Materials Elastomeric Impression

1/105

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

106 Terms

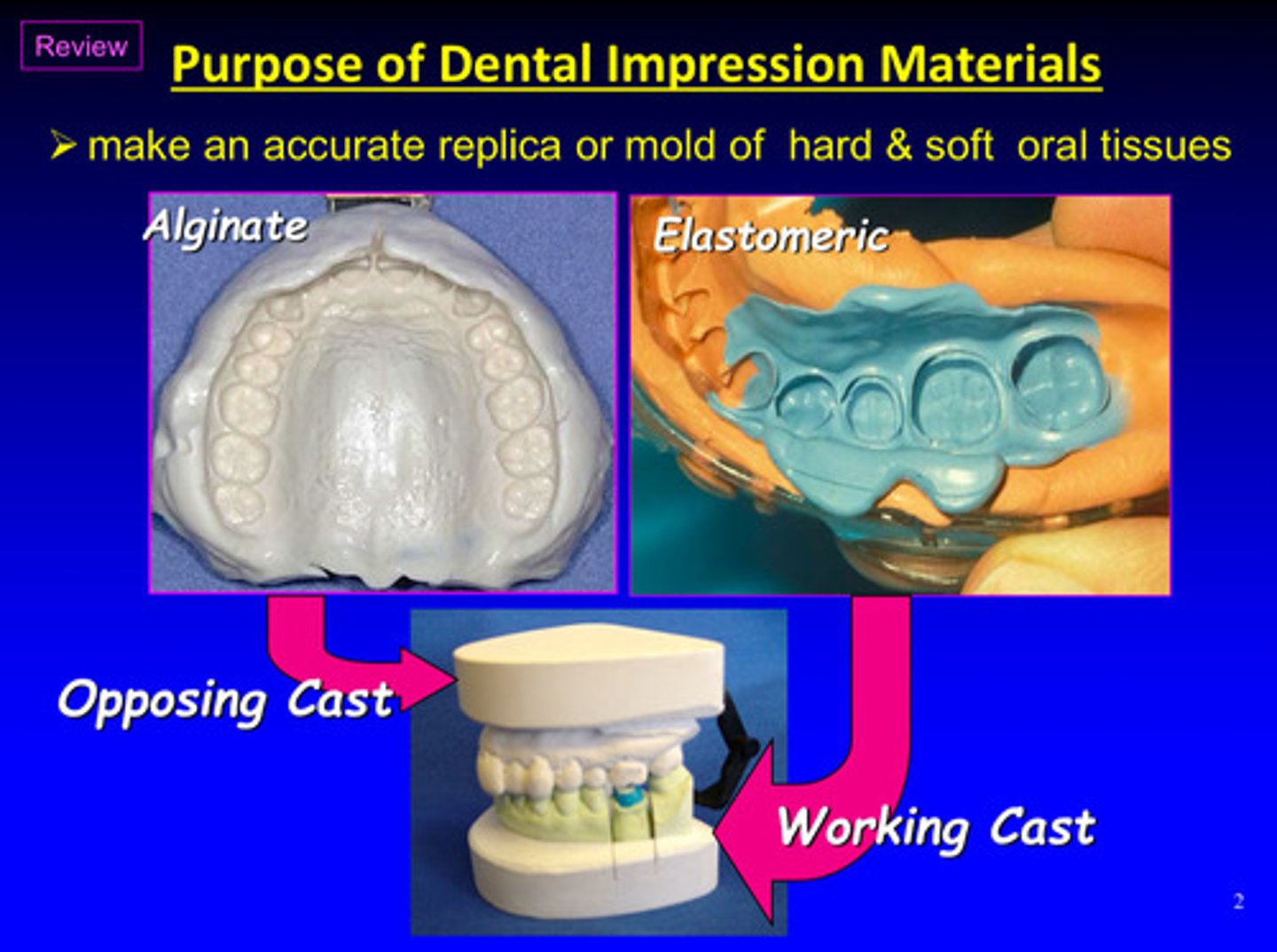

what is the purpose of dental impression materials

to make an accurate replica or mold of hard & soft oral tissues

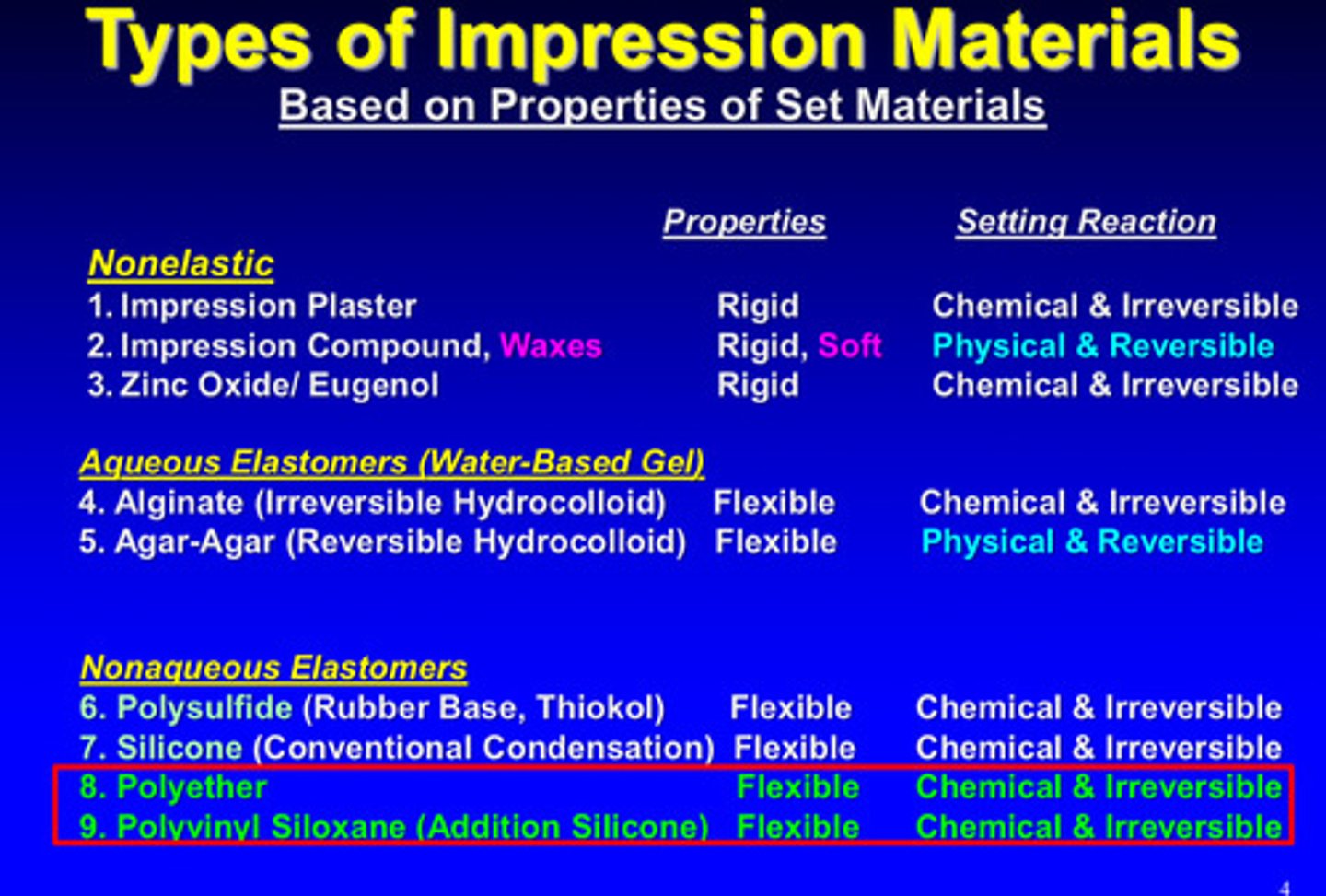

what are the 4 nonaqueous elastomers

1) polysulfide

2) silicone

3) polyether

4) polyvinyl siloxane (addition silicone)

what are the properties of polyether and polyvinyl siloxane (rigid or flexible)

flexible

what is the setting reaction of polyether and polyvinyl siloxane

chemical and irreversible

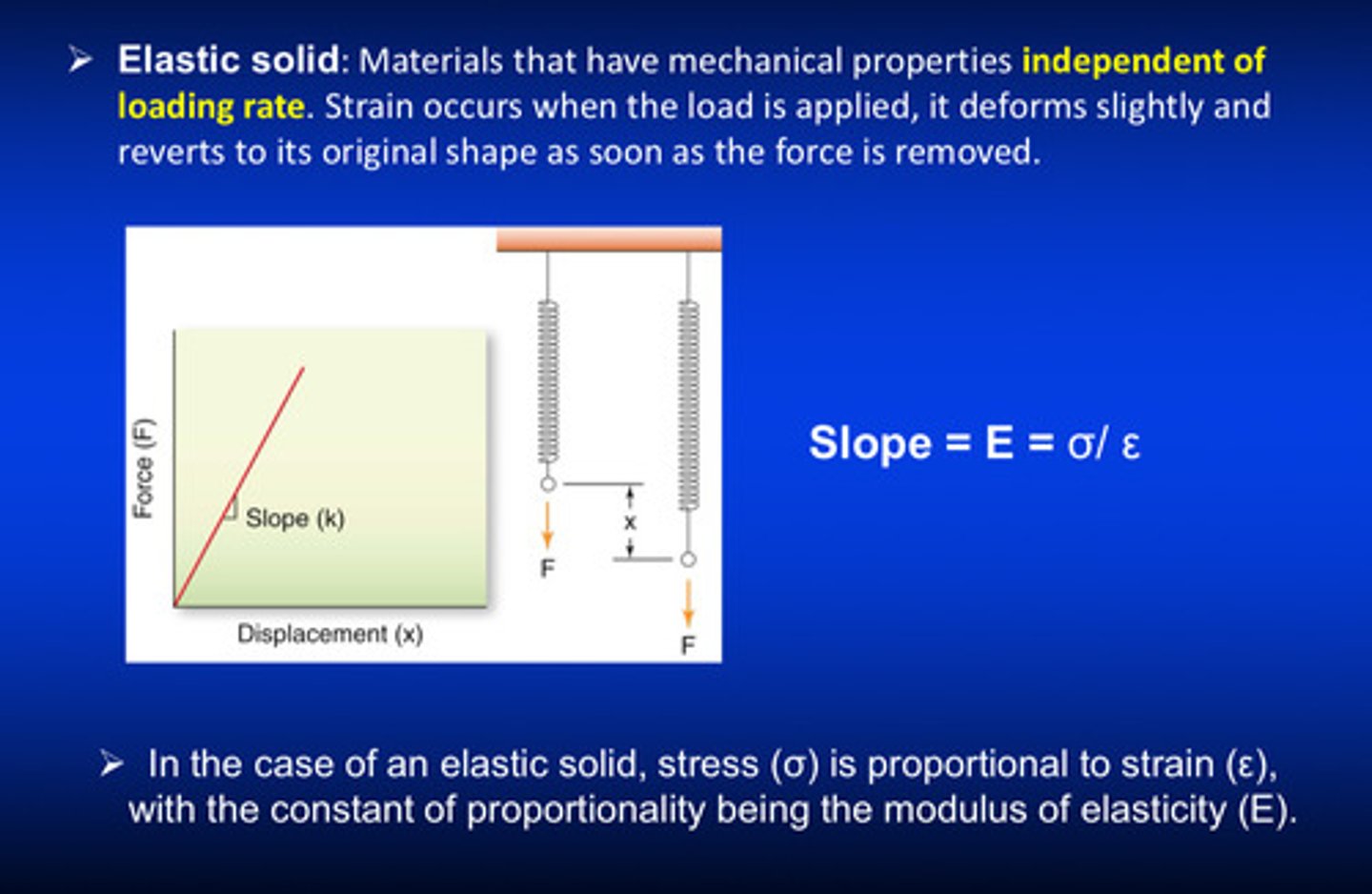

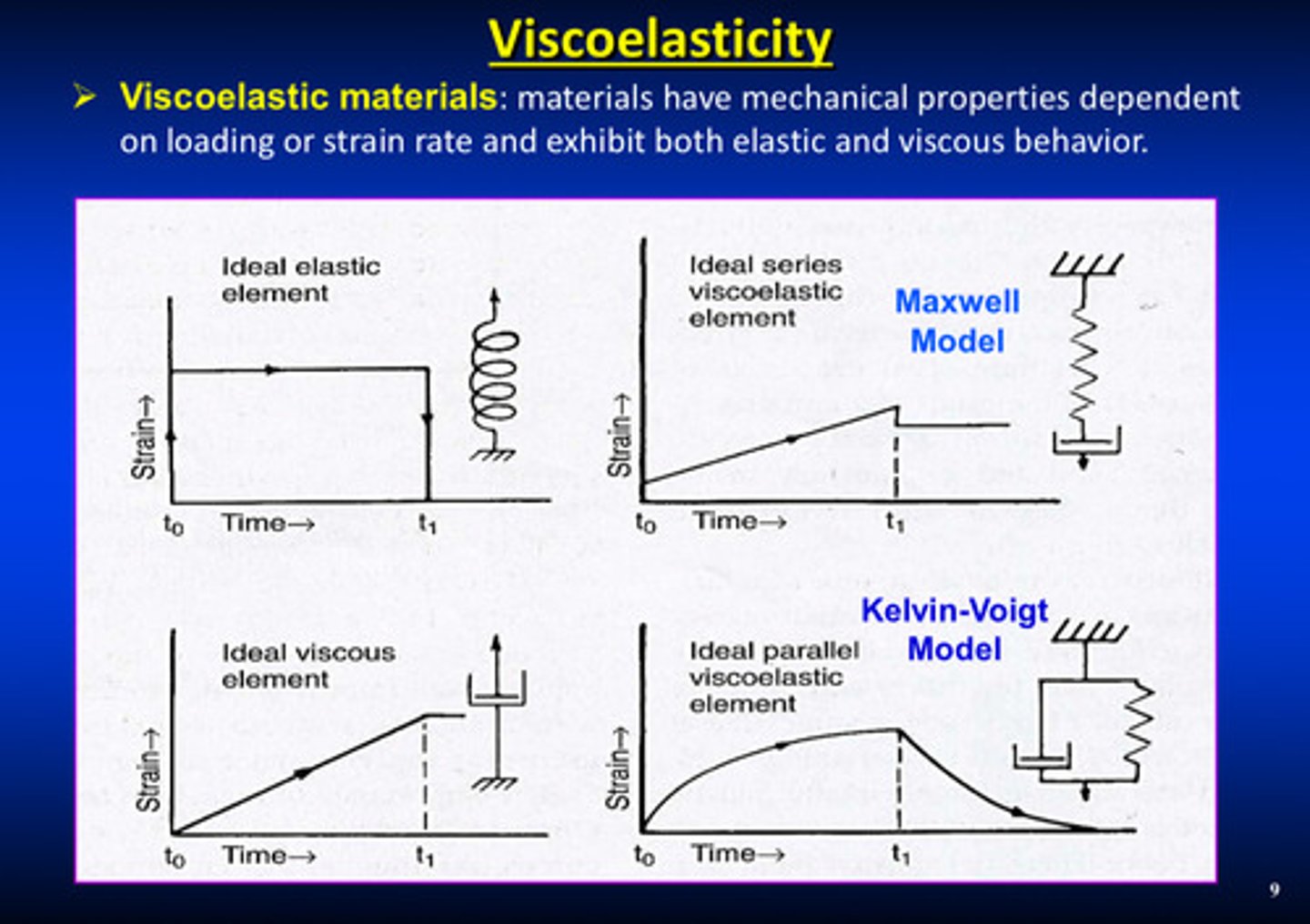

what is an elastic solid

materials that have mechanical properties independent of loading rate

strain occurs when the load is applied, but an elastic solid will deform slightly and…

revert to its original shape as soon as the force is removed

in the case of an elastic solid, stress is proportional to…

strain (constant of proportionality is the modulus of elasticity)

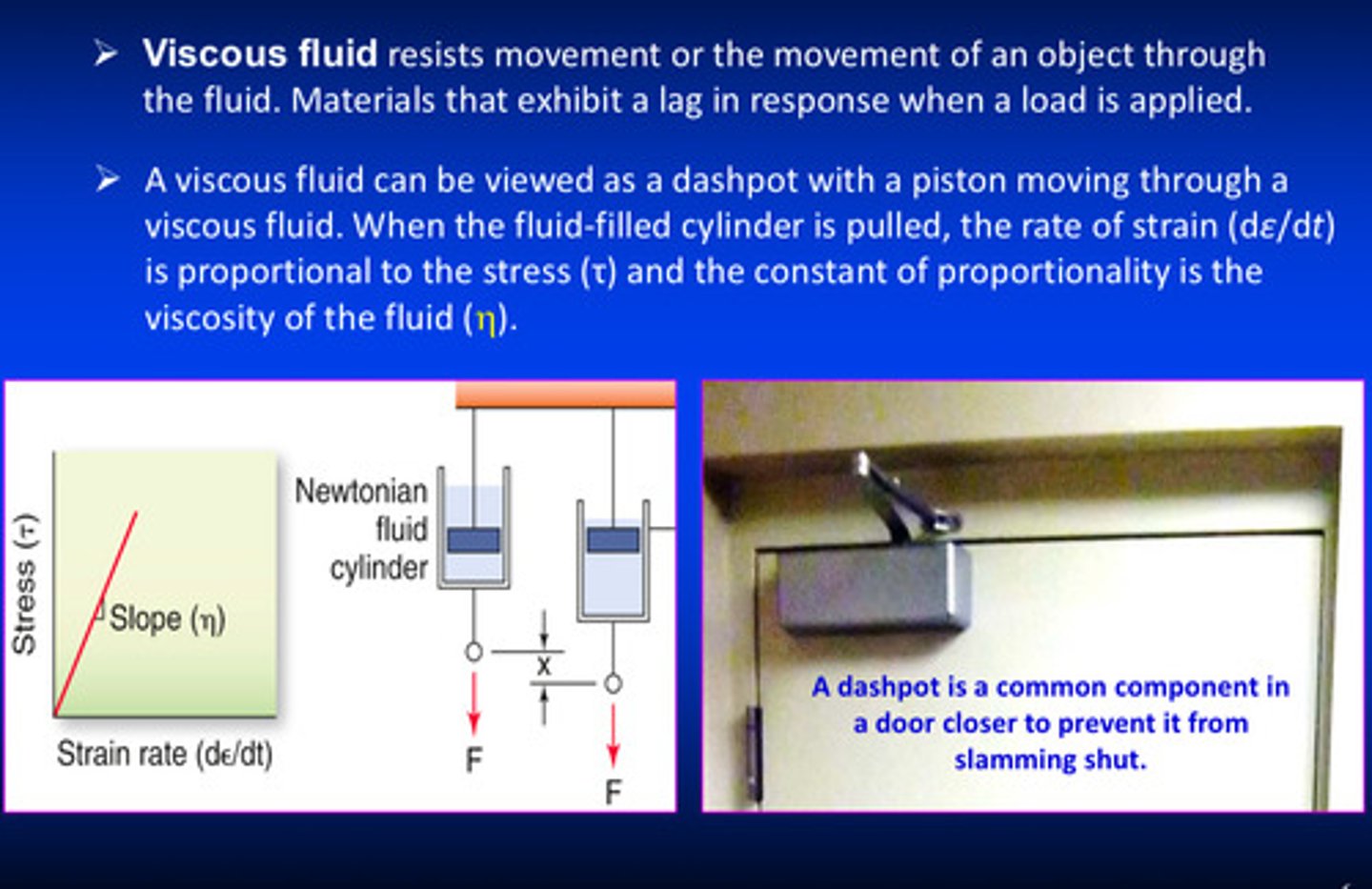

viscous fluid resists what

movement of an object through the fluid

viscous fluid are materials that exhibit a _____ in response when a load is applied

lag

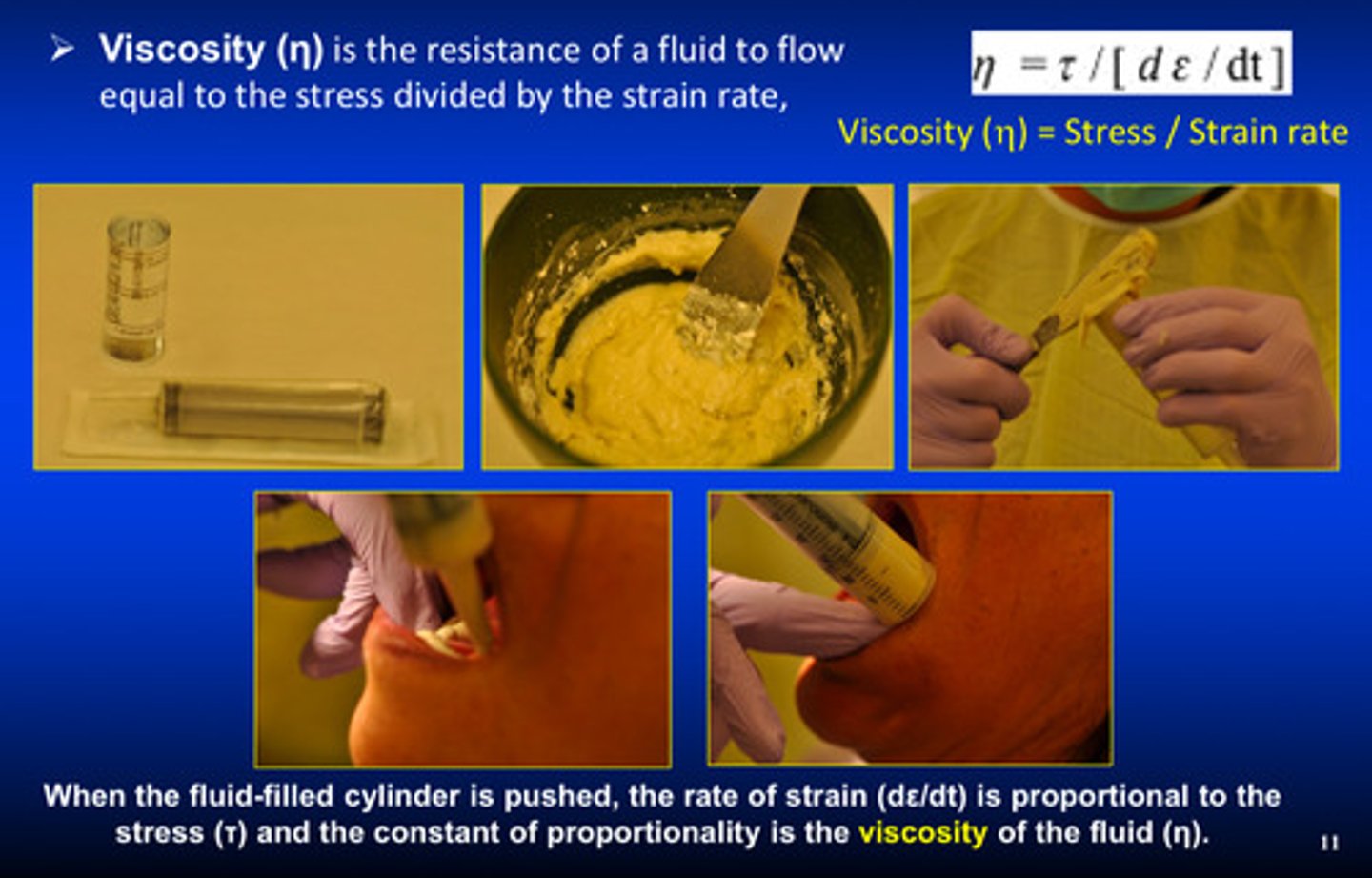

a viscous fluid can be viewed as a dash pot with a piston moving through a viscous fluid; when the fluid-filled cylinder is pulled, the rate of strain is proportional to the _______ and the constant of proportionality is the __________ of the fluid

stress; viscosity

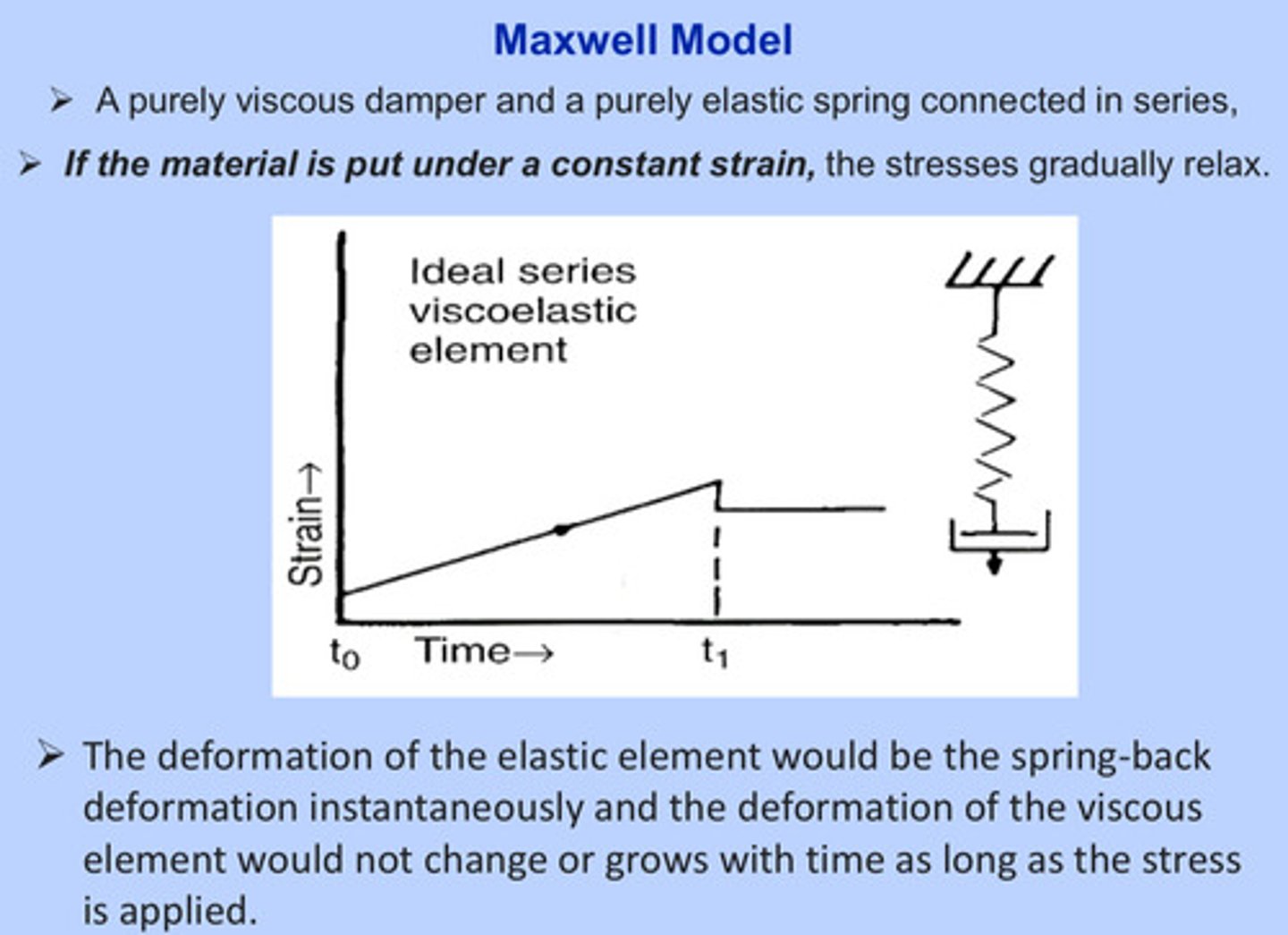

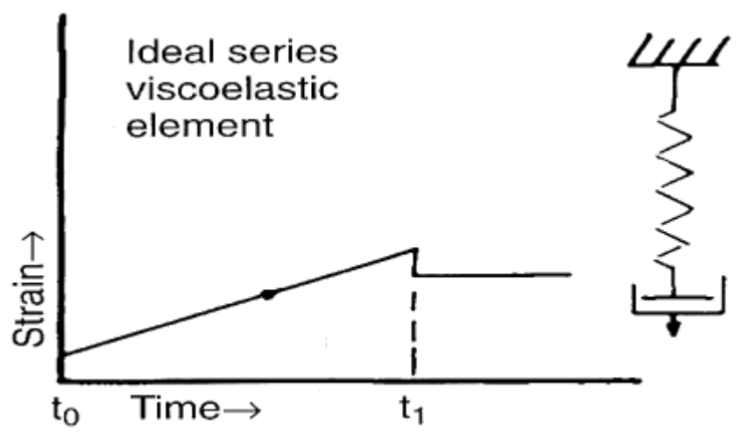

what is the maxwell model

a purely viscous damper (dash pot) and a purely elastic spring connect in series

in the maxwell model, if the material is put under a constant strain, what happens to the stresses

the stresses gradually relax

the deformation of the elastic element in the maxwell model would be the the spring-back deformation that occurs instantaneously, but the deformation of the viscous element would ____ ________/_____ with time as long as the stress is applied

not change/grow

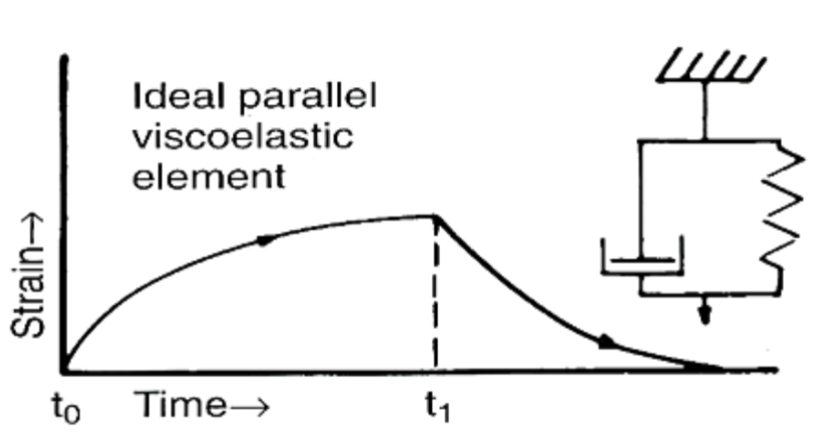

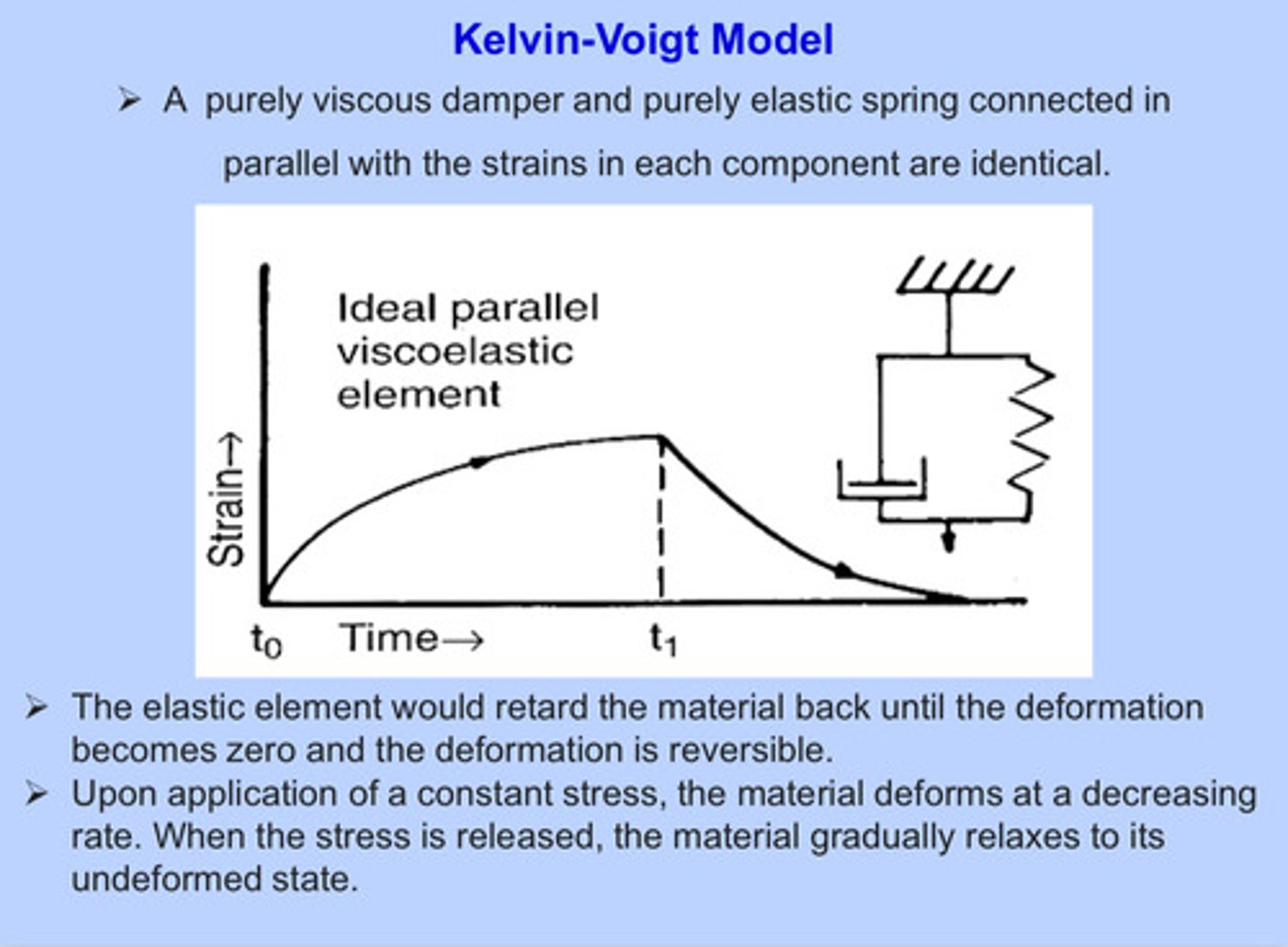

what is the kelvin-voigt model

a purely viscous damper (dash pot) and purely elastic spring connected in parallel with the strains in each component being identical

the elastic element in the kelvin-voigt model would ______ the material back until the deformation becomes zero and the deformation is reversible

retard

which model is this

maxwell model

which model is this

kevin-voigt model

upon application of a constant stress in the kelvin-voigt model, the material deforms at a ____________ rate; when the stress is released, the material gradually relaxes to its ______________ state

decreasing; undeformed

what are viscoelastic materials

materials that have mechanical properties dependent on loading or strain rate and exhibit both elastic and viscous behavior

viscoelasticity is a ___________ rearrangement

molecular

materials that have properties dependent on the strain rate are better characterized by what

by relating stress or strain as a function of time

what is stress relaxation

the reduction in stress in a material subjected to constant strain

what is creep

the increase in strain in a material under constant stress

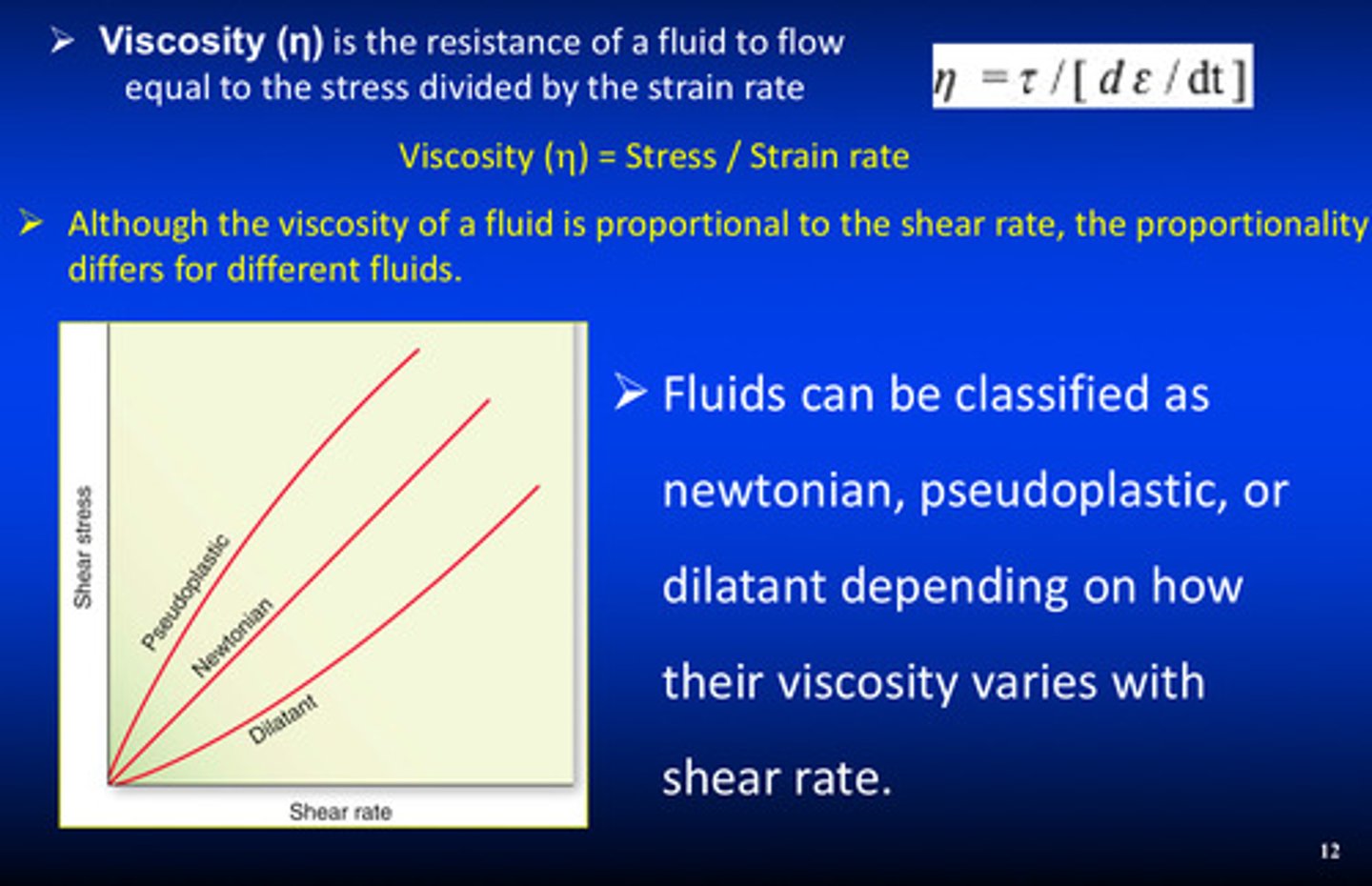

what is viscosity defined as

the resistance of a fluid to flow equal to the stress divided by the strain rate (viscosity = stress / strain rate)

although the viscosity of a fluid is proportional to the _______ _______, the proportionality differs for different fluids

shear rate

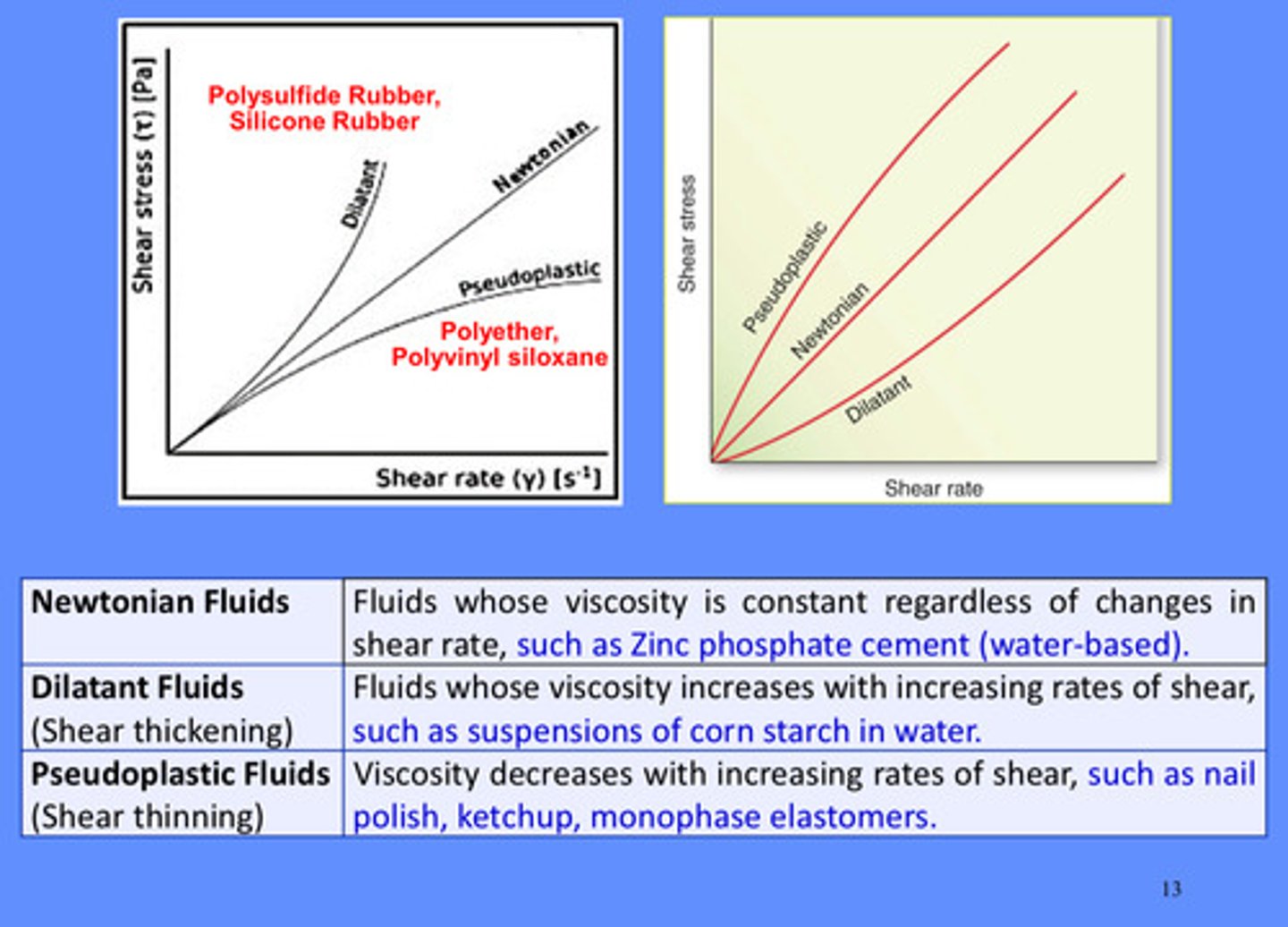

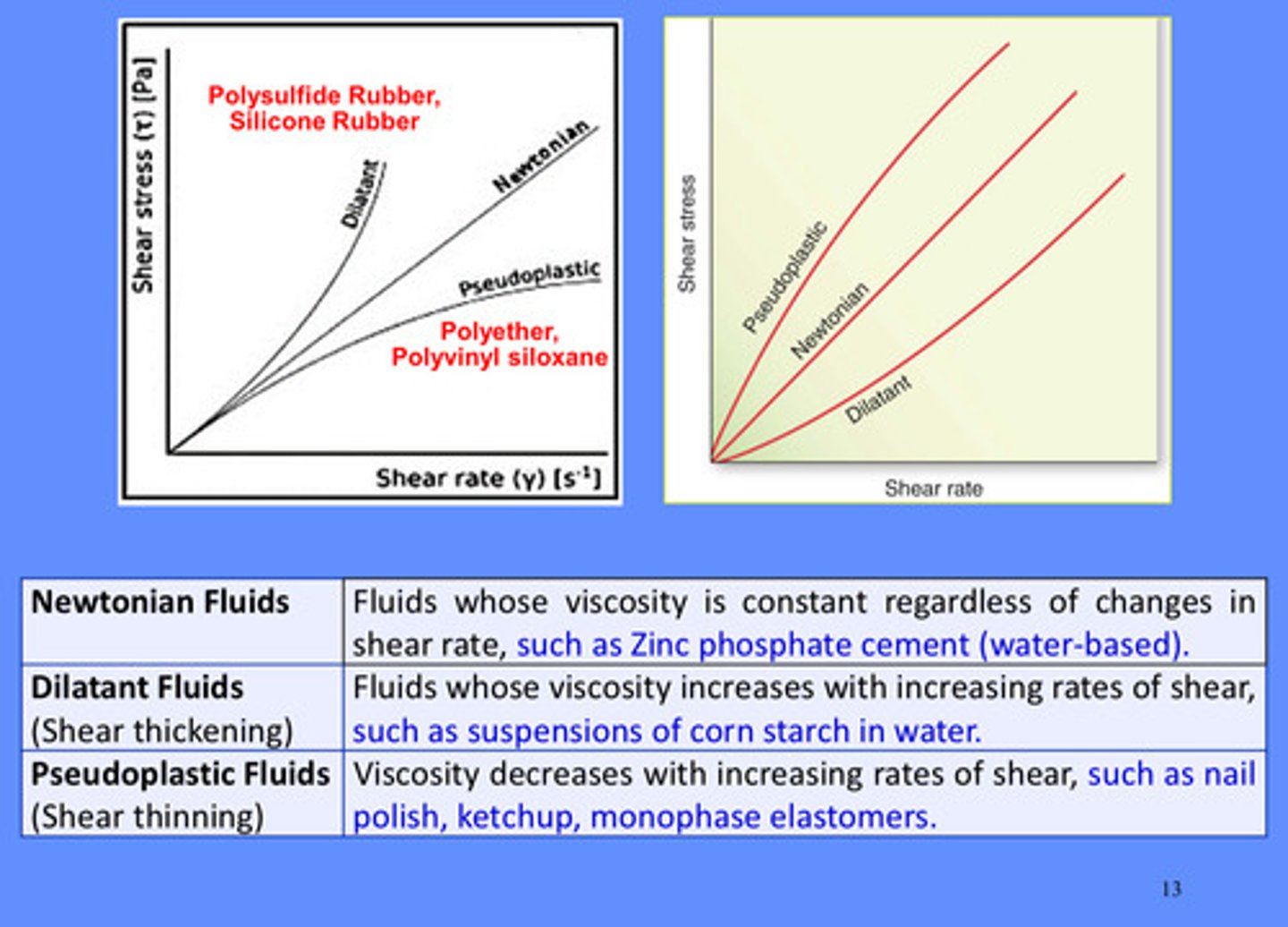

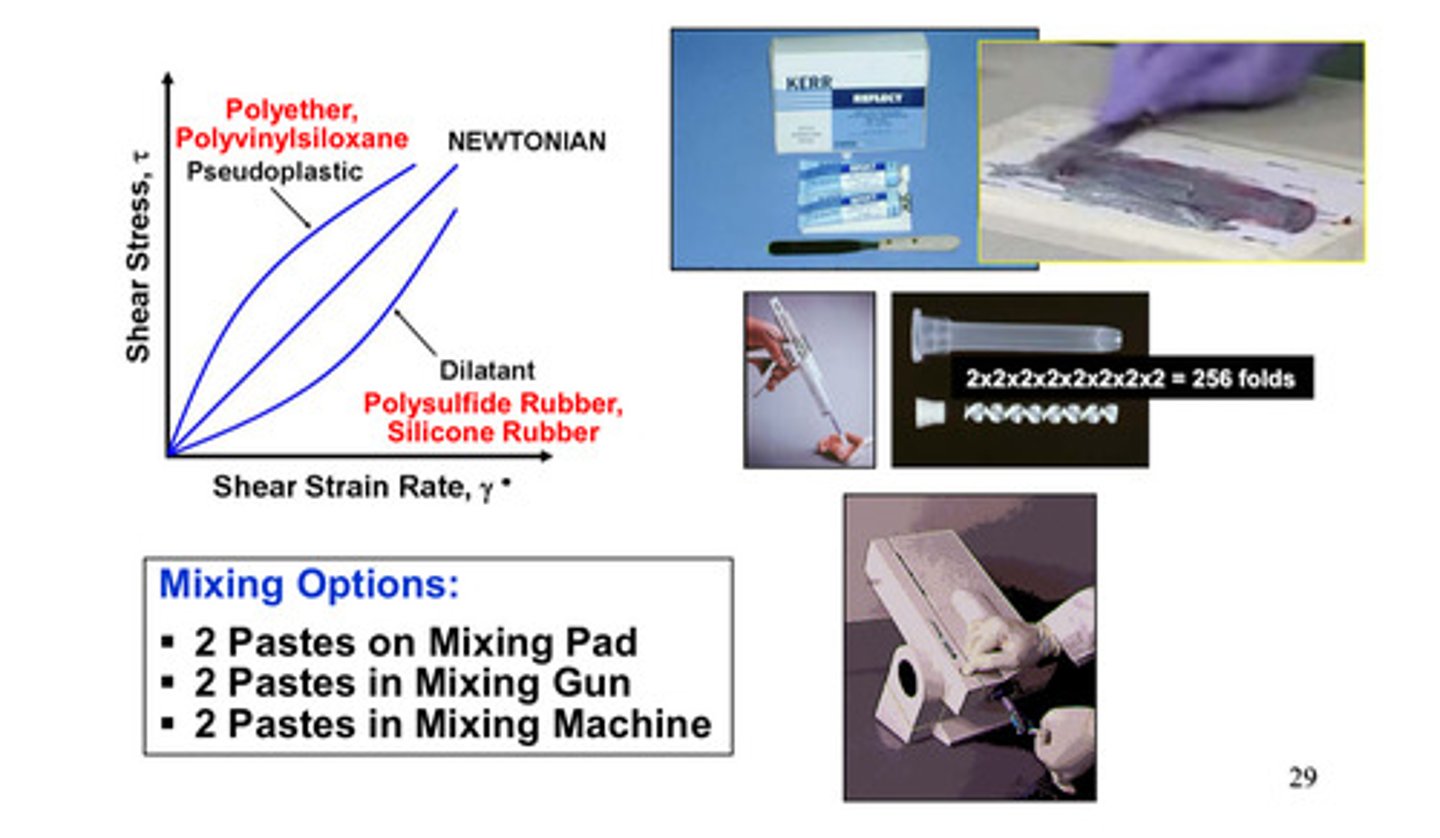

fluids can be classified as what 3 categories depending on how their viscosity varies with shear rate

1) newtonian

2) pseudoplastic

3) dilatant

newtonian fluids: fluids whose viscosity is ________ regardless of changes in shear rate, such as…

constant; zinc phosphate cement (water-based)

_________ / ___________ = viscosity

stress/strain

Newtonian fluids; fluids whose viscosity is _________ regardless of changes in shear rate, such as…

constant; zinc phosphate cement

dilatant fluids: fluids whose viscosity _______ with _________ rates of shear, such as suspensions of corn starch in water

inc; increasing

pseudoplastic fluids: fluids whose viscosity ________ with ___________ rates of shear, such as nail polish, ketchup, monophase elastomers

dec; inc

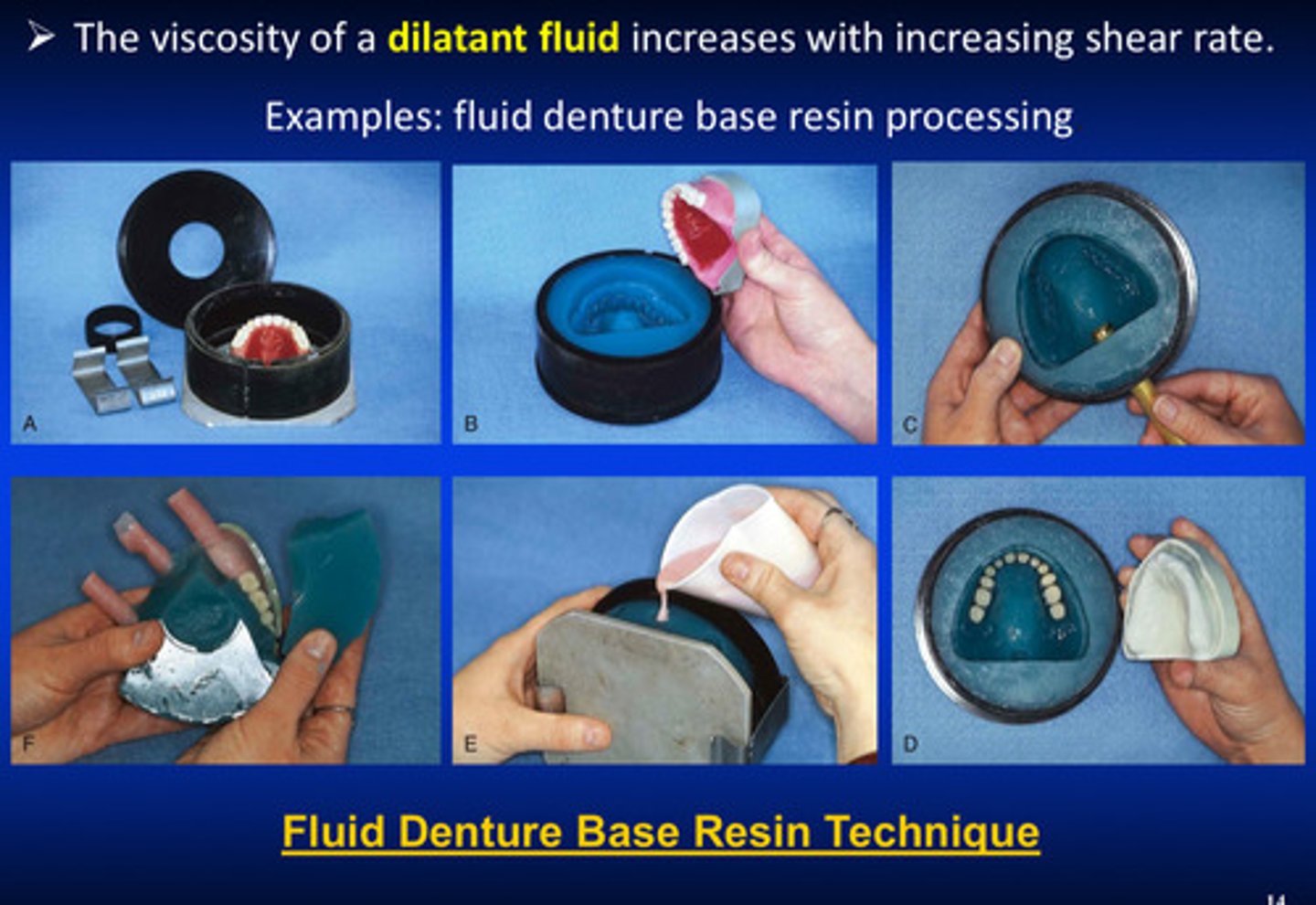

the viscosity of a dilatant fluid increases with what

inc w shear rate (ex: fluid denture base resin processing)

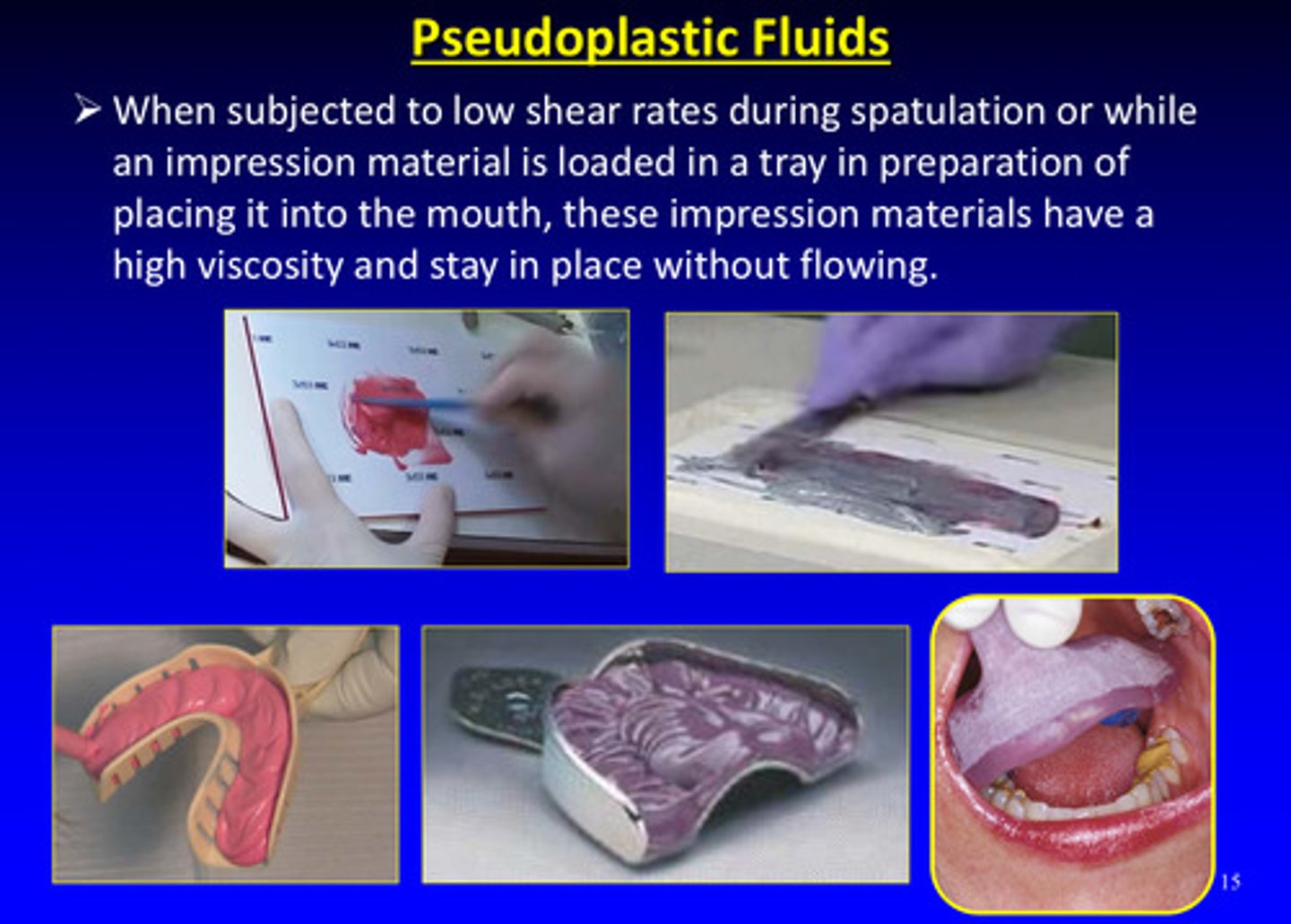

what kind of fluid does this describe: when subjected to low shear rates during spatulation or while an impression material is loaded in a tray in preparation of placing it into the mouth, these impression materials have a high viscosity and stay in place without flowing

pseudoplastic fluids

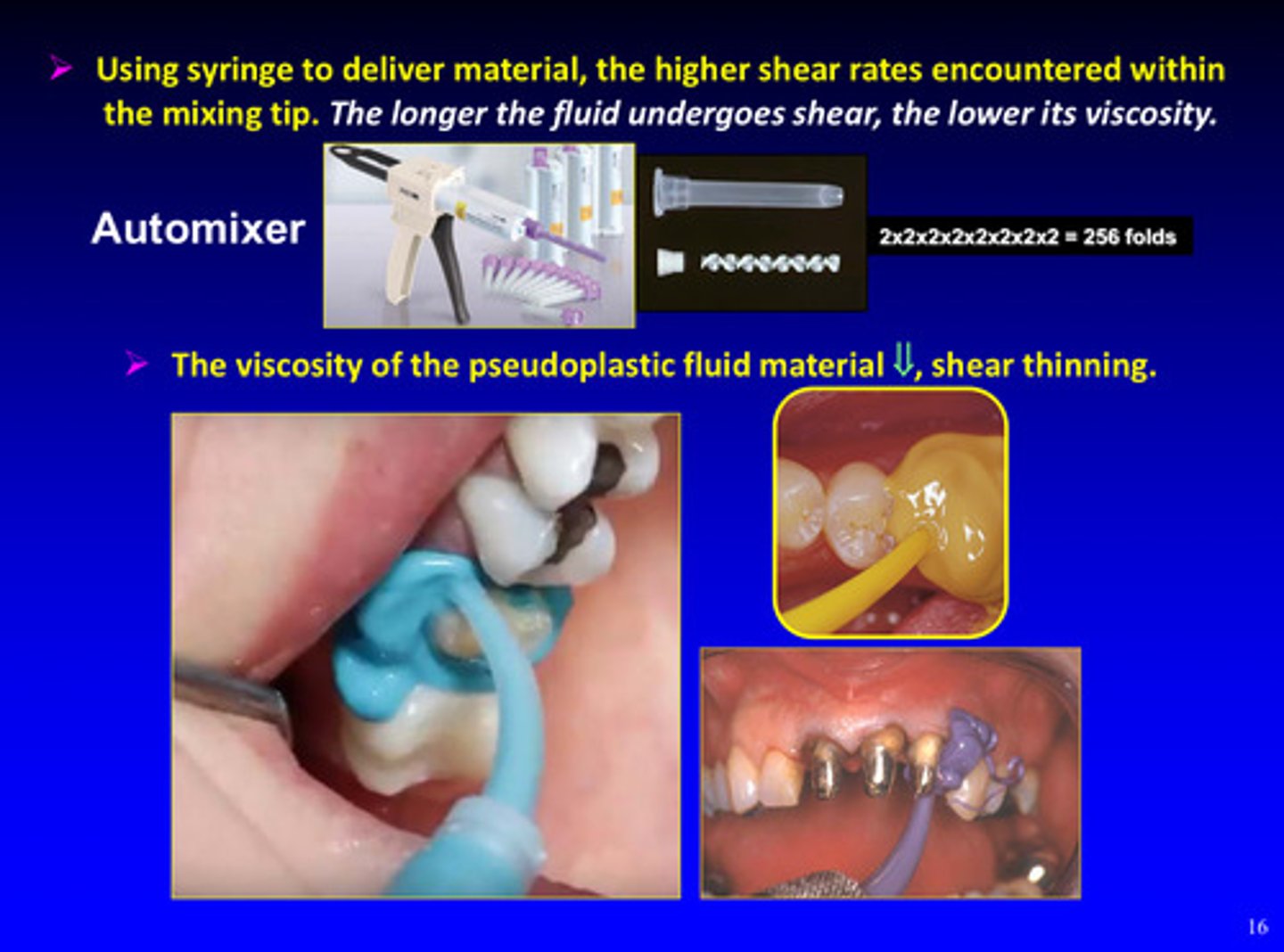

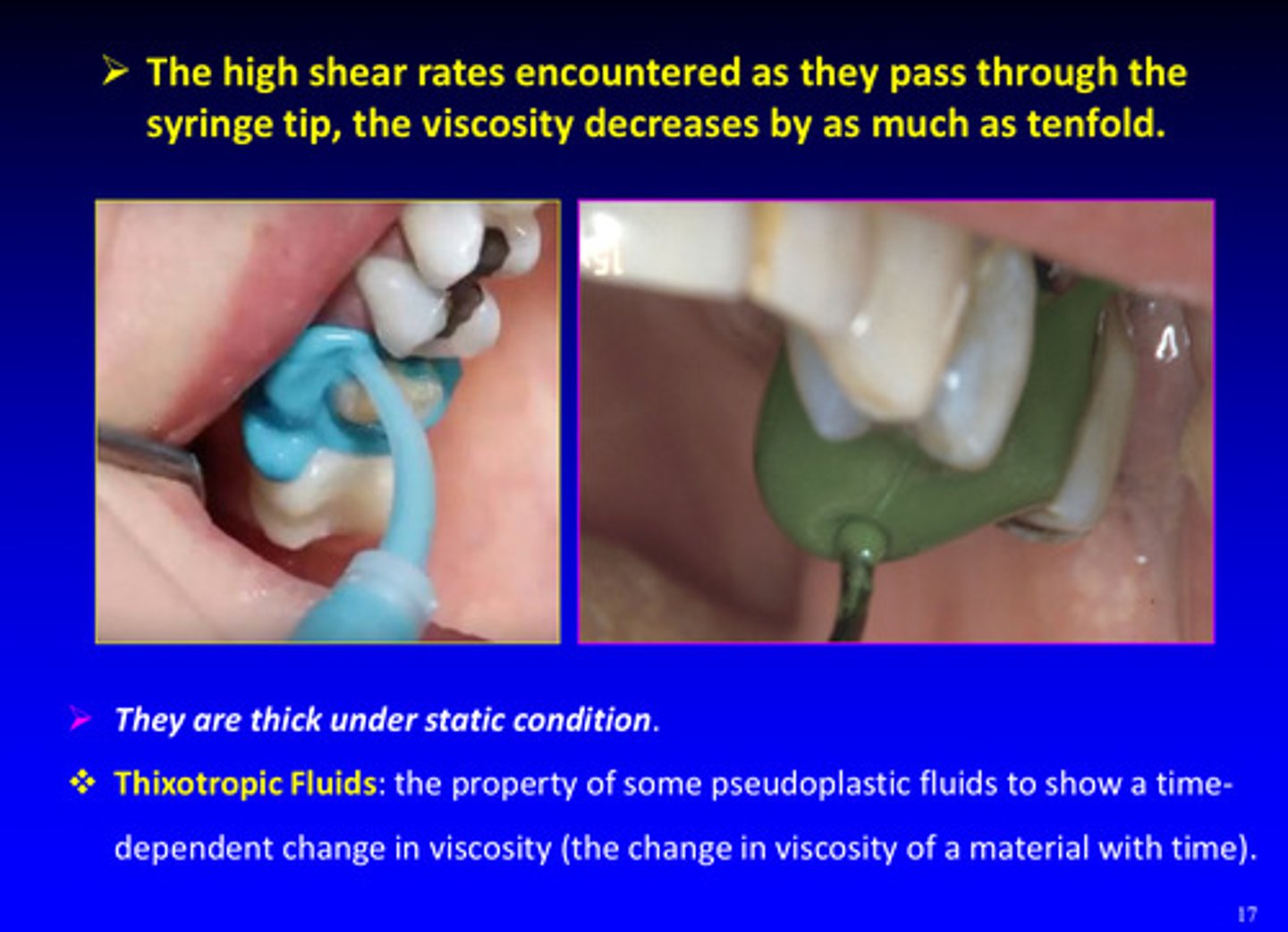

when using a syringe to deliver material, there are _________ shear rates encountered within the mixing tip

higher

the longer the pseudoplastic fluid undergoes shear, the lower its…

viscosity

the viscosity of the pseudoplastic fluid material decreases shear __________

thinning

the high shear rates encountered as pseudoplastic fluids pass through the syringe tips, the viscosity _________ by as much as tenfold

decreases

pseudoplastic fluids are _______ under static condition

thick

what are thixotropic fluids

the property of some pseudoplastic fluids to show a time-dependent change in viscosity (the change in viscosity of a material with time)

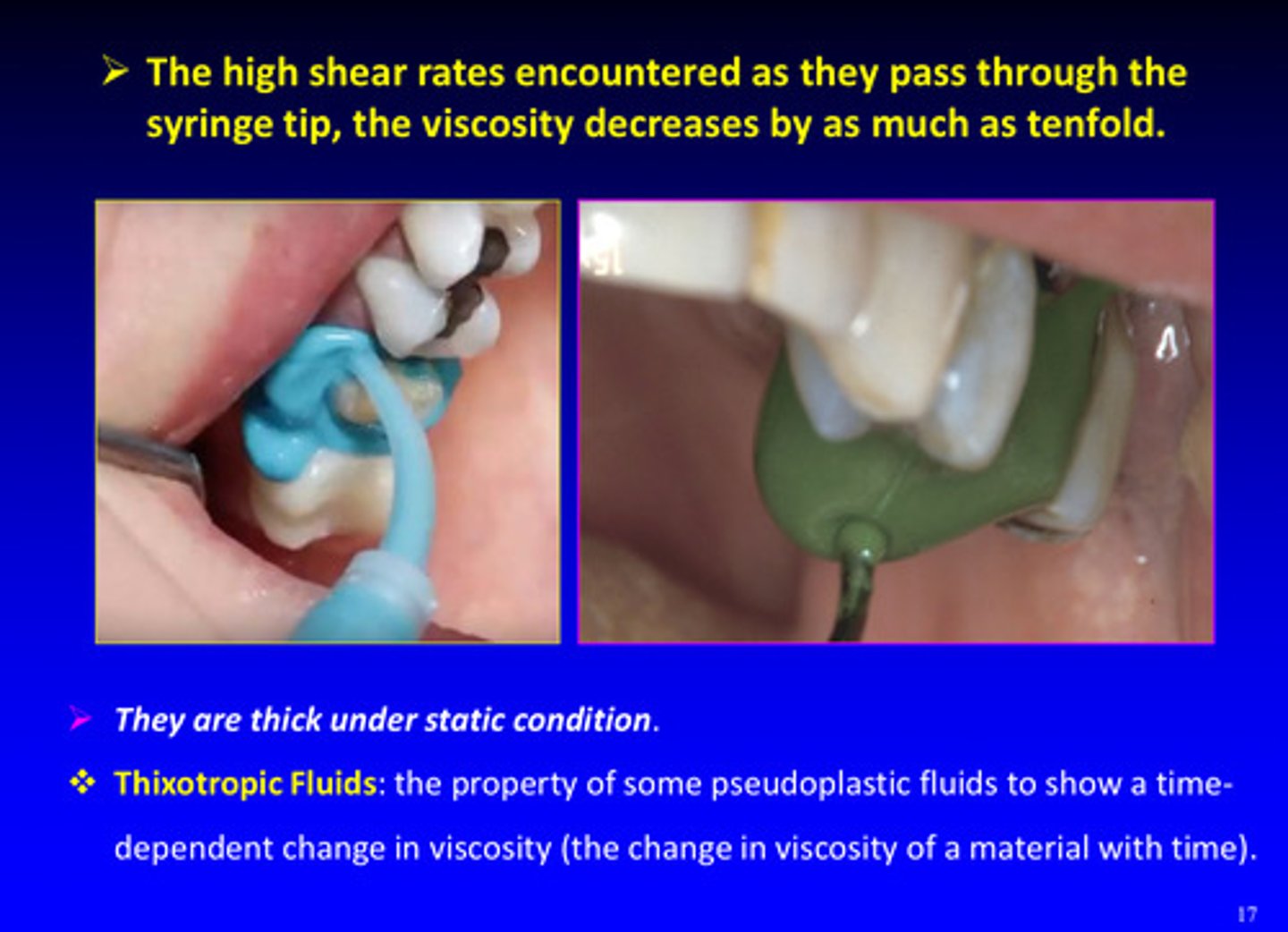

what are the 2 relevant nonaqueous elastomers we are focusing on

polyvinyl siloxane (PVS, VPS) and polyether

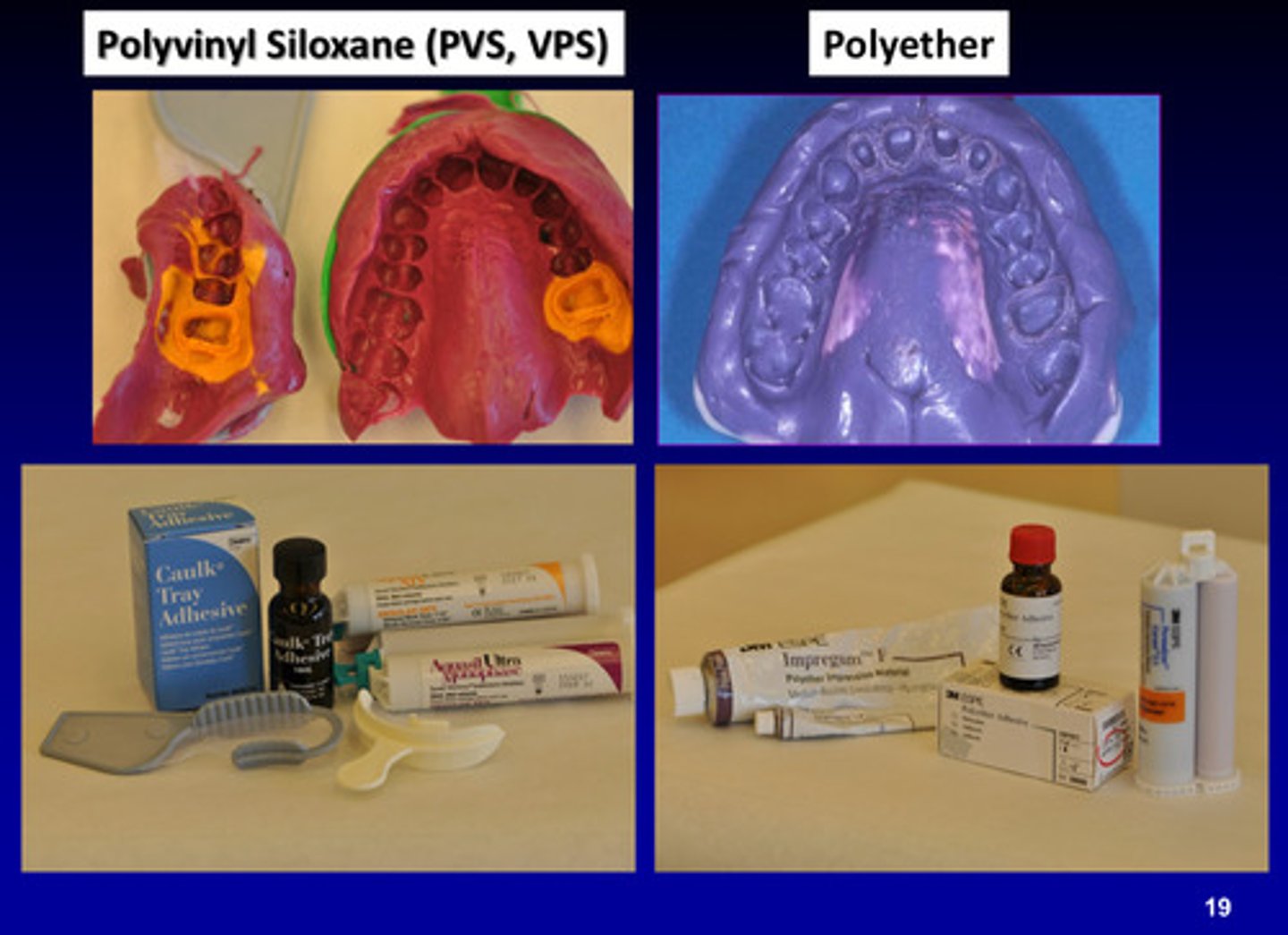

what are the 6 requirements for an elastomeric impression material

1) flow properly under load

2) good detail reproduction

3) adequate tear strength

4) high elastic recovery

5) good dimensional stability

6) gypsum compatibility

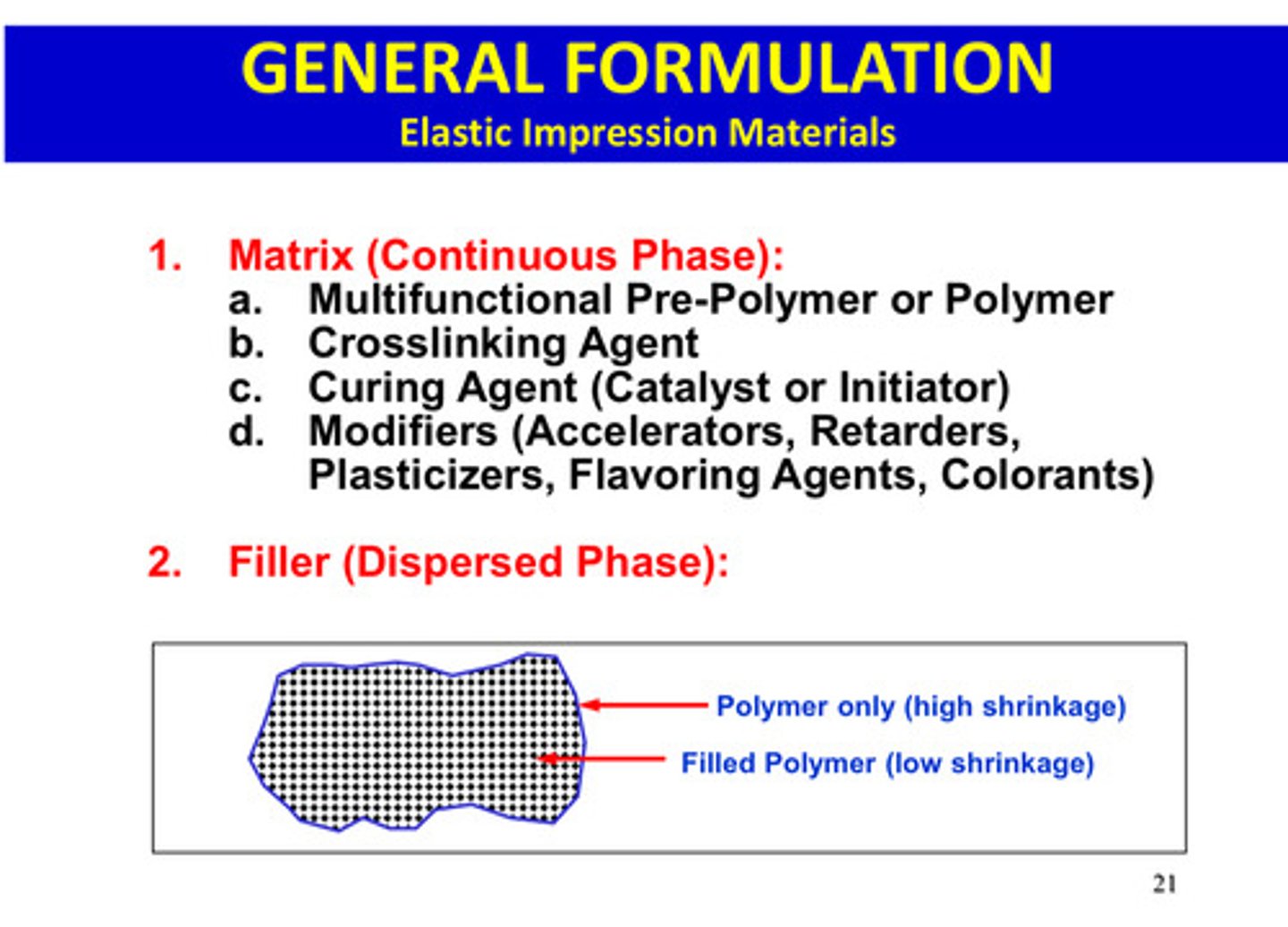

general formulation of elastic impression materials

matrix (continuous phase) and filler (dispersed phase)

what are the components of matrix in elastic impression materials

multifunctional pre-polymer or polymer

crosslinking agent

curing agent (catalyst or initiator)

modifiers (accelerators, retarders, plasticizers, flavoring agents, colorants)

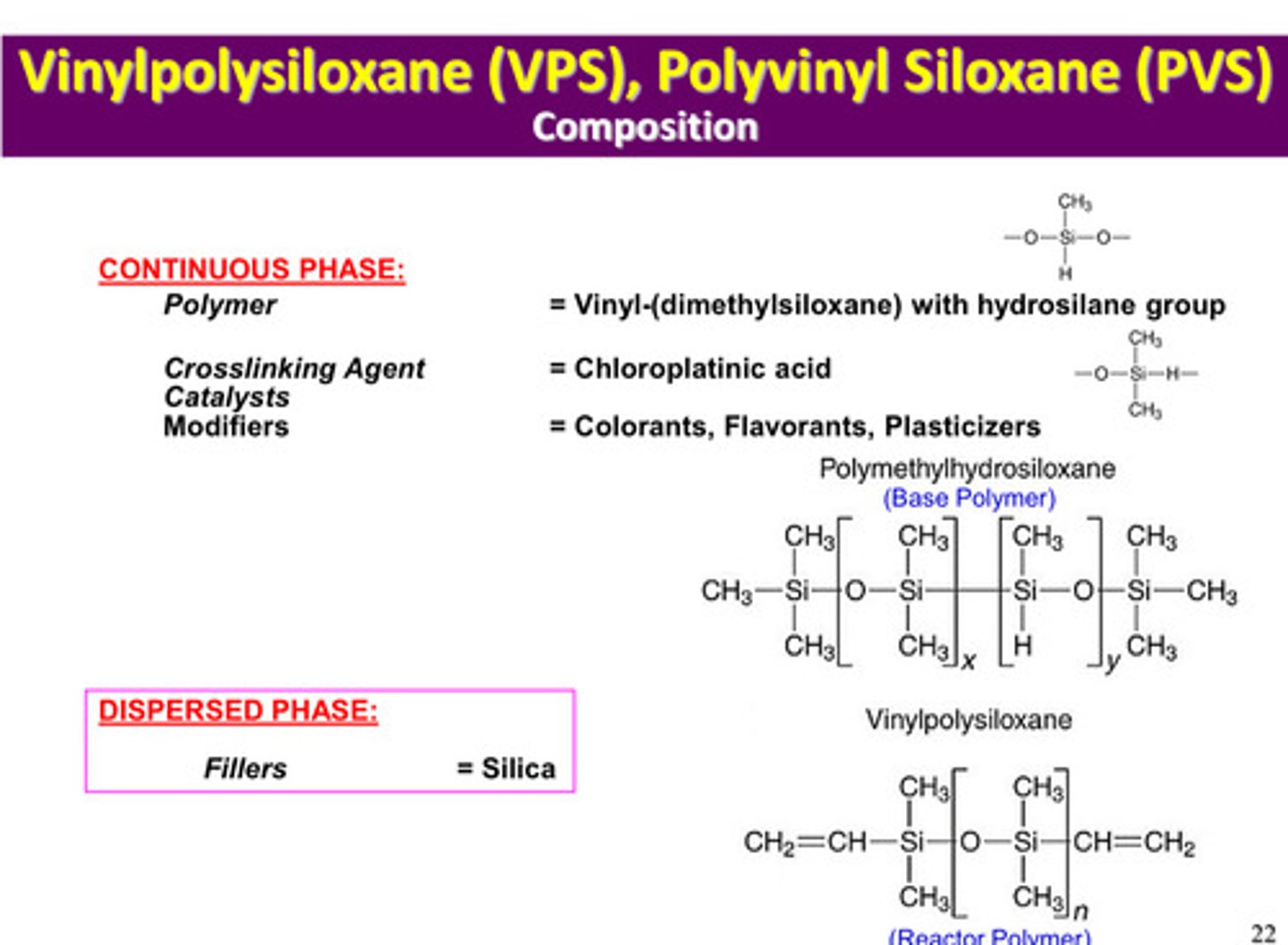

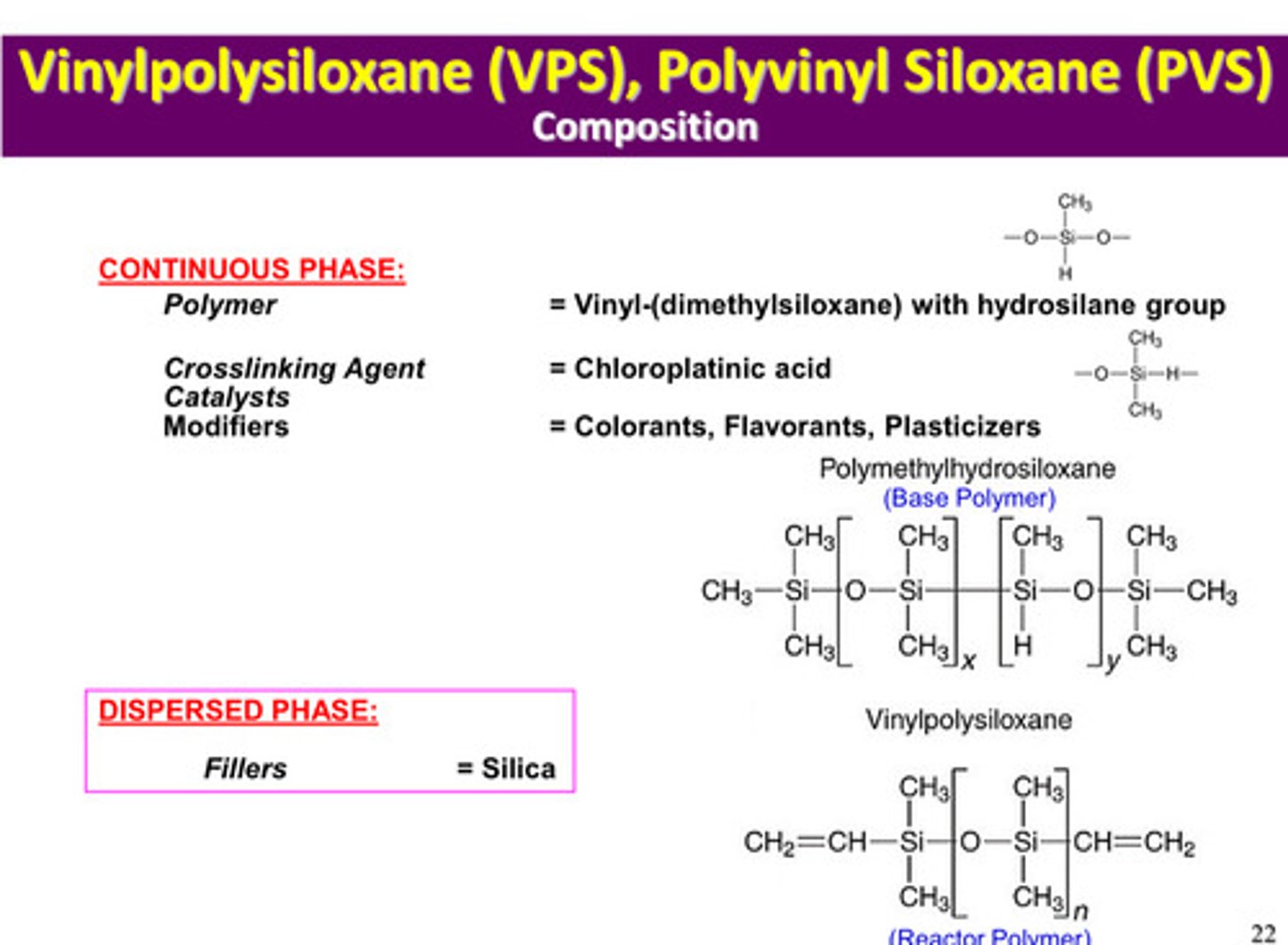

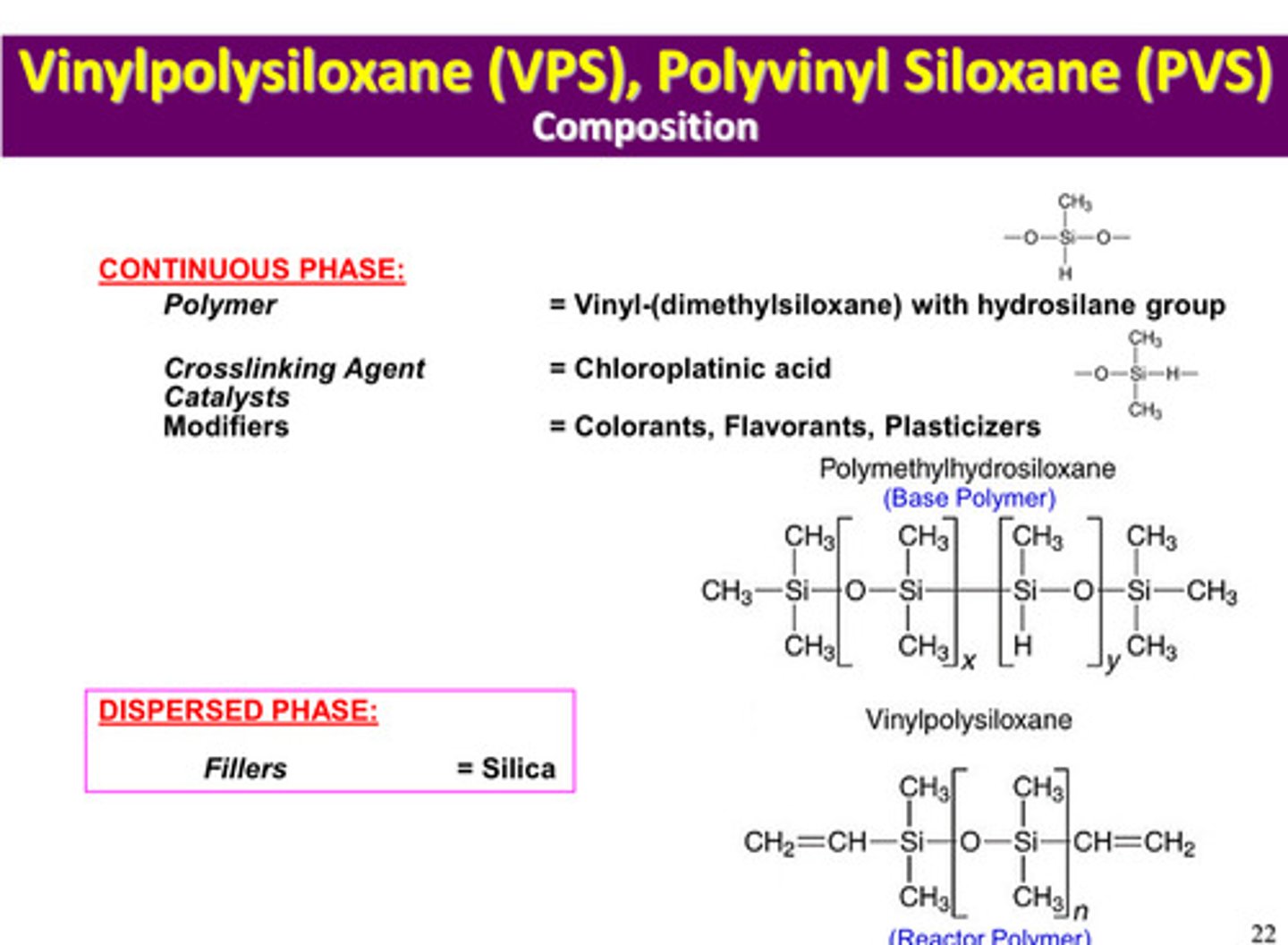

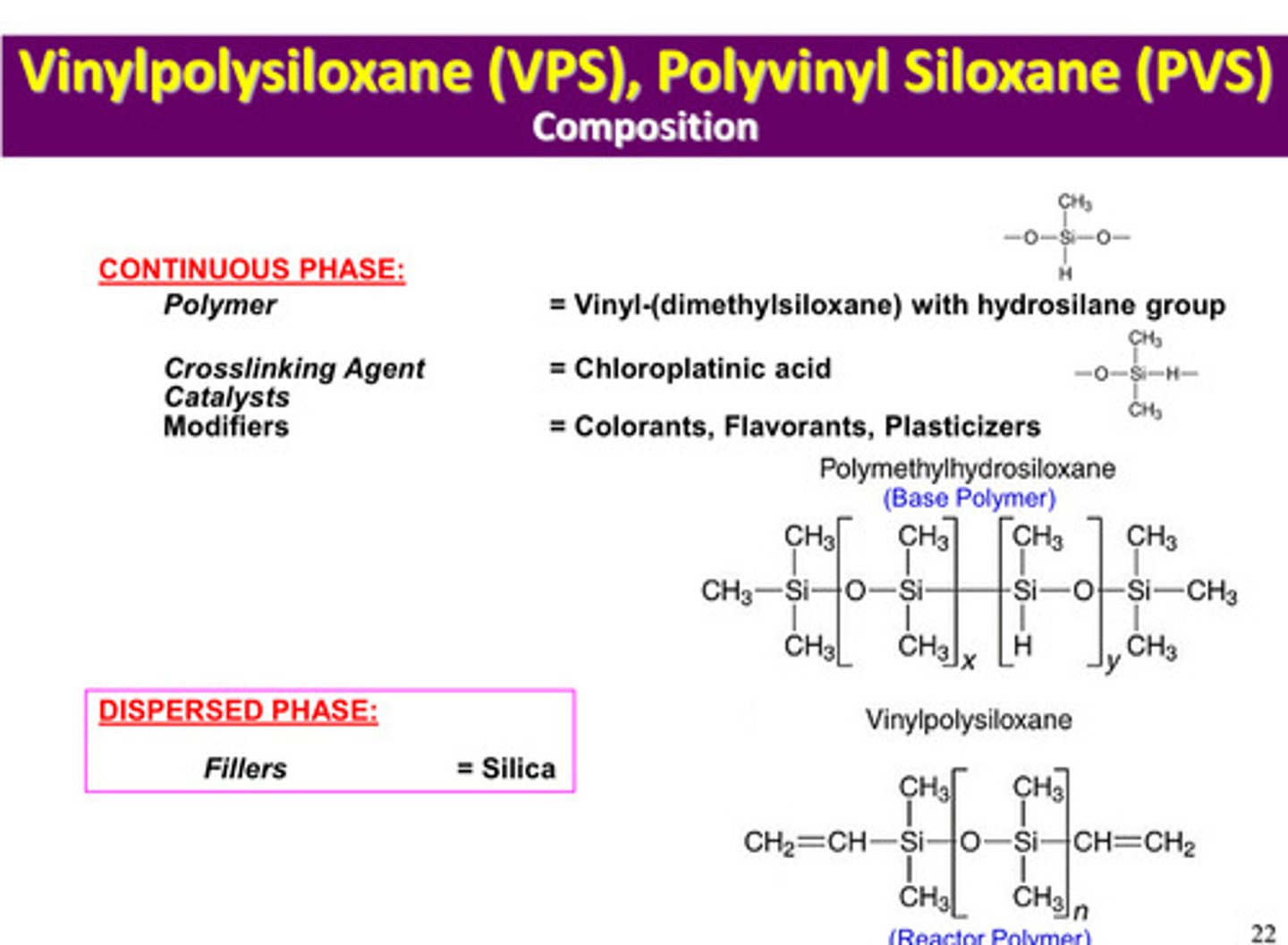

in PVS or VPS, what is the polymer of the continuous phase/matrix

vinyl-(dimethylsiloxane) with hydrosilane group

in PVS or VPS, what is the crosslinking agent/catalyst of the continuous phase/matrix

chloroplatinic acid

in PVS or VPS, what are the modifiers of the continuous phase/matrix

colorants, flavorants, plasticizers

in PVS or VPS, what is the filler of the dispersed phase/filler

silica

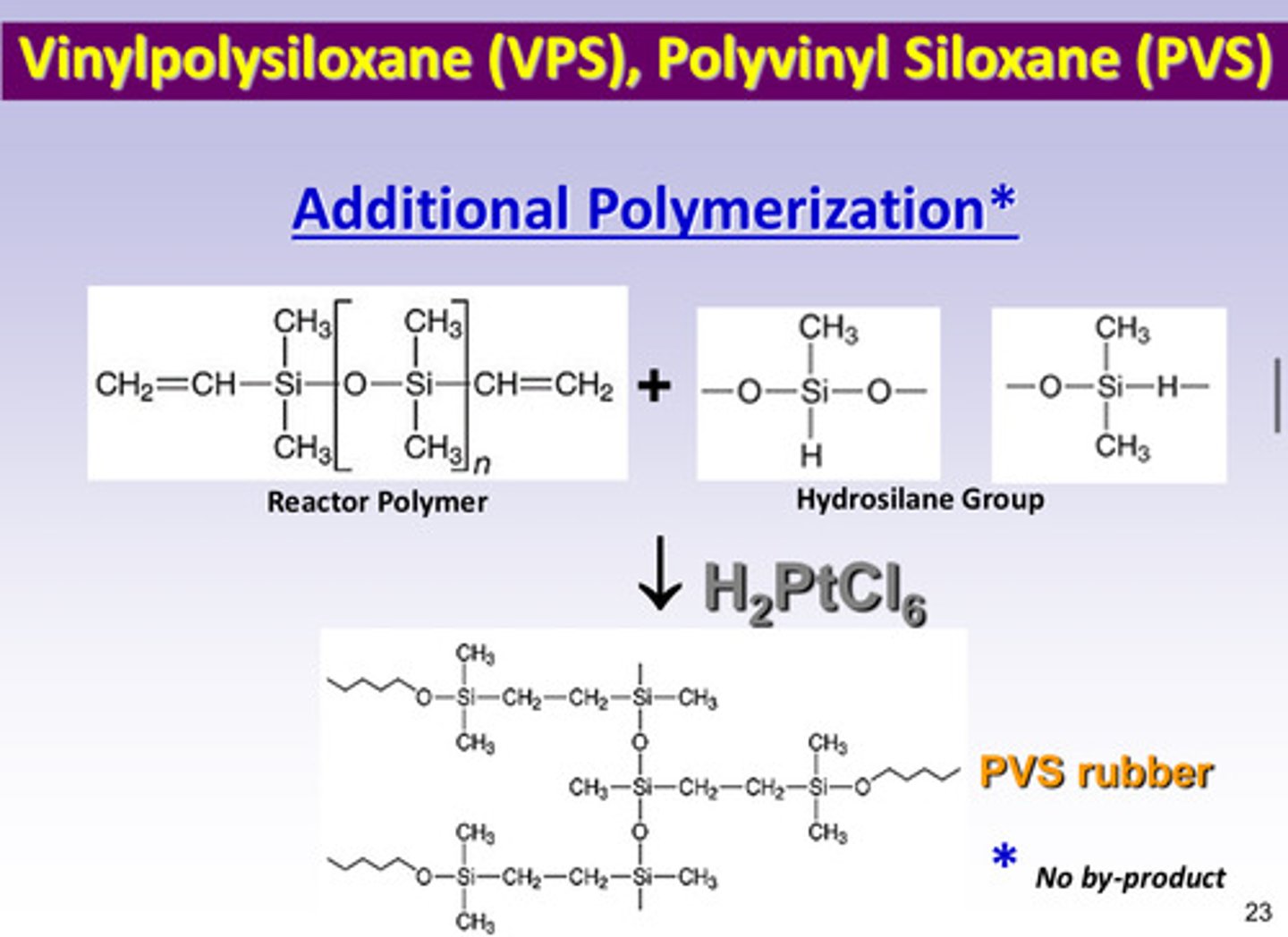

what kind of polymerization reaction occurs between the reactor polymer and the hydrosilane group of VPS/PVS

addition polymerization (product is PVS rubber with no by product)

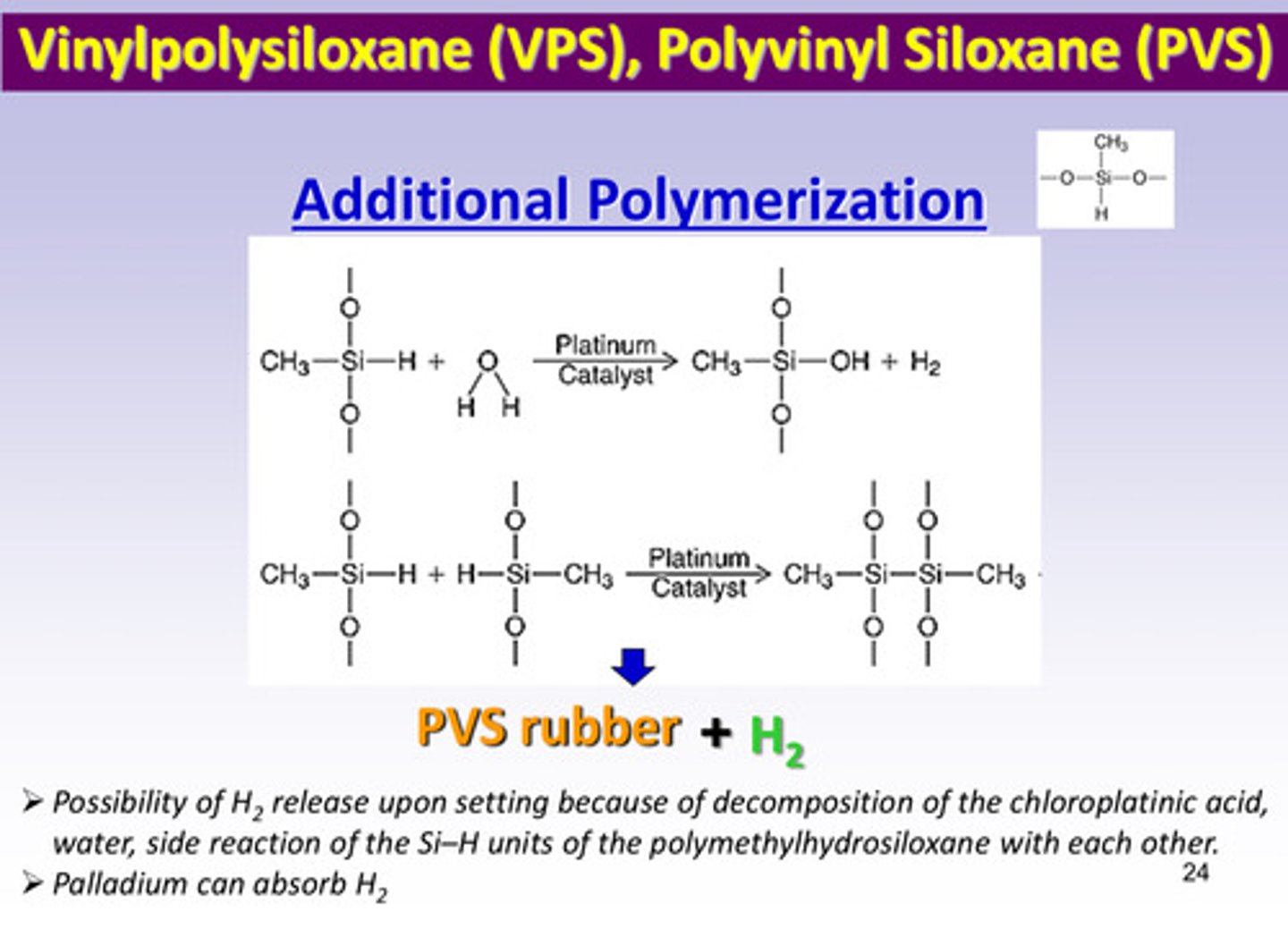

in addition polymerization, there is no by-product, but there is the possibility of ____ gas release upon setting because of what 3 things…

H2 gas; bc of decomposition of the chloroplatinic acid, water, and side rxn of Si-H units of polymethylhydrosiloxane with each other

what can absorb the H2 that is released by the addition polymerization reaction of VPS/PVS

palladium (ingredient that can be included in the impression material)

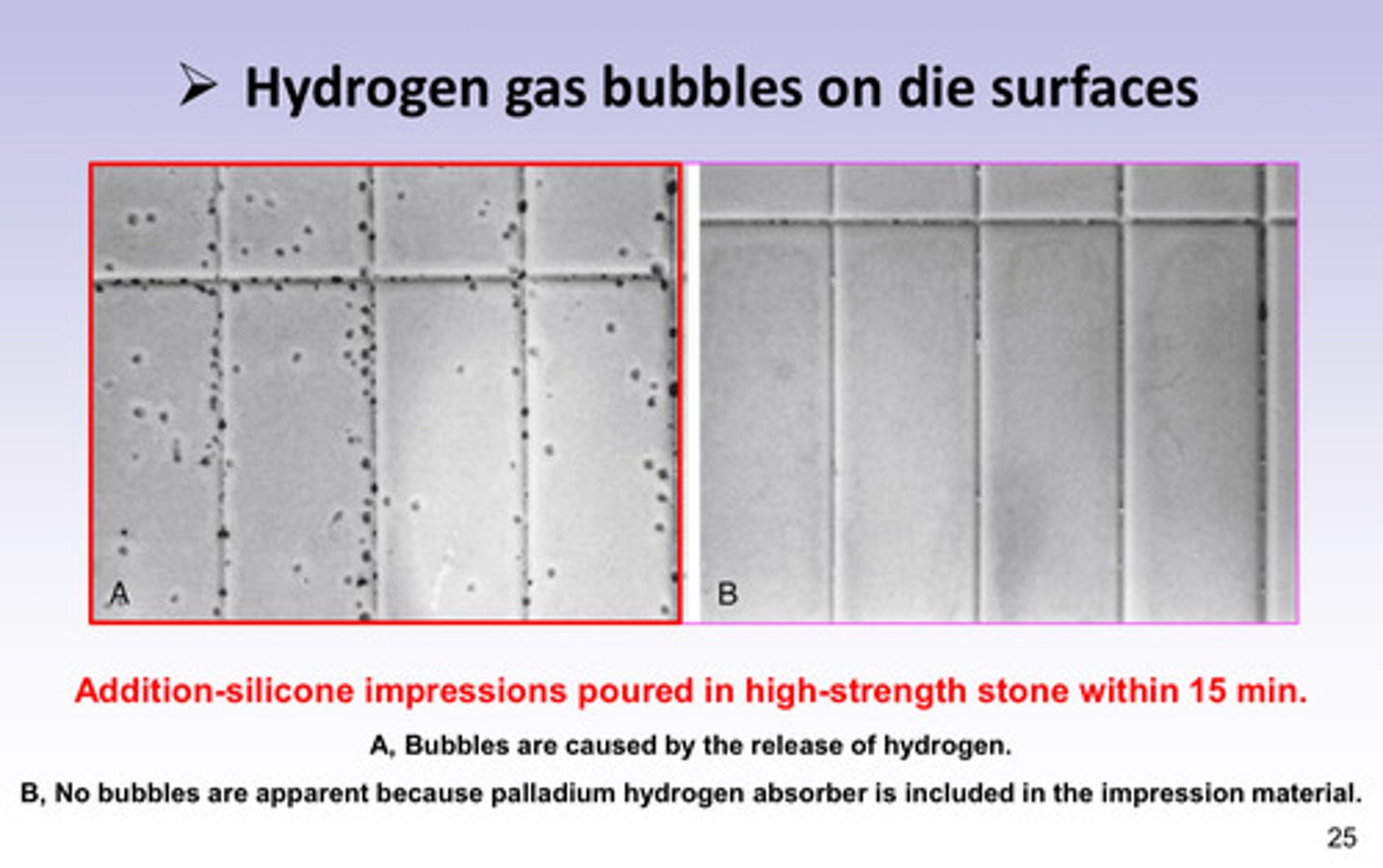

addition-silicone impressions should be poured in _________________ within __________ min

high-strength stone; 15

what are the 5 advantages of PVS/VPS

1) clean and pleasant for the patient

2) highly accurate

3) highly dimensional stability

4) delayed 30-60 min before casting

5) possible multiple pours

examples of hydrogen gas bubbles on die surface

A: bubbles caused by release of H2

B: no bubbles apparent because palladium hydrogen absorber is included in impression material

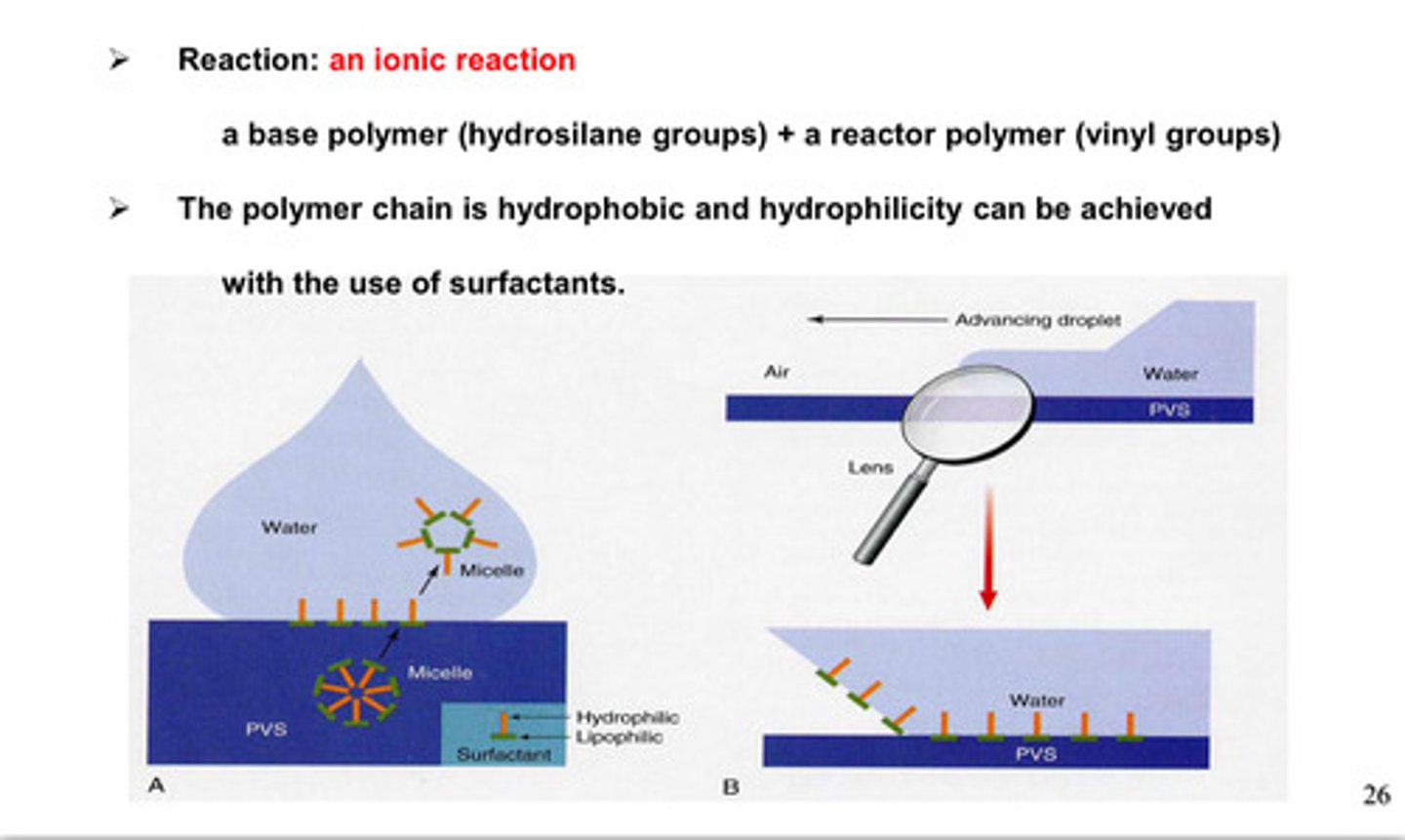

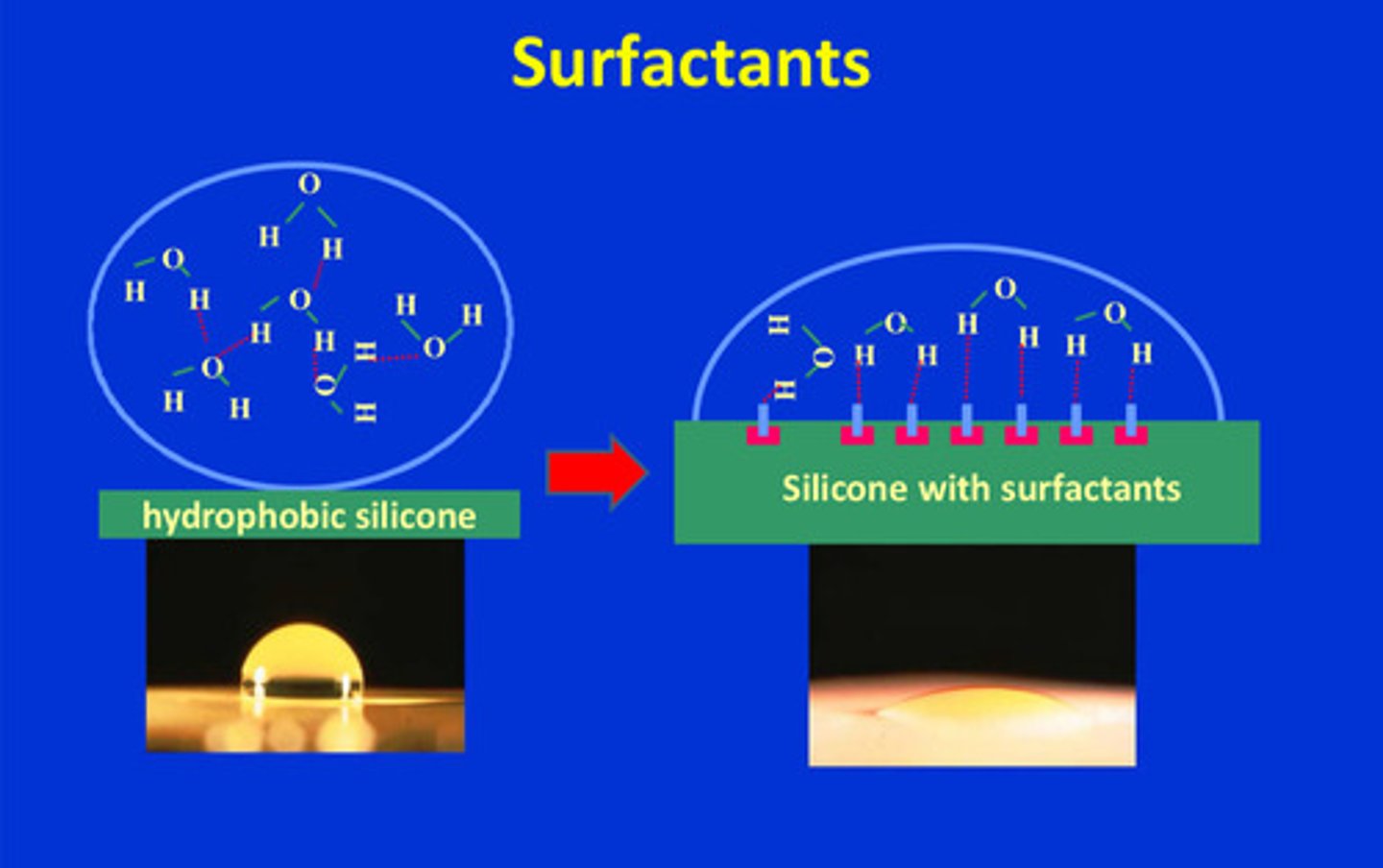

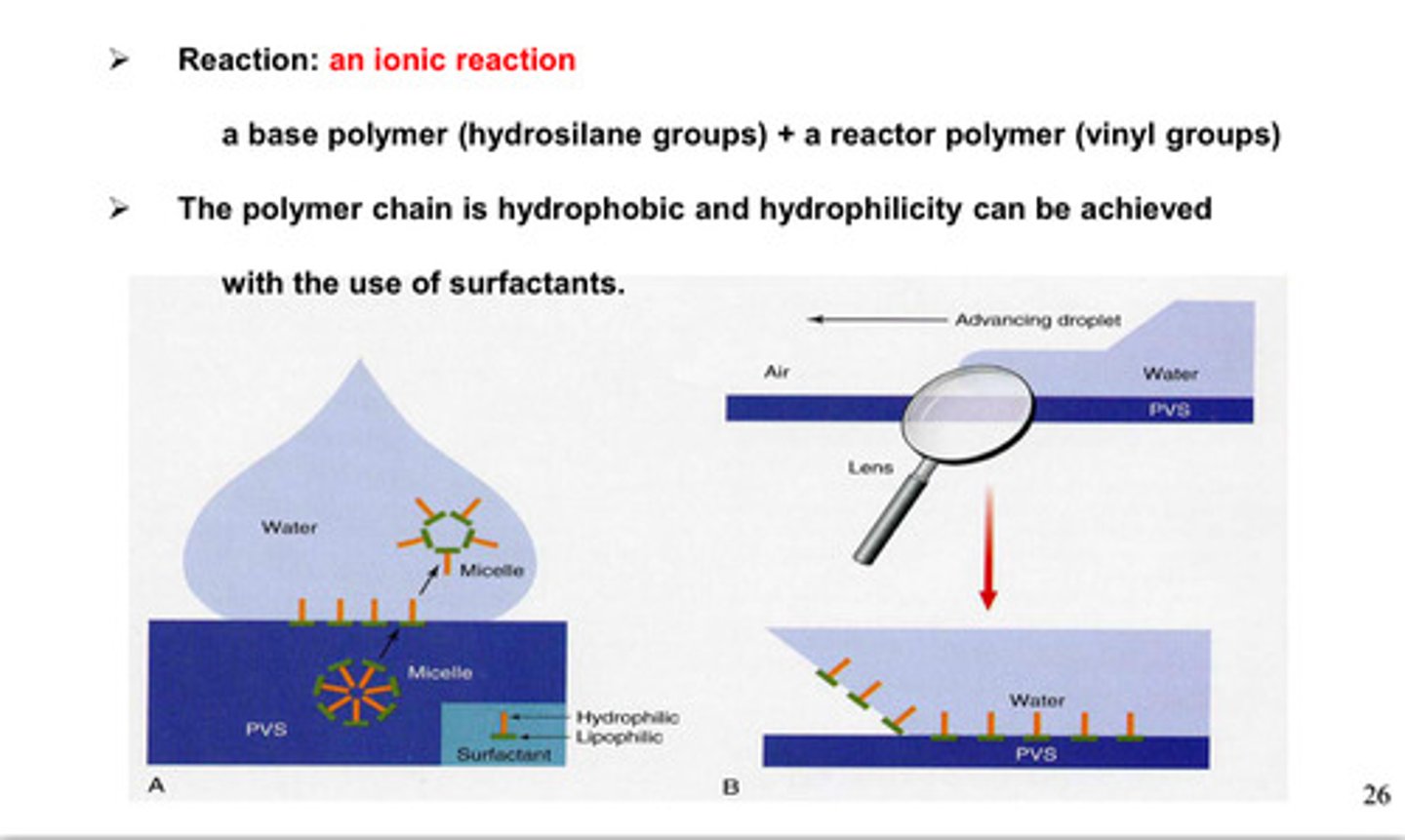

the polymer chain in VPS/PVS is ___________ and ___________ can be achieved w the use of surfactants

hydrophobic; hydrophilicity

what kind of reaction occurs between the base polymer (hydrosilane group) and reactor polymer (vinyl group) in VPS/PVS

ionic rxn

what are the 3 disadvantages of PVS/VPS

1) expensive

2) hydrogen gas bubbles on die surfaces

3) sulfur in rubbers (latex) inhibits polymerization

example of surfactant use

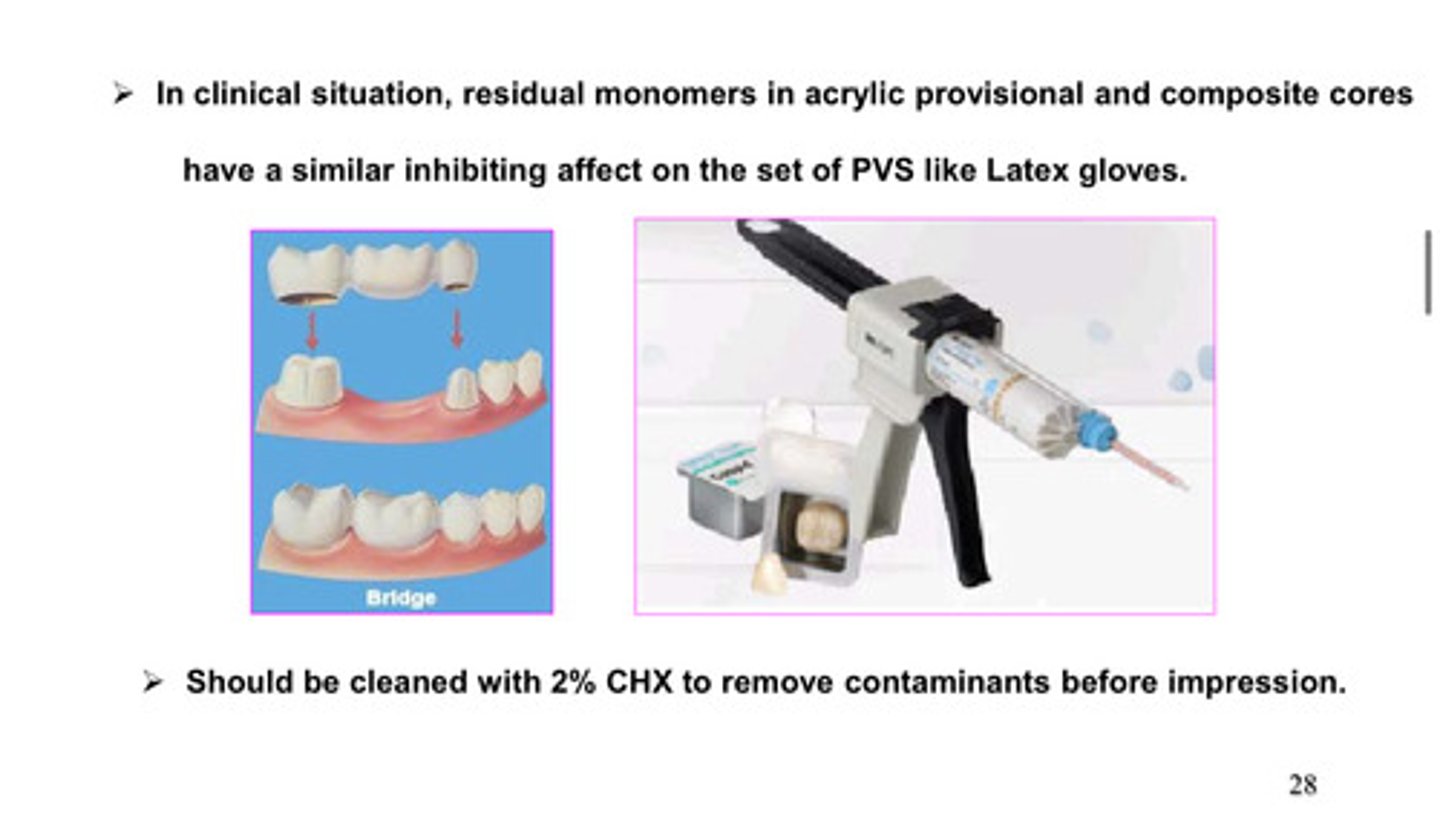

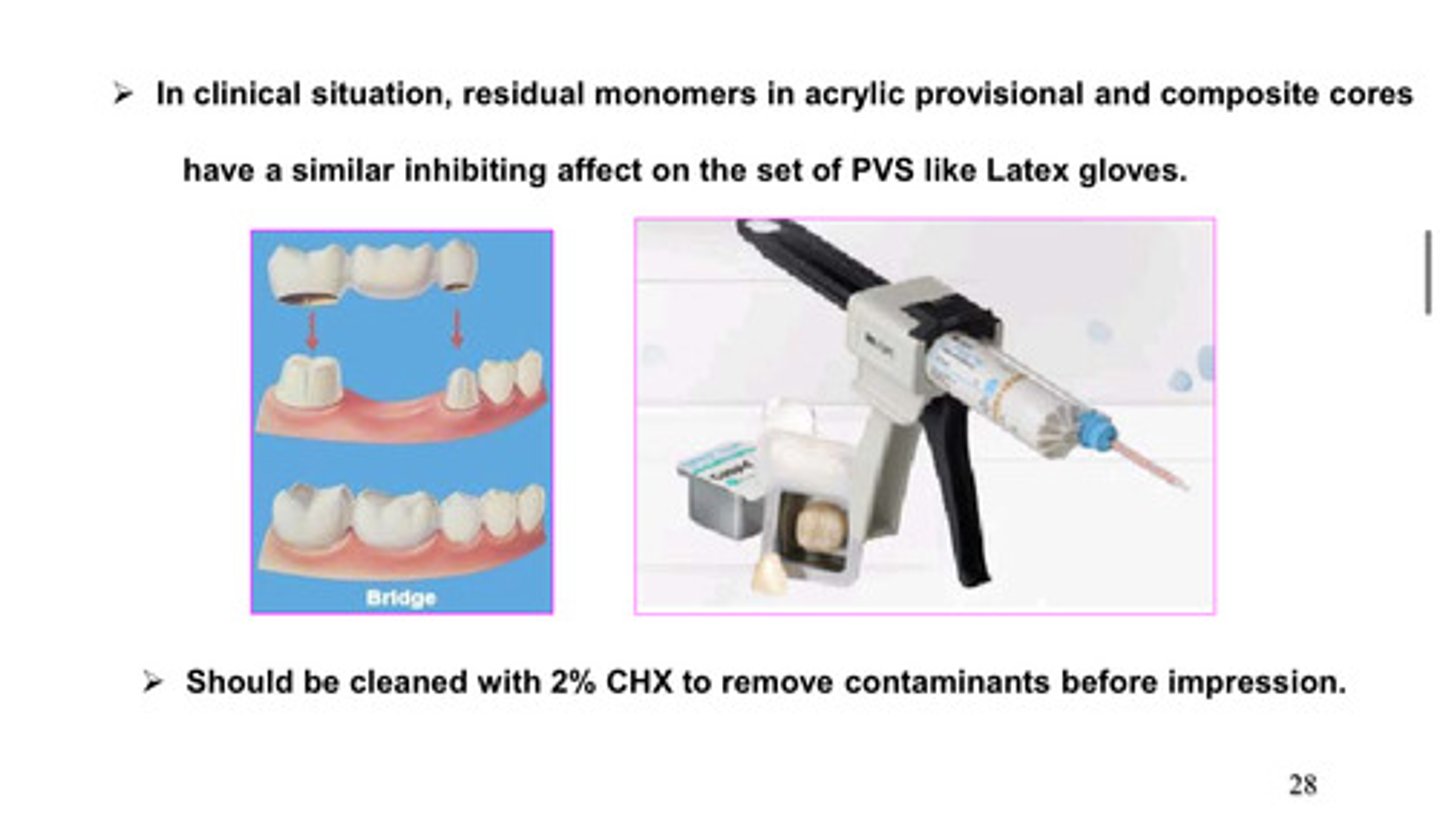

in clinical situation, residual monomers in acrylic provisional and composite cores have a similar _____________ effect on the set of PVS like latex gloves

inhibiting

acrylic provisional and composite cores should be cleaned with what to remove contaminants before impression

2% CHX

options of mixing and delivery systems for elastomeric materials (3)

2 pastes on mixing pad, in mixing gun, in mixing machine

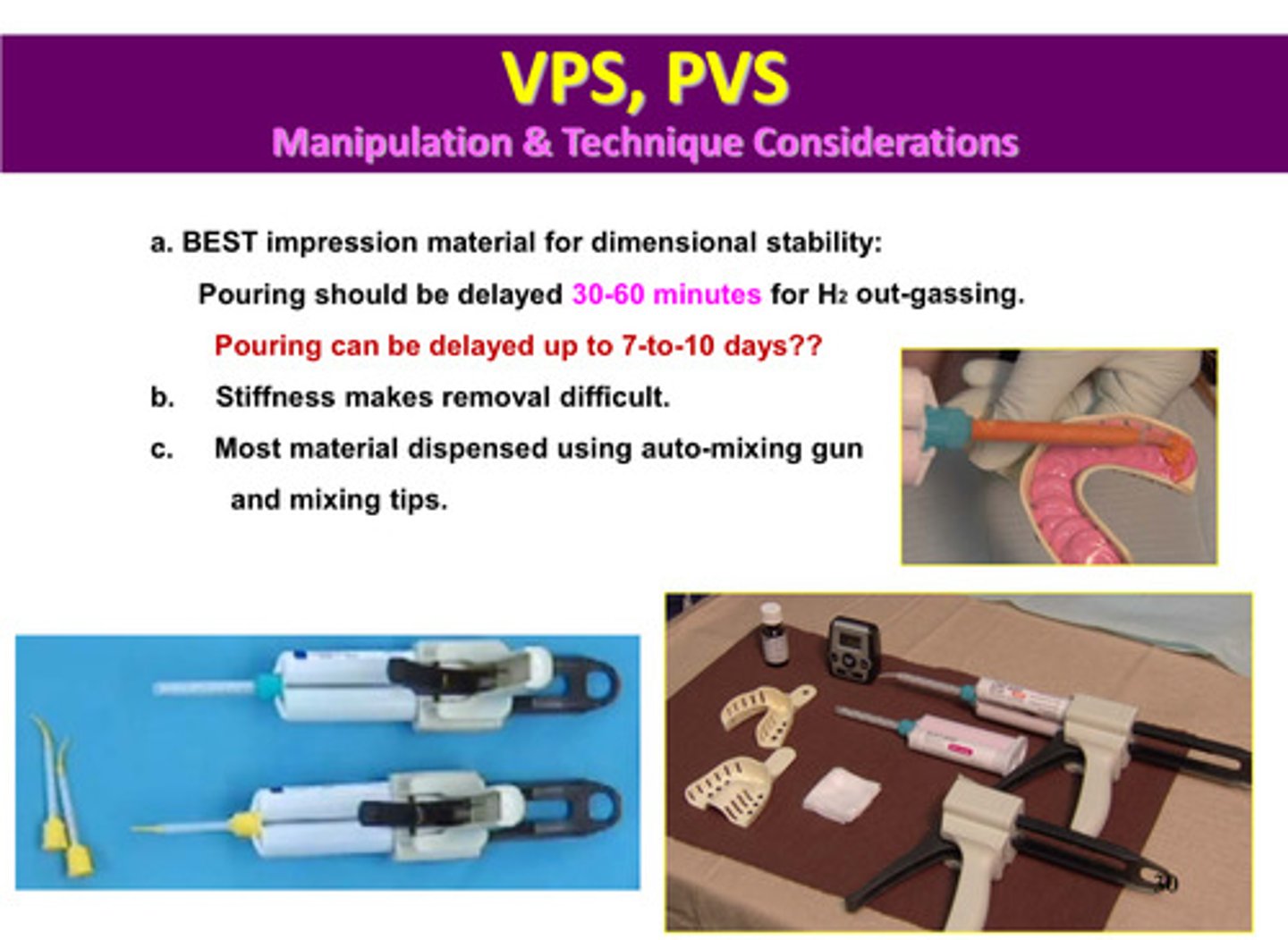

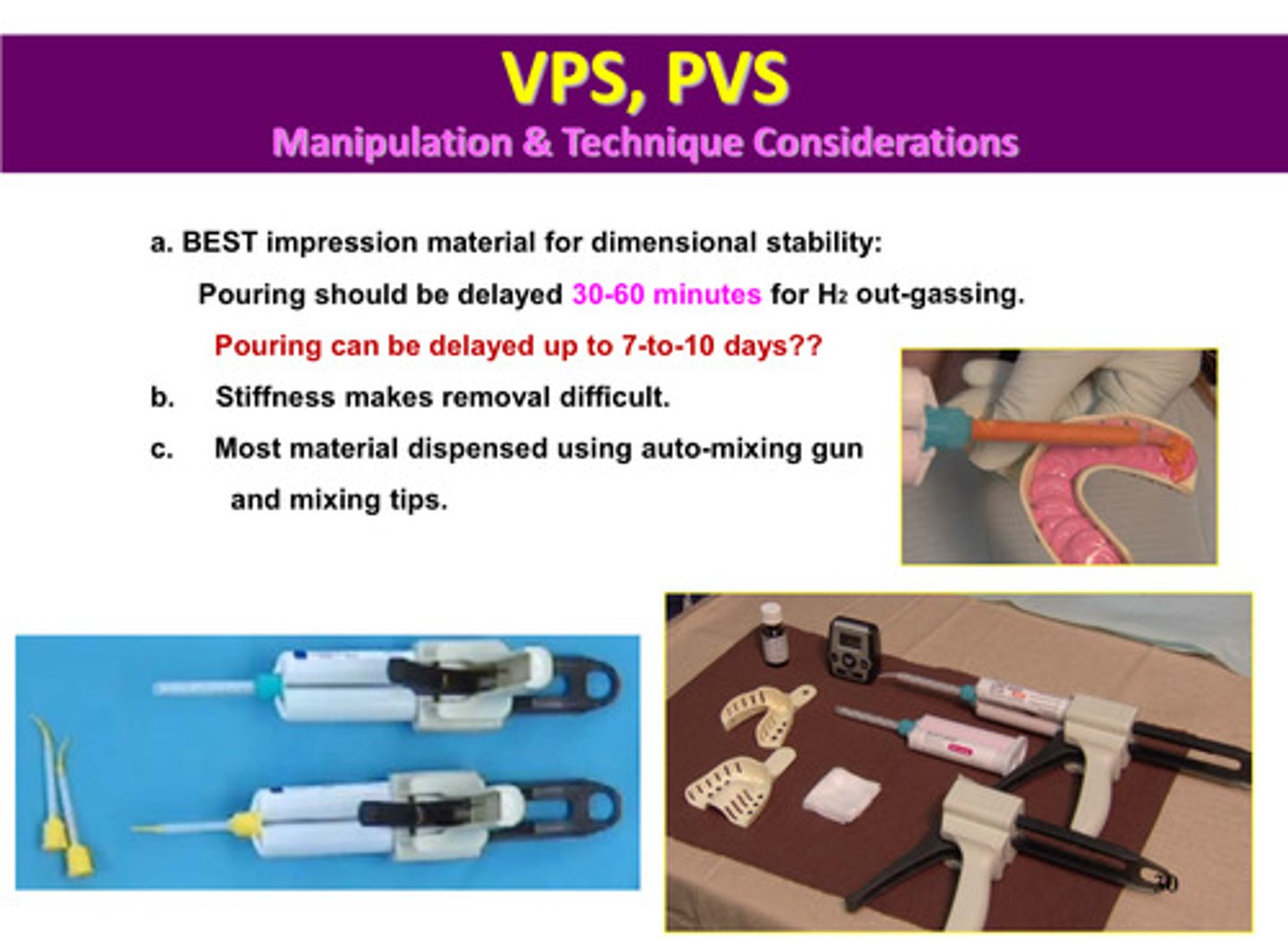

why is VPS/PVS the best impression material for dimensional stability

pouring should be delayed 30-60 minutes for H2 out-gassing and pouring can be delayed up to 7-10 days

the polymer chain are ___________ and ___________ can be achieved with the use of _____________

hydrophobic; hydrophilicity; surfactants

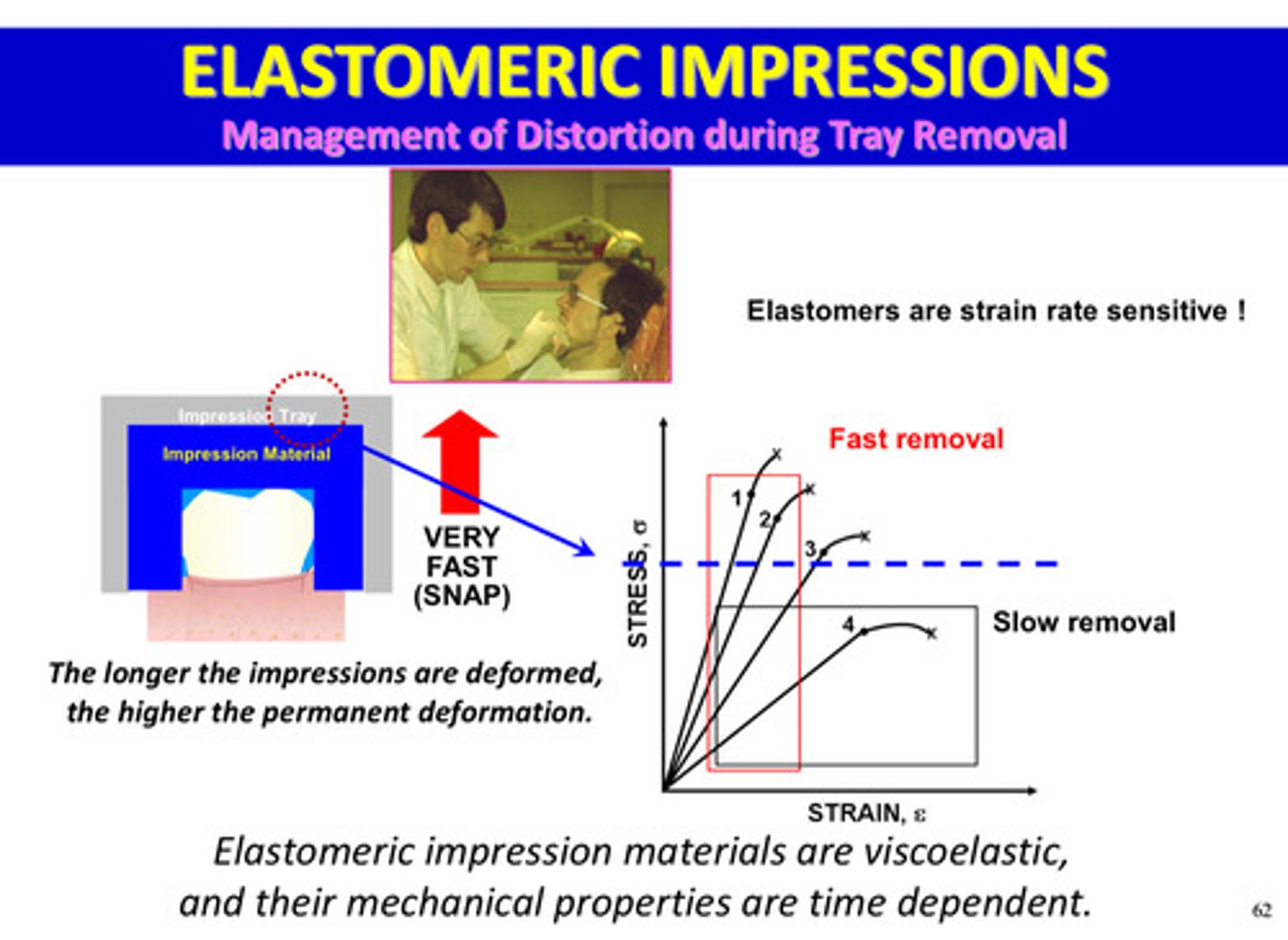

elastomers are strain rate ____________

sensitive

stiffness of VPS/PVS material makes what difficult

removal

most material is dispensed using what mixing/delivery systems

auto-mixing gun and mixing tips

all of the elastomeric impression materials showed linear viscoelastic behavior exhibiting __________ _____________ after 50 hrs of creep recovery

permanent deformation

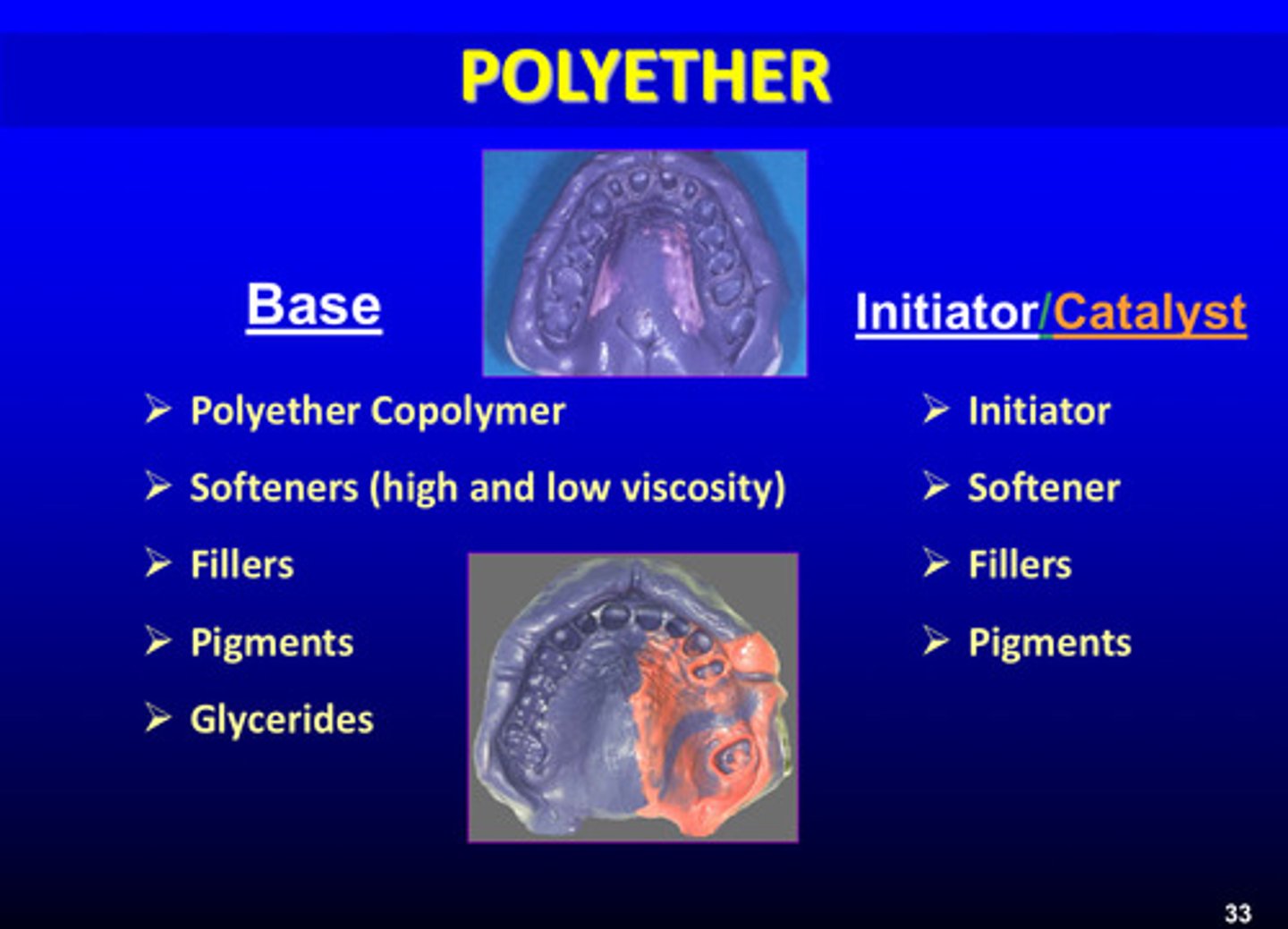

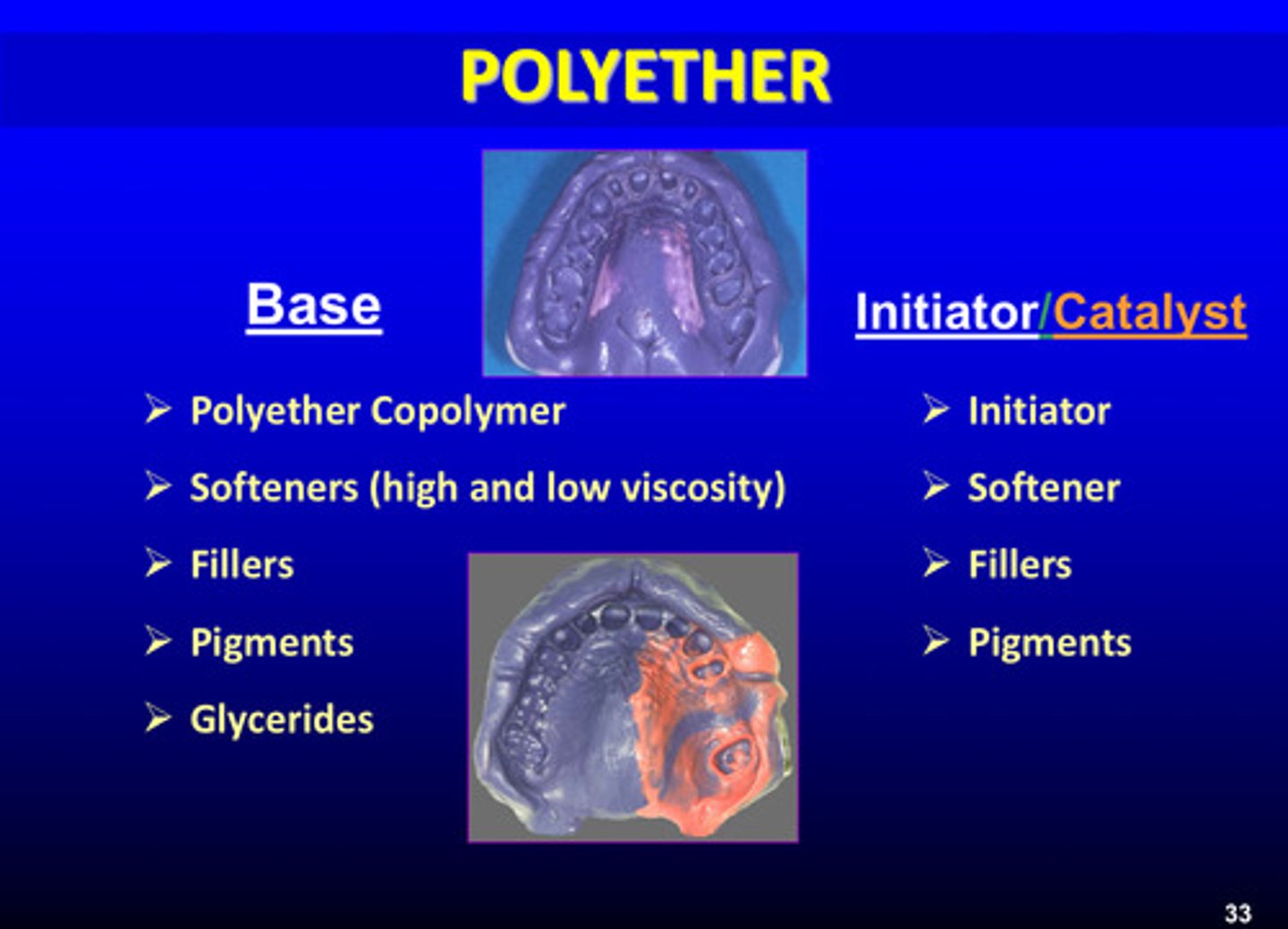

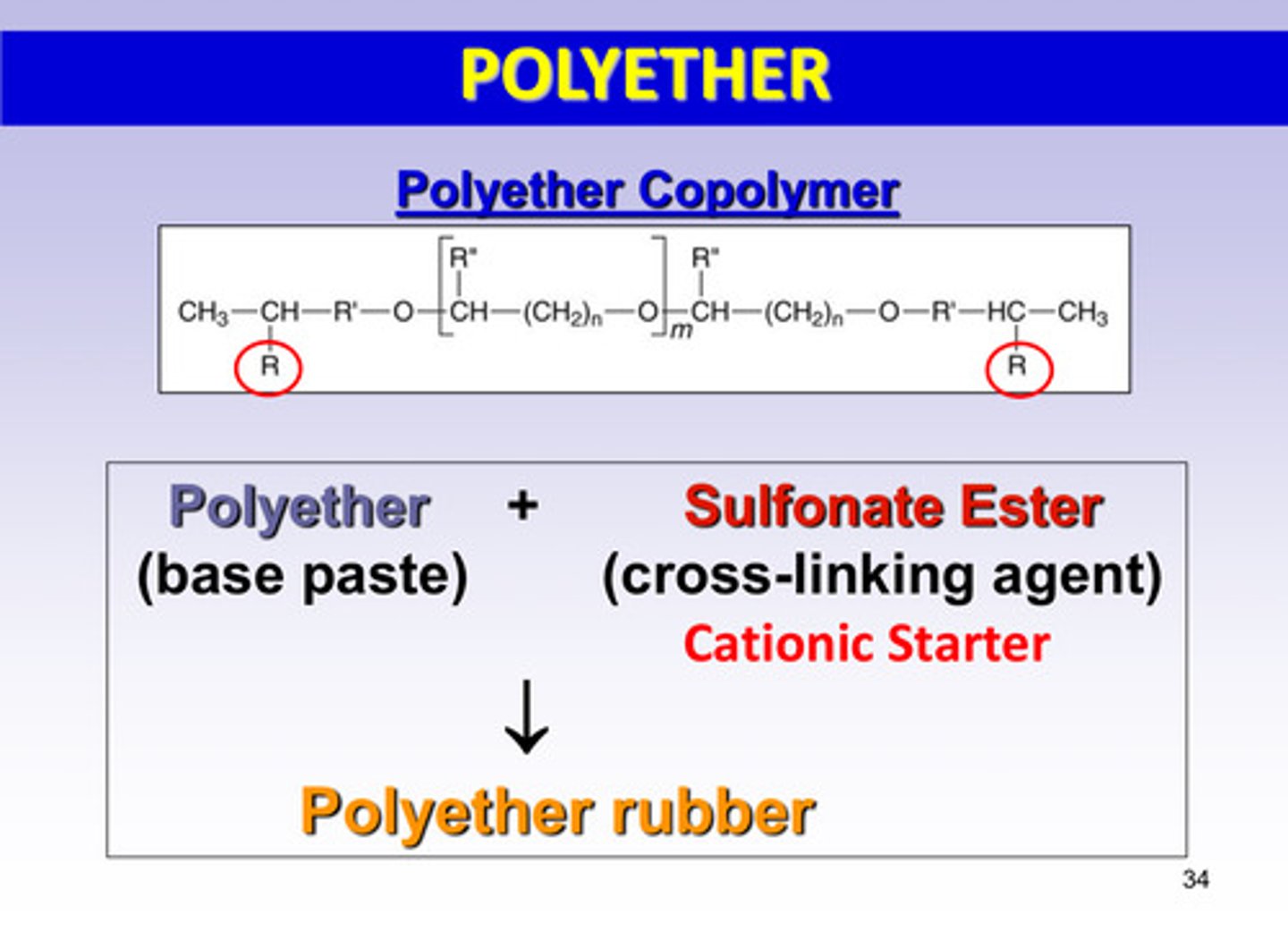

what are the 5 components of the base of polyether impression material

1) polyether copolymer

2) softeners (high and low viscosity)

3) fillers

4) pigments

5) glycerides

what are the 4 components of the initiator/catalyst of polyether impression materials

1) initiator

2) softener

3) fillers

4) pigments

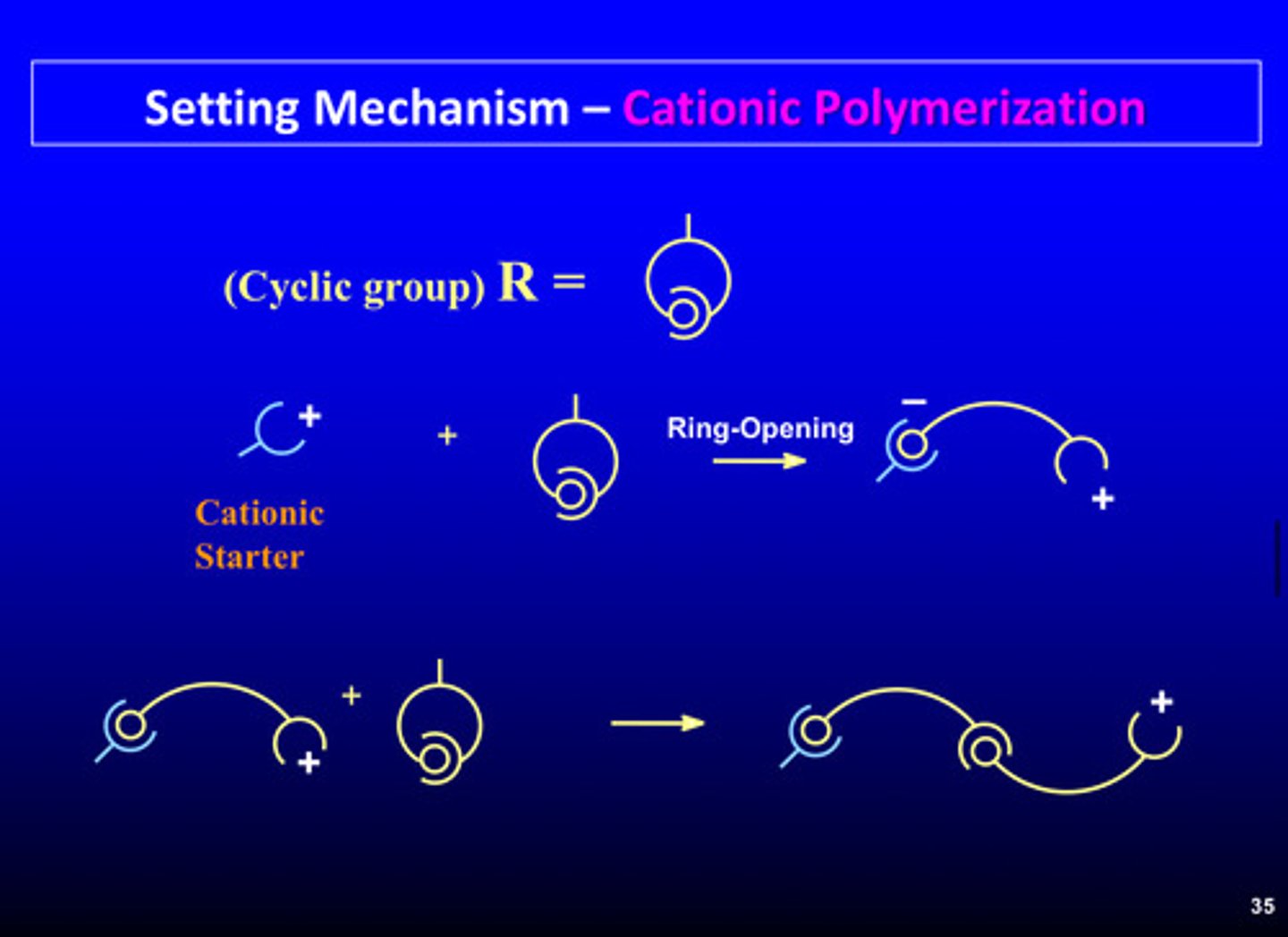

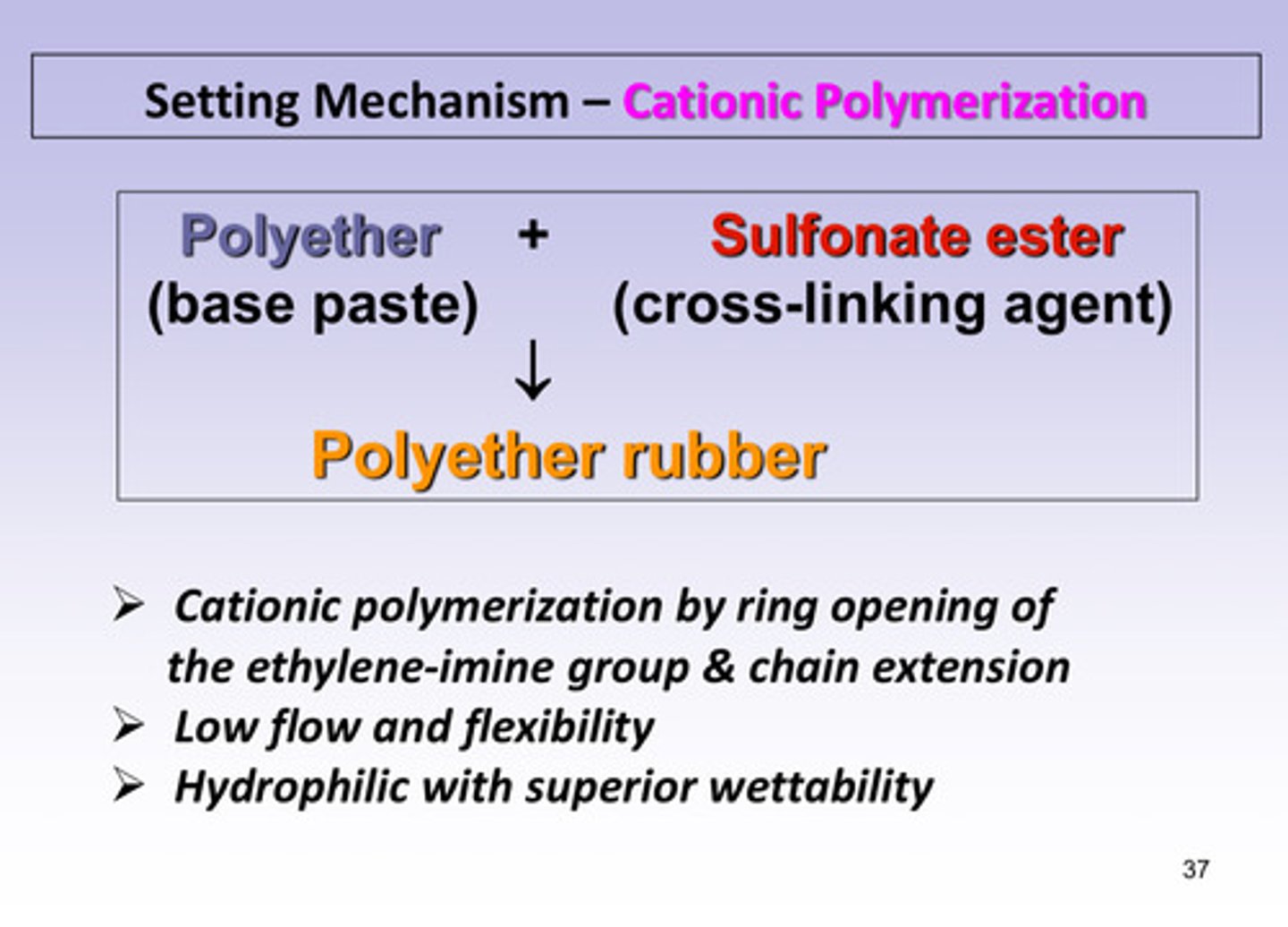

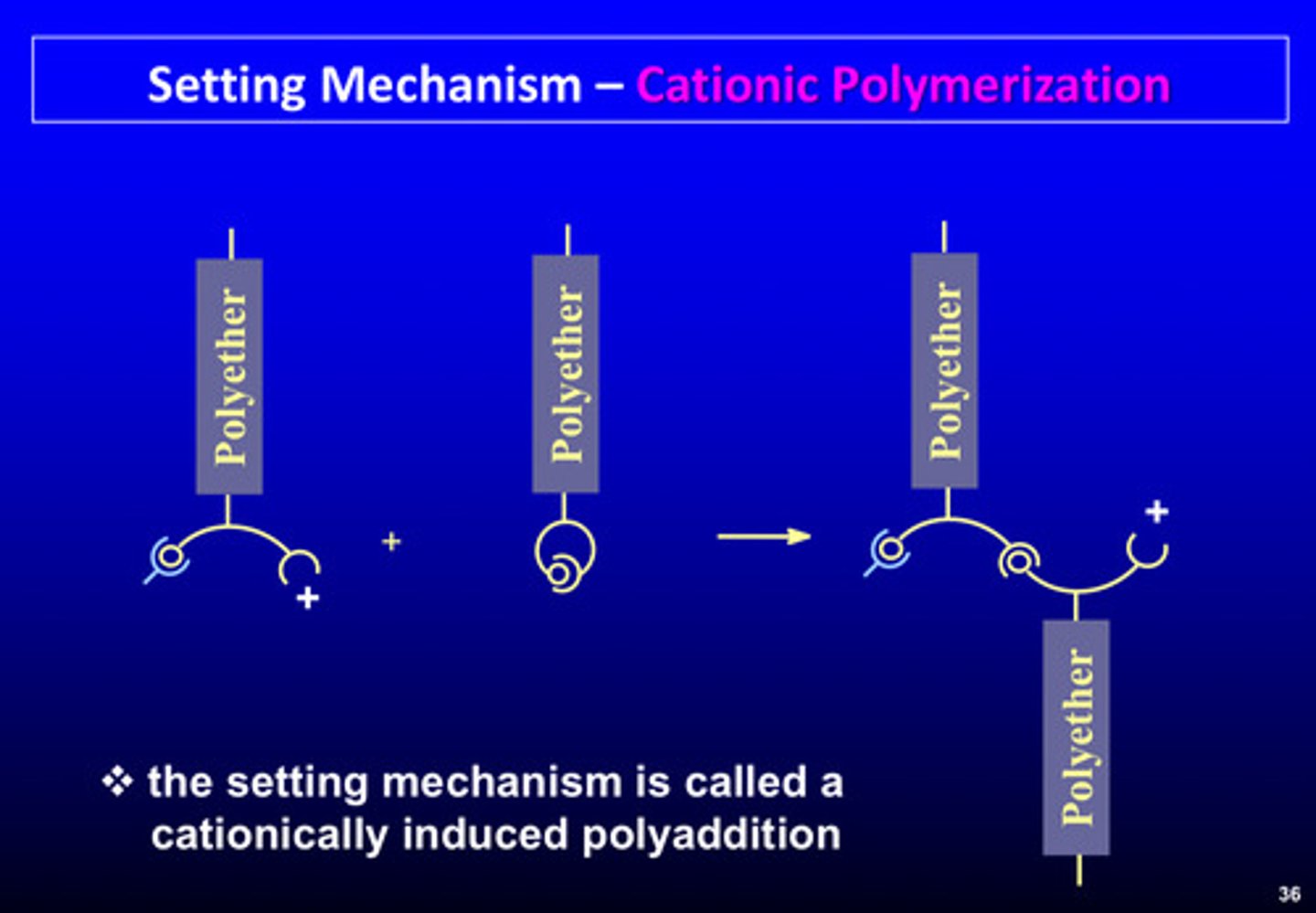

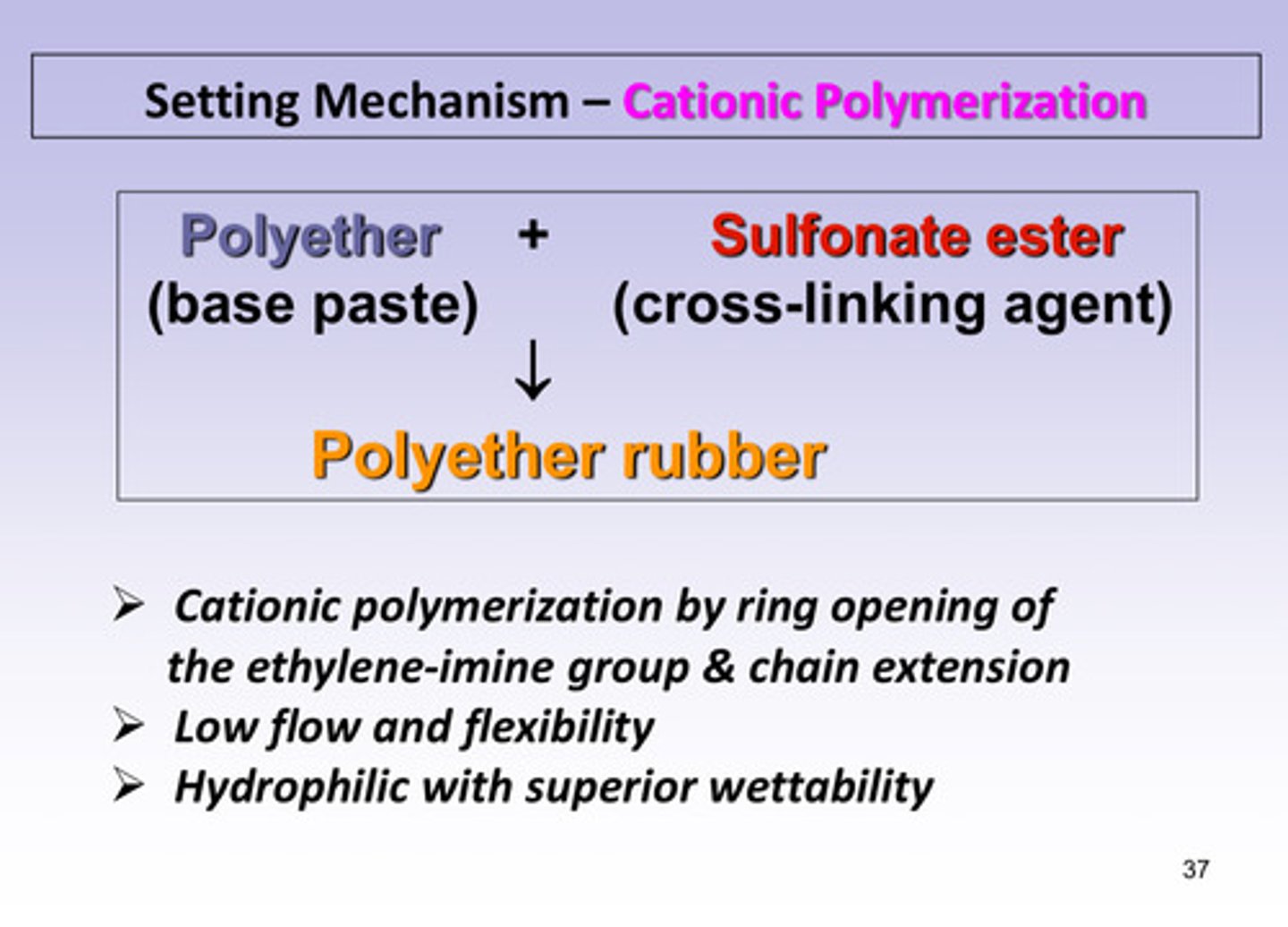

what kind of polymerization reaction occurs for polyether rubbers

cationic polymerization

what 2 reactants undergo the polymerization reaction to form the polyether rubber

polyether (base paste) + sulfonate ester (cross-linking agent/cationic starter)

polyether rubber is formed through cationic polymerization by ______ __________ of the ethylene-imine group and _______ __________

ring opening; chain extension

example of cationically induced polyaddition for polyether material

what are the 2 characteristics of polyether rubber

1) low flow and flexibility

2) hydrophilic with superior wettability

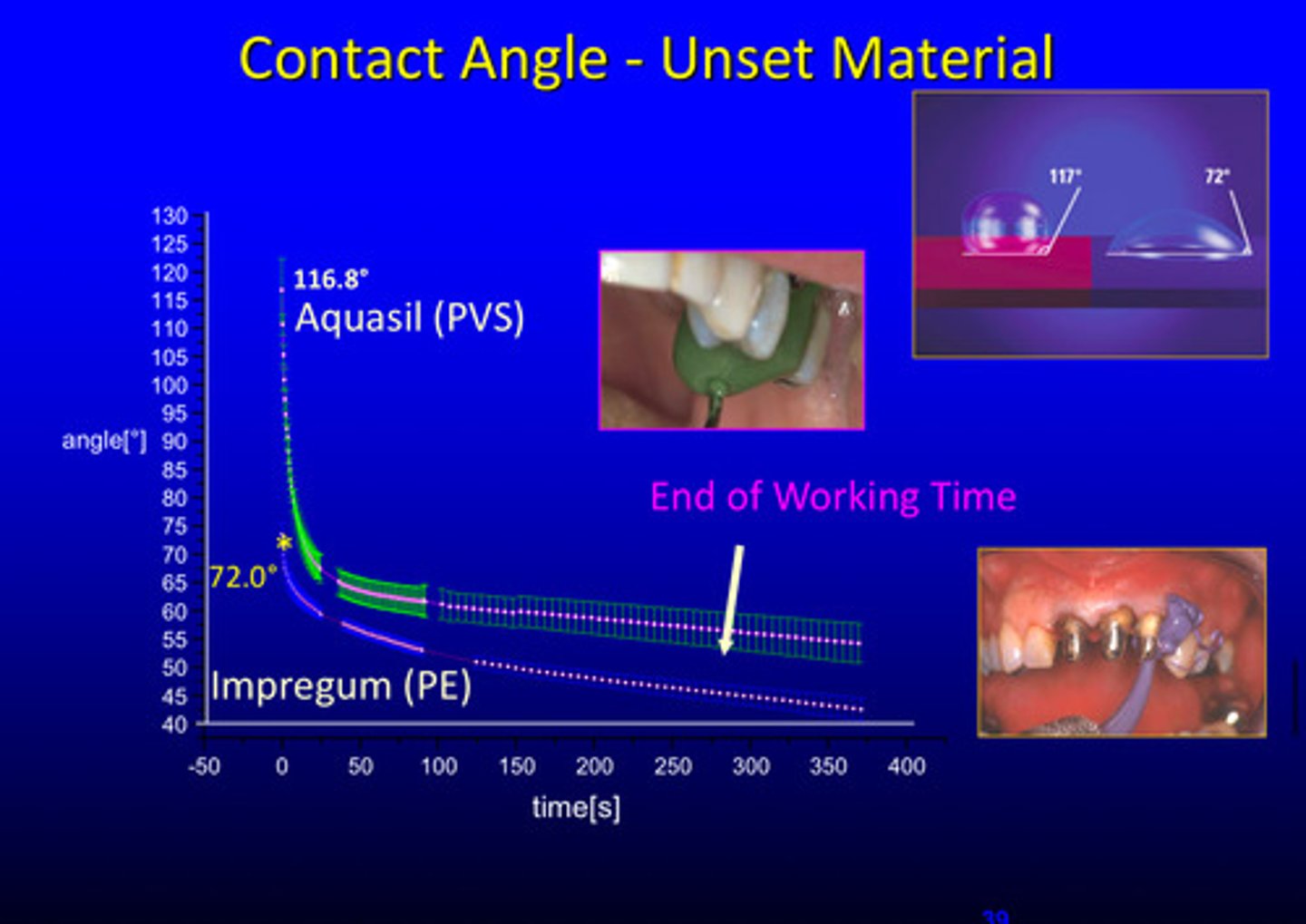

contact angle changes of unset material will… (inc/dec w time)

dec (72) as time inc (to the end of working time)

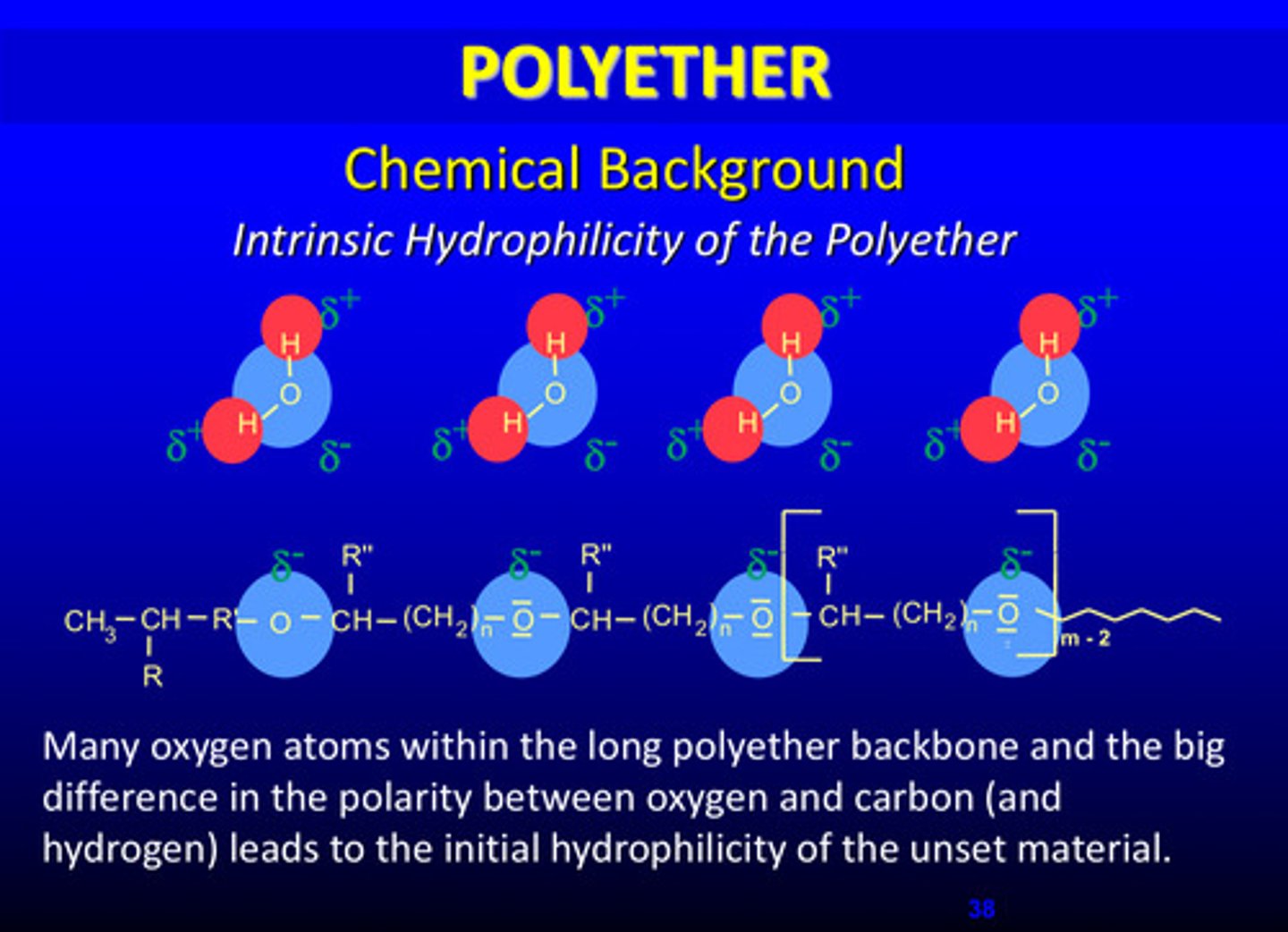

describe the chemical background of the intrinsic hydrophilicity of the polyether

many oxygen atoms within the long polyether backbone and a big difference in the polarity between oxygen and carbon (and hydrogen) leads to initial hydrophilicity of the unset material

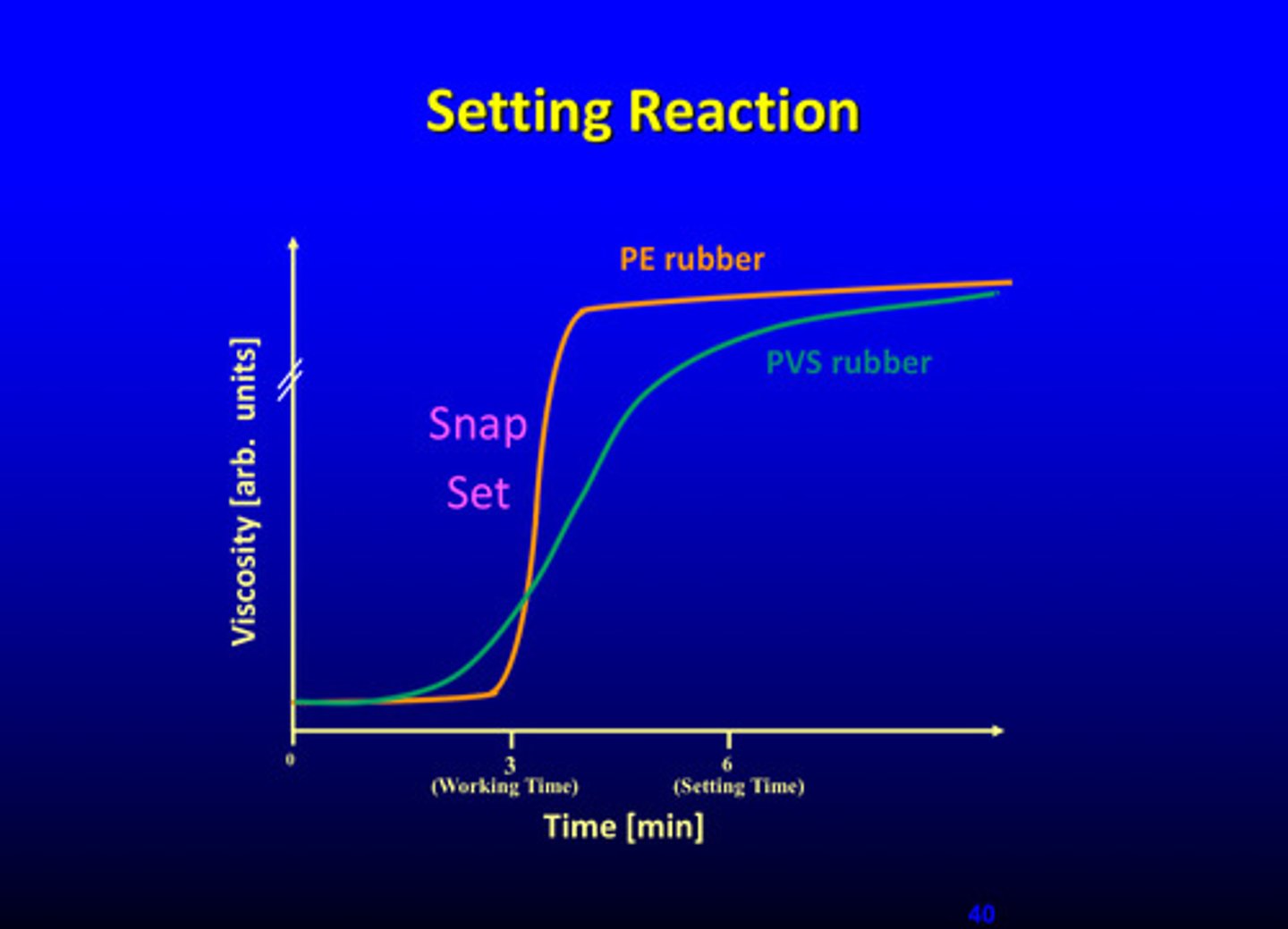

viscosity changes during setting reaction, compare PE and PVS rubber

PE rubber has higher viscosity than PVS

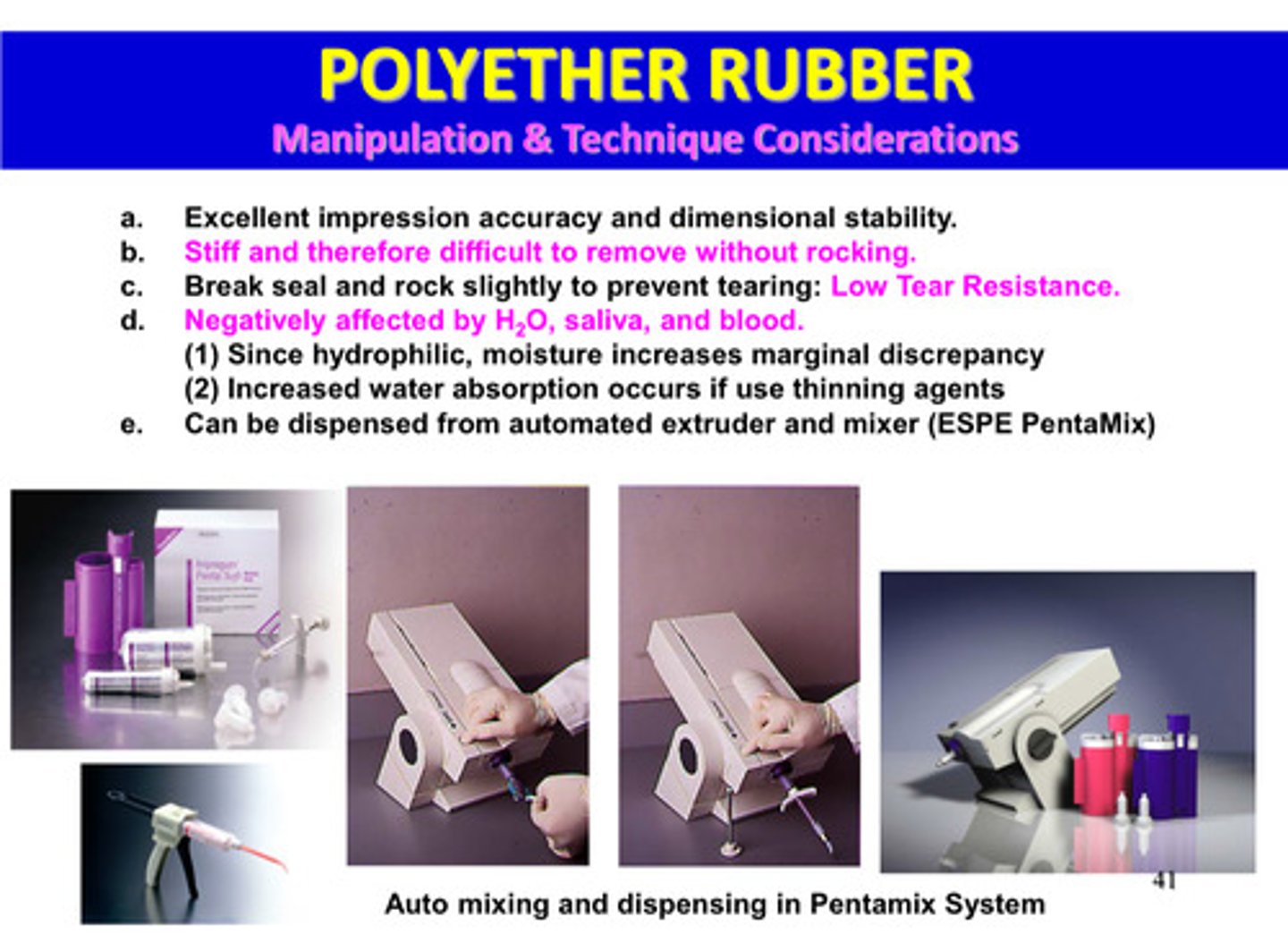

what are 5 polyether rubber manipulation and technique considerations

1) excellent impression accuracy and dimensional stability

2) stiff and therefore difficult to remove without rocking

3) break seal and rock slightly to prevent tearing: LOW tear resistance

4) negatively affected by H2O, saliva, and blood: since hydrophilic, moisture increases marginal discrepancy and increased water absorption occurs if thinning agents are used

5) can be dispensed from automated extruder and mixer (ESPECIALLY PentaMix)

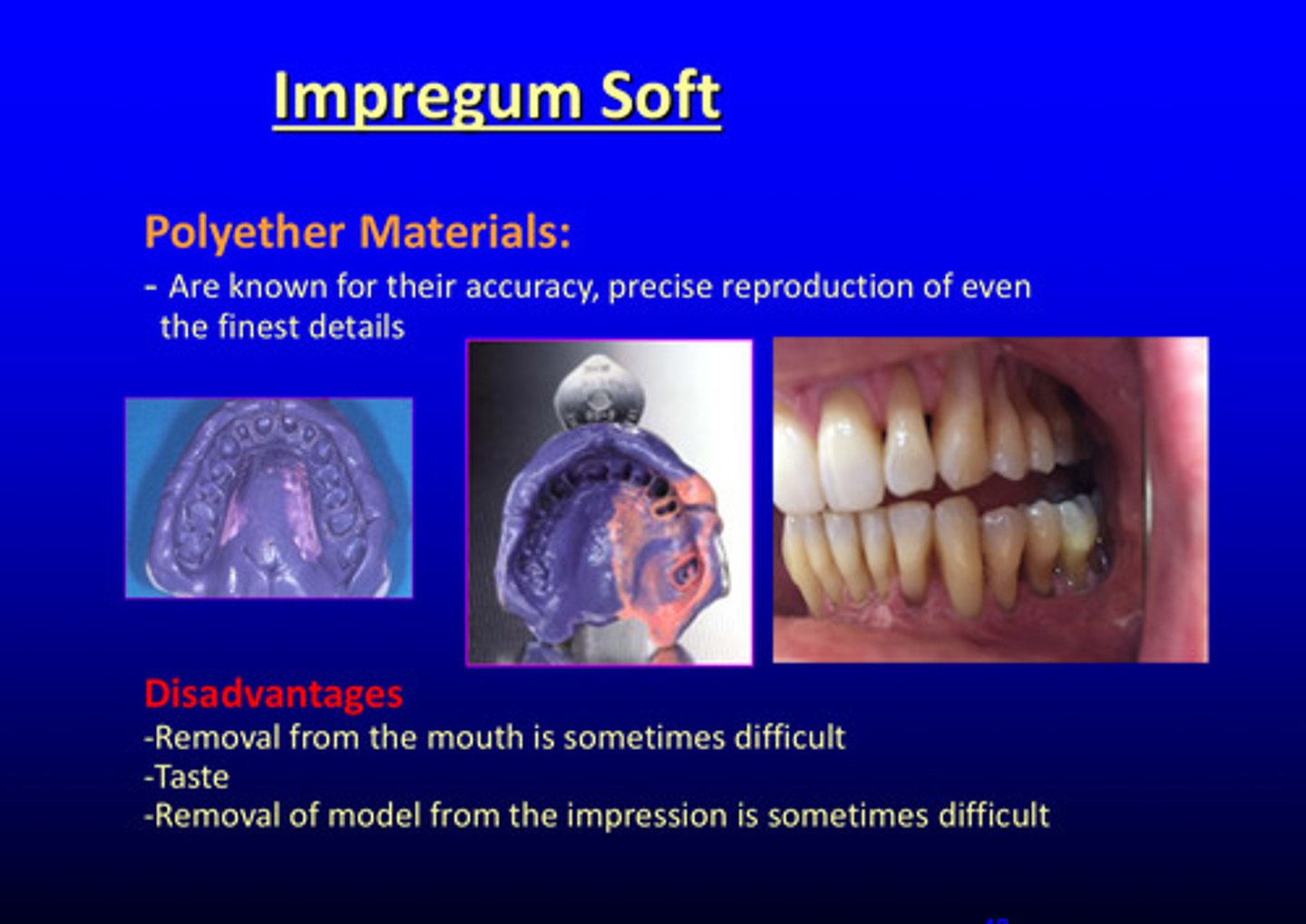

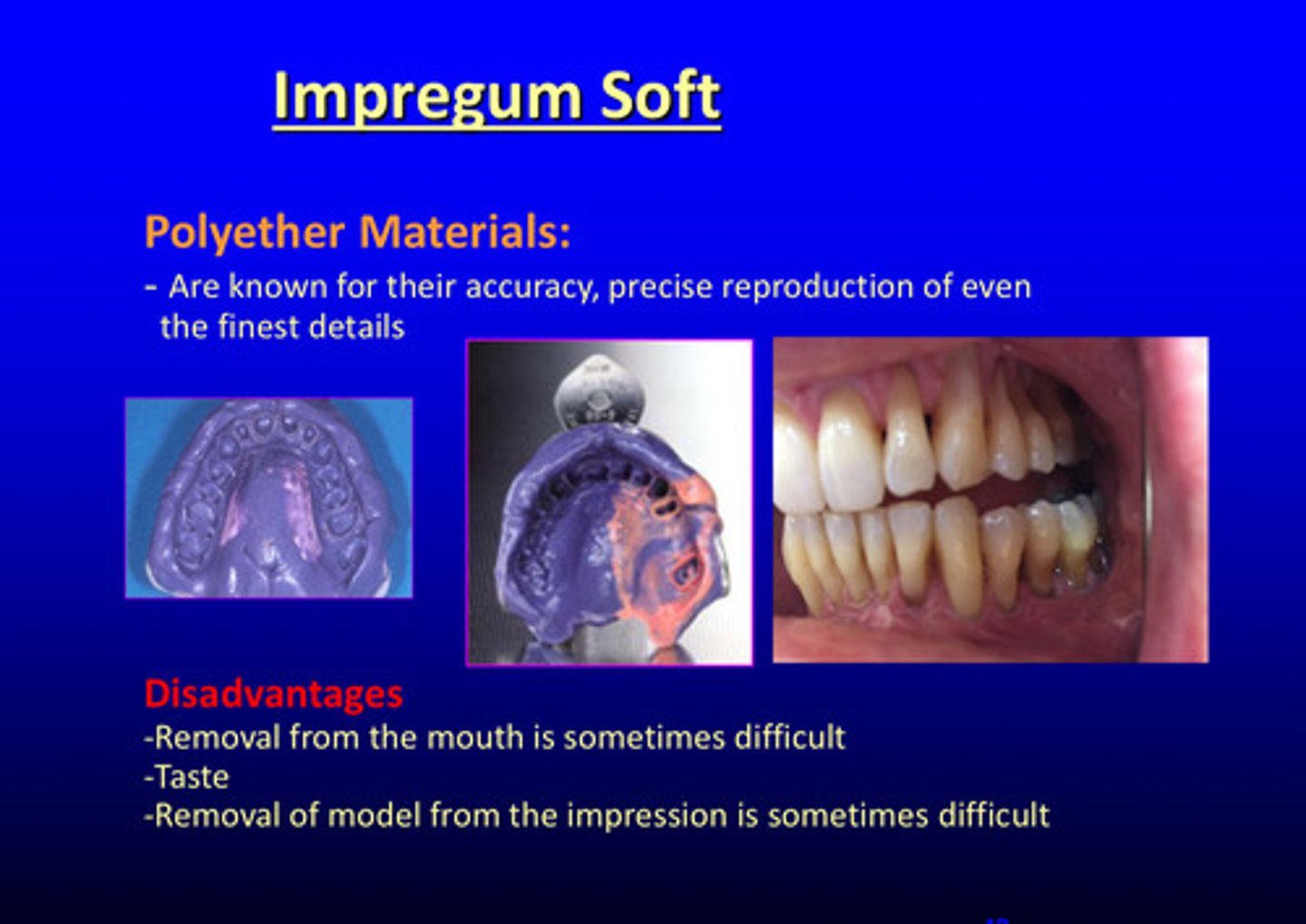

what are polyether materials known for

their accuracy and precise reproduction of even the finest details

what are the 3 disadvantages of polyether materials

1) removal from the mouth is sometimes difficult

2) taste

3) removal of model from the impression can be difficult

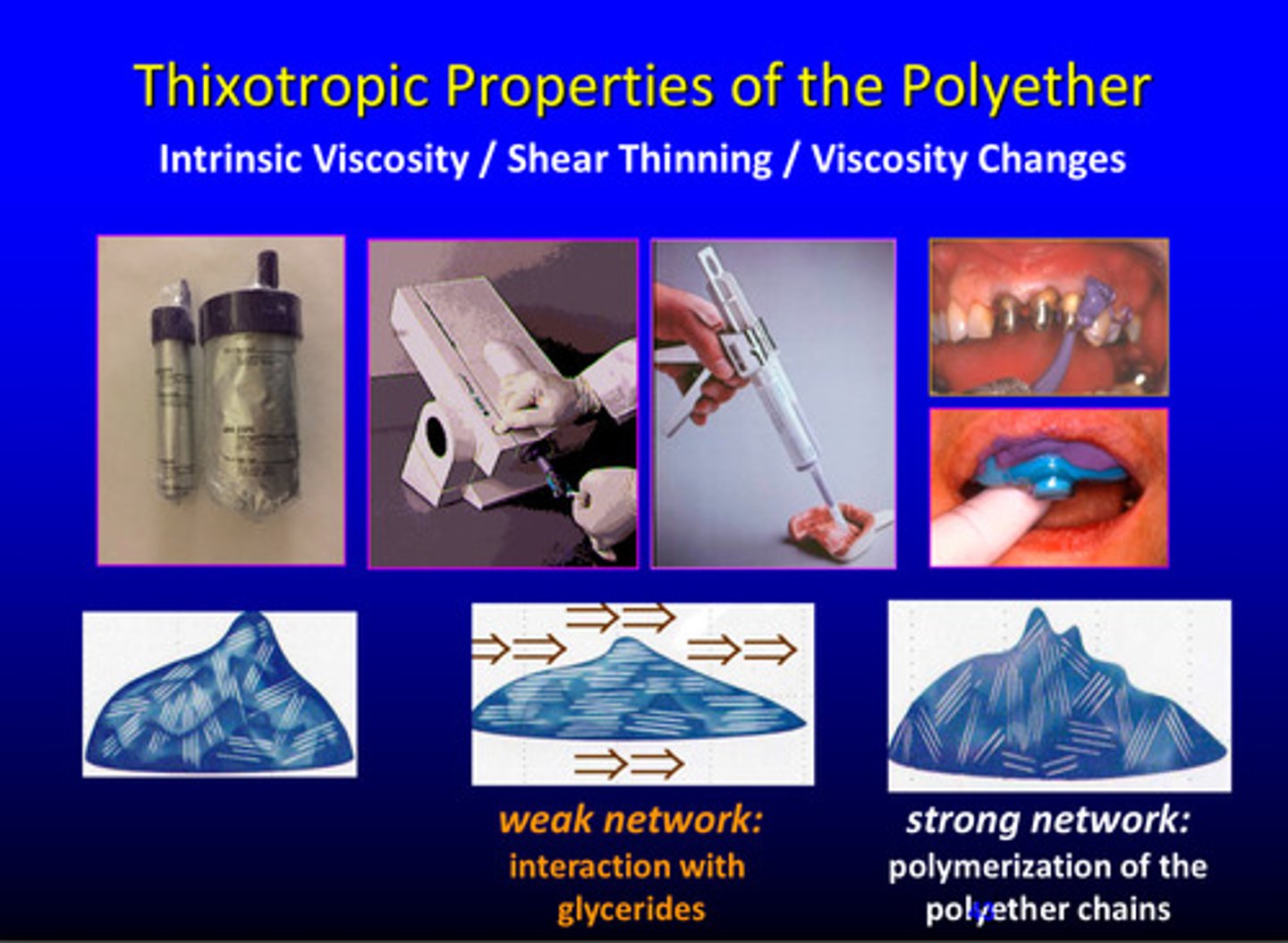

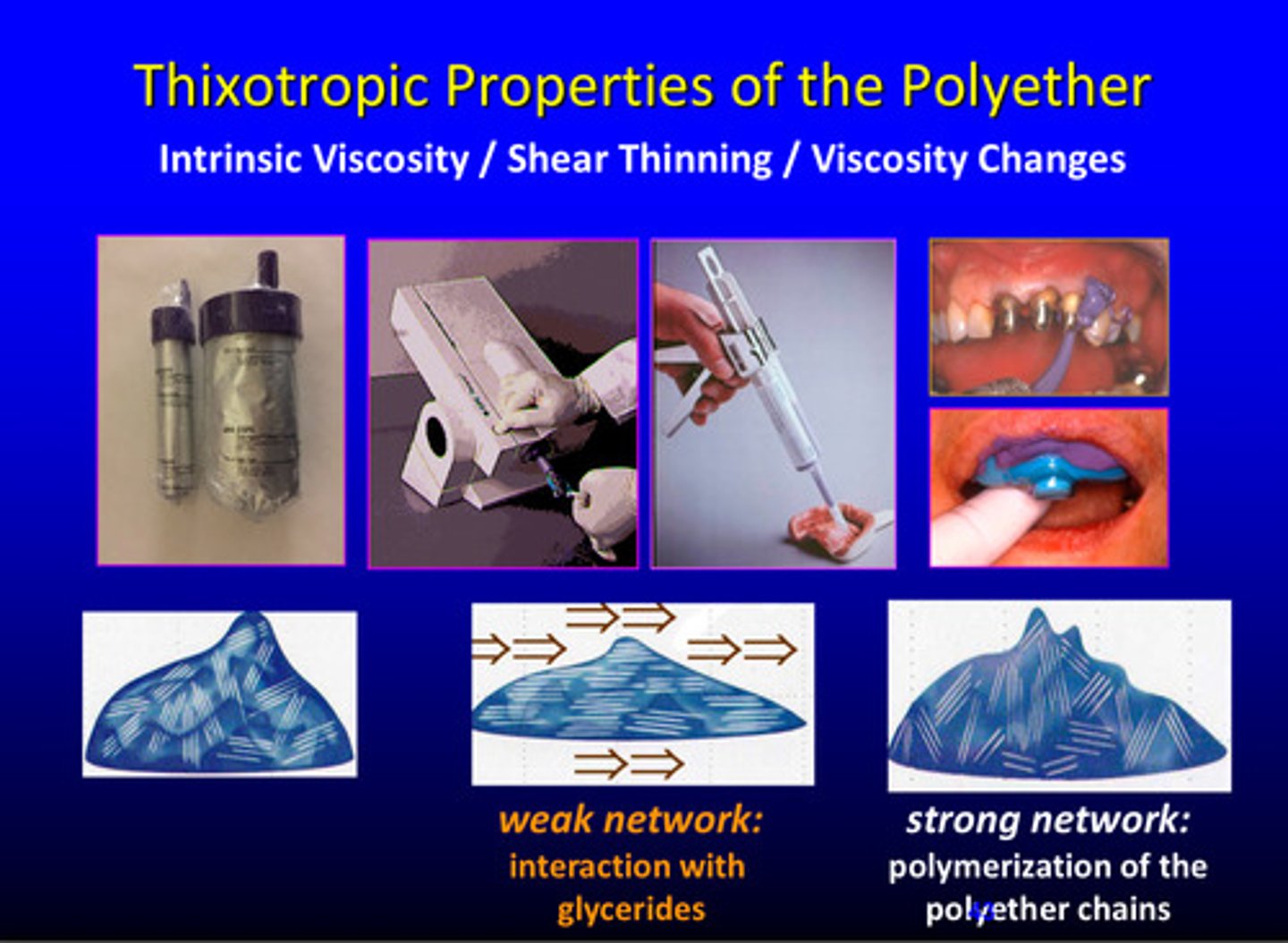

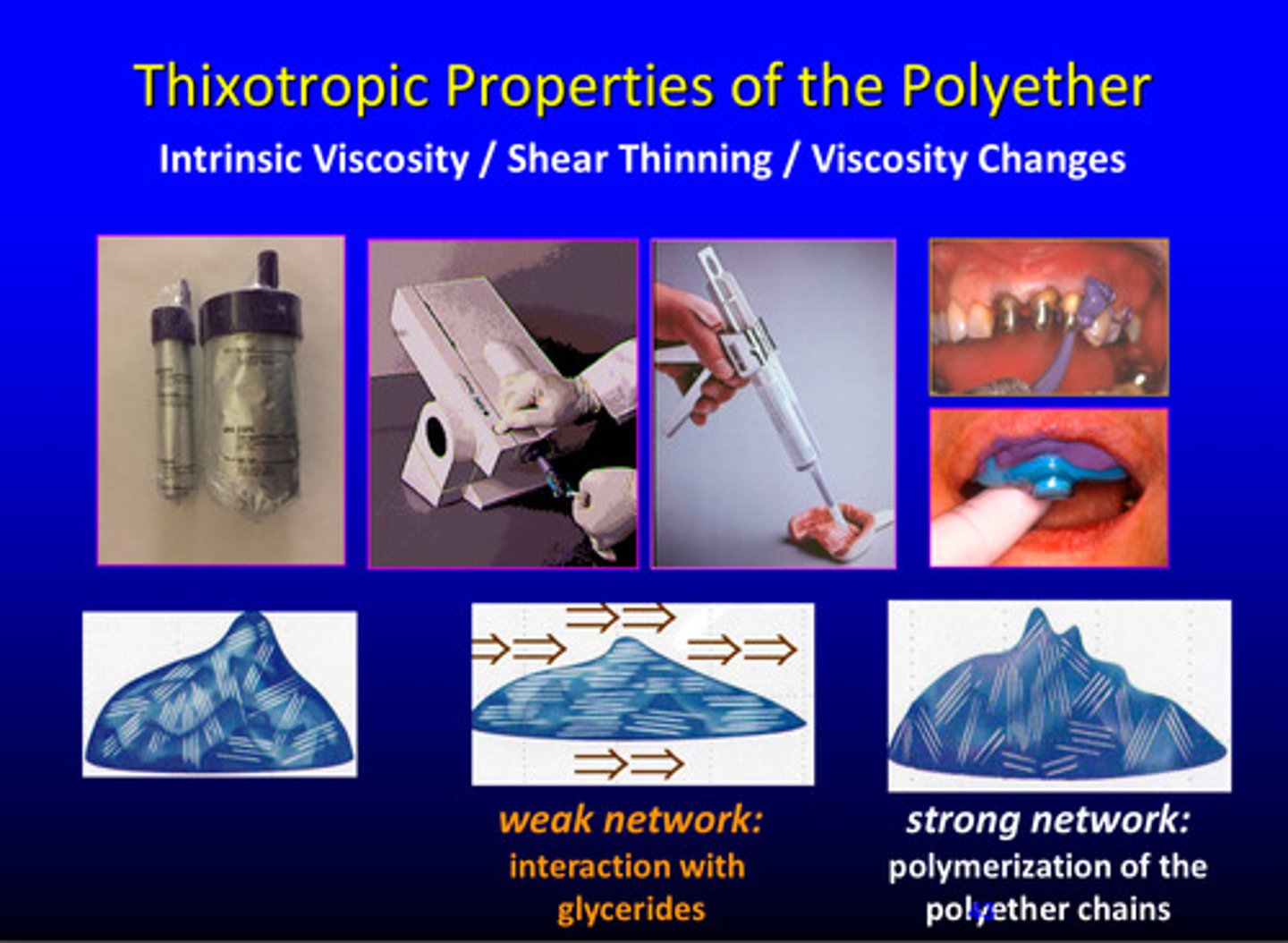

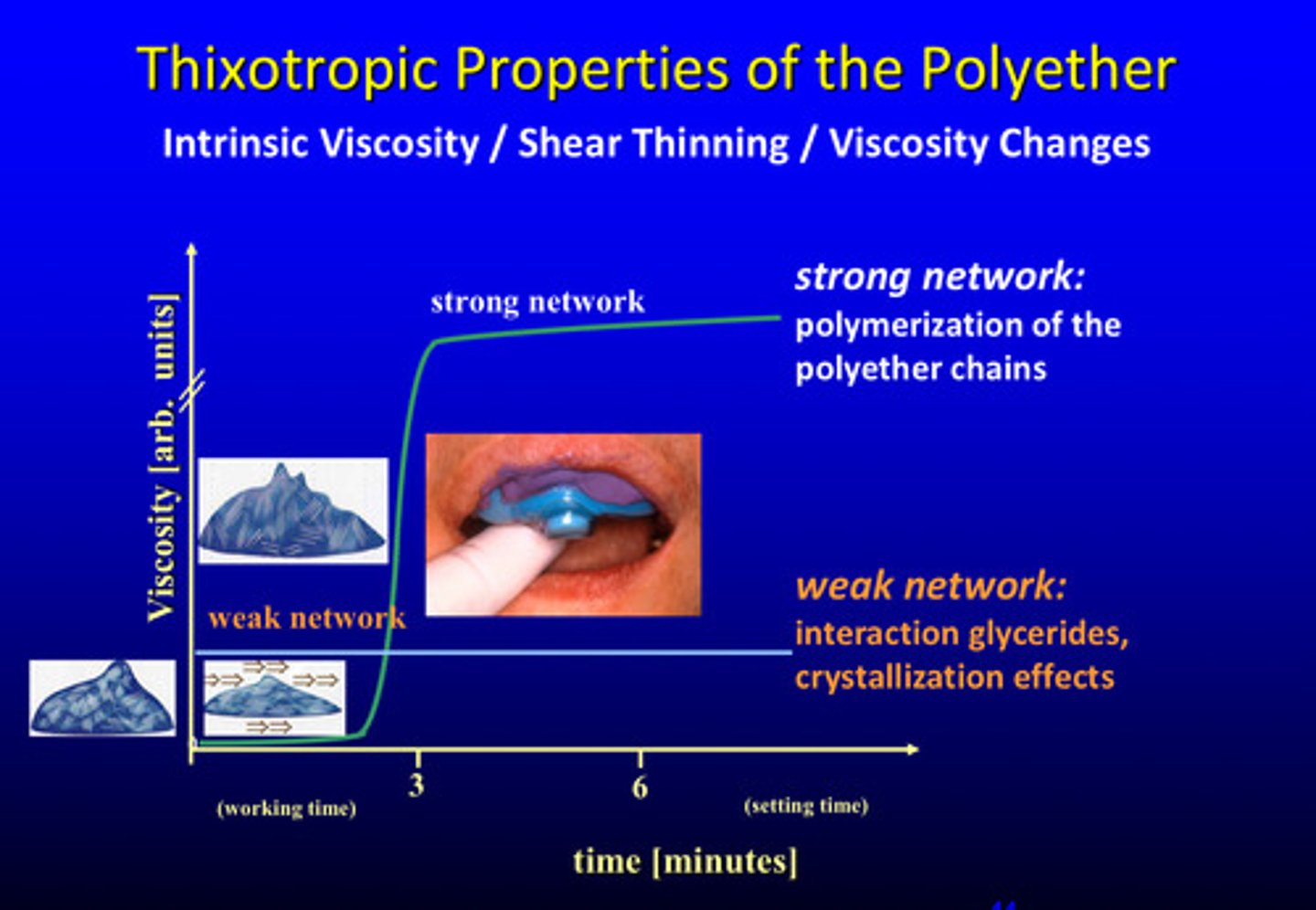

what are the thixotropic properties of the polyether (3)

intrinsic viscosity, shear thinning, and viscosity changes

what is the weak network of the polyether

interaction with glycerides

what is the strong network of the polyether

polymerization of the polyether chains

strong vs weak network of polyether

strong polymerization of polyether chains

weak interaction glycerides, crystallization effect

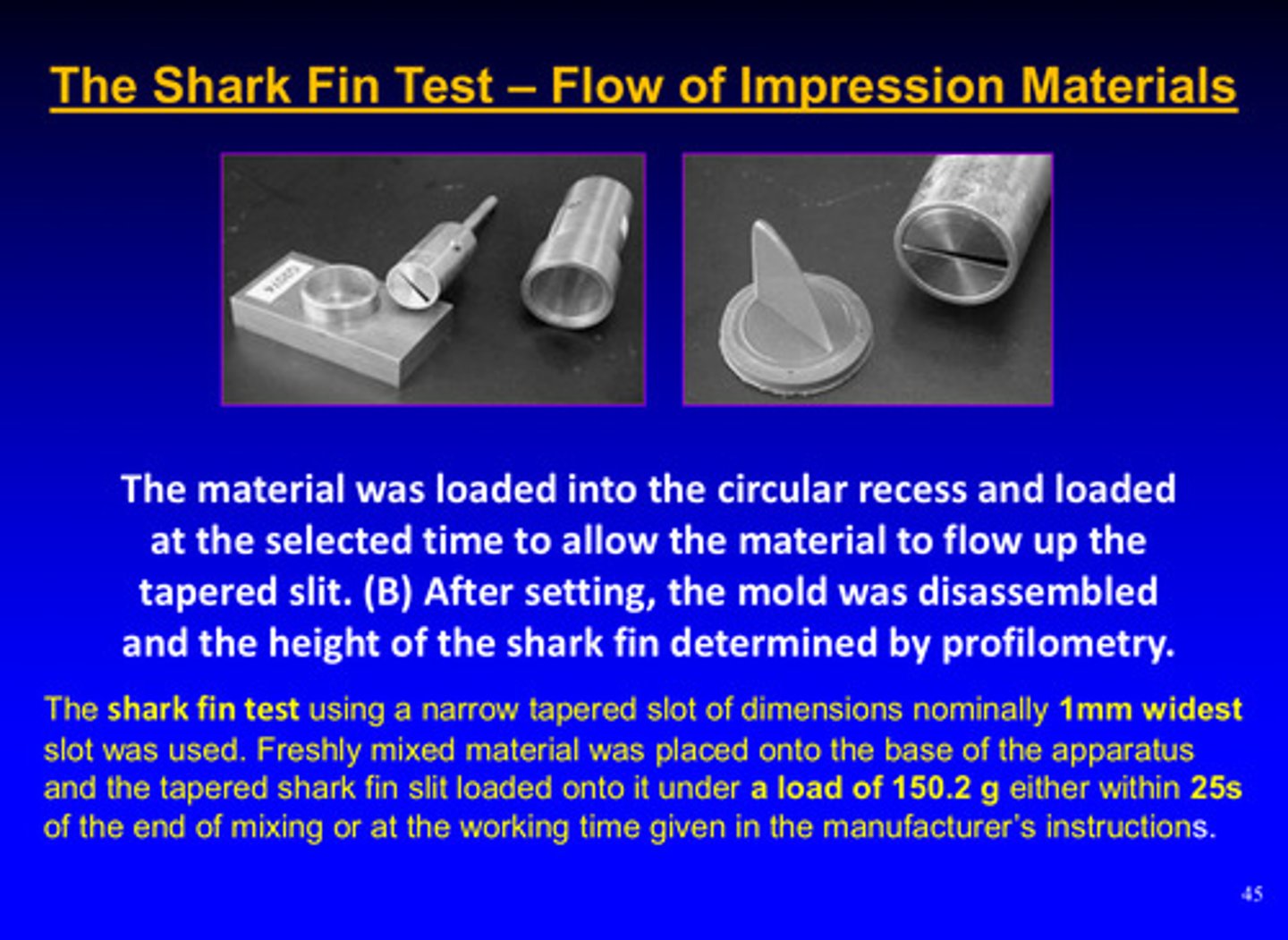

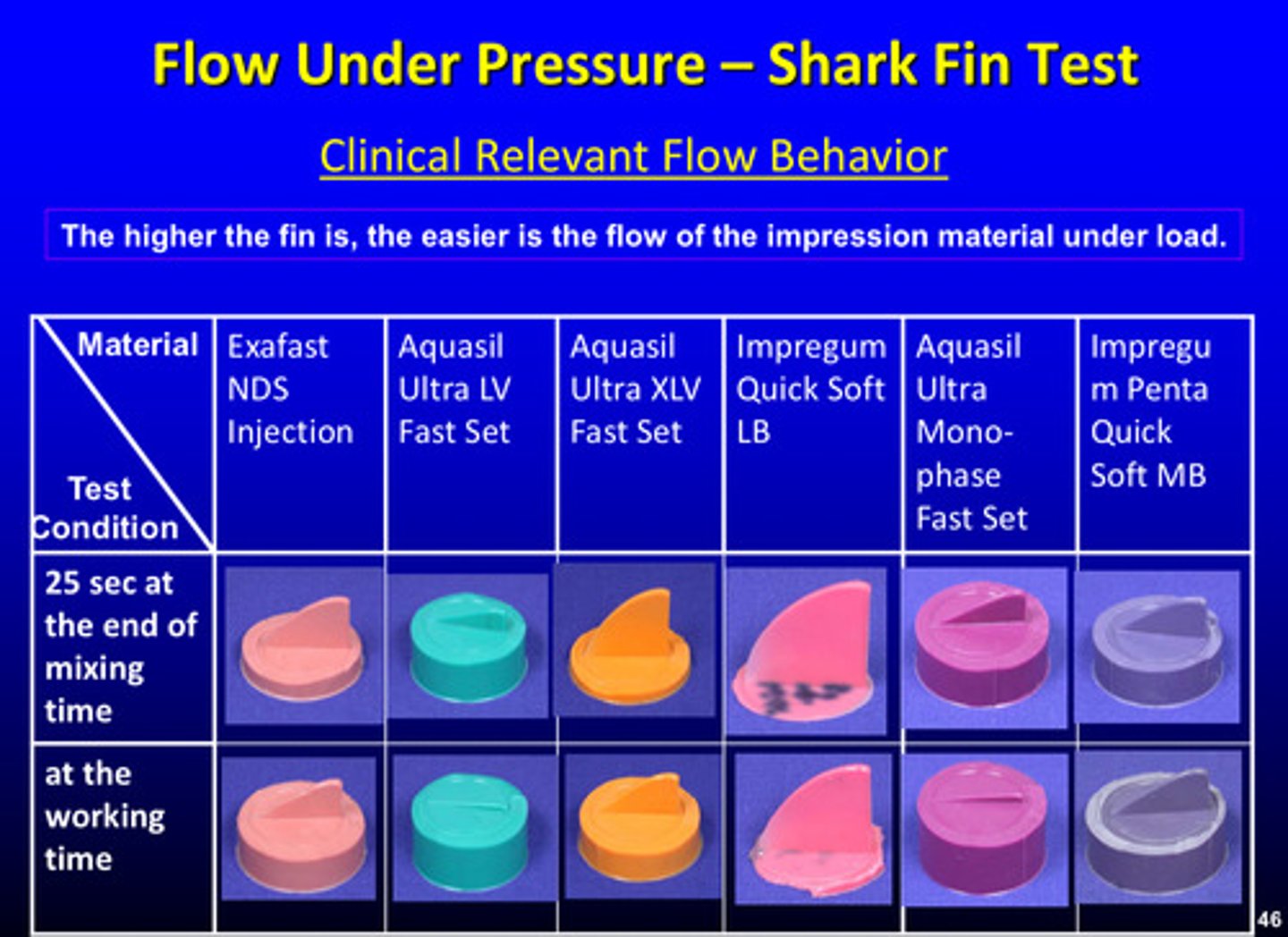

describe the shark fin test

material is loaded into the circular recess and loaded at the selected time to allow the material to flow UP the tapered slit; after setting, the mold is disassembled and the height of the shark fin is determined by profilometry

shark fin test: the higher the fin is, the easier…

the flow of the impression material under load

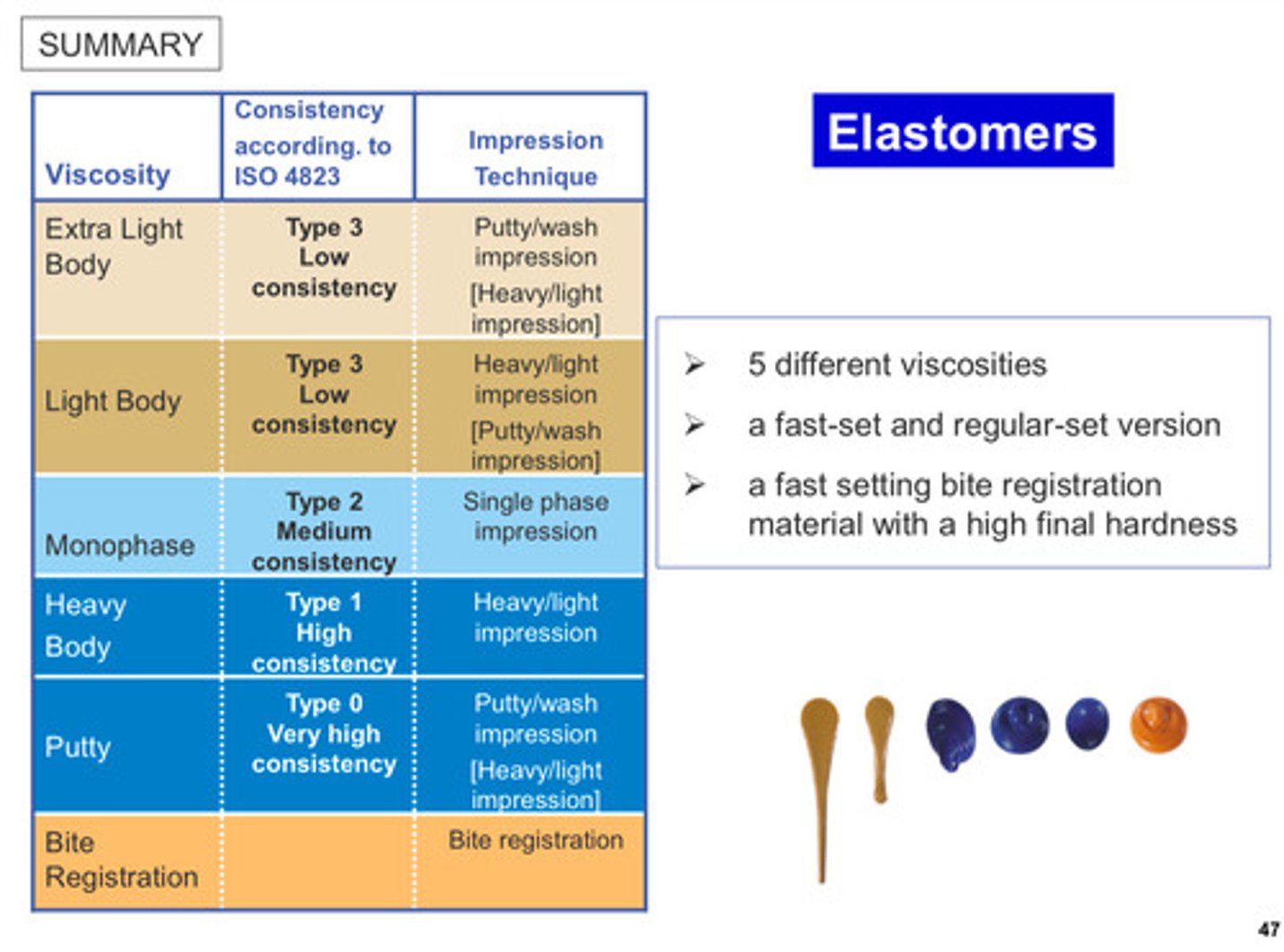

summary of elastomers with different viscosities (3 points)

1) 5 different viscosities

2) fast-set and regular-set version

3) fast setting bite registration material with a high final hardness

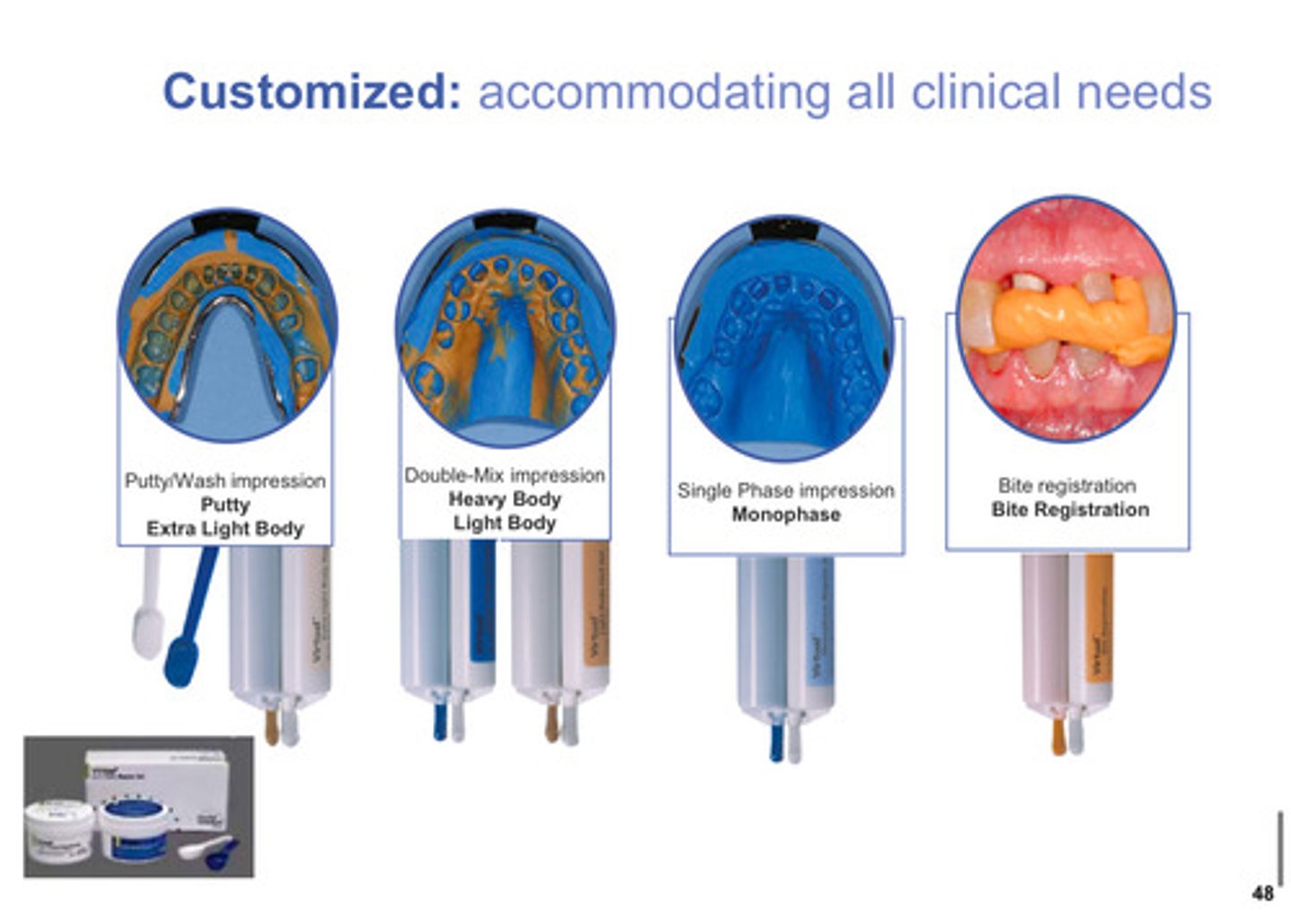

elastomers can be _________ to accommodate all clinical needs

customized

putty/wash (2 step) impression technique, what materials are needed

putty impression/trim → extra light body

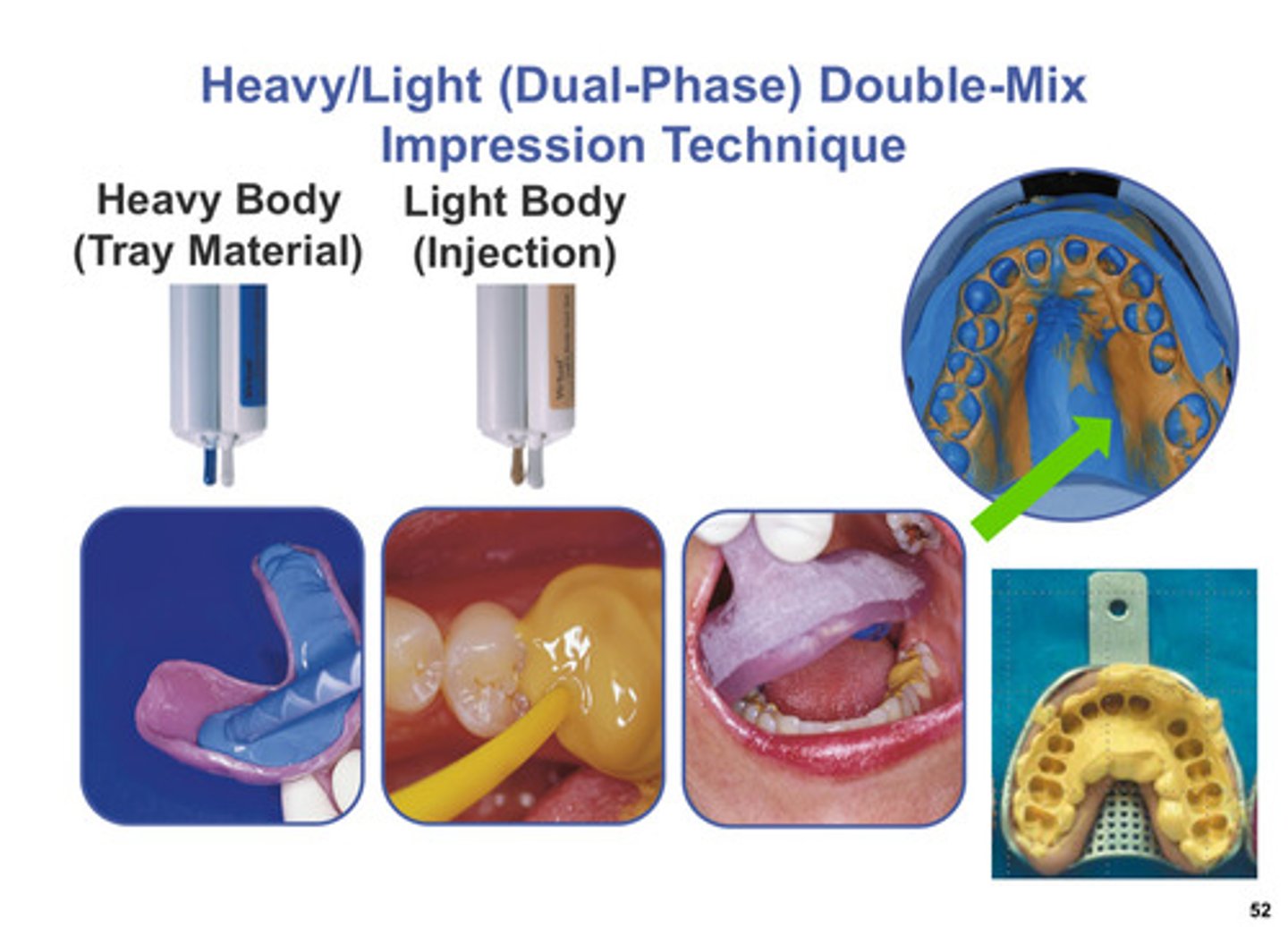

heavy/light (dual phase) double mix impression technique

place heavy body in tray and light body on teeth, then take impression

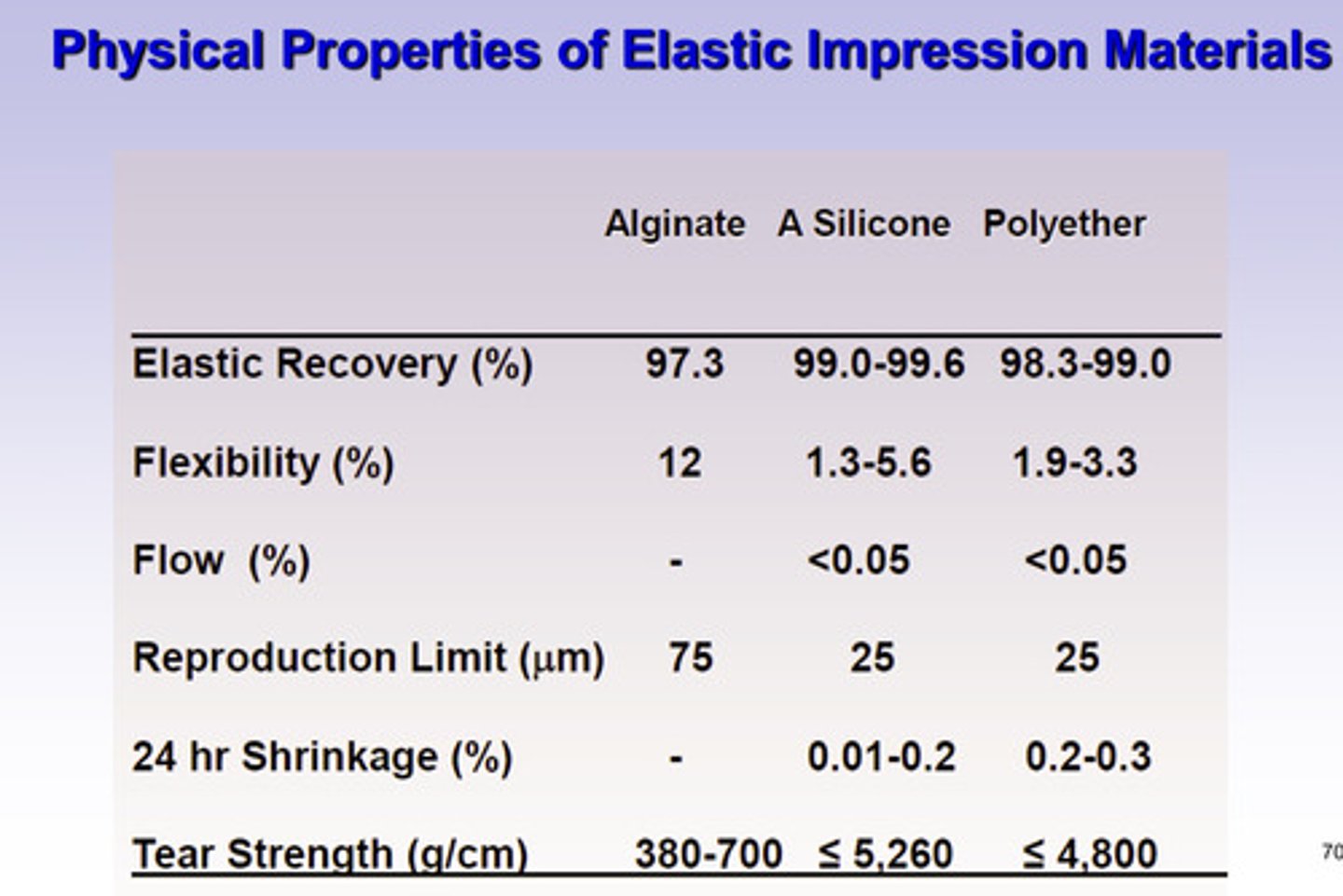

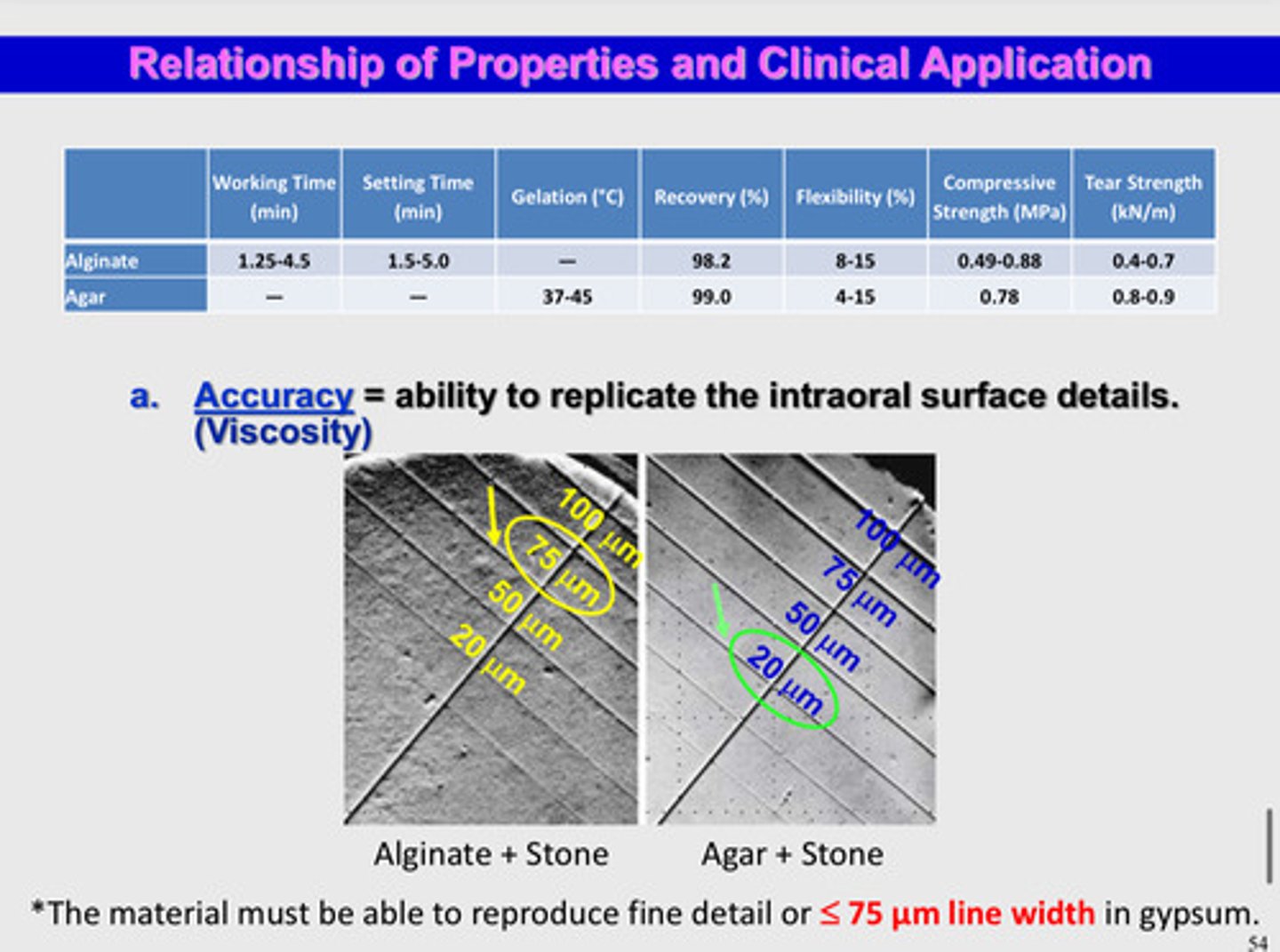

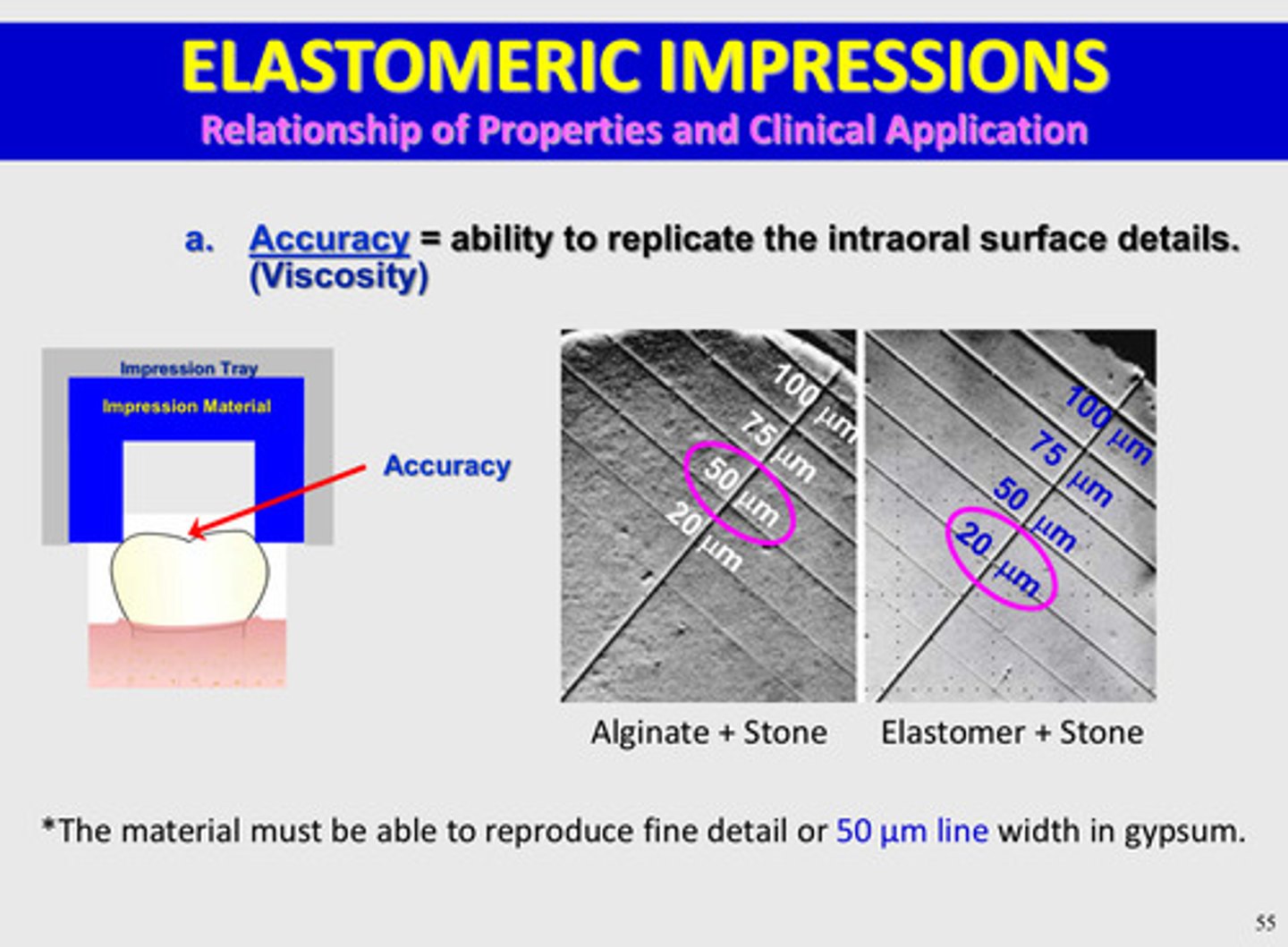

recall for alginate hydrocolloid: in terms of accuracy, the material must be able to reproduce fine detail or _______ line width in gypsum

75 um

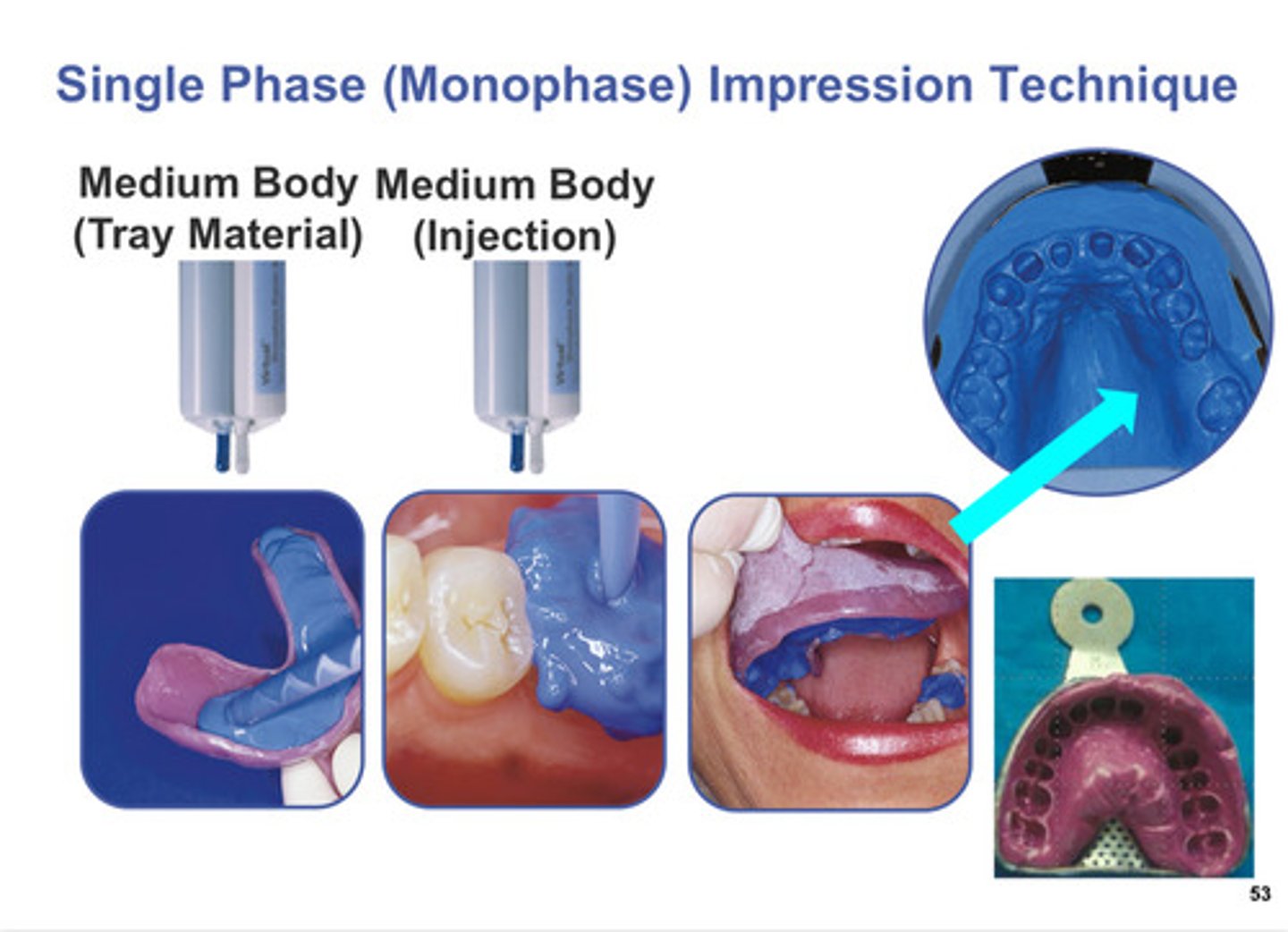

single phase (monophase) impression technique, you use what type of “body”

Medium body: put into tray and pt mouth, then take impression

for elastomer: in terms of accuracy, the material must be able to reproduce fine detail or _______ line width in gypsum

50 um

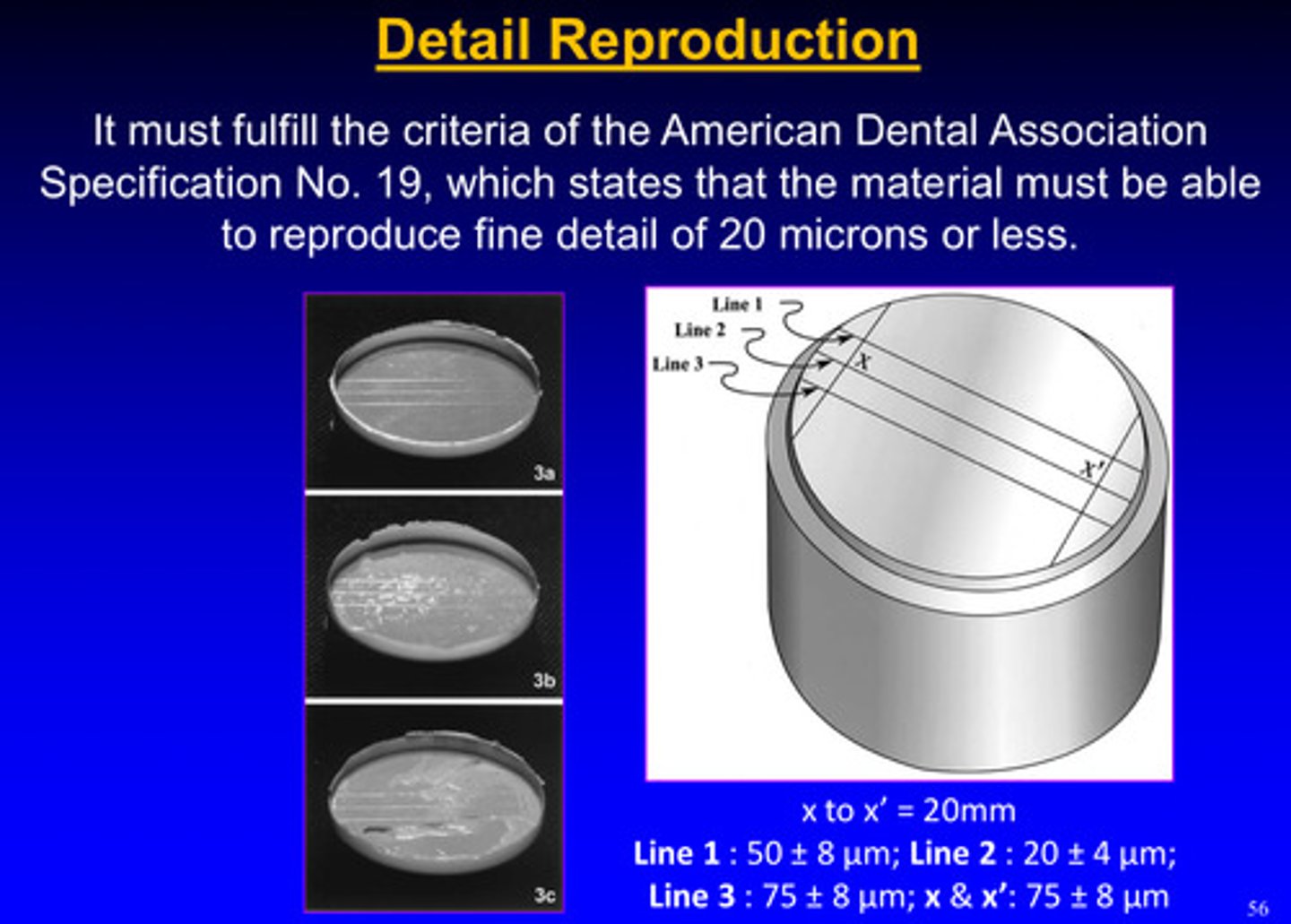

what is the ideal level of detail reproduction of elastomers

material must be able to reproduce fine detail of

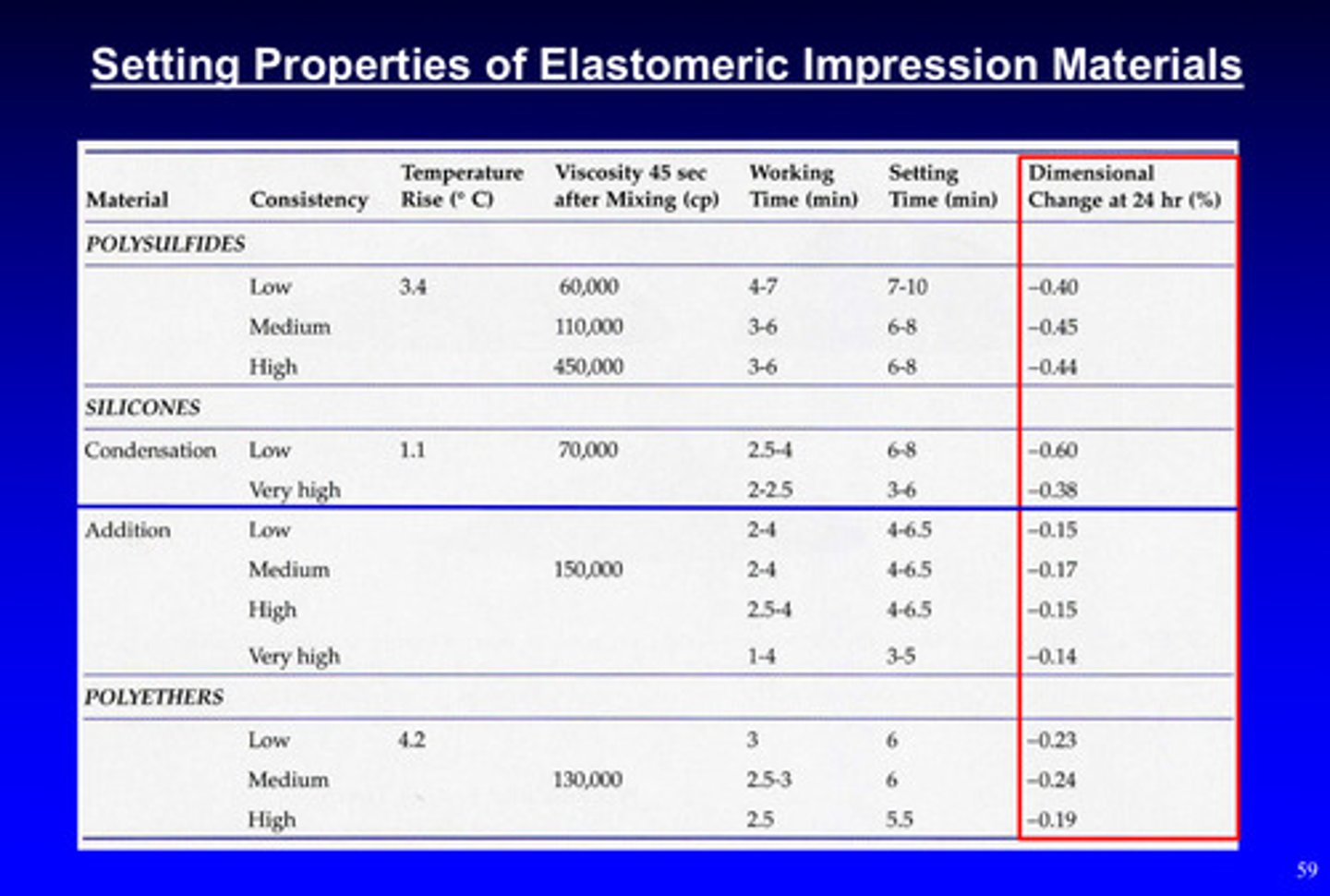

dimensional change of elastomeric impression materials

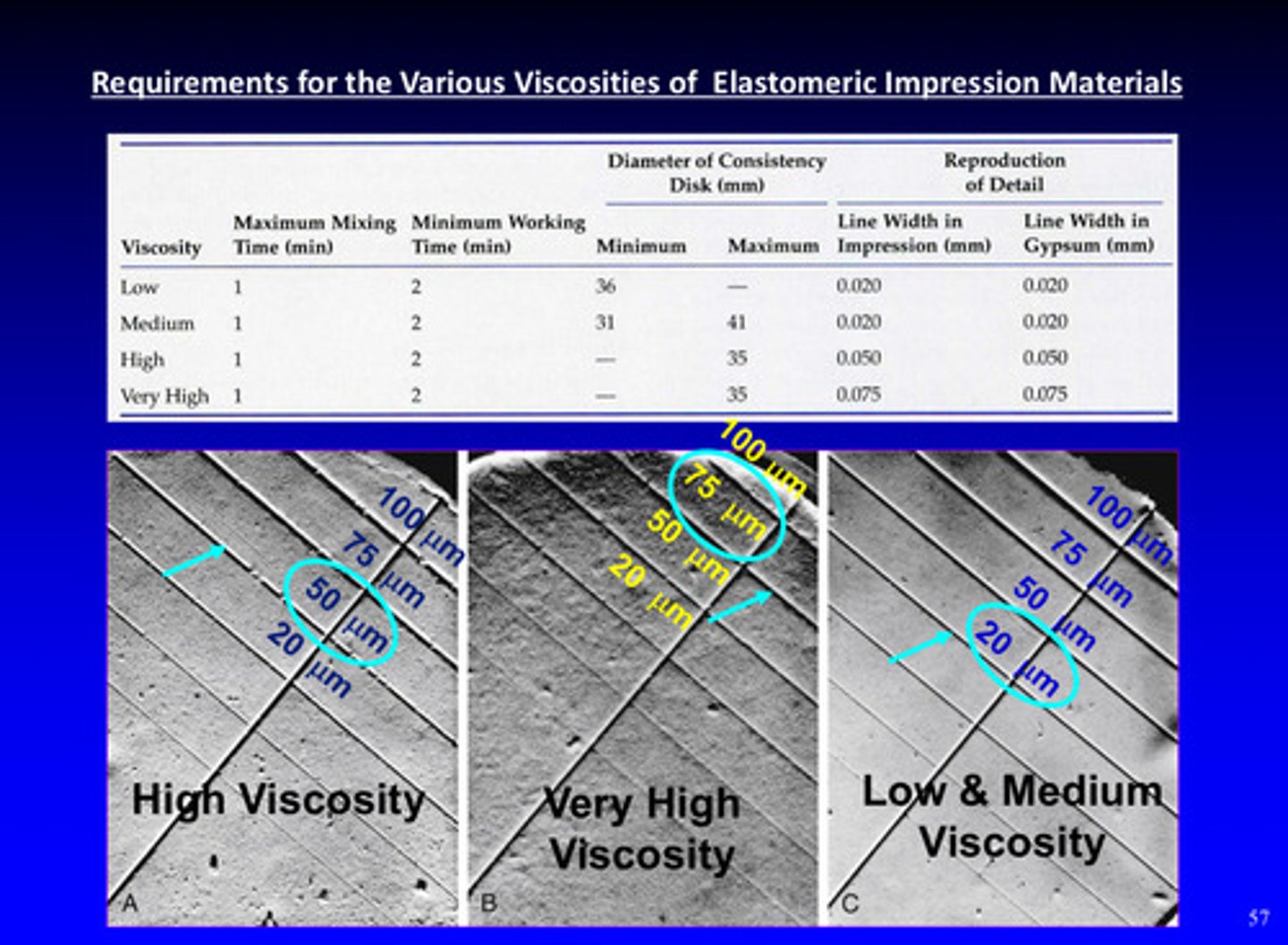

requirements of various viscosities of elastomeric impression materials

very high viscosity: 75 um

high viscosity: 50 um

low/medium viscosity: 20 um

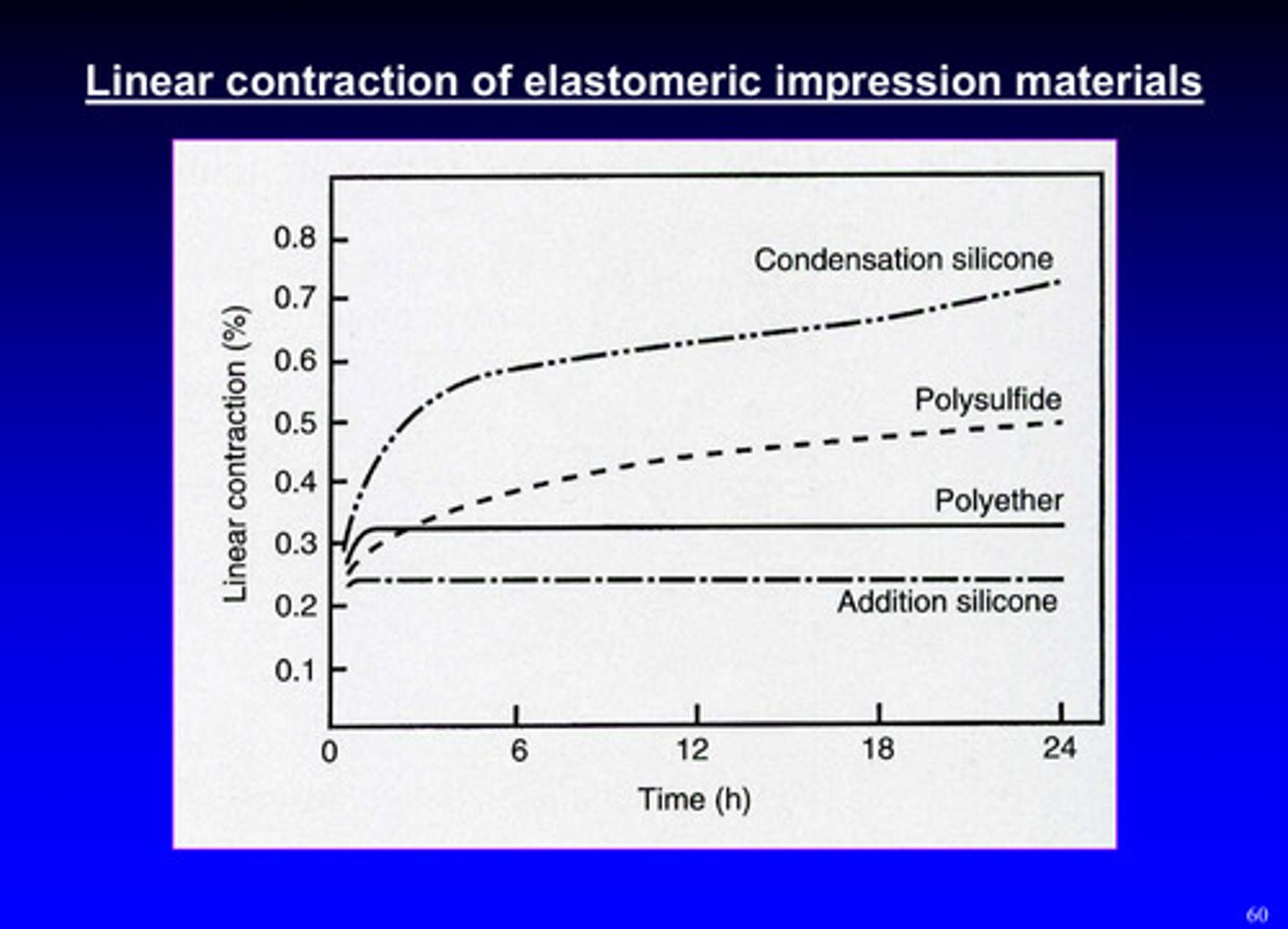

linear contraction of elastomeric impression materials, rank highest to lowest linear contraction including the following:

condensation silicone, addition silicone, polyether, polysulfide

condensation silicone > polysulfide > polyether > addition silicone

elastomeric impression materials are viscoelastic, and their mechanical properties are ______ dependent, meaning…

time; the longer the impressions are deformed, the higher the permanent deformation

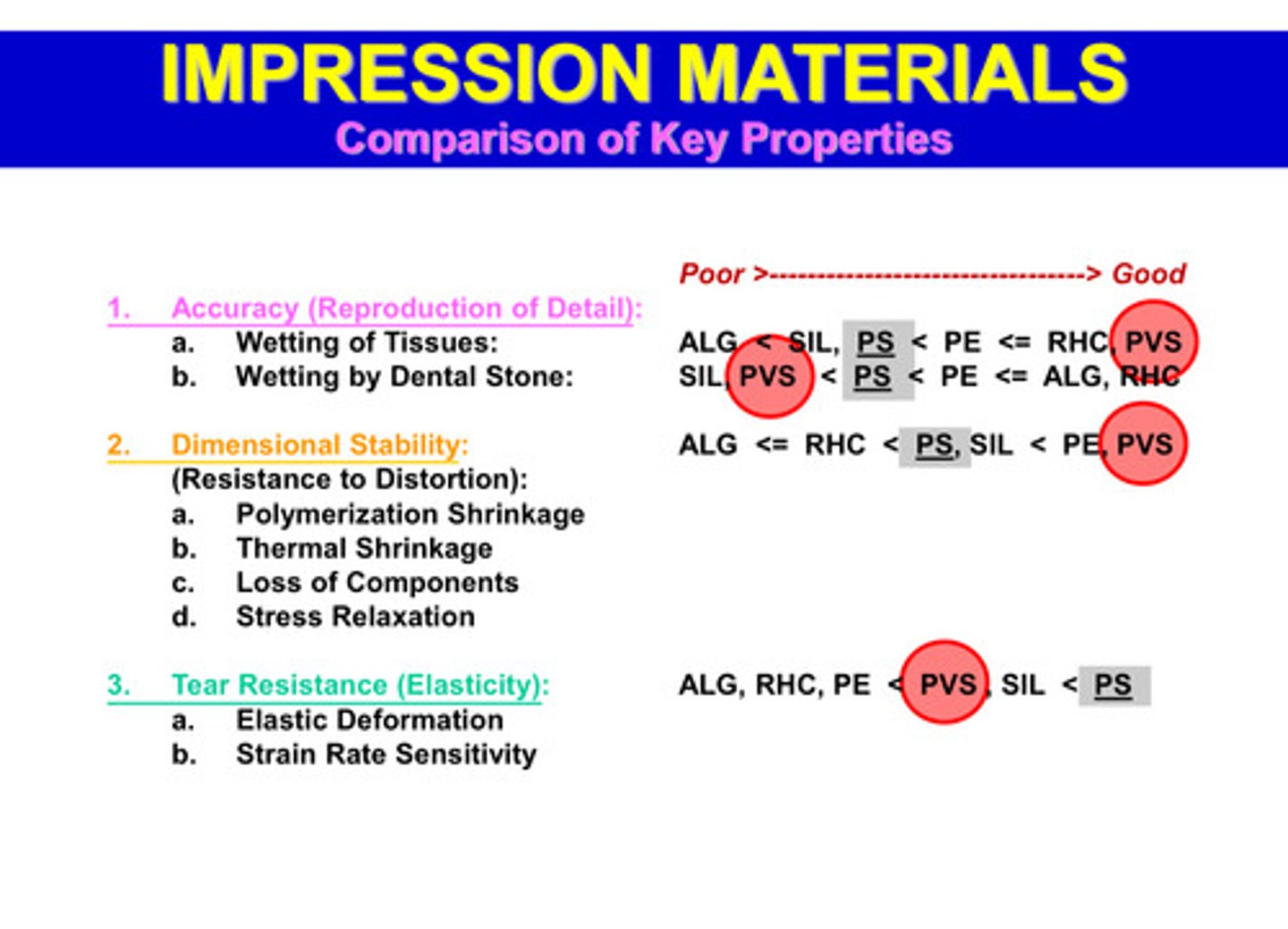

when thinking of the key properties of PVS, it is better than most materials in two things…

better at wetting of tissues, better dimensional stability

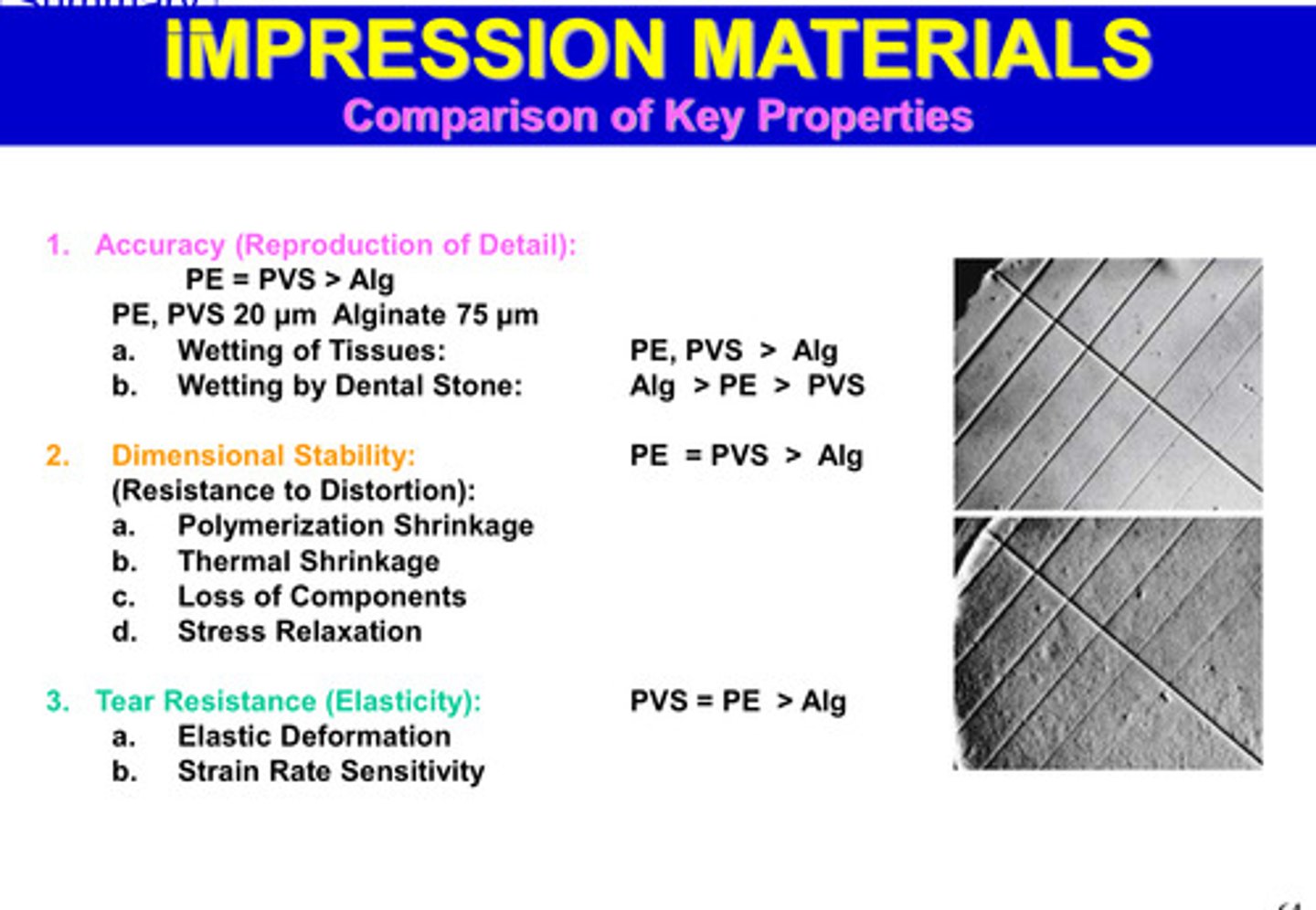

comparison of key properties of PE and PVS have higher …….. compared to alginate

PE, PVS have higher accuracy, dimensional stability, and tear resistance

alginate is more _______ and has a higher _____________ rate

flexible; reproduction