MAE 3324 Final Exam

1/70

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

71 Terms

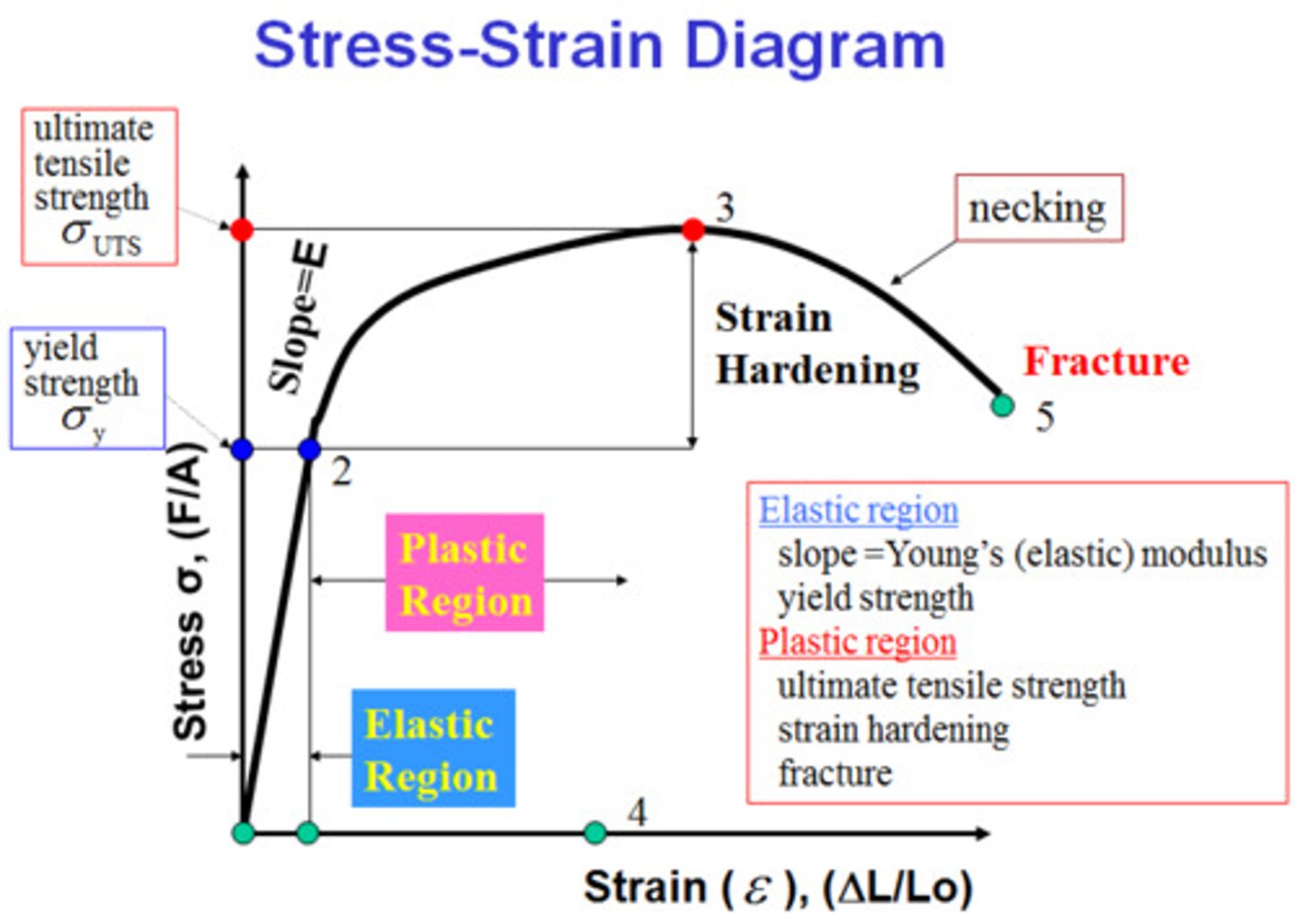

Tensile vs Yield Strength

Tensile is the maximum stress a material can withstand while being stretched before breaking; Yield is the stress at which a material begins to deform plastically

Hardness

The resistance of a material to localized plastic deformation, such as indentation or scratching (Rockwell Test)

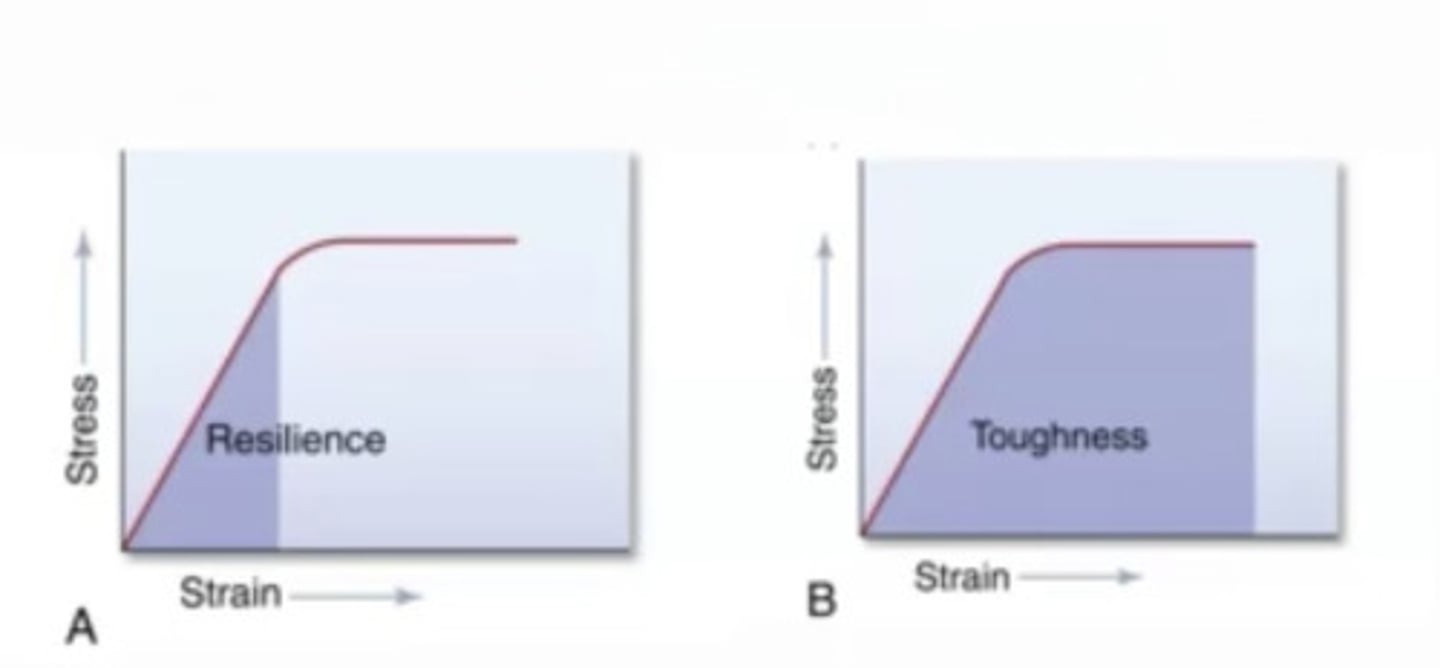

Toughness

The ability of a material to absorb energy and deform plastically without fracturing

Stress-Strain Curve

A graph showing the relationship between the applied stress and the resulting strain, Elastic Modulus, Yield Strength, and ultimate tensile strength

Elastic Modulus

The ratio of stress to strain in the elastic region, representing stiffness

Engineering vs True Stress

True stress considers the changing cross-sectional area while engineering just considers the original

Strengthening

The process of improving the mechanical properties of a material, alloying, work hardening, or heat treatment

Cold Work (Strain Hardening)

A metalworking process where the material is plastically deformed at or near room temperature, increasing its strength and hardness

Grain Size Reduction

A method of strengthening a material by decreasing the size of its grains, smaller grains act as barriers to dislocation movement

Solute Strengthening

Adding alloying elements to form solid solutions, disrupting the regular lattice structure making it more difficult for dislocations to move

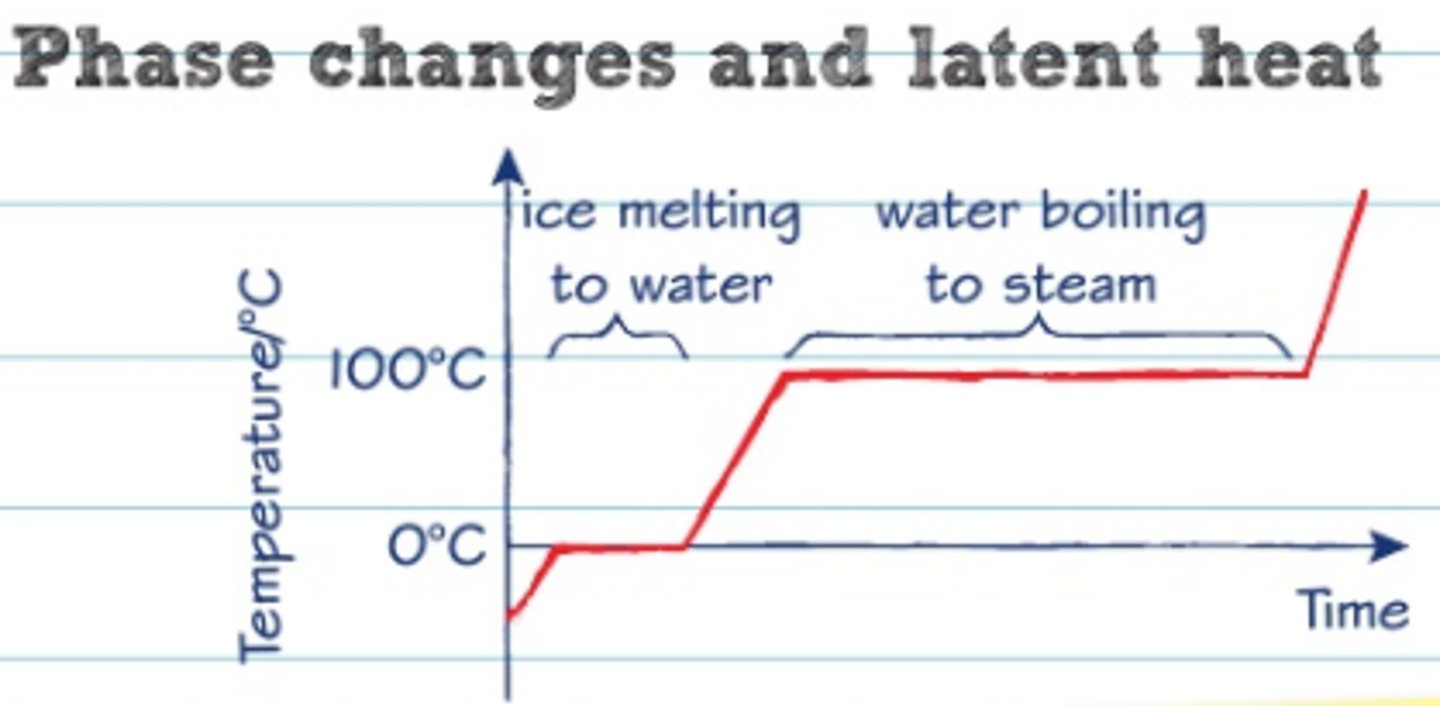

Phase Transformations

Changes in the microstructure of a material that alter its properties (Ex: Austenite to Martensite)

Precipitation

The formation of finely dispersed particles (precipitates) within a metal matrix from a supersaturated solid solution, which can enhance the material's strength and hardness by impeding dislocation movement

mepbp

Methane CH4

Ethane C2H6

Propane C3H8

Butane C4H10

Pentane C5H12

ECFPS

Polyethylene (PE C2H4)

Poly(Vinyl Chloride) (PVC C2H3Cl)

Polytetrafluoroethlyne (PTFE C2F4)

Polypropylene (PP C2H3(CH3))

Polystyrene (PS C2H3(C6H3))

Creep

Time-dependent deformation of a material under a constant load

Glass transistion

The reversible change in a material from a hard, glass state to a soft rubbery state as it is heated

Fiber in Martix

Fibers strengthen a matrix by transferring load to themselves through their high tensile strength

3 Steps in Precipitation

1. Solution Treatment (Heating to dissolve alloying elements into a solid solution)

2. Quenching (Rapid Cooling to retain solute atoms in the matrix)

3. Aging (Formation of fine precipitates to strengthen the material

Dislocation Hardening

Dislocations move through the material under stress; strengthening occurs by impeding the movement of these dislocations (Grain Size Reduction, Work Hardening, Solution Strengthening, Precipitation Hardening)

Overaging

The fine precipitates coarsen and become less effective at obstructing dislocations because the size increases, reducing the strength imparted to the material

Fatigue Limit (Endurance Limit)

The maximum stress level a material can endure for an infinite number of cycles without experiencing fatigue failure

Fatigue Strength

The maximum strength a material can handle for a specified number of cycles before it fails

Atomic Packing Factor

APF = Volume of atoms in the unit cell/Volume of the Unit Cell

Coordination Number

The number of nearest neighboring atoms surrounding a particular atom in a crystal structure

Improving Fatigue Life

1. reducing magnitude of mean stress

2. surface treatments

3. design changes

Isomerism

2 Compounds with the same chemical formula, different physical structure (must break bonds to make them look the same)

Fatigue

Cracks that grow in the cyclic range

Grain Boundaries

Boundaries between like crystals, produced by solidification process

When will a crack propagate

When the energy stored in material as strain E exceeds that needed to create new fracture surfaces

Recrystallization

Eliminates defective grains

Grain Growth

After recrystallization is complete, the strain-free grains will continue to grow if the metal specimen is left at the elevated temperature

Driving force for Recrystallization

Reduction in strain energy

Hardenability

How easy is it for a material to form martensite

Two types of linear defects

Edge and Screw Dislocations

Two thermal properties of a liquid at medium that influence its quenching effectiveness

Thermal Conductivity & Heat Capacity

4 Measures that may be taken to increase the fatigue resistance of a metal alloy

1. Polish the surface to remove stress amplification sites

2. Reduce the number of internal defects by means of altering processing and fabrication techniques

3. Modify the design to eliminate notches and sudden contour changes

4. Harden the outer surface of the structure by case hardening or shot peening

Case Hardening

A treatment process used to harden the outer surface (Case) of a metal while keeping the inner core softer and more ductile

Shot Peening

A mechanical surface treatment process used to improve the fatigue life and mechanical properties of a material by inducing compressive residual stresses on its surface

Isomer

Compounds with the same formula but different structures.

Thermoplastic

Softens at higher temperatures, loosens the secondary bonds, allowing for the chains to slide past each other, linear or branched Molecular structure

Thermoset

Harden with temperature increase, chemical decomposition at extreme temperatures. Cross-linked or Networked Molecular structure

Crystallinity Polymers

Ordered atomic arrangements involving molecular chains, crystal structures in terms of unit cells

Copolymers

Two or more monomers polymerized together

Isotactic

R groups on same side of chain

Synodiotactic

R groups alternate sides

How does the Youngs modulus change after being cold worked

No change

Why are small-angle grain boundaries not as effective in interfering with the slip process as are high-angle grain boundaries

Low-misorientation boundaries with low energy and less disruption to atomic alignment, making them less effective at impeding dislocation motion compared to high-angle grain boundaries

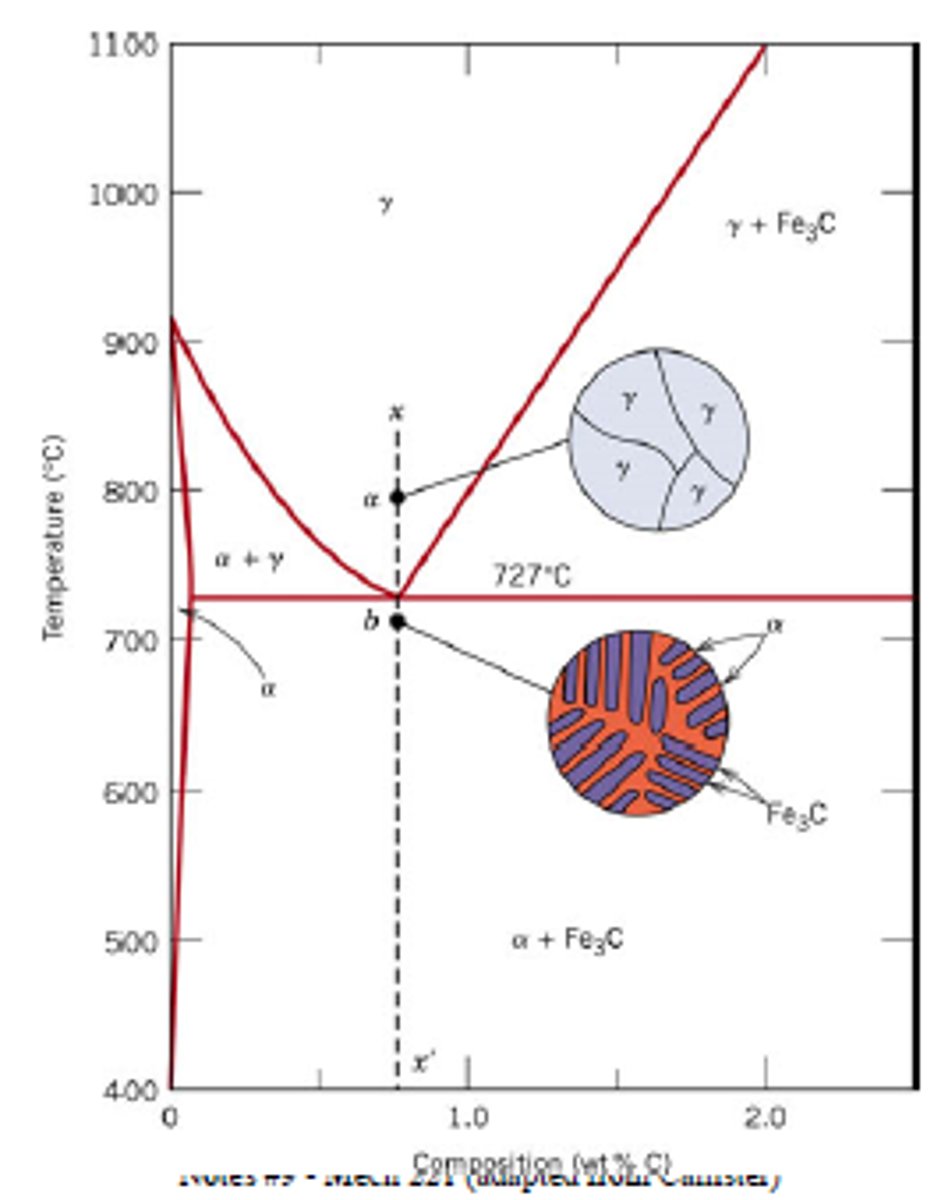

Considering coarse pearlite, as C concentration increases why does ductility decrease?

Because we are loosing our ductile phase, Ferrite

When is there a driving force for nucleation

When below the melting temperature

When is surface free energy positive

Always

When is Gibbs Free Energy (ΔGv) negative?

When phase transformation is thermodynamically favorable (i.e Solidifcation)

Lattice Parameters

The dimensions and angles that define a unit cell in a crystal lattice, including lengths (a, b, c) and angles (α, β, γ), for BCC FCC etc calculate the lattice parameters (a) length using r, ex: for BCC a=4r/(3^.5)

Diffusion

The movement of atoms or molecules from high to low concentration due to thermal energy, driving material mixing over time

Steady State

A condition where the properties of a system remain consistent over time despite ongoing processes

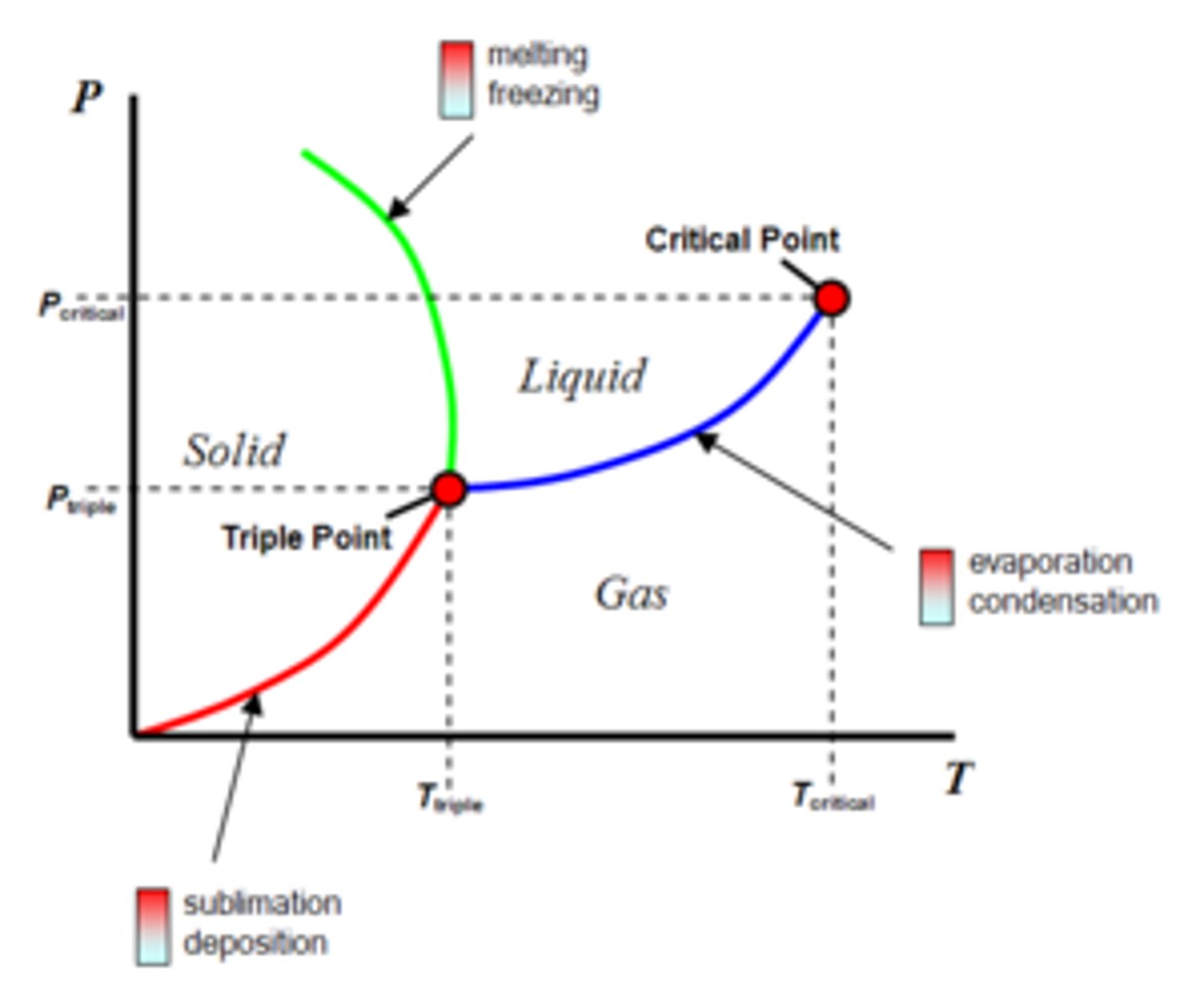

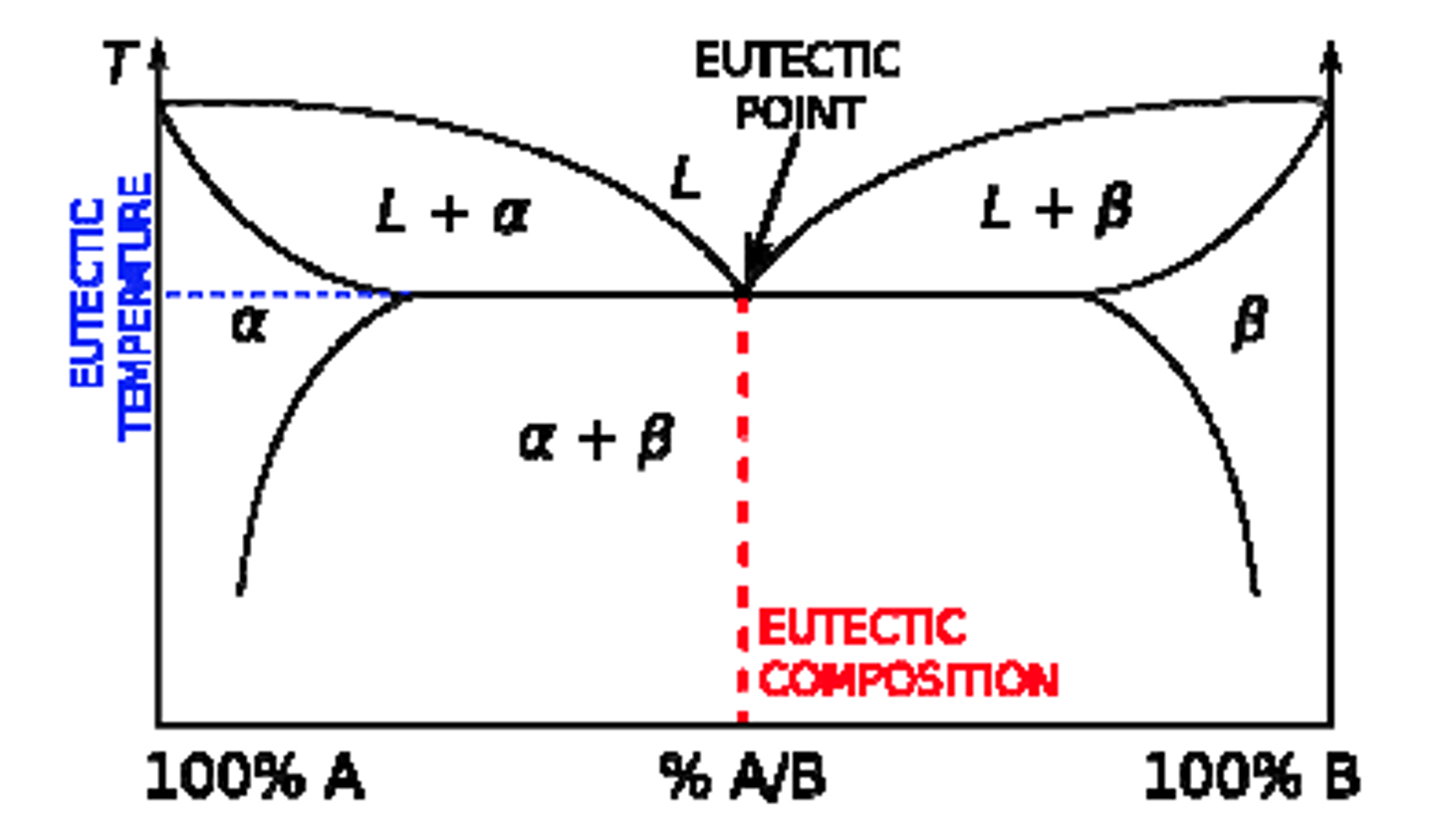

Phase Diagram

A chart showing the stable phases of a material under different temperature and composition conditions

Eutectic

A specific composition in an alloy system where the lowest melting point occurs, forming two distinct solid phases simultaneously upon cooling

Eutectoid

A phase transformation where a single solid phase transforms into two different solid phases at a specific temperature and composition

Time-Temperature Phase Diagram

Shows how temperature and time affect phase transformations in materials, indicating phase stability and transformation rates

Iron Carbon Phase Diagram

Shows the phases and microstructures of iron-carbon alloys as a function of carbon content and temperature (ferrite, austenite, cementite)

Microconsituents

Distinct phases or structures in a material's microstructure (pearlite, bainite) that influence its mechanical properties

Microstructure

The arrangement of differnet phases, grains, and micro constituents within a material

Mechanical Properties

Various types of Mechanical forces, ductility, hardness, strength, & toughness

Ductility

The ability of a material to undergo significant plastic deformation before fracture, calculated using Area Reduction or Elongation %

Interchange

When atoms diffuse by swapping positions with their neighboring atoms, involves atomic movement that overcomes the energy barriers

Vacancy

When atoms diffuse into nearby vacant lattice sites

Intersticial

When small atoms (like hydrogen or carbon) diffuse through the interstitial spaces (gaps) between larger atoms in crystal lattice

Slip System

A crystallographic plane, with a direction along which dislocation motion (slip) occurs

Do all metals have the same slip system?

No, different metals have distinct slip systems depending on their crystal structure, affecting their ductility and mechanical properties

Recovery vs Recrystallization Process

Recovery relieves some internal strain energy by dislocation motion but virtually no change in grain structure or mechanical characteristics, Recrystallization forms a new set of strain-free grains

Driving force for recrystallization

∆Gv, change in internal energy

Driving force for grain growth

Reduction in grain boundary energy as the total grain boundary area decreases