Pceutics Final Exam

1/131

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

132 Terms

granules

aggregates of powder particles formed by the granulation process

can contain one or more APIs with or without other ingredients

commonly used in making tablets or filled into capsules and binding agents

can be swallowed orally, dispersed in food, or dissolved in water

offer additional advantages over powders

larger

size of a granule is __ than powder

less

the surface area of granules is ___ than powder

less

the cohesive forces of granules is __ than the cohesive forces of powders

greater

the flowability of granules is __ than powders because thee are less cohesive forces

greater

stability to the effects of atmospheric humidity is __ for granules than powders because the surface area is less than that of a powder

less

caking or hardening upon standing is __ for granules than powders because the surface area is less than that of a powder and less cohesive forces

better

wettability by a liquid is __ for granules than powders because of larger particle size and reduced surface area and less cohesive forces

wet method

A technique in pharmaceutical formulation that involves dissolving a certain amount of solvent to aid in granulation, leading to improved particle cohesion and flow properties.

moisten the powder and add binding agents to facilitate particle aggregation (liquid bridging) → sieve → dry

dry method

A granulation technique that utilizes no liquid but compacts powders using mechanical forces, often resulting in increased particle size and improved flow characteristics.

powder or powder mixture (binding agents are incorporated into the powder formulation) → compress at high temperature → large tablets → granulate by mills → granules

powder

starting material for both wet and dry methods of preparation of granules

binding agents

what is added to promote aggregation in both wet and dry method of granulation?

binds the particles together (liquid briding)

what purpose does the liquid serve in the wet method?

granules

what type of solid passes through the sieve in the wet method?

wet powder

what type of solid is trapped in the sieve and moved to the oven for drying?

tablets

what type of solid is formed prior to granulation in the dry method?

grinding

what particle size reduction technique is used to produce granules in the dry method

wet method vs dry method

The wet method involves using a liquid binder to agglomerate powders, while the dry method uses mechanical forces to form granules without liquids.

compressed tablets

prepared with punches and ides under very high pressure

compaction of powder/granules

most tablets are these

use automatic tabletting press

molded tablets

prepared by forcing dampened powder material into a mold

moist tablets allowed to dry

soft, soluble and rapidly dissolve

much lower pressure involved

molded tablets

which type of tablet manufacturing requires water?

4 stages of compressed tablet manufacturing

filling→ powder added to hopper in order to get into machine

metering→ removes excess powder, set exact amount per tablet

compression→ high pressure to compress powder to create tablet

ejection→ takes tablet out of the machine

lactose

a common excipient used as a filler in tablet formulations, providing bulk and stability.

sucrose

A type of sugar used as a sweetener in various pharmaceutical formulations and medicines.

dye

a substance used to add color to pharmaceuticals or other formulations, enhancing their appearance and characteristics.

multi layer tablet

A pharmaceutical tablet designed with multiple layers, each potentially containing different active ingredients or excipients, allowing for controlled release or distinct functional properties.

tablet coating

serves several possible purposes

provides strength to the tablet (reduces friability)

masks unpleasant tastes or odors of the tablet

protects the drug from light, moisture, and oxidation

enteric coating prevents drugs from releasing in the stomach

coating can modify drug release (dissolution) form the tablet

separates incompatible materials by selective coating (multi-layered/coated tablets)

can be used for product identity or brand recognition

reduces operator exposure to active substances

tablet coating

include sugar, film, enteric, and controlled release

primary purpose of enteric coating

to prevent drug release in the stomach, allowing for targeted release in the intestine.

primary purpose of controlled release coating

to allow for a gradual release of the drug over an extended period, enhancing therapeutic effect and minimizing side effects.

primary purpose of sugar coating

to improve taste and mask bitterness, as well as to enhance appearance and protect the tablet.

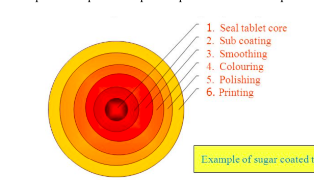

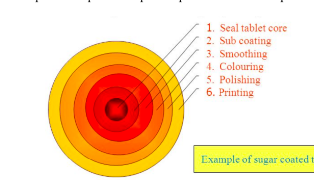

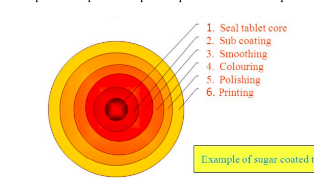

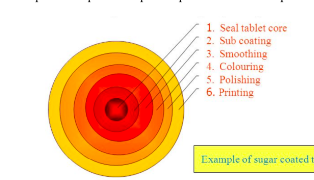

sugar coating

often involves multiple coats adding 30-50% extra mass to the tablet

the process requires 6 steps as depicted

seal tablet core

application of specialized polymer based coating directly to the tablet core

sub coating

provides the rapid buildup necessary to round up the tablet edge

smoothing

even out the tablet surface and fill the irregularities generated during subcoating

coloring

multiple application of syrup solutions containing the requisite materials necessary to achieve the desired shade

polishing

reduces the very dull appearance and fives them the high degree of gloss that typifies finished sugar coated tablets

accomplished by applying mixtures of waxes

printing

application of special edible inks to the coated tablet surface for identification

film coating

often entails applying a single, thin (20-100 um) polymer coat adding less than 2-3% extra mass to the tablet

difference between film coating and sugar coating

Film coating generally uses a polymer-based layer that adds minimal weight and provides a smooth finish, while sugar coating involves multiple layers of sugar and can significantly increase the tablet's size and weight.

cracking

tablets core expands when exposed to typical coating process temperatures

too dry, too cold

roughness

coating formulation is too viscous

excessive pigments concentration

sprayed droplets dry too rapidly

spraying nozzle is too far

chipping

high degree of attrition associated with the coating process

low amount of polymers

high pan speed

sticking and picking

inefficient drying (low temperature)

peeling

tablet core ingredients do not promote good coating adhesion

adhesive failure

insufficient film strength

cohesive failure

twinning

inefficient drying

shape of tablets is not appropriate (happens to flat surfaces)

too slow pan speed

logo bridging

logo design is inadequate for a film coated product

too high coating viscosity

oral, vaginal, buccal, sublingual

how are tablets administer?

advantages of tablets

dose accuracy, compactness, portability, ease of administration, systemic effects, convenient, stability, preparation, modified release

disadvantages of tablets

variability in absorption process, delayed action, adverse reaction, not long lasting, difficult to compress into tablet, API needs good water solubility, API must be a solid, API must be a small molecule

capsule

solid dosage form containing at least one API and/or insert substances enclosed in a small hard or soft shell

capsule shell

normally made from gelatin and cellulose polymers

hard capsules

consist of two prefabricated cyclindrical sections, body and cap

usually contain powders and granules (but can contain paste, liquid, tablets)

come in a variety of sizes

soft capsules (soft gel)

consist of a continuous gelatin shell (one piece)

contain a semi-solid or liquid fill

come in a variety of shapes

shells are softened by addition of glycerol or sorbitol

2 major types of capsules

hard and soft capsules

powder and granules

what is a hard capsule filled with?

semi-solid or liquid

what is a soft capsule filled with?

easier to swallow

how does the addition of glycerol or sorbitol assist with administration of the dosage form?

gelatin or cellulose polymers

what substances are used to prepare the shells?

collagen is heated to denature and then cooled

how is gelatin produced from collagen?

amino acids

collagen and gelatin are both polymers. what are the monomers that form them called?

liquid

when gelatin cools following denaturation of collagen, it forms a gel that can harden into a shell upon drying. if gelatin is heated, why physical state results?

store in cool area

what are the implication for storage of capsules?

dry

gelatin is stable when ___

nontoxic

since gelatin is edible, it must be ____

soluble

gelatin is ___ in biological fluids at body temperature

HPMC (hydroxypropylmethylcellulose)

derived from plants (bark of pine and spruce trees)

can be used to produce capsules

good for patients who are allergic to gelatin, vegan, or vegetarian

preparation of hard capsules

3 step process

capsule sizes vary in length and volume

step 1: develop and prepare formulation, select the capsule size

step 2: fill the capsule shells, seal the capsule

step 3: clean and polish the filled capsule

soft gel capsule preparation

prepared in a single step process (formed, filled, and sealed) using two common methods

rotary (punching) method, seamless (dropping) method

inversely proportional

the relationship between hard capsule volume and the size number

rotary (punching) method

A technique used in soft gel capsule preparation where the capsules are formed and filled simultaneously by pressing a die to create individual capsules.

two film sheets are placed between two die rolls while injecting a liquid such as medicine between the two sheets, and the dies perform pressured formation, sealing and cutting of the capsules

seamless (dripping) method

A soft gel capsule preparation technique where capsules are formed without seams by dropping a liquid formulation into a mold. This method allows for a continuous production process.

a liquid such as medicine is dropped from the inner section of a double concentric nozzle while film liquid containing a gelling agent form the outer section, and round seamless capsules are formualted by means of the interfacial tension

advantages of capsules

dose accuracy, compactness, portability, ease of administration, mask unpleasant taste, convenient, non-water soluble liquids (fish oil), modified release

disadvantages of capsules

variability in absorption process, delayed action, adverse reactions, not long lasting, manufacturing, not suitable for hygroscopic or deliquescent drugs (absorb water from the shell), not suitable for efflorescent drugs (soften the capsules)

release

rate limiting step of controlled release drug systems

drug in dosage form→ drug at absorption site

absorption

rate limiting step of the immediate release dosage forms

drug at the absorption site→ drug in the body

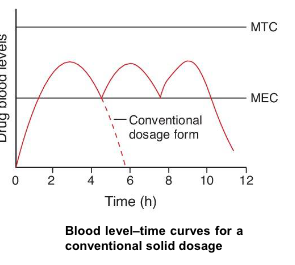

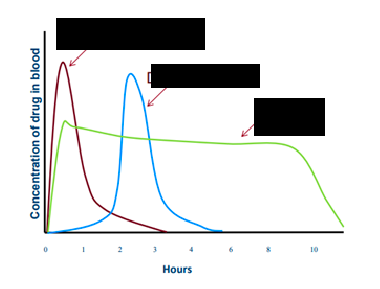

conventional (immediate-release) dosage forms

when they are taken on schedule and more than once daily, they cause sequential therapeutic blood level peaks and valleys (troughs)

however, when doses are not administered on schedule, the resulting peaks and valleys reflect less than optimum drug therapy

if doses are administered frequently, minimum toxic concentrations of drug may be reached, with toxic side effects resulting

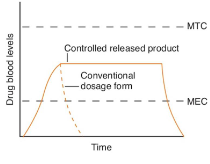

modified release (MR) dosage forms

refer to the modification of drug release from a dosage form with the specific aim of delivering drugs at

desired rates

specific sites in the gastrointestinal tract

most are orally administered tablets and capsules

other forms include ocular, parenteral, sub-dermal, and vaginal products, transdermal patches

classification: delayed release, extended release

many terms such as sustained release, sustained action, prolonged action, controlled release, extended release, timed release, and long action have been used interchangeably

on schedule and more than once daily

when immediate release dosage forms are taken ____ they cause sequential therapeutic blood level peaks and valleys (troughs)

less than optimum drug therapy

when immediate release dosage forms when doses are not administered on schedule, the results peaks and valleys reflect _____

toxic side effects resulting

if immediate release dosage forms are administered too frequently, minimum toxic concentrations of drug may be reached with _____

classification of modified release dosage forms

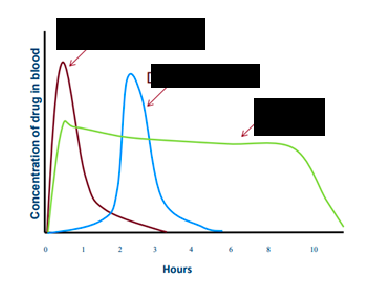

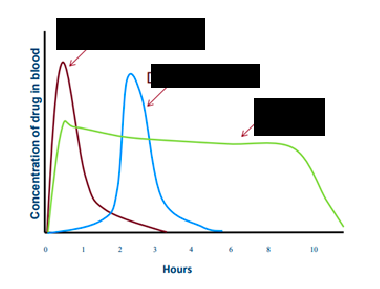

delayed release

extended release

delayed release

release the drug at a time or location later than immediately after administration

extended release

also called prolonged release or sustained release

drug plasma levels are sustained for longer periods of time

gastro-retentive systems

extended release systems which are retained in the stomach

floating on the surface of gastric fluid or attaching to the mucus surface of the stomach

sustained release

SR

sustained action

SA

prolonged action

PA

controlled release

CR

extended release

ER

timed release

TR

long acting

LA

immediate release

red line

delayed release

blue line

extended release

green line

advantages of modified release dosage forms

less fluctuation in drug blood levels

less frequent administration

enhanced convenience and compliance

reduction in adverse side effects

reduction in overall health care costs

disadvantages of modified release dosage forms

loss of flexibility in adjusting the drug dose and/or dosage regimen (you can’t split the dose or take 2 doses at once)

dose dumping: sudden and total drug release

dose dumping

the rapid release of the entire dose of a drug from a modified release formulation, potentially leading to toxicity or adverse effects.

causes of dose dumping

improper coating

the dosage form is chewed or crushed prior to ingestion

prevention of dose dumping

sufficient coating should be applied uniformly across the surface of the material that is to be coated

educate patients (the dosage form should not be chewed or crushed prior to ingestion)