quality control intro + quality chart for variable data

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

32 Terms

statistical process control (SPC)

verify that business processes are meeting the specifications

identifies special cause variation

signals the need to take corrective action when appropriate

control charts

what is the main graphical tool that statistical process control (SPC) relies on?

types of variation in a system

common causes

special causes

common causes

what type of variation is described as natural or random and is inherent in any process?

common causes alone

a process is considered in statistical control only if the variation is present due to _____

special causes

non-random (assignable) variation due to identifiable factors

out of control

when special causes of variation are present in a process, the process is deemed to be ______

it is expensive

testing can be destructive

it should be unnecessary for a controlled process

what are three key disadvantages of inspecting every single item (100% inspection?)

statistical sampling

in quality control, what is the more economic alternative to examining an entire lot?

lots

in sampling, the flow of products is broken down into discrete batches called ____

random sample

a sample in which each unit in the lot has an equal chance of being included

subject it to 100% inspection

all defective items are repaired or replaced

return the entire quantity to the supplier

if a random sample from a lot fails a quality test, what are three potential actions for the entire lot?

variable data (quantitative data)

product or service characteristics that can be measured on a continuous scale

EX] length, weight, time

expressed with statistics such as averages and standard deviations

SPC metrics

variable data (quantitative data)

attribute data (qualitative data)

attribute data (qualitative data)

product or service characteristics evaluated with discrete choice

EX] either in or out of tolerance, error/defect present or absent, yes or no, good or bad

expressed as proportions or rates

Control charts

a specialized run chart that helps an organization track changes in key measures over time

under control

if a sample falls inside the control limits, the process is considered…

mean

upper control limit (UCL)

lower control limit (LCL)

what are the three fundamental lines calculated and plotted on every control chart?

histograms vs control charts

histograms do not take into account changes over time

control charts can tell us when a process changes

developing control charts

prepare

collect data

determine control limits

analyze and interpret results

use a problem-solving tool

compute process capability

controlled process

most points near the center line

no points are outside control limits

points fall randomly aboce and below the center line

out-of-control

instability → points outside control limits

sudden shift in process average

cycles

trends

nelson rules

nelson rules

the set of guidelines developed by llyod nelson in 1984 for detecting out-of-contol conditions are known as ______

the average value (central tendency) of a variable

what aspect of a process do x-bar charts specifically monitor?

the variation or dispersion among items within each sample

what aspect of a process do R-charts specifically monitor?

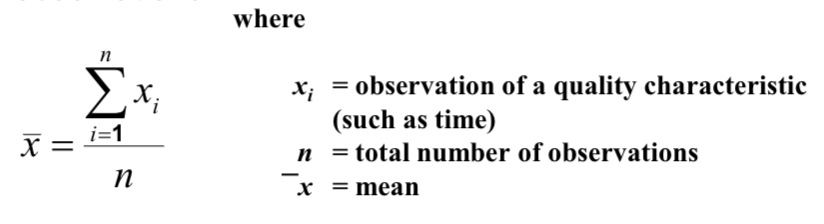

X-bar

sum of observations divided by the total number of observations

R-bar

the difference between the largest observation in a sample and the smallest observation

the overall mean which is the average of all the individual sample means

when constructing control charts, what does the x-double bar symbol represent?

the average range which is the average of the ranges from all the individual samples

when constructing control charts, what does the R-bar symbol represent?

the size of the sample (n)

the values for the control chart factors A2, D3, and D4 are determined by what parameter?

R-chart

when constructing and analyzing control charts for variables, which chart must always be analyzed first?

on a daily basis to monitor performance and identify any new special causes that might arise

once a process is confirmed to be in a state of statistical control, how should control charts be used?