Additive manufacturing MECH3775

1/17

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

18 Terms

What is Photolithography?

Photolithography is a process that uses light to transfer a geometric pattern from a photomask to a light sensitive chemical called a photoresist.

What are some manufactured electronics photolithography can be used to make?

semiconductors

MEMS (micro-electrical-mechanical systems)

PCBs

LCD and OLED displays

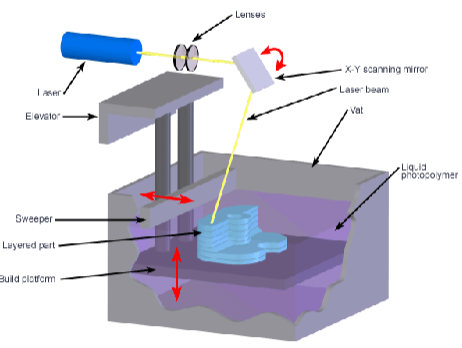

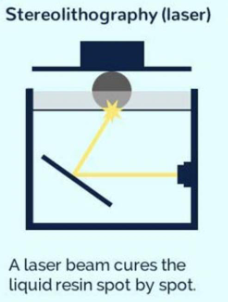

What was the original SLA process?

used a uv wavelength laser

the laser scans the liquid surface and causes the liquid to polymerise

the platform drops and layer and repeats

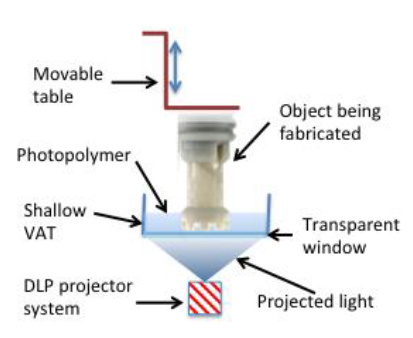

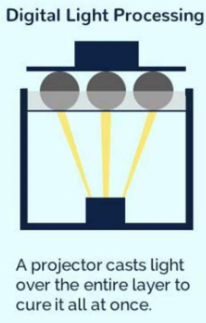

What is projection based SLA?

typically uses a DLP but LCD are now emerging

image is projected from below and polymerises a layer at a time

the part is moved up and this repeats

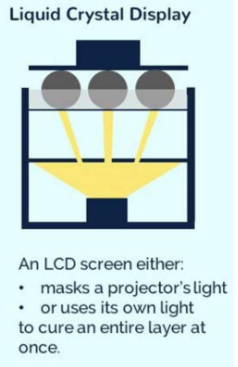

What is LCD SLA?

Uses a LCD screen to mask regions of light

the systems can be low cost

What is SLA? (method of patterning with light)

What is DLP? (method of patterning with light)

What is LCD? (method of patterning with light)

What are the advantages of top down projection methods?

resolution of the part is higher

the current later only adheres to the previous layer

simplicity for retrofitting

What are the Disadvantages of top down projection methods?

surface characteristics of the resin can affect the part quality

the process is usually longer due to the re coating step

viscosity of the resin determines the thickness of the part

What are the advantages of bottom up projection methods?

so specific re coating stage needed

ultra thin layers can be produced

reduce of waste materials

What are the disadvantages of bottom up projecting?

light has to pass through more surfaces causing aberrations and less intensity

the current layer may adhere to the surface of the vat (damaging the part)

harder to retrofit components

what are the materials used for Stereolithography?

light curable resins

resins consist of a monomer, photo initiator and an inhibitor

How does photopolymerisation work?

Photopolymerisation is initiated by excitement of the photoinitiator by UV radiation which produces free radicals

Photopolymerisation causes the linking of small molecules (monomers) to larger chain like molecules (polymers)

Why do the materials used for Photopolymerisation contain additives and what are they?

to try to simulate common engineering materials

they are all based on epoxy/acrylic formulations of non-polymerised liquid

some can change the colour/improve stability/are used for specialised applications

What is post-processing of materials for Photopolymerisation?

ensures complete polymerisation

ensures complete cross linking of polymer bonds

more stable and integrity

curing time depends on mass and material

What are some positives of the post processing for Photopolymerisation?

supports can be easier to remove before final cure

materials can mimic traditional engineering polymers

process energy input low compared to thermal AM systems

Very accurate / very good surface finish

parts can be mechanically/chemically smoothed

What are some negatives of the post processing for Photopolymerisation?

the machine is expensive

support structures are always required

stereolithogrpahy resins are often toxic (PPE is needed)

materials must be photo-curable resins

parts age in the sunlight

material change requires thorough cleaning

part orientation affects surface finish