be labeled unless it is administered by, or the administration is witnessed by, the preparer

ex. prep of epinephrine drip at bedside by nurse of pharmacist for patient in cardiac arrest

Category 1 CSP

must be compounded in an ISO Class 5 air quality environment or better

Class 5/PEC does not have to be located within Class 7 buffer room

can be in segregated compounding area (SCA)

ex. PEC located directly in regular pharmacy satellite

PEC: primary engineering control

max BUD of 12 hours at room temp, 24 hours in fridge

short bc of higher risk for contamination when there’s no buffer or ante room

Category 2 CSP

preparation compounded in PEC, within buffer room, with ante-room separating the buffer room from the rest of the pharmacy

assigned BUD based on whether or not they are produced from sterile products only or produced from non-sterile products but terminally sterilized (ex. sterilization after the CSP has been produced using dry heat, steam, irradiation), and whether or not sterility testing has been performed on them

Category 3 CSP

allows for longest dating

requirements in addition to those for Cat2 to ensure safety

additional requirements: increased frequency of aseptic manipulation competency, sterile garbing, increased viable air and surface sampling, and increased frequency of sporicidal applications during cleaning

BUDs must be supported by stability data obtained using a stability-indicating analytical method

Sterility testing and endotoxin testing required for all cat3

Multi-dose Vial

contains preservatives

max BUD: 28 days after entering with needle or puncturing stopper

if any type of contamination of multi-dose vial is suspected, discard immediately

Single-dose vial

max BUD: 12 hours after first entry

if vial is entered in at least ISO class 5 environment

may be removed from ISO class 5 PEC for storage at appropriate temp during 12 hour period

once ampules have been opened, they must not be stored for any period of time, regardless of air quality

Sources of ISO-Class 5

Laminar airflow

Horizontal

Vertical

good when drug is hazardous, do not have molecules to flow toward you

continuous flow of air through HEPA filter (air filter that removes 99.97% of particles with size of 0.3 microns)

compounding aseptic isolator

Hazardous drug preparation

present health risk to compounding personnel

should be prepared in an ISO class 5 environment in an ISO class 7 negative pressure area physically separated from other prescription areas

negative pressure: so air from inside room doesn’t escape; air from outside will come in when person enters

Proper Hygiene and Garbing

Prior to entering buffer area or segregated compounding area