Apparel Contruction final

1/63

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

64 Terms

Shaping Manipulaitons

Things you sew into the garment so that it has shape

Darts (definition and construction)

A wedge shape tuck

the lines on the outside are called dart legs

The point where the dart legs meet is called the Apex

The distance between the dart legs is called the dart excess or intake

These shaping manipulations should release one inch away from the fullest part of your body

Dart

The apex should taper gradually since it will be pointing to the largest part of the body

If the apex does not taper gradually the garment will have a dimple

Darts give a _______ Shaping

subtle

we would use a dart

on a straight skirt where you want the transition from your waist to your hips to be really subtle.

if you have two darts on the front or back you want the center dart to be slightly longer than the side darts.

When we sew these dart we want the dart intake on vertical darts to be pressed to the _______

Center

When we sew these dart we want the dart intake on Horizontal darts to be pressed _______

Down

When we press in our dart we use the

Pressing ham

-the small part of the dart goes to the wide part of the ham because that is where the small part of the dart will sit on your actual body

There are two different darts and they are ______________ and _______ or ___________

One point dart- One Apex

Two point or fish eye dart- Has two apex (allows you to have a garment that comes in at the waist and releases at bust and hips)

One way to get a nice taper at the point you can

decrease the stitch length towards the bottom of the dart

as well as doing several knot applications rather than backstitching

Tucks

Slender folds in the fabric that are stitched down

they are usually more decorative

often times the fold is on the outside of the garment

tucks are going to be a quarter of an inch or less

really narrow tucks are called

pin tuck (the amount of the fold is the diameter of a pin, they are less than a quarter of inch wide)

Release tuck

The stitching is stopped.These tucks are sewn a few inches and then stopped so that upper part where the tucks are made will take in the fabric.

Pleats

They are typically 5/8 of inch to two inches

give us a controlled fullness

Knife pleats

Folds all go to the same direction

They lay side by side

All of the folds are the same width ( they are very uniform

Box Pleat

Folds are going away from each other

Inverted Pleat

The folds are coming towards each-other.

pleats

you can hard press the pleats to keep the pleats straight

you can also stitched down the pleats

you can do nothing for a more flowy look

combination

kick pleat

allows you to walk

has to overlap

Accordion pleat

3 dimensional

goes into fabrics that are thermoplastic

they are usually heat set, or rolled into place

like an athleisure skirt

gathers

small soft folds in the fabric

puffy kind of shaping

we typically run two rows of gathering stitches because it makes our gathers more even

Zipper

A slide closure meaning that it locks the teeth together

the fabric on the zipper is called the zipper tape

the rigid things in the center are called the teeth

if you have a long strand of just the teeth and and tape is called a coil

the thing we hold on to is called the pull

slider is the thing that the pull is attached to

the metal things on the top is called the top stop

most of the teeth now are synthetic meaning they are more comfortable to wear as well as more flexible

metal teeth are much stronger and they

Conventional zipper

meaning you see the zipper teeth

metal zippers

must be sewn into to strong fabrics that can handle them

thread stop

use to to lengthen and shorten zipper with synthetic teeth

we make the zipper shorter at the bottom

seperating zipper

used when we want the whole garment to open. Does not have a bottom stop. It instead has a box and pin. The pin has to engage both exactly to go all the way up.

four ways to apply conventional zippers

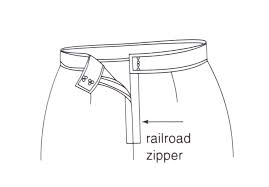

-railroad/slot/center zipper

Railroad/slot/centered zipper

we are pulling the two edges of the opening together and they are meeting over the the top of the zipper. There is stitching on both sides of the zipper. Doesn’t really close too good since its meeting on top of the zipper teeth.

A very fast and easy way to put in the zipper

Lapped zipper

Has one edge that is lapping over the whole zipper. Since it is wider than the centered zipper application it is able to hide the zipper better.

pick stitch

more formal stitching done on to stitch the lapped zipper application

Fly zipper application

only ever done on a bottom garment in the center front. You have different pieces making that curve on the zipper application

Seen on jeans.

Exposed zipper application

you can see the zipper teeth

invisible zipper

you can not see the teeth. made so that the coil is folded so the teeth are tucked underneath. the only thing you see on the outside of the garment is the pull

half foot

used on industrial machines. traditional zipper foot

you want to stitch

zipper → needle → foot

invisible zipper foot

has deep grooves were the teeth go which help us stitch the crease to the fabric so we don’t see the zipper.

well constructed zippers

if it is lapped, centered, fly, or an invisible zipper, the zipper should be concealed the entire length of the zipper

the top stitching should be parallel to the teeth

the placket should be the same length as your zipper

everything should lay smooth and flat

natural waistline

the smallest part of your body where you ben.

High waisted

anything that is above your natural waistline

empire waistline

waistline right below your bust

low waisted

below your natural waist line

waistline seam

found if you join a bodice and a bottom

waistline

you only want a half inch to an inch in ease at your waistline in fabric that does not stretch

since it needs to sit closer to your body the waistline needs support

peter sham or gross-grain sham

peter sham is woven more intricately than the gross-grain ribbon meaning it is a little bit more expensive

the Regis in the ribbon are made since it is an uneven weave and allows the ribbon to conform. The strong yarns in the ribbon provide stableness.

twill tape

uses fine yarns, strong but very thin. sew in with the seam.

stay tape

waistbands

band that sits on top of the rest of the garment

-has a separate closure than the garment

straight waistband

a straight piece of fabric that is going around the body

the stronger yarns are going around the body in the waistband

may be in two parts found in garment you are looking to alter

contoured waIistband

shaped waistband

more than one piece

there will be a seam either on the center back or on the side seam

faced waistline

we don’t want the band on top so we just face the edge for a cleaner look

always an applied facing

Yoke

helps us get smaller at the waistline and bigger at the hips

can be found where there is a waistband on top of it

or it can be found alone on the top pf the waistband

the yoke is different than the contoured waistband because the yoke is part of the body of the garment so the zipper would go all the way up through the yoke

specialized interfacing

used only on straight wasitbands

belt loops

also called carriers

waistlines

cant be are same waist measurement (for fabric that doesn’t stretch) or you wont be able to move it will have ease just less ease than other places on your body

your waistline should look comfortable on you

apparel Quality

The degree to which a garment meets expectations or the degree of excellence and conformance to requirements

ISO defines it as: the totality of characteristics of an entity that bear on its ability to satisfy stated or implied needs

ISO

the international organization of standards

Quality features

it is composed of performance features and quality features

Performance features

What the garment does for the consumer.

Aesthetic performance

Appearance

Design

Trend/Classic

Functional Performance

Utility

Durability

Fit

Comfort

Physical features

What the garment is

Tangible form and composition

Fabric

What increases the cost of the goods

fabric and labor

Construction quality

The effort and time the maker was willing to expend in the pursuit of less bulk, thinner and more flexibility, and in making sure that transition from thick to thin are as imperceptible as possible.

cut

stitching

seams

shaping manipulations

hem closures

plackets/openings

support fabrics

Fit

intangible difference between the costumer purchasing your goods and not.

Characteristics of Good Fit

Ample ease for movement

No excess folds/wrinkles

Grain

shaping manipulations

seams

well fitter garments

you have to have enough ease to fit

excess fold or wrinkles- shows where there is too much fabric or not enough fabric

the lengthwise grain runs up and down the body

the cross grain runs parallel to the floor at the chest, waist, and hips

in a well fitted garment darts release one inch away from your garment

major seams should be where they are supposed to be