Regulations (FAA General Test Prep)

1/97

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

98 Terms

8506. (1) Propellers are NOT included in the Airworthiness Directive system.

(2) A certificated powerplant mechanic may make a minor repair on an aluminum propeller and approve for return to service. Regarding the above statements,

A—only 2 is true.

B—both 1 and 2 are true.

C—neither 1 nor 2 is true.

[a] Statement 1 is false. Propellers are included in the Airworthiness Directive system. Statement 2 is true. A certificated powerplant mechanic can make a minor repair to an aluminum propeller and can approve it for return to service. (AM.I.I.K1) — 14 CFR §39.1

8516-5. What is the maximum penalty for cheating or other unauthorized conduct when taking an FAA mechanic test?

A—Ineligibility to receive any certificate or rating for one year.

B—Ineligibility to receive any certificate or rating for one year, and suspension or revocation of any certificate held.

C—Ineligibility to receive any certificate or rating for one year, and suspension of any certificate held.

[b] 14 CFR §65.18(b) states that no person who cheats, gives or receives help from another, takes a part of the test for another, uses unauthorized material during the test is eligible for any airman or ground instructor certificate or rating for a period of one year after the date of that act. In addition, the commission of that act is a basis for suspending or revoking any airman or ground instructor certificate held by that person. (AM.I.I.K1) — FAA-H-8083-30

8519. Certificated mechanics with a powerplant rating may perform

A—any inspection required by the Federal Aviation Regulations on a powerplant or propeller or any component thereof, and may release the same to service.

B—100-hour and/or annual inspections required by the Federal Aviation Regulations on powerplants, propellers, or any components thereof, and may release the same to service.

C—100-hour inspections required by the Federal Aviation Regulations on a powerplant, propeller, or any component thereof, and may release the same to service.

[c] A certificated mechanic holding a powerplant rating is authorized to perform a 100-hour inspection on a powerplant or propeller or any component thereof and may release the same for service. (AM.I.I.K1) — 14 CFR §65.87

8520-1. Under the Federal Aviation Regulations, an aviation maintenance technician is required to perform maintenance on an aircraft so that it

A—always meets its original type design.

B—is at least equal to its original or properly altered condition.

C—exceeds minimum standards with regard to aerodynamic function, structural strength, resistance to vibration, and other qualities affecting airworthiness.

[b] 14 CFR §43.13(b) states: Each person maintaining or altering, or performing preventive maintenance, shall do that work in such a manner and use materials of such a quality, that the condition of the aircraft, airframe, aircraft engine, propeller or appliance worked on will be at least equal to its original or properly altered condition (with regard to aerodynamic function, structural strength, resistance to vibration and deterioration, and other qualities affecting airworthiness). (AM.I.I.K1) — 14 CFR §43.13(b)

8524. A person working under the supervision of a certificated mechanic with an airframe and powerplant rating is not authorized to perform

A—repair of a wing brace strut by welding.

B—a 100-hour inspection.

C—repair of an engine mount by riveting.

[b] A 100-hour inspection is the only procedure listed in these alternatives that a person working under the supervision of an appropriately rated mechanic is not allowed to perform. Only a mechanic holding the appropriate ratings can perform the inspection. (AM.I.I.K1) — 14 CFR §65.81

8525. Certificated mechanics, under their general certificate privileges, may

A—perform minor repairs to instruments.

B—perform 100-hour inspection of instruments.

C—perform minor alterations to instruments.

[b] A properly certificated mechanic may perform a 100-hour inspection of instruments, but he or she may not make any repair or alteration to an instrument. (AM.I.I.K1) — 14 CFR §65.81

8526. An Airworthiness Directive requires that a propeller be altered. Certificated mechanics could

A—perform and approve the work for return to service if it is a minor alteration.

B—not perform the work because it is an alteration.

C—not perform the work because they are not allowed to perform and approve for return to service, repairs or alterations to propellers.

[a] A certificated mechanic with a powerplant rating is authorized to perform the work called for in an AD on a propeller that requires a minor alteration to the propeller. After complying with the AD, the mechanic can approve the propeller for return to service. (AM.I.I.K1) — 14 CFR §65.81(a)

8528. FAA certificated mechanics may

A—approve for return to service a major repair for which they are rated.

B—supervise and approve a 100-hour inspection.

C—approve for return to service a minor alteration they have performed appropriate to the rating(s) they hold.

[c] FAA-certificated mechanics may approve for return to service a minor alteration they have performed appropriate to the rating(s) they hold. This privilege, of course, assumes that the mechanic understands the current instructions of the manufacturer and has the maintenance manuals for the specific operation concerned. A certificated mechanic is not authorized to supervise a 100-hour inspection. (AM.I.I.K1) — 14 CFR §65.81

8529. A certificated mechanic with a powerplant rating may perform the

A—annual inspection required by the Federal Aviation Regulations on a powerplant or any component thereof and approve and return the same to service.

B—100-hour inspection required by the Federal Aviation Regulations on a powerplant or any component thereof and approve and return the same to service.

C—100-hour inspection required by the Federal Aviation Regulations on an airframe, powerplant or any otter component thereof and approve and return the same to service.

[b] A certificated mechanic with a powerplant rating is authorized to conduct a 100-hour inspection on a powerplant or any component thereof and approve the return to service of the same. (AM.I.I.K1) — 14 CFR §65.87

8531. A certificated mechanic shall not exercise the privileges of the certificate and rating unless, within the preceding 24 months, the Administrator has found that the certificate holder is able to do the work or the certificate holder has

A—served as a mechanic under the certificate and rating for at least 18 months.

B—served as a mechanic under the certificate and rating for at least 12 months.

C—served as a mechanic under the certificate and rating for at least 6 months

[c] A certificated mechanic shall not exercise the privileges of the certificate and rating unless, within the preceding 24 months, the Administrator has found that the certificate holder is able to do the work or the certificate holder has served as a mechanic of the certificate and rating for at least six months. (AM.I.I.K1) — 14 CFR §65.83

8531-3. How long is a mechanic certificate with airframe and/or powerplant rating(s) valid?

A—Until the holder is relieved of duties for which the holder was employed and certificated.

B—Until voluntarily surrendered, permanently revoked, or temporarily suspended.

C—24 months after the holder has last exercised the privileges of the certificate.

[b] 14 CFR §65.15 states that a mechanic certificate with airframe and/or powerplant rating is effective until it is surrendered, suspended, or revoked. (AM.I.I.K1) — 14 CFR §65.15

8531-5. What is the maximum duration of a temporary airman certificate?

A—60 days.

B—90 days.

C—120 days.

[c] 14 CFR §65.13 provides for a temporary certificate and rating effective for a period of 120 days to be issued to a qualified applicant. (AM.I.I.K1) — 14 CFR §65.13

8531-6. When may an otherwise qualified mechanic who does not read, write, speak, and understand the English language be eligible to apply for a mechanic certificate?

A—When a special authorization has been issued by the supervising FAA Flight Standards Office.

B—When employed outside the United States by a U.S. air carrier.

C—When employed outside the United States.

[b] 14 CFR §65.71(a)(2) requires that the applicant for a mechanic certificate be able to read, write, speak, and understand the English language, or in the case of an applicant who is employed outside of the United States by a U.S. air carrier, have their certificate endorsed “Valid only outside the United States.” (AM.I.I.K1) — 14 CFR §65.71

8531-7. Which of the following statements is true for a certificated and appropriately rated mechanic regarding repairs and alterations?

A—He or she may perform an airframe major repair or major alteration, but cannot approve the work for return to service.

B—He or she may perform airframe minor repairs and minor alterations and approve the work for return to service, but cannot perform an airframe major repair or major alteration.

C—He or she may perform an airframe major repair or major alteration and approve the work, but not the entire aircraft, for return to service.

[a] 14 CFR §65.81(a) states that a certificated mechanic may perform or supervise the maintenance, preventive maintenance or alteration of an aircraft or appliance, or a part thereof for which he or she is rated (but excluding major repairs to or major alterations of propellers, and any repair to, or alteration of instruments). The mechanic must complete the FAA Form 337, filling in the compliance statement, but the person approving the work for return to service must hold an Inspection Authorization. (AM.I.I.K1) — 14 CFR §65.81

8532. (1) Certificated mechanics with an airframe rating may perform a minor repair to an airspeed indicator providing they have the necessary equipment available.

(2) Certificated mechanics with a powerplant rating may perform a major repair to a propeller providing they have the necessary equipment available. Regarding the above statements,

A—only 1 is true.

B—neither 1 nor 2 is true.

C—only 2 is true.

[b] Statement 1 is not true. No certificated mechanic, regardless of his or her ratings, is allowed to perform minor or major repairs, or minor or major alterations to instruments. Statement 2 is not true. A mechanic holding a powerplant rating cannot perform major repairs or major alterations to propellers. (AM.I.I.K1) — 14 CFR §65.81

8598. Which of the following instrument discrepancies could be corrected by an aviation mechanic?

A—Case paint chipped, leaking at line B nut, mounting screws loose, or case leaking.

B—Red line missing, case leaking, glass cracked, or fogged.

C—Red line missing, mounting screws loose, case paint chipped, or leaking at line B nut.

[c] A certificated aviation mechanic can correct any of these discrepancies: red line missing from an instrument, provided the red line is marked on the outside of the instrument glass; loose mounting screws; chipped paint on the outside of the instrument case; and leaking B-nut on the line connected to the instrument. (AM.I.I.K1) — 14 CFR §65.81

8444. If work performed on an aircraft has been done satisfactorily, the signature of an authorized person on the maintenance records for maintenance or alterations performed constitutes

A—approval of the aircraft for return to service.

B—approval for return to service only for the work performed.

C—verification that the maintenance or alterations were performed referencing approved maintenance data.

[b] The signature constitutes the approval for return to service only for the work performed. (AM.I.I.K3) — 14 CFR §43.9

8450. Which aircraft record entry is the best description of the replacement of several damaged heli-coils in a casting?

A—Eight 1/4—20 inch standard heli-coils were replaced. The damaged inserts were extracted, the tapped holes gaged, then new inserts installed, and tangs removed.

B—Eight 1/4—20 inch standard heli-coils were installed in place of damaged ones.

C—Eight 1/4—20 inch standard heli-coil inserts were repaired by replacing the damaged inserts with a lock-type insert, after the tapped holes were checked for corrosion.

[a] Heli-coils are patented, precision-formed screw-thread coils of 18-8 stainless steel wire having a diamond-shaped cross section. Heli-coil inserts are replaced by extracting the damaged insert with a special extracting tool, gaging the holes with a Heli-coil thread gage, installing the new insert using the proper inserting tool and finally, breaking off the tang with the proper break-off tool. (AM.I.I.K3) — FAA-H-8083-30

8448. Where should you find this entry? “Removed right wing from aircraft and removed skin from outer 6 feet. Repaired buckled spar 49 inches from tip in accordance with figure 8 in the manufacturer’s structural repair manual No. 28-1.”

A—Aircraft engine maintenance record.

B—Aircraft minor repair and alteration record.

C—FAA Form 337.

[c] The description of the repair, as is shown here, would be made on FAA Form 337 (Major Repair and Alteration Form). This form must be completed when an airframe, engine, propeller, or appliance has been subjected to a major repair or major alteration. (AM.I.I.K5) — FAA-H8083-30

8452-5. If more space is needed for a work description entered on FAA Form 337, what information should be included on the attached sheet(s), in addition to the rest of the work description?

A—Make, model, and serial number of the aircraft.

B—Aircraft nationality and registration mark, and the date the work was accomplished.

C—Name, date, and office designator of the FAA inspector from the supervising office.

[b] AC 43.9-1F paragraph 6.h.(3) states that if additional space is needed to describe the repair or alteration, attach sheets bearing the aircraft nationality and registration mark and the date the work was completed. (AM.I.I.K5) — AC 43.9-1

8454-2. A certificated mechanic without an inspection authorization who signs the appropriate block on FAA Form 337 is doing what?

A—Certifying that the work was done in accordance with the requirements of 14 CFR Part 43.

B—Approving the work for return to service.

C—Certifying the maintenance information used as FAA-approved data.

[a] When a certificated mechanic without an inspection authorization signs the conformity statement in item 6 of the FAA Form 337, he or she is certifying that the repair and/or alteration made to the unit(s) identified in item 4 and described on the reverse or attachments hereto have been made in accordance with the requirements of 14 CFR Part 43 and that the information furnished herein is true and correct to the best of his or her knowledge. (AM.I.I.K5) — FAA-H-8083-30

8457-1. When work is performed on an aircraft that necessitates the use of FAA Form 337, who should prepare the form?

A—The person who performs or supervises the work.

B—The person who approves for return to service.

C—Either the person who approves for return to service, or the aircraft owner or operator.

[a] AC 43.9-1F paragraph 6 states that the person who performs or supervises a major repair or major alteration should prepare the FAA Form 337. (AM.I.I.K5) — AC 43.9-1F

8457-3. Which statement is true regarding the use of FAA Form 337?

A—FAA Form 337 is authorized for use with both U.S. and foreign registered aircraft.

B—FAA Form 337 is authorized for use with U.S. registered aircraft, and foreign registered aircraft when located in the United States.

C—FAA Form 337 is not authorized for use with other than U.S. registered aircraft.

[c] AC 43.9-1F paragraph 7.d. states that FAA Form 337 is not authorized for use on other than U.S.-registered aircraft. (AM.I.I.K5) — AC 43.9-1F

8458. After making a certain repair to an aircraft engine that is to be returned to service, an FAA Form 337 is prepared. How many copies are required and what is the disposition of the completed forms?

A—Two; one copy for the aircraft owner and one copy for the FAA.

B—Two; one copy for the FAA and one copy for the permanent records of the repairing agency or individual.

C—Three; one copy for the aircraft owner, one copy for the FAA, and one copy for the permanent records of the repairing agency or individual.

[a] When a major repair or a major alteration has been made to any equipment that requires an FAA Form 337, the form must be prepared in duplicate. The original goes to the aircraft owner to be kept with the aircraft records. The copy is forwarded to the local FAA office within 48 hours after the aircraft is approved for return to service. (AM.I.I.K5) — 14 CFR Part 43

8462. An FAA Form 337 is used to record and document

A—preventive and unscheduled maintenance, and special inspections.

B—major and minor repairs, and major and minor alterations.

C—major repairs and major alterations

[c] FAA Form 337 is used to describe any major repairs or major alterations that have been made to an airframe, powerplant, propeller, or appliance. (AM.I.I.K5) — 14 CFR Part 43

8503-1. Which of the following are sometimes used as authorization to deviate from an aircraft’s original type design?

A—FAA Form 337, Supplemental Type Certificate, and Technical Standard Order.

B—Supplemental Type Certificate, Airworthiness Directive, and Technical Standard Order.

C—FAA Form 337, Supplemental Type Certificate, and Airworthiness Directive.

[c] The FAA Form 337 is the form the FAA uses to authorize a major alteration that may deviate from the aircraft’s original type design.

An STC is an authorization for a major change in the type design that is not great enough to require a new application for a type certificate.

An AD identifies an unsafe condition that exists in a product and that is likely to exist or develop in other products of the same type design. ADs may require alterations that deviate from the aircraft’s original type design.

A TSO is a minimum performance standard used to evaluate an article. An article can be a material, part, component, process, or appliance (see 14 CFR §21.1(b) (2)). Each TSO covers a certain type of article. When authorized to manufacture an article to a TSO standard, this is referred to as a TSO authorization. Receiving a TSO authorization is both a design and production approval but is not used as an authorization to deviate from an aircraft’s original type design. (AM.I.I.K5) — FAA-H-8083-30

8449. Which maintenance action is an airframe major repair?

A—Changes to the wing or to fixed or movable control surfaces which affect flutter and vibration characteristics.

B—Rewinding the field coil of an electrical accessory.

C—The repair of portions of skin sheets by making additional seams.

[c] According to the list of major alterations, major repairs and preventive maintenance listed in 14 CFR Part 43, Appendix A, the repair of portions of skin sheets by making additional seams is considered to be an airframe major repair. Neither of the other alternatives listed here is an airframe major repair. (AM.I.I.K6) — 14 CFR Part 43

8516-4. Which of the following includes all the regulatory definitions of “maintenance”?

A—Overhaul, repair, parts replacement, and preservation, and preventive maintenance.

B—Overhaul, repair, parts replacement, preservation, inspection, and preventive maintenance.

C—Overhaul, repair, parts replacement, inspection, and preservation.

[c] 14 CFR Part 1 defines maintenance as inspection, overhaul, repair, preservation, and the replacement of parts, but excludes preventive maintenance. (AM.I.I.K6) — FAA-H-8083-30

8520. A repair, as performed on an airframe, shall mean

A—the upkeep and preservation of the airframe including the component parts thereof.

B—the restoration of the airframe to a condition for safe operation after damage or deterioration.

C—simple or minor preservation operations and the replacement of small standard parts not involving complex assembly operations

[b] A repair to an aircraft structure is an operation that restores the structure to a condition for safe operation after it has become deteriorated or has been damaged. (AM.I.I.K6) — 14 CFR Part 43

8447. Which is an appliance major repair?

A—Overhaul of a hydraulic pressure pump.

B—Repairs to a propeller governor or its control.

C—Troubleshooting and repairing broken circuits in landing light circuits.

[a] Overhaul of pressure-type carburetors and pressure-type fuel, oil, and hydraulic pumps are examples of appliance major repairs. (AM.I.I.K7) — 14 CFR Part 43

8521. The replacement of fabric on fabric-covered parts such as wings, fuselages, stabilizers, or control surfaces is considered to be a

A—minor repair unless the new cover is different in any way from the original cover.

B—minor repair unless the underlying structure is altered or repaired.

C—major repair even though no other alteration or repair is performed.

[c] Replacing the fabric on fabric-covered parts such as wings, fuselages, stabilizers, or control surfaces is considered to be a major repair even though no other alteration or repair is performed. (AM.I.I.K7) — 14 CFR Part 43

8522. Which is classified as a major repair?

A—The splicing of skin sheets.

B—Installation of new engine mounts obtained from the aircraft manufacturer.

C—Any repair of damaged stressed metal skin.

[a] 14 CFR Part 43, Appendix A (b)(1)(xxiv) lists the splicing of skin sheets as an airframe major repair. (AM.I.I.K7) — 14 CFR Part 43

8527. The replacement of a damaged vertical stabilizer with a new identical stabilizer purchased from the aircraft manufacturer is considered a

A—minor alteration.

B—major repair.

C—minor repair

[c] The replacement of a damaged vertical stabilizer with a new identical stabilizer purchased from the aircraft manufacturer is a minor repair. A rule of thumb for determining whether a repair is minor or major is that if the part can be bolted on and not require any riveting or welding, the repair is minor. This rule of thumb might well have exceptions. (AM.I.I.K7) — 14 CFR Part 43, Appendix A

8535. The replacement of a damaged engine mount with a new identical engine mount purchased from the aircraft manufacturer is considered a

A—major or minor repair, depending upon the complexity of the installation.

B—major repair.

C—minor repair.

[c] The replacement of a part such as an engine mount with a new, identical part obtained from the aircraft manufacturer is considered to be an airframe minor repair. (AM.I.I.K7) — 14 CFR Part 43

8505. Which regulation provides information regarding instrument range markings for an airplane certificated in the normal category?

A—14 CFR Part 21.

B—14 CFR Part 25.

C—14 CFR Part 23.

[c] Information regarding instrument range markings that must be used on aircraft certificated in the normal category is found in 14 CFR Part 23, “Airworthiness Standards: Normal, Utility, Acrobatic and Commuter Category Airplanes.” (AM.I.I.K8) — 14 CFR §23.1543

8505-1. Which regulation provides the airworthiness standards for an airplane certificated in the normal category?

A—14 CFR Part 27.

B—14 CFR Part 25.

C—14 CFR Part 23.

[c] 14 CFR Part 27 provides the airworthiness standards for normal category rotorcraft. Part 25 provides airworthiness standards for transport category airplanes. Part 23 provides airworthiness standards for normal, utility, acrobatic, and commuter category airplanes. (AM.I.I.K8) — 14 CFR Part 23

8505-2. What regulations are covered by 14 CFR Part 1?

A—Certification of airmen other than crewmembers.

B—General operating and flight rules.

C—Definitions and abbreviations.

[c] 14 CFR Part 1 covers definitions and abbreviations. This regulation is helpful for learning the legal terms and their associated meanings as well as the many acronyms used in aviation. (AM.I.I.K8) — 14 CFR Part 1

8530. What part of the Federal Aviation Regulations prescribes the requirements for issuing mechanic certificates and associated ratings and the general operating rules for the holders of these certificates and ratings?

A—14 CFR Part 43.

B—14 CFR Part 91.

C—14 CFR Part 65.

[c] 14 CFR Part 65, “Certification: Airmen Other Than Flight Crewmembers” prescribes the requirements for the issuance of mechanic certificates and associated ratings and the general operating rules for the holders of these certificates and ratings. (AM.I.I.K8) — 14 CFR Part 65

8530-1. 14 CFR Part 65 contains regulations regarding the certification of

A—pilots, flight Instructors, and ground instructors.

B—airmen other than flight crewmembers.

C—flight crewmembers other than pilots.

[b] 14 CFR Part 65, “Certification: Airmen Other Than Flight Crewmembers,” prescribes the requirements for the issuance of mechanic certificates and associated ratings, air traffic control operators, aircraft dispatchers, repairmen, and parachute riggers and the general operating rules for the holders of these certificates and ratings. (AM.I.I.K8) — 14 CFR Part 65

8530-2. 14 CFR Part 65 Subpart D contains regulations regarding the certification of

A—repairmen.

B—pilots.

C—mechanics.

[c] 14 CFR Part 65, “Certification: Airmen Other Than Flight Crewmembers,” prescribes the requirements for the issuance of mechanic certificates and associated ratings, air traffic control operators, aircraft dispatchers, repairmen, and parachute riggers and the general operating rules for the holders of these certificates and ratings. Subpart D specifically covers mechanics. Subpart E specifically covers repairman. Pilot certification is covered in 14 CFR Part 61. (AM.I.I.K8) — 14 CFR Part 65

8531-1. Under Title 14 of the Code of Federal Regulations, what is the maximum penalty for falsification, alteration, or fraudulent reproduction of certificates, logbooks, reports, and records?

A—Ineligibility to receive any certificate or rating for one year.

B—Imprisonment for one year and a $5,000 fine.

C—Suspension or revocation of any certificate held.

[c] 14 CFR §65.20 states that any person who falsifies or makes a fraudulent entry in a logbook, report, or record is subject to the suspension or revocation of any airman or ground instructor certificate or rating held by that person. (AM.I.I.K8) — 14 CFR §65.20

8531-4. Why is a mechanic applicant issued a temporary certificate after successful completion of the required tests?

A—To allow for review of their application and supplementary documents.

B—So that a background check/investigation may be completed.

C—Both of the other two choices.

[a] 14 CFR §65.13 provides for a temporary certificate and rating effective for a period of 120 days to be issued to a qualified applicant, pending review of their application and supplementary documents and the issue of the certificate and ratings for which they applied. (AM.I.I.K8) — 14 CFR §65.13

8533. Who is responsible for determining that materials used in aircraft maintenance and repair are of the proper type and conform to the appropriate standards?

A—The installing person or agency.

B—The owner or operator of the aircraft.

C—The manufacturer of the aircraft.

[a] It is the responsibility of the person or agency (the certificated mechanic or the approved repair station) performing aircraft maintenance or making repairs to an aircraft, to make sure that all of the materials used in the maintenance or repair conform to the appropriate standards. (AM.I.I.K8) — 14 CFR §43.13(b)

8443. Where is the record of compliance with Airworthiness Directives or manufacturers’ service bulletins normally indicated?

A—FAA Form 337.

B—Aircraft maintenance records.

C—Flight manual.

[b] The aircraft maintenance records (generally in the form of logbooks) are the correct place to record compliance with FAA Airworthiness Directives or manufacturer’s service bulletins. (AM.I.I.K9) — FAA-H-8083-30

8446. What is the means by which the FAA notifies aircraft owners and other interested persons of unsafe conditions and prescribes the condition under which the product may continue to be operated?

A—Airworthiness Directives.

B—Aviation Maintenance Alerts.

C—Aviation Safety Data.

[a] If a condition is found that causes a particular design of aircraft to fail to meet its certification for airworthiness, the FAA can issue an AD. An AD describes the conditions that must be met to allow the aircraft to continue to be operated. (AM.I.I.K9) — FAA-H-8083-30

8492. Airworthiness Directives are issued primarily to

A—provide information about malfunction or defect trends.

B—present recommended maintenance procedures for correcting potentially hazardous defects.

C—correct an unsafe condition.

[c] The FAA issues ADs to correct unsafe conditions that have been discovered on certificated aircraft, engines, propellers, or appliances. An unsafe condition causes the device to fail to meet the conditions for its certification. An AD specifies the corrective action that must be taken to return the device to the conditions specified for its certification. (AM.I.I.K9) — 14 CFR Part 39

8493. (1) A Supplemental Type Certificate (STC) may be issued to more than one applicant for the same design change, providing each applicant shows compliance with the applicable airworthiness requirement.

(2) An installation of an item manufactured in accordance with the Technical Standard Order (TSO) system requires no further approval for installation in a particular aircraft. Regarding the above statements,

A—both 1 and 2 are true.

B—neither 1 nor 2 is true.

C—only 1 is true.

[c] Statement 1 is true. More than one person may apply for a STC that covers the same change to an aircraft. An STC is not a patent and it is not protected. Each applicant must furnish proof that their alteration meets all of the applicable airworthiness requirements.

Statement 2 is not true. A part produced according to a TSO requires specific approval for installation on a particular aircraft. Even though the part is built according to a TSO, it may be neither suitable nor approved for the particular aircraft. (AM.I.I.K9) — 14 CFR Part 21

8493-1. What does the acronym TSO mean regarding a type certificated aircraft part, material, component and/ or process?

A—Training Specific Organization.

B—Type Supplement Original.

C—Technical Standard Order.

[c] A Technical Standard Order (TSO) is an approval for the manufacture of a component for use on certificated aircraft. (AM.I.I.K9) — FAA-H-8083-30

8494. Primary responsibility for compliance with Airworthiness Directives lies with the

A—aircraft owner or operator.

B—certificated mechanic holding an Inspection Authorization who conducts appropriate inspections.

C—certificated mechanic who maintains the aircraft.

[a] The aircraft owner or operator is responsible for determining that the aircraft continues to meet the requirements for its certification. This includes the compliance with all ADs. (AM.I.I.K9) — 14 CFR Part 39

8495. An aircraft Type Certificate Data Sheet contains

A—maximum fuel grade to be used.

B—control surface adjustment points.

C—location of the datum.

[c] Since the location of all items in an aircraft are measured from the datum and this datum can be at any location the aircraft manufacturer chooses, the technician must know exactly where this reference is located. The location of the datum is included in the information furnished on a Type Certificate Data Sheet. (AM.I.I.K9) — FAA-H-8083-30

8496. Suitability for use of a specific propeller with a particular engine-airplane combination can be determined by reference to what informational source?

A—Propeller Specifications or Propeller Type Certificate Data Sheet.

B—Aircraft Specifications or Aircraft Type Certificate Data Sheet.

C—Alphabetical Index of Current Propeller Type Certificate Data Sheets, Specifications, and Listings.

[b] The Aircraft Specifications or Type Certificate Data Sheets list all of the allowable engine-propeller combinations approved for a specific aircraft. (AM.I.I.K9) — FAA-H8083-30

8500. Where are technical descriptions of certificated propellers found?

A—Applicable Airworthiness Directives.

B—Aircraft Specifications.

C—Propeller Type Certificate Data Sheets.

[c] Technical specifications for certificated aircraft propellers are found in the Propeller Type Certificate Data Sheets. (AM.I.I.K9) — FAA-H-8083-30

8501. What information is generally contained in Aircraft Specifications or Type Certificate Data Sheets?

A—Empty weight of the aircraft.

B—Useful load of aircraft.

C—Control surface movements.

[c] The amount of control surface movement determines the structural loads that can be put on an aircraft and also the flight characteristics of the aircraft. Because this information is so critical, it is included on the Type Certificate Data Sheets of an aircraft. (AM.I.I.K9) — FAA-H-8083-30

8509-1. A Technical Standard Order (TSO) is issued by whom?

A—The Aircraft industry.

B—Part manufacturers.

C—The Administrator.

[c] TSOs are issued by the Administrator under 14 CFR Part 21. (AM.I.I.K9) — FAA-H-8083-30

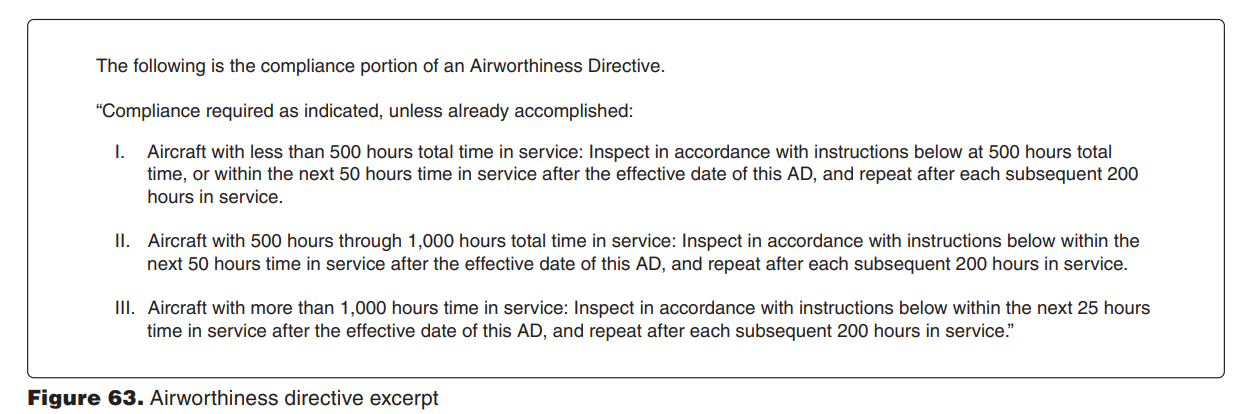

8515. (Refer to Figure 63.) An aircraft has a total time in service of 468 hours. The Airworthiness Directive given was initially complied with at 454 hours in service. How many additional hours in service may be accumulated before the Airworthiness Directive must again be complied with?

A—46.

B—200.

C—186.

[c] The aircraft has less than 500 hours total time in service, so compliance with the AD falls in category I. The AD has been complied with and the aircraft has operated for 14 hours since the compliance. The AD must be complied with each 200 hours of time in service, so the aircraft can operate for another 186 hours before the AD note must be complied with again. (AM.I.I.K9) — 14 CFR Part 39

8515-1. The following words are an example of what kind of statement in an AD? “Required within the next 25 hours time-in-service after the effective date of this AD, unless already accomplished.”

A—Amendment.

B—Compliance.

C—Applicability.

[b] “Within the next 25 hours time-in-service after the effective date of this AD,” is a statement of compliance time or date. (AM.I.I.K9) — FAA-H-8083-30

8515-2. The action required by an AD may take what form?

1. Inspection.

2. Part(s) replacement.

3. Design modification.

4. Change in operating procedure(s).

5. Overall change in the content, form and disposition of aircraft maintenance records.

A—1, 2, 3, and/or 4.

B—1, 2, 3, and/or 5.

C—1, 2, 3, 4, and/or 5.

[a] The action required by an AD is described in the Compliance statement which specifies the action that is required by the AD, and specifies the method of compliance. An AD does not specify an overall change in maintenance records. (AM.I.I.K9) — FAA-H-8083-30

8515-3. Type Certificate Data Sheets are issued for which of the following products?

A—Aircraft, engines, and propellers.

B—Aircraft, engines, and appliances.

C—Aircraft, engines, propellers, and appliances.

[a] Type Certificate Data Sheets and Specifications set forth essential factors and other conditions which are necessary for U.S. airworthiness certification of aircraft, engines and propellers. (AM.I.I.K9) — FAA-H-8083-30

8516-2. How long are AD compliance records required to be kept?

A—Until the work is repeated or superseded by other work.

B—For one year after the work is performed, or until the work is repeated or superseded by other work.

C—They shall be retained, and then transferred with the aircraft when it is sold.

[c] 14 CFR §91.417(b)(2) states that the record of the current status of applicable AD including, for each, the method of compliance, the AD number, and revision date be retained and transferred with the aircraft at the time the aircraft is sold. (AM.I.I.K9) — FAA-H-8083-30

8516-3. What does the Type Certificate Data Sheet designation code “2 PCSM” mean? (K01)

A—Two place (number of seats), closed, sea, monoplane.

B—Two wing (biplane), primary category, semimonocoque (airframe).

C—Neither of the other two choices.

[a] The FAA uses coded information for the configuration of aircraft and engines in the Type Certificate Data Sheets. The code 2 PCSM identifies the aircraft as a two-place, closed, sea, monoplane. (AM.I.I.K9) — FAA-H-8083-30

8510. The Air Transport Association of America (ATA) Specification No. 100

(1) establishes a standard for the presentation of technical data in maintenance manuals.

(2) divides the aircraft into numbered systems and subsystems in order to simplify locating maintenance instructions. Regarding the above statements,

A—both 1 and 2 are true.

B—neither 1 nor 2 is true.

C—only 1 is true.

[a] Statement 1 is true. The ATA Specification 100 is a standard for arranging and presenting technical data in maintenance manuals. Statement 2 is also true. The ATA Specification 100 divides the aircraft into numbered systems and subsystems to simplify locating maintenance instructions. (AM.I.I.K12) — FAA-H-8083-30

8511. Aviation Maintenance Alerts (formerly General Aviation Airworthiness Alerts)

A—provide mandatory procedures to prevent or correct serious aircraft problems.

B—provide information about aircraft problems and suggested corrective actions.

C—provide temporary emergency procedures until Airworthiness Directives can be issued.

[b] Aviation Maintenance Alerts, formerly General Aviation Airworthiness Alerts, provide a common communication channel through which the aviation community can economically interchange service experience and thereby cooperate in the improvement of aeronautical product durability, reliability, and safety. The contents include items that have been reported to be significant but have not been evaluated fully by the time the material went to press. (AM.I.I.K12) — FAA-H-8083-30

8508. What is the maintenance recording responsibility of the person who complies with an Airworthiness Directive?

A—Advise the aircraft owner/operator of the work performed.

B—Make an entry in the maintenance record of that equipment.

C—Advise the FAA office of the work performed, by submitting an FAA Form 337.

[b] When a technician complies with an Airworthiness Directive, it is his or her responsibility to make an entry in the maintenance record of the affected equipment. This entry must include the method of compliance and the date of compliance. (AM.I.I.K13) — FAA-H-8083-30

8537. Instrument repairs may be performed

A—by the instrument manufacturer only.

B—by an FAA-approved instrument repair station.

C—on airframe instruments by mechanics with an airframe rating.

[b] Repairs to an instrument, either major or minor repairs, may be performed only by an FAA-approved instrument repair station. The manufacturer of the instrument has this type of rating. (AM.I.I.K13) — 14 CFR §43.3

8452-1. Which statement is true regarding the requirements for maintenance record format?

A—Any format that provides record continuity and includes the required information may be used.

B—The format provided by the manufacturer of the aircraft must be retained.

C—Any desired change from manufacturer provided format requires approval from the Federal Aviation Administration

[a] AC 43-9 paragraph 5.b. states that maintenance records may be kept in any format that provides record continuity, includes required contents, lends itself to the addition of new entries, provides for signature entry, and is intelligible. (AM.I.I.K14) — AC 43-9

8459. Who is responsible for upkeep of the required maintenance records for an aircraft?

A—The maintaining repair station or authorized inspector.

B—The maintaining certificated mechanic.

C—The aircraft owner

[c] According to 14 CFR §91.417, the aircraft owner or operator is responsible for “ensuring that maintenance personnel make appropriate entries in the aircraft and maintenance records indicating the aircraft has been approved for return to service.” (AM.I.I.K14) — 14 CFR §91.417

8504. (1) The Federal Aviation Regulations require approval after compliance with the data of a Supplemental Type Certificate.

(2) An installation of an item manufactured in accordance with the Technical Standard Order system requires no further approval for installation in a particular aircraft. Regarding the above statements,

A—only 2 is true.

B—neither 1 nor 2 is true.

C—only 1 is true.

[c] Statement 1 is true. After an aircraft has been altered in accordance with a Supplemental Type Certificate, it must be inspected for conformity with the information included in the STC before it can be approved for return to service. Statement 2 is not true. Even though a part has been manufactured according to a Technical Standard Order, it is not necessarily approved for installation on a particular civil aircraft. (AM.I.I.K14) — 14 CFR §43.13

8516-1. When is a mechanic responsible for checking AD compliance?

A—Never, the owner or operator is solely responsible.

B—When performing an inspection required under part 91, 125, or 135.

C—Anytime an aircraft or portion thereof is returned to service

[b] It is the responsibility of the mechanic performing an inspection required under Part 91, 125, or 135 to determine the status of any AD affecting the airframe, engine, propeller, rotor, and any installed appliances. (AM.I.I.K14) — FAA-H-8083-30

8517. A complete detailed inspection and adjustment of the valve mechanism will be made at the first 25 hours after the engine has been placed in service. Subsequent inspections of the valve mechanism will be made each second 50-hour period.

From the above statement, at what intervals will valve mechanism inspections be performed?

A—100 hours.

B—50 hours.

C—125 hours.

[a] Since the valve mechanism is required to be inspected only every second 50-hour period, the engine can operate for 100 hours between valve mechanism inspections. (AM.I.I.K14) — 14 CFR §43.13

8518. Check thrust bearing nuts for tightness on new or newly overhauled engines at the first 50-hour inspection following installation. Subsequent inspections on thrust bearing nuts will be made at each third 50-hour inspection.

From the above statement, at what intervals should you check the thrust bearing nut for tightness?

A—150 hours.

B—200 hours.

C—250 hours.

[a] Since the thrust bearing nuts must be checked for tightness after the first 50 hours in service and then on every third 50-hour inspection, the engine can operate for 150 hours between inspections of tightness of the thrust bearing nuts. (AM.I.I.K14) — 14 CFR §43.13

8451. Which maintenance record entry best describes the action taken for a control cable showing approximately 20 percent wear on several of the individual outer wires at a fairlead?

A—Wear within acceptable limits, repair not necessary.

B—Removed and replaced the control cable and rerigged the system.

C—Cable repositioned, worn area moved away from fairlead.

[a] Flexible and extra-flexible control cable should be replaced when the individual wires in each strand appear to blend together (outer wires worn 40 to 50 percent). Since these wires are only worn 20 percent, the wear is within acceptable limits and repair is not necessary. (AM.I.I.K15) — AC 43.13-1B

8452. Which maintenance record entry best describes the action taken for a .125-inch deep dent in a straight section of 1/2-inch aluminum alloy tubing?

A—Dented section removed and replaced with identical new tubing flared to 45°.

B—Dent within acceptable limits, repair not necessary.

C—Dented section removed and replaced with identical new tubing flared to 37°.

[c] The dent is in a straight portion of the tube and is deep enough to warrant its removal. A dent of up to 0.1 inch (20 percent of the tube diameter) deep would be acceptable and would not have to be removed. The dented section would have to be removed and replaced with identical new tubing flared to 37°. (AM.I.I.K15) — FAA-H-8083-30

8452-3. For aircraft operated under Part 91, when is aircraft total time required to be recorded in aircraft maintenance records?

A—After satisfactorily completing maintenance, preventive maintenance, rebuilding, and alteration (excluding inspections).

B—After satisfactorily completing inspections.

C—After satisfactorily completing airframe, component, or propeller maintenance.

[b] 14 CFR §43.11 states that the person approving for return to service an aircraft, airframe, aircraft engine, propeller, appliance, or component part after any inspection performed in accordance with Part 91…shall make an entry in the maintenance record of that equipment containing the following information…(2) The date of the inspection and aircraft total time in service. (AM.I.I.K15) — 14 CFR §43.11

8452-4. For aircraft operated under Part 91, what difference is there, if any, between the record entry requirements for maintenance (e.g., repair or alteration) and the record entry requirements for inspections (beyond the description of the work performed and the type and extent of inspection)?

A—There is no difference.

B—Aircraft total time is required to be included only in the maintenance entry.

C—Aircraft total time is required to be included only in the inspection entry

[c] 14 CFR §43.11 states that the person approving for return to service an aircraft, airframe, aircraft engine, propeller, appliance, or component part after any inspection performed in accordance with Part 91…shall make an entry in the maintenance record of that equipment containing the following information…(2) The date of the inspection and aircraft total time in service.

Records specified in 14 CFR §43.9 do not require the recording of the aircraft total time. (AM.I.I.K15) — 14 CFR §43.9(a)(2)

8452-6. A person installing a product, part, or appliance on a type certificated product must make certain that the item’s records document the

A—product, part, or material meets FAA airworthiness standards.

B—source from which the part came.

C—product or material was not produced under an FAA production approval.

[a] Any product, part, or material installed on a type certificate product must meet FAA airworthiness standards. (AM.I.I.K15) — FAA-H-8083-30

8453. Which aircraft record entry best describes a repair of a dent in a tubular steel structure dented at a cluster?

A—Removed and replaced the damaged member.

B—Welded a reinforcing plate over the dented area.

C—Filled the damaged area with a molten metal and dressed to the original contour

[b] If an aircraft welded-steel tubular structure is dented at a cluster, a patch plate of the same material and as thick as the thickest member of the cluster is cut and welded over the dented area. (AM.I.I.K15) — AC 43.13-1B

8454-1. For aircraft operated under Part 91, which of the following records must be retained for at least one year, or until the work is repeated or superseded?

A—Records of time since overhaul of items requiring overhaul on a time specified basis.

B—Records of maintenance, alterations, preventive maintenance, 100-hour, annual, and progressive inspections.

C—Records of the current inspection status of the aircraft, including time since last required inspection.

[b] 14 CFR §91.417 states that records of the maintenance, preventive maintenance, and alteration and records of the 100-hour, annual, progressive, and other required or approved inspections, as appropriate for each aircraft (including the airframe) and each engine, propeller, rotor, and appliance of an aircraft must include the total time in service of the airframe, each engine, each propeller, and each rotor, and shall be retained until the work is repeated or superseded by other work or for 1 year after the work is performed. (AM.I.I.K15) — 14 CFR §91.417

8454-3. For aircraft operated under Part 91, which of the following records must be retained and transferred with the aircraft when it is sold?

A—Records of maintenance, alterations, preventive maintenance, 100-hour, annual, and progressive inspections.

B—Records of inspections performed in accordance with 14 CFR Part 43, Appendix D.

C—Records of the current status of applicable ADs, and date and time when recurring ADs are next due.

[c] 14 CFR §91.417 (a) and (b) state that among the records that must be retained and transferred with the aircraft when it is sold is the current status of the applicable ADs including for each the method of compliance, the AD number, and revision date; also, if the AD involves recurring action, the time and date when the next action is required. (AM.I.I.K15) — FAA-H-8083-30

8455-2. In order to reconstruct lost or destroyed aircraft maintenance records, what is it necessary to establish?

A—Dates of all maintenance, preventive maintenance and alterations.

B—Dates and/or times of all 100-hour, annual, or progressive inspections.

C—Total time-in-service of the airframe.

[c] AC 43-9C paragraph 12 states that in order to reconstruct lost or destroyed maintenance records, it is necessary to establish the total time-in-service of the airframe. (AM.I.I.K15) — AC 43-9C

8456. When approving for return to service after maintenance or alteration, the approving person must enter in the maintenance record of the aircraft

A—the date the maintenance or alteration was begun, a description (or reference to acceptable data) of work performed, the name of the person performing the work (if someone else), signature, and certificate number.

B—a description (or reference to acceptable data) of work performed, date of completion, the name of the person performing the work (if someone else), signature, and certificate number.

C—a description (or reference to acceptable data) of work performed, date of completion, the name of the person performing the work (if someone else), signature, certificate number, and kind of certificate held.

[c] A maintenance record entry that is made after maintenance or alteration must contain the following:

1. A description (or reference to data acceptable to the Administrator) of the work performed;

2. The date of completion of the work performed;

3. The name of the person performing the work if other than the person approving the work for return to service; and

4. The signature, certificate number, and kind of certificate held by the person approving the work for return to service. (AM.I.I.K15) — 14 CFR §43.9

8464-1. What is ATA iSpec 2200?

A—Standardized electronic documentation for aircraft models.

B—Fuel specifications for transport-category airplanes.

C—Airline transport catalog for aircraft parts.

[a] ATA iSpec 2200 is a compilation of what used to be ATA Spec 100 and ATA Spec 2100. This ATA iSpec 2200 standardizes the format in which maintenance information is presented in aircraft maintenance manuals, and makes it available in electronic format. (AM.I.I.K15) — FAA-H8083-30

8499. Specifications pertaining to an aircraft model manufactured under a type certificate of which less than 50 are shown on the FAA Aircraft Registry, can be found in the

A—Aircraft Listing.

B—Summary of Discontinued Aircraft Specifications.

C—FAA Statistical Handbook of Civil Aircraft Specifications.

[a] The certification specifications for aircraft of which there are fewer than 50 currently in service or of which there were fewer than 50 certificated are found in the Aircraft Listing. (AM.I.I.K15) — 14 CFR Part 21

8503. Technical information about older aircraft models, of which no more than 50 remain in service, can be found in the

A—Aircraft Listing.

B—Summary of Deleted and Discontinued Aircraft Specifications.

C—Index of Antique Aircraft.

[a] The certification specifications for aircraft of which there are fewer than 50 currently in service, or of which there were fewer than 50 certificated, are found in the Aircraft Listing. (AM.I.I.K15) — FAA-H-8083-30

8507. An aircraft mechanic is privileged to perform major alterations on U.S. certificated aircraft; however, the work must be done in accordance with FAA-approved technical data before the aircraft can be returned to service. Which is NOT approved data?

A—Airworthiness Directives.

B—AC 43.13-2A.

C—Supplemental Type Certificates.

[b] The FAA issues or approves two types of data for aircraft:

1. Regulatory data is approved data that specifies the way something will be done. It is specific and it must be complied with as it applies.

2. Data in Advisory Circulars, such as that in AC 43.13- 2A, is advisory in nature and is “acceptable data.” While it shows a way that things can be done, it is neither specific nor mandatory. It is not considered to be “approved data.”

(AM.I.I.K15) — FAA-H-8083-30

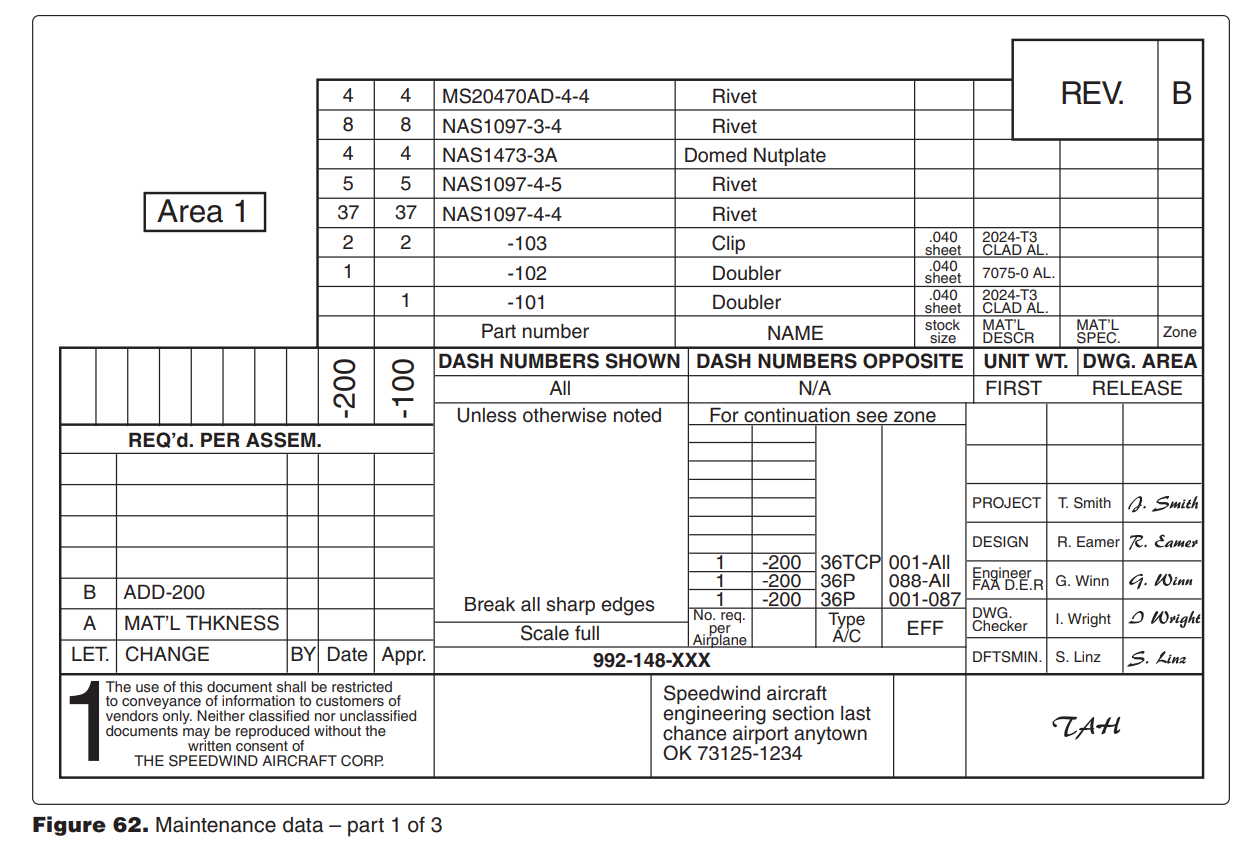

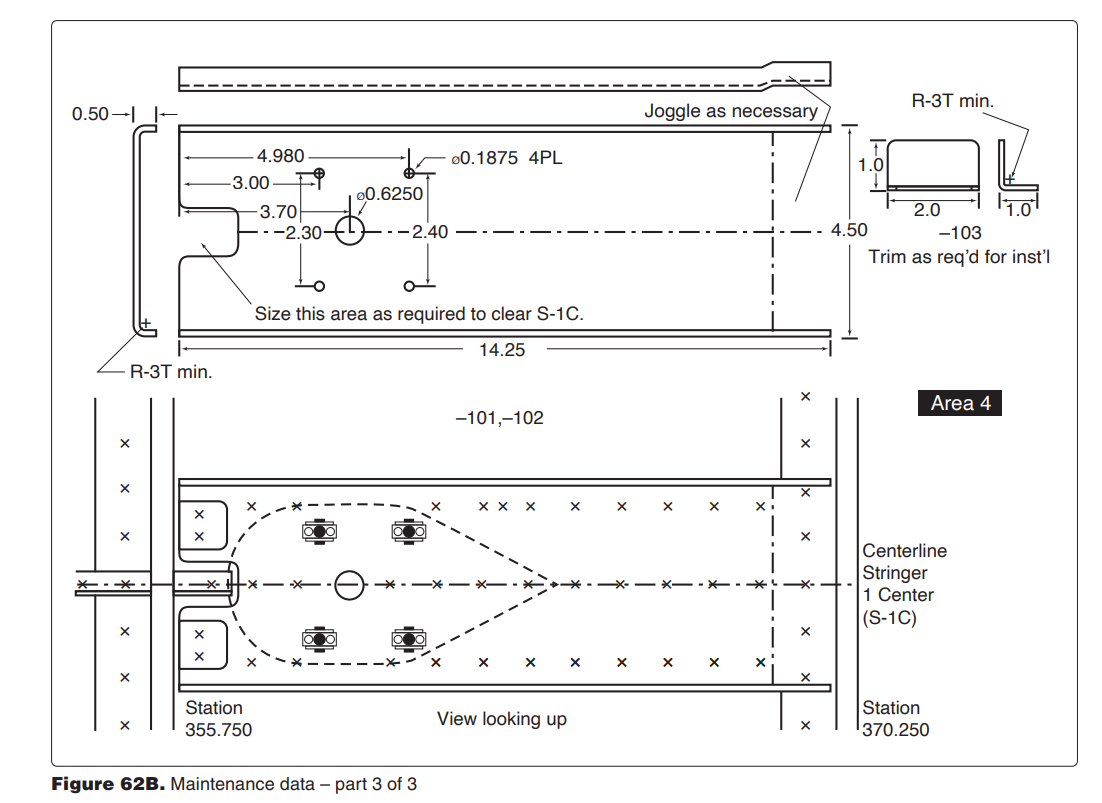

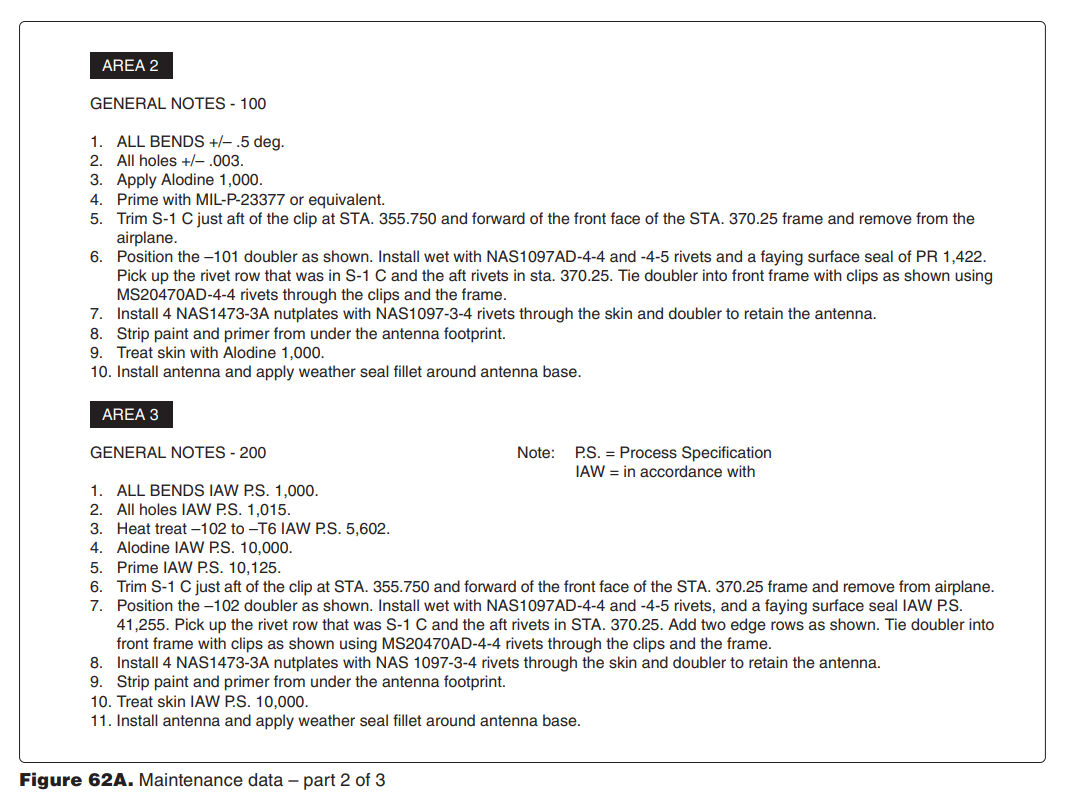

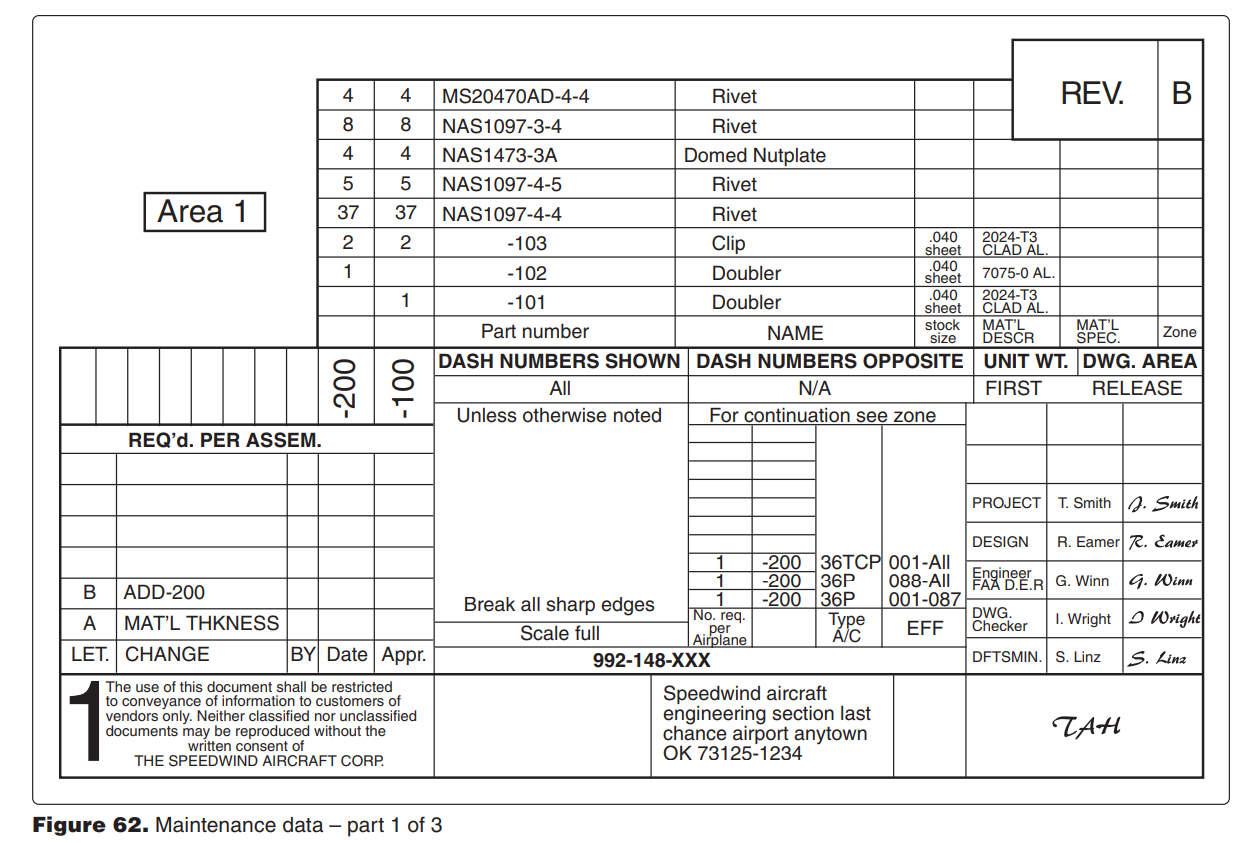

8512. (Refer to Figure 62, 62A, & 62B as necessary.) Which doubler(s) require(s) heat treatment before installation?

A—-101.

B—-102.

C—Both.

[b] Doubler -102 is made of .040 7075-O Alclad. This material is in its annealed (-O) condition, and it must be heat-treated to its -T6 condition before it is installed. Doubler -101 is made of 2024-T3 Alclad which is already heat-treated. According to General Notes-200 in Figure 62A, the -102 doubler should be heat-treated to -T6 condition in accordance with Process Specification 5602. (AM.I.I.K15) — FAA-H-8083-30

8512-1. (Refer to Figures 62, 62A, and 62B as necessary.) How many parts will need to be fabricated by the mechanic in the construction and installation of one doubler?

A—2.

B—3.

C—4.

[b] The mechanic must fabricate three parts to install the doubler. For the -100 installation, one doubler -101 and two clips -103 are needed. For the -200 installation, one doubler -102 and two clips -103 are needed. (AM.I.I.K15) — FAA-H-8083-30

8513. (Refer to Figure 62, 62A, & 62B as necessary.) Using only the information given (when bend allowance, set back, etc. have been calculated) which doubler is it possible to construct and install?

A—-101.

B—-102.

C—Both.

[a] There is enough information given here to construct and install the -101 doubler. There is not enough information to construct the stronger -102 doubler in the -200 installation. The -102 doubler requires certain Process Specifications that are not furnished. (AM.I.I.K15) — FAA-H-8083-30

8514. (Refer to Figure 62.) The -100 in the title block (Area 1) is applicable to which doubler part number(s)?

A—-101.

B—-102.

C—Both.

[a] In Figure 62, follow the column for the -100 assembly upward to see the components it requires. The -101 doubler is in this column. (AM.I.I.K15) — 14 CFR Part 43, Appendix A

8534. Which of these publications contains standards for protrusion of bolts, studs, and screws through selflocking nuts?

A—AC 43.13-1B.

B—AC 43.13-2.

C—Aircraft Specifications or Type Certificate Data Sheets

[a] AC 43.13-1B states that “After the nut has been tightened, make sure that the bolt or stud has at least one thread showing past the nut.” (AM.I.I.K15) — AC 43.13-1B

8457-2. What is the status of data used as a basis for approving major repairs or alterations for return to service?

A—Data must be least FAA-acceptable when it is used for that purpose.

B—Data must be FAA-approved prior to its use for that purpose.

C—Data may be FAA-approved after its use for that purpose.

[b] AC 43.9-1F paragraph 6.h.(2) states that data used as a basis for approving major repairs or alterations for return to service must be FAA-approved prior to its use for that purpose. (AM.I.I.K16) — AC 43.9-1F

8509. (1) Manufacturer’s data and FAA publications such as Airworthiness Directives, Type Certificate Data Sheets, and advisory circulars are all approved data.

(2) FAA publications such as Technical Standard Orders, Airworthiness Directives, Type Certificate Data Sheets, and Aircraft Specifications and Supplemental Type Certificates are all approved data. Regarding the above statements,

A—both 1 and 2 are true.

B—only 1 is true.

C—only 2 is true.

[c] Statement 1 is not true. Not all manufacturer’s data is FAA approved and Advisory Circulars are not considered to be approved data. Statement 2 is true. All of the items listed in this statement are considered to be approved data. (AM.I.I.K16) — FAA-H-8083-30

8455-1. When a discrepancy list is provided to an aircraft owner or operator after an inspection, it says in effect that

A—the item inspected is unairworthy.

B—except for these discrepancies, the item inspected is airworthy.

C—the item inspected may or may not be airworthy depending on the discrepancies found.

[b] AC 43-9C paragraph 11.b. states that when a discrepancy list is provided to an owner or operator, it says in effect, that except for these discrepancies, the item inspected is airworthy. (AM.I.I.K17) — AC 43-9C

8497. When an aircraft is sold domestically, the Airworthiness Certificate

A—must be surrendered to the local Flight Standards District Office.

B—becomes invalid until the new owner makes application for a new Airworthiness Certificate.

C—is transferred with the aircraft at the time of sale.

[c] The Airworthiness Certificate issued to an aircraft is transferred with the aircraft to the new owner when the aircraft is sold. (AM.I.I.K17) — 14 CFR §21.179

8498. The issuance of an Airworthiness Certificate is governed by

A—14 CFR Part 23.

B—14 CFR Part 21.

C—14 CFR Part 39.

[b] 14 CFR Part 21 entitled “Certification Procedures for Products and Parts” governs the issuance of an Airworthiness Certificate. (AM.I.I.K17) — 14 CFR Part 21

8531-8. Which of the following is an instance when a special flight permit may not be issued?

A—Flying passengers on a scheduled operation.

B—Flying the aircraft to a location where repairs or maintenance can be performed.

C—Flying a customer demonstration flight

[a] A special flight permit may be issued for an aircraft that may not currently meet applicable airworthiness requirements but is capable of safe flight, for the following purposes:

1. Flying the aircraft to a base where repairs, alterations, or maintenance are to be performed, or to a point of storage.

2. Delivering or exporting the aircraft.

3. Production flight testing new production aircraft.

4. Evacuating aircraft from areas of impending danger.

5. Conducting customer demonstration flights in new production aircraft that have satisfactorily completed production flight tests.

6. Operating an aircraft at a weight in excess of its maximum certificated takeoff weight under specific circumstances.

To request a special flight permit, the applicant must submit to the FAA: the purpose of the flight, the proposed itinerary, the crew required to operate the aircraft and its equipment, the ways in which the aircraft does not comply with the applicable airworthiness requirements, any restrictions the FAA deems necessary for the purpose of prescribing operating limitations. Flying passengers on a scheduled operation is not one of the allowed reasons for a special flight permit. (AM.I.I.K17) — 14 CFR §21.179, 21.199

8516. The following is a table of airspeed limits as given in an FAA-issued aircraft specification:

Normal operating speed..................................260 knots

Never-exceed speed .......................................293 knots

Maximum landing gear operation speed......... 174 knots

Maximum flap extended speed ....................... 139 knots

The high end of the white arc on the airspeed instrument would be at

A—260 knots.

B—293 knots.

C—139 knots.

[c] The maximum flap extended speed is marked on an aircraft airspeed indicator by the top of the white arc. The white arc would extend to 139 knots. (AM.I.I.K18) — 14 CFR §23.1545

8502. Placards required on an aircraft are specified in

A—AC 43.13-1B.

B—The Federal Aviation Regulations under which the aircraft was type certificated.

C—Aircraft Specifications or Type Certificate Data Sheets.

[c] Placards that furnish information vital to the safety of flight and that must be installed in a certificated aircraft are specified in the Type Certificate Data Sheets for the aircraft. (AM.I.I.K20) — 14 CFR §43.11(b)

8531-2. How long does the holder of a certificate issued under Part 65 have to notify the FAA after any change in permanent mailing address?

A—30 days.

B—120 days.

C—90 days.

[a] 14 CFR §65.21 states that within 30 days after any change in their permanent mailing address, the holder of a certificate issued under this part shall notify the Department of Transportation, Federal Aviation Administration, Airman Certification Branch, Post Office Box 25082, Oklahoma City, OK 73125 in writing, of their new address. (AM.I.I.K23) — 14 CFR §65.21