MOD 6 - Intro to QA/QC Tests

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

18 Terms

Quality Control in Imaging

the monitoring, testing and maintenance of the x-ray equipment to ensure it's working optimally to minimize patient dose and ensure high quality images

Total Quality Management (TQM)

all members of an organization participate in improving processes, products, services and the culture in which they work

everyone in the medical imaging department is involved in one way or another with QA and QC

Continuous Quality Improvement (CQI)

focusses on improving processes or systems in place

Quality Assurance (QA)

what

features

the planned and systematic actions for personnel that provide confidence that a diagnostic x-ray facility will produce high-quality images with minimum exposure of patients and it's personnel

Features Include:

Information Quality = provides diagnostic images and info

Clinical Efficiency = provides diagnostic images quickly and efficiently

Patient Dose = ALARA

Requirements to achieve a QA goal

working equipment

all staff understands the goal of the program

all staff is fully committed to the program

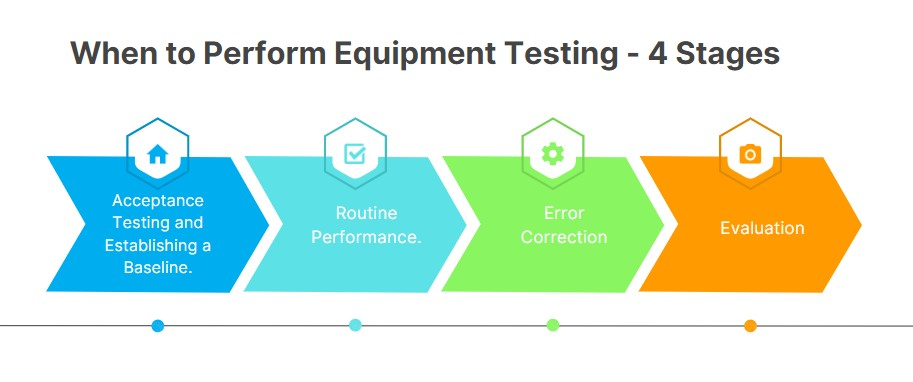

Equipment Testing Step Process

Acceptance Testing and Establishing a Baseline

done before the equipment is put to use (eg. new equipment)

conducted by a medical physicist (who has no relation/bias towards the equipment)

calibrated and a reference image is stored

takes around 8-10 hrs

Routine Performance

daily inspections of equipment to weekly, monthly and annual testing and inspections

done by medical physicists, biomed, QC team, techs

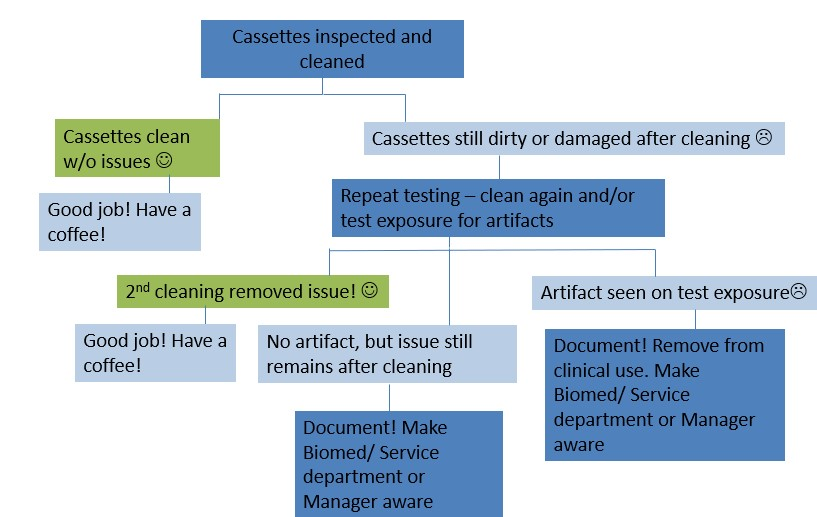

Error Correction

a decision tree that answers the following

done by biomed, vendor service

A repeat of the test to confirm

What to do if repeated test confirms performance failure

what to do if test fails only marginally

what to do if the test shows a history of failure

what to do if the test fails substantially

Evaluation

if an equipment has a +/- 10% acceptable test limit in place, the equipment is deemed unsafe for patient use, if repaired it needs to be tested again before use

done by med physicists, rads, chief tech

Implementation of a QA Program

list of personnel and their duties

policies to minimize dose to personnel

policies to minimize dose to patients

Guidelines to QC Tests

Policies to acquire new X-ray equipment

Policies for Record Keeping

QC Team

owner of the facility = primarily responsible

plan and managing = department supervisor, QC coordinator, physicist

sets litmits, evaluates QC = physicist

performs annual testing = physicist, biomed

repairing equipment = biomed

performs rest of QC tests = techs

Documentation

documented in the QC logbook

Format of a QC Test

Aim = overall goals of the test

Equipment = test tools/equipment needed for this test

Method = specific steps to conduct this test

Frequency = how often is the test completed

Data Record Keeping = QC log

Tolerances = setting max/min limits

Action = what to do after the results show equipment issues

1-6 is set by the med physicist, so we just have to follow

5 and 7 are our responsibility to record in the QC logbook

Determination of Testing Frequency

If equipment is showing significant signs of wear and tear between testing, then testing frequency may need to increase.

QC tests should NOT be less frequent if the QC tests always show stable results

Diagnostic Accreditation Program (DAP)

a governing body assigned to monitor for upkeep and adherence to a Quality Standard

regulated by College of Physicians and Surgeons of British Columbia