MCHE 3920 Midterm

1/291

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

292 Terms

Casting Benefits

1. large form freedom

2. retain properties at elevated temperatures

3. distinct character and texture

Examples of Casting

- pots/pan

- clothes iron

- sculptures

- engine blocks

- jet engine turbine blades

Liquid metal poured into a mold that defines ____ shape of product

negative

Filling the mold "bottom up" prevents _____, therefore ____, which will cause loss of ______ and prevent ________.

splashing; oxidation; material properties; gas entrapment

Casting have a higher

alloy content

ex.) steel (Fe > 2% C) not cast; cast iron (Fe 2-4% C) cast

Reasons for higher alloy content:

1. lower viscosity (better mold filling)

2. lower melting temp (lower energy, faster throughput)

Want casting metals to be near _______ composition.

eutectic

Eutectic Composition

homogeneous composition and lowest possible melting temp, typically lower viscosity

Higher alloy content comes at expense of

material properties

tradeoff: castability vs. material properties

Alloy presence reduces

toughness, ductility, and fatigue strength

In cast iron, stiffness is ____ relative to low carbon steel

lower

Slow filling speeds, so liquid flow is

laminar

Laminar flow minimizes _______ and _______ and ________.

free surface area; oxidation; loss of material properties

Low flowing speeds are good for

quality

Low flow speed trade-offs

1. takes more time, lower productivity

2. cold running: chance of solidifying portions before mold is filled- fatal defect

Increase fill speed by

using multiple gates

Gates increase need for

finishing

Prevent cold running by

making thick parts

Thicker parts increase ___ and _____.

weight; cost

Mold filling is either slow at ______ or fast at ______.

low pressure; high pressure

Quality consequence in favor of

faster production

Cooling from liquid to solid causes _____ in volume.

reduction

Rate of volume reduction is _____ in solidification region.

highest

Cooling Phases

1. Tpour to T liquid

(specific heat, liquid phase J/kg*K)

2. Liquid to solid transition

(latent heat of solidification, J/kg)

3. Tsolid to RT

(specific heat, solid phase J/kg*K)

What can be done about solidification shrinkage?

feeding: add extra material during filling

What about shrinkage after solidification?

make mold bigger (1-2%)

How long does it take before part is cool/strong enough to handle?

Chvorinov's Rule

Tsolidification = C(V/A)^2

coefficient *(volume/surface area)^2

Chvorinov's Rule works well for

- large solid castings

- underestimates time for hollow and thin-walled parts for solidification/cooling

Chvorinov's Rule underestimates for hollow/thin-walled parts because

inner walls of mold do not absorb as much heat as outer walls

Thin-walled parts (<4 mm thick), use model

V/A

Mold expands while casting contracts, which creates air gaps, which act like _____, limiting _________

insulator; heat dissipation

Casting Defects

1. Porosity (gas-filled voids in metal)

2. Internal Stresses

3. Distortion

Ways to avoid casting defects

careful alloy selection

design part to avoid large thickness changes

Porosity Causes

1. Shrinkage Porosity

2. Gas Bubbles

Shrinkage Porosity

not enough extra material fed into casting to compensate for solidification shrinkage

Avoid shrinkage porosity with

good mold and filling design

Shrinkage Porosity happens when thin section of mold or poorly designed runner _____, which ____ flow into thicker sections

solidifies; blocks

Gas Bubbles

released during solidification, trapped in solid

Gas bubbles can't be completely avoided, but minimized by

dispersing gas so it forms small bubbles

Which cools quicker, thinner or thicker sections?

thinner

Different sections/thicknesses cool at different rates, leading to

temperature gradients in casting

Local temperature differences will cause differences in contraction, which will cause

stresses by Hooke's Law (σ = Eε)

Stresses can lower part

capability

Casting free to deform, stresses exceed yield stress, then _____ can occur

permanent deformation

Extreme stresses can cause

crack or rupture

Prediciting internal stresses/deformations requires

computer simulations (due to complex geometries)

Casting Metallurgy

choosing best alloy for job

Metals have crystalline

grain structure

Grain Boundary

grains grow in solid and on mold wall, where they impinge on each other

Cast Grain Size

0.05-5 mm large

Small Grain Size

better properties

Grain size dictated by

cooling rate

Fast cooling rate leads to

small grains

Alloying Elements Use

1. improve processability (lower viscosity or melting temperature)

2. improves material properties (strength)

3. minimizes effects of impurities or improves microstructure

Alloy elements can introduce

detrimental impurities

Alloy Segregation

non-uniform distribution of dissolved elements during solidification

Liquid state, alloy elements dissolved in

"atomic soup"

During cooling first solids to form are _____ than average, remainder relatively ____, lead to _______.

purer; enriched; impurities

Last part to solidify is ________, so ______ concentrated there.

grain boundaries; impurities

Inoculants

high melting point powders added before pouring

As liquid cools, solid forms around inoculant

promotes smaller grains and less segregation

Poisoning

sometimes small additions of the right element can dramatically improve tensile strength of cast metal

ex.) trace amounts of Na in Al casting

Sand Casting

silica sand and bonding agent form mold

"Patterns" are used to form negative space inside mold

wood/plastic/metal

Sand Casting Perks

- very cheap

- made to wide range of sizes

- fragile, support low filling speeds and pressures

- long solidification times = larger grains

- rough surface properties

- poor tolerances

Parting Plane

plane where drag and cope meet

Sprue

filling through a downward channel

Sand cores allow manufacture of

hollow products

Riser (feeder)

shows when filling is complete; helps allow for shrinkage

Gravity Die Casting

- uses reusable steel dies

- shorter cycle times = finer microstructure

- smoother products, good control over tolerances

- filling speeds are low

- product size more limited than sand casting

- Al and Mg commonly cast

Lower Pressure Die Casting

- use reusable steel dies

- pressure from 2-5 bar

- good reproduction of die details

- dies often placed on top of furnace, fed through riser tube using gas pressure

- Al and Mg commonly cast using this method

High Pressure Die Casting

- uses very expensive steel dies

- pressures up to 2000 bar

- cannot use sand cores (can use sliding elements to make undercuts)

- high injection speeds

- fast throughput, lower quality, thinner prodcuts

- limited to Zn, Al, Mg

Investment Casting

-rare method

- pattern made of wax, attached to sprue

- dipped in ceramic slurry that cures while max melts away

- hollow ceramic shell used as mold

- after casting, shell is destroyed to remove part

- time consuming

- good for complex geometries

Virtually any given assembly will have 1+ _____ parts

sheet metal

High Production Volumes, up to ______ units

10^8

Sheet metal parts can be

finished/painted

Method: simple, cheap, single-curved parts, small volumes

bending

Method: complex, expensive, double-curved parts, high volumes

matched die forming

Cutting sheet metal to size

blanking

Structural Design wants to keep stress below

yield

Need to exceed yield stress in order to

bend metal

Some anisotropy, but assume

isotropic materials

Stress-Strain Curve

1. elastic: yield stress

2. plastic: tensile (ultimate) strength

3. necking: failure strength

4. unloading

Elastic Region

- stress increases linearly with strain

- interatomic bonds act like springs

- load removed: material returns to original state (no permanent deformation)

Slope =

E (Young's modulus)

Yield Stress

- dislocations form in crystal lattice

- difficult to find yield stress from test (0.2% off-set method)

Movement of dislocations occur along "slip planes", cause one part of lattice to

slip relative to other

Strain/Work Hardening

slip planes hinder each other, takes more stress to deform material

Ultimate(Tensile) Strength

max stress before material fails

Beyond ultimate strength, stress drops while material deforms

due to decrease in diameter (necking)

True Stress

calculate using time-varying area

Stress calculated with original area, but if instantaneous area used,

stress continues to increase in necking region

Load reduced/removed, material follows

linear unloading curve parallel to elastic portion of curve

Amount of permanent deformation is at intersection of

unloading curve with strain axis

Strain-to-failure

indicates amount of material elongation at failure

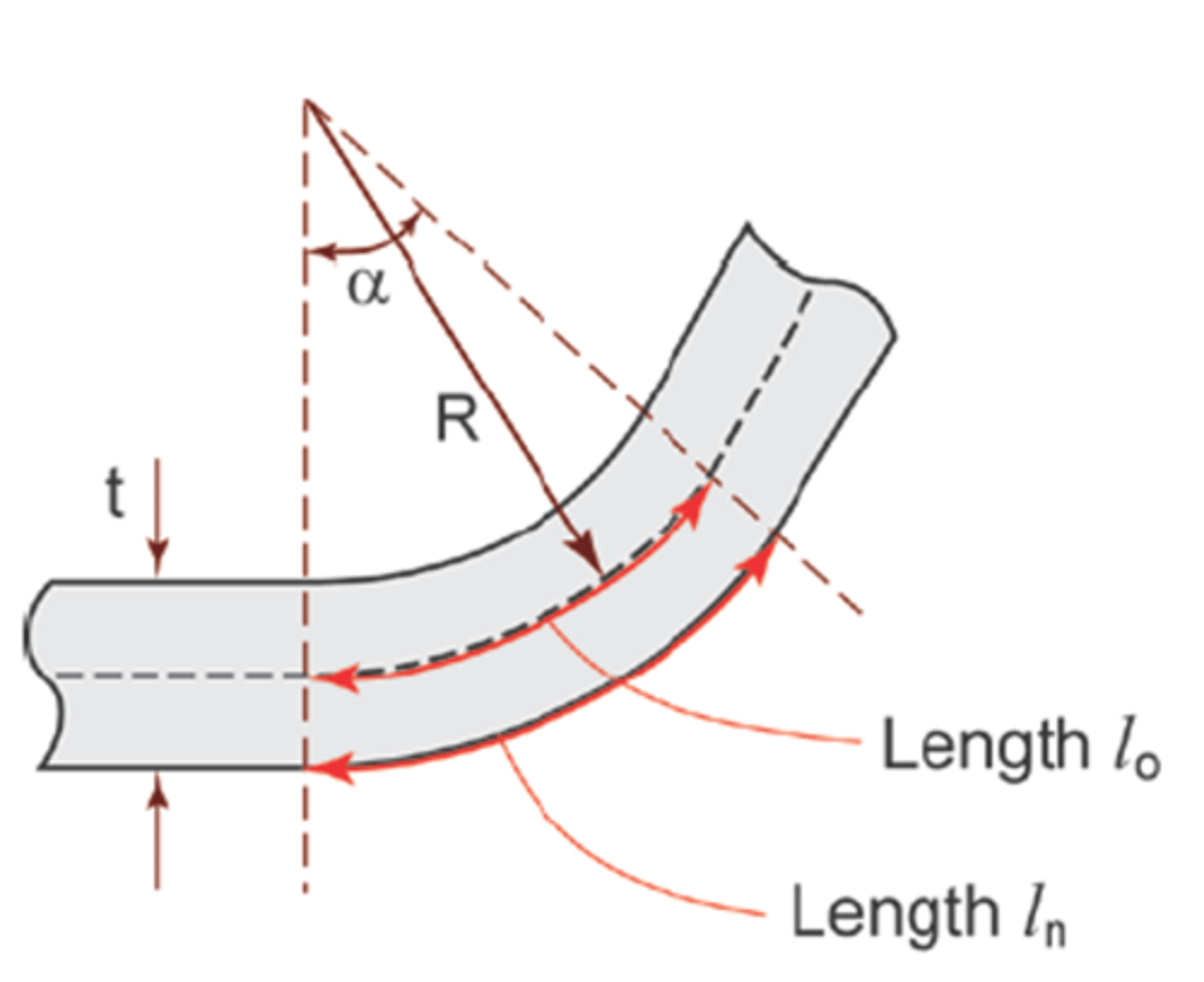

Minimum Bending Radius (MBR)

most basic sheet metal forming is bending blank at angle, with some radius R

- how small R can be

MBR Assumptions

1. all deformations take place in zone defined by angle and R

2. metal deformation has same behavior in tension/compression (anti-symmetric stress-strain curve)

3. Neutral Axis doesn't change in length

4. metal outside NA becomes thinner, inside becomes thicker

5. metal is isotropic and homogenous

Max strains occur at

surfaces R +/- t/2

Tensile Strain-to-failure (emax)

sets MBR