Bituminous Materials and Testing in Construction

1/67

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

68 Terms

Bituminous Materials

Materials containing bitumen for construction purposes.

Bitumen

Hydrocarbon material from petroleum distillation.

Paving Grade Bitumen

Composite material for roads and airports.

OXIDIZED BITUMEN

also known as blown bitumen is a bitumen type produced by blowing air into the pure bitumen

LIQUID BITUMEN

s bitumen that is dissolved in a solvent. Typical solvents include naphtha, gasoline and kerosine, white spirit, etc.

NATURAL BITUMEN

naturally occurring deposits of the solid or semi-solid form of petroleum. Extracted from oil sands or derived from natural lakes

PETROLEUM REFINING

- or Oil refining is an industrial process in which crude oil is extracted from the ground and transformed and refined into useful products like Liquefied Petroleum Gas (LPG), kerosene, asphalt base, jet fuel, gasoline, heating oil, fuel oils etc.

Fractional Distillation

crucial process in oil refineries, where crude oil is separated into various hydrocarbon products based on their relative molecular weights

Asphalt

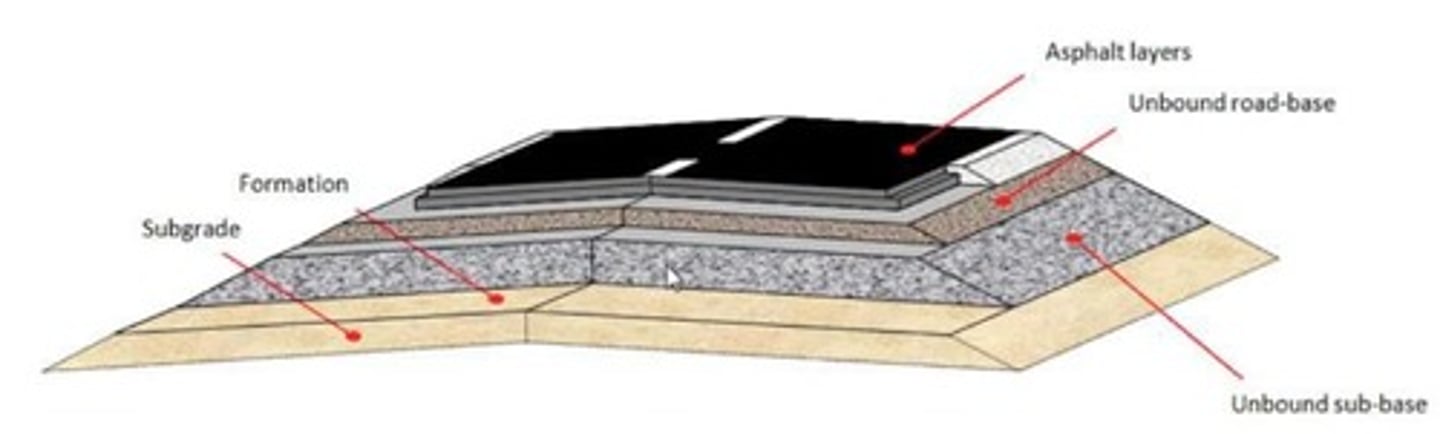

Bitumen mixed with aggregates for pavement.

Natural Asphalt

also referred to as asphaltum or bitumen, is a black, viscous, and semi-solid substance found in nature.

Manufactured Asphalt

is just gravel covered in an oily glue. Asphalt cement or a mixture of chemical solvents is required for these manufactured materials to bond.

Stability

durability

Impermeability

Workability

Skid resistance

Plasticity

Properties of Asphalt

Hamburg Wheel Tracking Test

Test for rutting resistance in asphalt mixtures.

Semi-Circular Bending Test

It's often referred to as a "flexibility index test." It can predict whether the material is resilient enough to meet its intended longevity.

Disc Shaped Compact Tension Test

measures the fracture energy of asphalt pavements.

Marshall Stability Test

Assesses stability of bituminous mixtures under load.

Bituminous Mixture

Combination of bitumen and aggregates for paving.

Light Fractions

Low boiling point products like gasoline and kerosene.

Middle Fractions

Moderate boiling point products, including diesel and jet fuel.

Heavy Fractions

High boiling point products, including bitumen and fuel oils.

Distillation Column

Equipment where crude oil is heated for separation.

Hot-Mix Asphalt (HMA)

Produced by mixing aggregates and asphalt at high temperature.

Hydroplaning

Loss of tire contact due to water film.

Aggregate

Crushed stones, sand, or gravel in asphalt mixtures.

Cold-laid plant mix

Asphalt mix applied at ambient temperature.

Mixed-in-place

Aggregates mixed on-site with asphalt binders.

Penetration macadam

Layers of aggregate treated with asphalt.

Asphaltenes

high-molecular-weight polycyclic hydrocarbons that provide the rigidity and stiffness to bituminous materials

Resins

serve as an intermediate component between asphaltenes and maltenes, maintaining the colloidal stability of bitumen

Aromatics

Hydrocarbons enhancing fluidity and workability.

Saturates

Low molecular weight hydrocarbons improving flexibility.

Viscosity

Resistance of bitumen to flow under stress.

Softening Point

the temperature at which bitumen transitions from a solid to a semi-liquid state

Thermal cracking

Cracking due to temperature fluctuations.

Colloidal stability

Maintaining uniform dispersion of components.

Aging characteristics

Changes in material properties over time.

Application efficiency

Effectiveness of applying materials in construction.

High-viscosity bitumen

Preferred for high-temperature applications.

Low-viscosity bitumen

Used for mixing in cold climates.

Penetration Value

Measures bitumen hardness via needle penetration depth.

Higher Penetration Value

Indicates softer bitumen for colder climates.

Lower Penetration Value

Signifies harder bitumen for hot climates.

Softening Point

Temperature where bitumen becomes semi-liquid.

Ductility

Ability to stretch bitumen without breaking.

Elasticity and Cohesion

refers to the ability of bitumen to return to its original shape after deformation, particularly in polymer-modified bitumen.

ensures internal strength, which is vital for withstanding traffic loads and mechanical stresses

Temperature Susceptibility

Behavior changes with temperature extremes in bitumen.

Adhesion to Aggregates

Bitumen's ability to bond with mineral aggregates.

Poor Adhesion

Leads to stripping and pavement failures.

Oxidation Resistance

Resists aging from air and UV exposure.

Oxidative Aging

Increases stiffness and reduces ductility over time.

Solubility in Organic Solvents

Pure bitumen dissolves in carbon disulfide.

Aging and Volatilization

Loss of volatile hydrocarbons increases brittleness.

Polymer-Modified Bitumen (PMB)

Enhances elasticity and durability using polymers.

Crumb Rubber Modification

Improves flexibility using recycled tire rubber.

Anti-Stripping Agents

Enhance adhesion between bitumen and aggregates.

Ductility Test

Measures bitumen's ability to stretch without breaking.

Flash Point

Temperature where vapors ignite upon exposure to flame.

Fire Point

Temperature sustaining combustion for at least 5 seconds.

Float Test

Assesses bitumen's flow characteristics in warm conditions.

Loss on Heating Test

Evaluates volatile component loss at high temperatures.

Penetration Test

Measures depth of needle penetration in bitumen.

Softening Point Test

Temperature where bitumen softens to specified consistency.

Specific Gravity Test

Determines bitumen density compared to water.

Viscosity Test

Measures flow characteristics under specified conditions.

Water Content Test

Determines amount of water present in bitumen.

Temperature for Ductility Test

Conducted at 27°C for accurate results.

Capillary Tube

Used in viscosity test to measure flow time.

Load for Penetration Test

Needle applied under 100 g load for measurement.