supply chain logistics SCL-3323-01-202530 Topic Guide: Exam 1

1/43

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

44 Terms

controlled decisions

Day-to-day decisions that define how an operation runs, focusing on efficiency, material flow, and quality assurance

design decisions

Long-term, strategic decisions that determine where and how a firm deploys its assets (infrastructure) to create value. T

Differences between Product and Service Operations

Product operations create tangible, storable goods (inventory), and consumption typically follows production.

Service operations create intangible outputs, often involve direct customer interaction, and are consumed simultaneously with production.

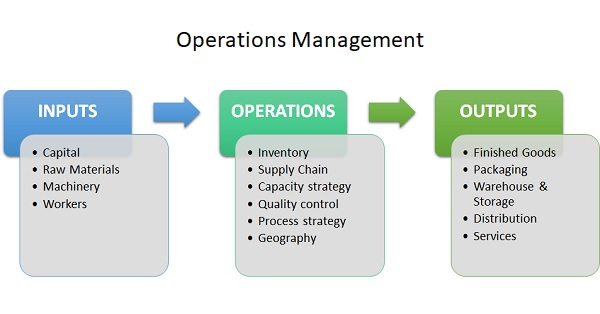

Input/Output Model of Operations

A conceptual model where various inputs (materials, labor, capital, information) are transformed through a process (operations) into desired outputs (goods or services).

The Internet of Things (IoT)

A network of physical objects ("things") embedded with sensors, software, and other technologies for the purpose of connecting and exchanging data with other devices and systems over the internet.

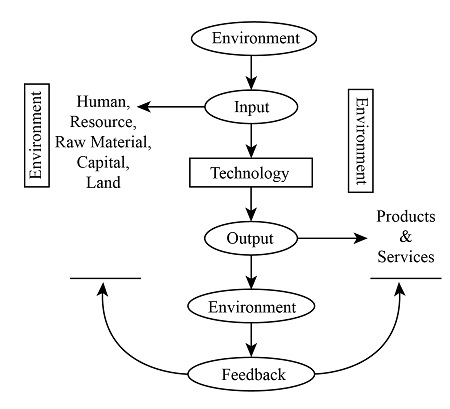

open systems model

A view of an organization or operation that emphasizes its continuous interaction with its external environment (suppliers, customers, competitors, government, etc.). It is constantly receiving feedback and adapting.

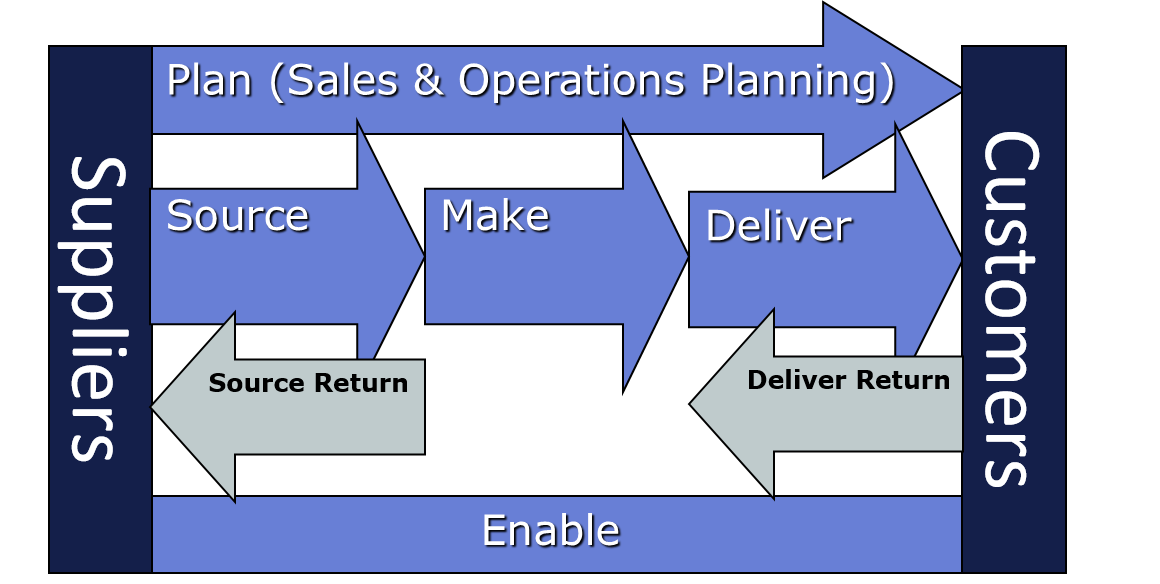

The SCOR model

Standing for Supply Chain Operations Reference model, it's a management tool for addressing, improving, and communicating supply chain management practices.

supply chain tiers

A method of classifying a company's suppliers based on their proximity to the final manufacturing or assembly process.

A Tier 1 Supplier provides directly to the manufacturer (e.g., an engine builder for a car company).

Tier 2 Supplier provides materials or components to the Tier 1 Supplier (e.g., a producer of pistons to the engine builder).

Customer Satisfaction, Service and Success

Satisfaction is meeting expectations;

Service refers to the activity of supporting the customer (e.g., technical support)

Success is the ultimate goal—helping the customer achieve their own objectives using your product/service.

Five Dimensions of Value

Cost (or Price)

Quality

Delivery (or Time)

Agility (or Flexibility)

Innovation.

The Eight Factors of Quality

Performance,

Features

Reliability

Conformance

Durability

Serviceability

Aesthetics

Perceived Quality.

The four utilities

The economic value added to a product or service through supply chain and logistics activities.

Time Utility (available when needed)

Place Utility (available where needed)

Quantity Utility (available in the right amount)

Possession Utility (transfer of ownership, facilitated by marketing/sales).

Means of Measuring Customer Wants

Methods used to gather information about customer needs and preferences.

EX: Market research, surveys, focus groups, customer interviews, analysis of sales data, and social media monitoring

Offshoring v. Outsourcing

Outsourcing is contracting a business process to an outside provider (internal or external to your country).

Offshoring is relocating a business process to a different country (often to reduce labor costs), whether it's done by the firm or a third party.

Order Disqualifiers, Qualifiers and Winners

Criteria that determine a product's success in the marketplace.

Disqualifiers are characteristics that make a product unacceptable.

Qualifiers are the minimum standards needed to be considered by the customer.

Winners are the criteria that ultimately win the customer's business.

Pareto Analyses

A technique stating that roughly 80% of effects come from 20% of the causes. Used to prioritize efforts in quality management, inventory, and sales.

EX: Identifying the 20% of customers who generate 80% of sales to focus resources on retaining them.

Balanced Score Cards (BSC)

A strategic performance management tool that measures organizational performance beyond just financial metrics. It provides a balanced view across four perspectives.

The four perspectives are:

Financial

Customer

Internal Business Process

Learning & Growth.

Benchmarking

process of comparing one's own business processes and performance metrics (e.g., quality, time, cost) against industry bests or best practices from other companies.

CSFs v. KSIs

Critical Success Factors (CSFs) are the few key areas where a company must perform well to achieve its mission.

Key Success Indicators (KSIs) are the metrics used to measure the achievement of the CSFs

Total Costs (Landed Costs)

The total cost of a product once it has arrived at the buyer's or final destination, including: the original purchase price, transportation fees, customs duties, insurance, and other charges.

bottleneck

The point in a production or supply chain process that limits the overall capacity or speed of the entire system. It's where the work-in-process piles up.

Process Maps

A workflow diagram used to visually represent the steps, sequence, and flow of activities in a process. They help in analyzing and improving operations.

Project Types (The Product Process Matrix)

A framework that links the volume and variety of products a firm produces to the type of process it uses.

Key types include:

Job Shop (high variety, low volume)

Batch (moderate variety/volume)

Assembly Line (low variety, high volume)

Continuous Flow (very low variety, very high volume).

Theory of Constraints (TOC)

A management philosophy that focuses on identifying and improving the most restrictive constraint (the bottleneck) to increase overall system throughput.

Throughput

The rate at which the system generates money through sales, or more generally, the rate at which a system processes work and generates output.

Definitions of Logistics

the part of supply chain management that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services, and related information between the point of origin and the point of consumption to meet customer requirements.

Tapering Principle

The principle that states that total freight costs increase with distance, but at a decreasing rate.

the cost per mile decreases as distance increases. This is a key principle of the Economy of Distance.

transportation modes

The different means or methods used to move freight between locations.

Rail

Truck (Motor Carrier)

Water (Ship)

Air

Pipeline.

Warehouse Types and Characteristics

warehouse- a generic term for a facility where product is stored

distribution center (DC)- combine inventory from multiple locations to mix and match to fulfill customers orders

cross-dock- receive incoming products and unload and reload on a waiting trailer , mixed with other products for shipment

breakbulk- warehouse receives large-volume truckload (TL) shipments that are destined for several customers.

Accessibility

The ability to easily obtain a service or reach a facility, often relating to geographical location or ease of use (e.g., website accessibility).

Affordability

The degree to which a product's price is within the financial reach of the target customer.

Economy of Distance

The decrease in transportation cost per unit of weight as the distance of the shipment increases, as fixed costs (like loading/unloading) are spread over more miles.

Economy of scale

The reduction in the cost per unit as the volume or size of an operation or shipment increases. Fixed costs are spread over more units.

Horizontal Gaps

Disconnects or failures in communication and coordination across functions within a single organization

Incoterms

A set of globally recognized trade terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers for the delivery of goods under sales contracts.

The Lesson of the Barefoot Wine example

The importance of building a brand and distribution strategy that focuses on simplicity and velocity through the supply chain. Barefoot's success came from focusing on a low-cost, high-volume model with limited product complexity and wide distribution.

Milk supply chains

A classic example of a supply chain that requires cold chain logistics and is extremely time-sensitive due to the highly perishable nature of the product.

OMCs

Operations Management & Control- management and oversight of operations processes.

-Refers to the tools, techniques, and systems used to effectively plan, organize, and control production and service delivery.

Porter’s Value Chain

A framework that breaks down a company's activities into a sequence of value-creating actions:

Primary Activities (e.g., Inbound Logistics, Operations, Outbound Logistics, Marketing & Sales, Service)

Support Activities (e.g., Procurement, Technology Development).

Predictive Logistics

The use of data analysis, algorithms, and machine learning to forecast demand, predict potential disruptions, and proactively optimize logistics operations.

Simplicity

striving for the easiest, most straightforward, and least complex processes, product designs, and information flows to reduce costs and errors.

Supply chains

A system of organizations, people, activities, information, and resources involved in moving a product or service from supplier to customer.

Transportation Participants

The different entities involved in the process of moving goods.

Shipper (consignor)

Carrier (trucking company, airline)

Consignee (receiver)

Government (regulators)

Third-Party Logistics (3PL) providers.

Vertical Gaps

Disconnects or failures in communication and coordination between different levels (tiers) of a supply chain, such as between a manufacturer and their Tier 2 supplier.