PPFA 13- Good manufacturing practice and documentation

1/23

Earn XP

Description and Tags

explain both large- scale and small scale manufacturing approaches , identify reliabke sources for product formulations and apply core principles of good manufacturing practice

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

24 Terms

What do you need to know to understand pharmaceutics ?

To achieve this, one needs knowledge of:

• Fundamental physical chemistry

• Human body systems and drug kinetics

• Formulation science and product design

• Both small- and large-scale manufacturing processes

• Methods to prevent and control microbial contamination

pharmaceutics- transforms an active drug into a usable medicine

What is the PQS and what do they do ?

Pharmaceutical Quality System (PQS) ensures medicines are consistently made to required quality standards:

Responsibility led by senior management; commitment from all

staff essential.

Integrates GMP principles and Quality Risk Management (QRM).

Emphasizes thorough design, documentation, monitoring, and.

continuous improvement.

Applies across all stages: from development and tech transfer to full -scale commercial production

What are the GMP s for medicinal products ?

Processes must be clearly defined and validated

Requires qualified staff, proper facilities, and suitable equipment

All steps documented with clear procedures and records

Deviations must be investigated and addressed through Corrective and Preventive Actions (CAPA)

What is the GMP quality control ?

Quality Control

• No product released without thorough testing

• Detailed records of tests and release decisions kept

• Samples retained for future checks

What is GMP risk management ?

Product Quality Review

• Annual reviews assess process consistency and trends

• Supports ongoing improvements and revalidation

What is GMPs Quality risk management ?

Quality Risk Management

• Risk assessments based on scientific evidence and patient safety.

• Level of formality and documentation depends on risk severity.

What are the types of GMP documentations ?

Specifications for materials- is it amorphous or crystalline (starting, packaging, intermediates, finished products).

Manufacturing formulae and processing instructions.

Packaging instructions.

Batch processing and packaging records.- for the safety of the patient - no variations between batches

Standard operating procedures (SOPs) for receipt, sampling, testing, etc.

Why are documentation principles importance and what are some good key features ?

Documentation Principles are critical for demonstrating GMP compliance and traceability.

key features :

Documents must be accurate, clear, and available at points of use.

• Corrections should not obscure original entries.

• Records retained for a defined period (usually at least 1 year after expiry).

What are the 2 type of scale considerations ?

large scale manufacturing

small scale manufacturing

Describe large scale manufacturing

Large scale focuses on mass production - products are not tailored to individual patients needs

Focuses :

precise , standardized processes

use rigorous quality control , testing procedures

uses large- scale , specialized equipment

includes both sterile and non-sterile production settings

uses packaging to maintain stability

products licensed and approved

Describe small - scale manufacturing ?

small - scale manufacturing- to meet specialized needs like early-stage clinical trials, personalized medicine, or niche markets

In pharmacy - extemporaneous dispensing

•Community settings

•Hospital settings

•Specials manufacturing

Generally , less expensive - used only when no alternative exists

reasons for use:

•No licensed product available

•Product has been discontinued

•A specific individual dose is needed

•A tailored formulation is required

•For veterinary use

What is specials small scale manufacturing ?

Specials manufacturing

• Custom-made medicines

• Typically used for toxic or complex formulations

• Involves high costs for each individual prescription

The NHS is working to lower the expenses

associated with specials manufacturing

Large vs small scale GMP ( summary )

Large vs Small Scale

GMP principles are the same regardless of scale.

Large scale: higher complexity, more automation, larger volume of documentation, more formalized controls.

Small scale: systems may be simpler but must still ensure equivalent product quality.

Documentation

• Fundamental for compliance and audit readiness.

• Covers specifications, SOPs, batch records, quality control data, CAPA records.

• Good Documentation Practices (GDP) essential for both scales.

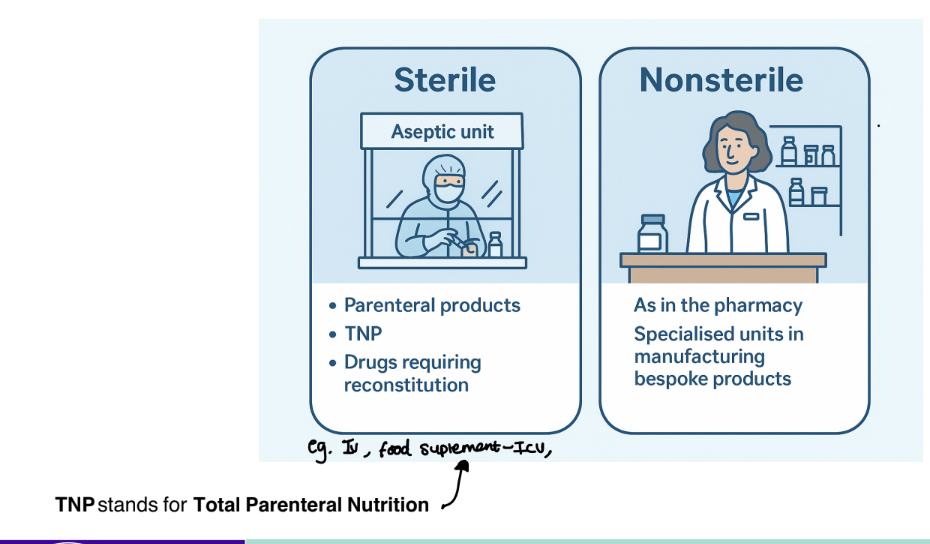

what are the 2 types of hospital extemporaneous dispensing ?

sterile

non sterile

What is the risk assessment GPhC ?

Use a formula from an authoritative source, such as an official pharmacopoeia

Verify the preparation method (for example, using the pharmacopoeia method)

Double-check all calculations

Ensure the use of appropriate specialist equipment

Assess and minimize the risk of contamination

Implement strict hygiene measures

Confirm the quality and safety of ingredients and starting materials

Ensure the premises are suitable for preparation

Verify that staff have the necessary skills, training, and competence

Define the situations that would require a new risk assessment

How do you make sure to have quality control ?

equipment is suitable and functional

formula and dose are accurate and safe

raw materials are properly sourced

calculations are correct

records are complete

labelling is correct

staff are well trained

What are the requirements for record keeping ?

Legal requirement:

• Must be kept for a min of 2 years (5 years)

• The pharmacist is responsible and so must ensure

accuracy of final product

• Name + signatures of staff involved in the production

What do records include ?

Formula + source

• Calculations - checked!

• Ingredients - checked!

• manufacturer, quantities, batch number and expiry

• Names and signatures of all people involved in the preparation of the product

• Date prepared

• Expiry date + BN

• Date supplied

• Pt details

• Drs details

• Label

What are key techniques from GPhC ?

Combining liquids: Mix thoroughly by careful stirring or shaking to ensure even distribution.

Dissolving solids in liquids: Reduce particle size (e.g., by grinding or sieving) to improve solubility and accuracy.

Blending solids:

Use a pestle and mortar to achieve uniform mixing.

For equal small amounts, simple mixing is appropriate.

For unequal quantities, adopt the geometric dilution method to ensure even blending.

Mixing semi-solids (e.g., creams and ointments):

Use a smooth, clean surface (e.g., ceramic tile).

Add ingredients incrementally to achieve a homogeneous final product.

How is stability checked over time ?

Appearance: no visual changes

Chemistry: ingredients stay the same

Microbiology: remains sterile or has acceptable microbial levels

Effectiveness: therapeutic action unchanged

Safety: no new toxic effects

What is the expiry date guidance ?

The date after which the product must not be used.

Large-scale manufacture: expiry set using accelerated stability testing.

Extemporaneous dispensing: expiry guided by official monograph.

If no standard available, use a cautious approach:

Stable products (solids for internal or external use): up to 3 months.

Less stable products (liquids or semi-solids for internal or external use): up to 4 weeks; considered "recently prepared."

Some liquids: up to 2 weeks; considered "freshly prepared."

What are the use of preservatives ?

Purpose:

To prevent bacterial growth, especially in aqueous (water-based) liquid preparations.

What are commonly used preservatives 🇦:

chloroform spirit , water - these are available at single strength , double strength

According to GPhC guidance, pharmacists must ensure correct preservative concentrations, validate preparation methods, and document calculations to protect patient safety and product stability.

What are common packaging used for extemporaneous preparations ?

Packaging must protect quality, safety, and

stability:

Amber glass bottles

Dropper bottles

Jars (plain or amber)

Cartons

Summary

GMP Principles essential to understand before making any medicine.

All types of manufacturing require strict good practice.

Detailed records must be kept for extemporaneous preparations.

Product stability determines its expiry date.