Module 8 - High Voltage Production & Control

1/38

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

39 Terms

X-ray production requires a

step-up high turns

ratio transformer

A HV transformer can increase 50-240 volts up

to

30-150 KV

Why is the voltage transformer immersed in high dielectric oil

To prevent arcing

The center tap for a HV Transformer creates

less potential reference to

ground for the HV cable

The diodes are located

in a tank of dielectric

oil along with the HV transformer

The diodes are also called

Sticks

What can be used to test the diodes

A megger

Diode sticks should always be replaced in

Pairs

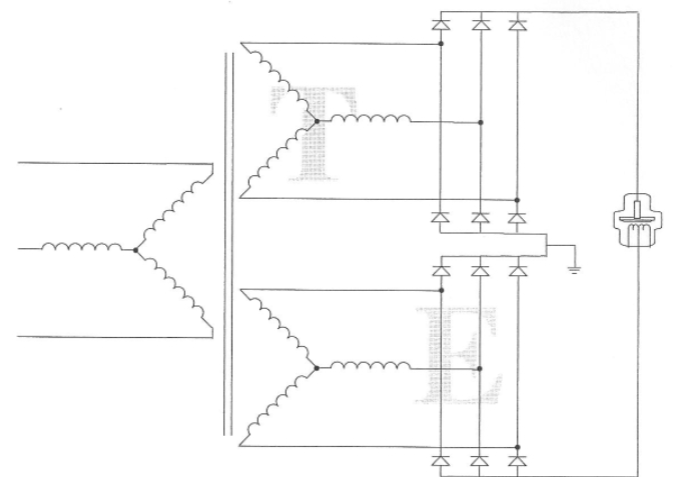

Phase and Pulse

3 Phase

6 Pulse

Phase and Pulse

3 Phase

12 Pulse

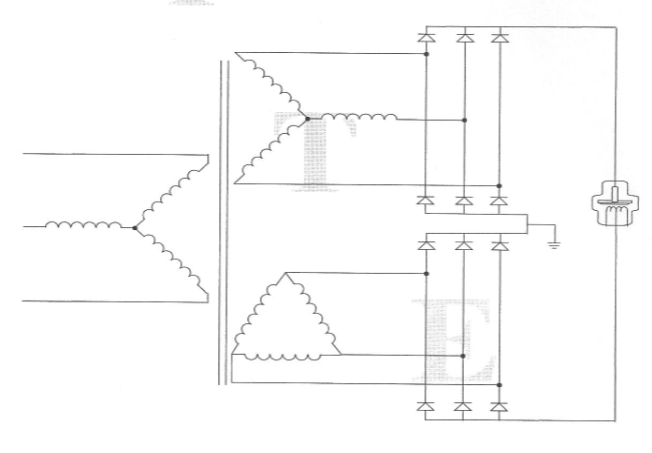

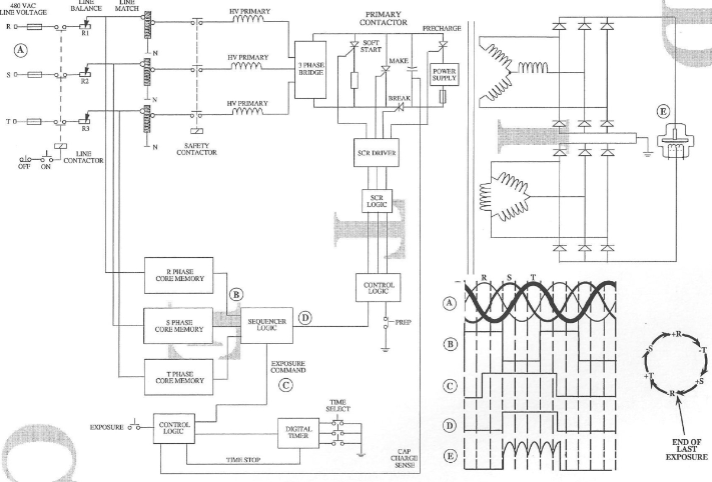

High frequency inverter

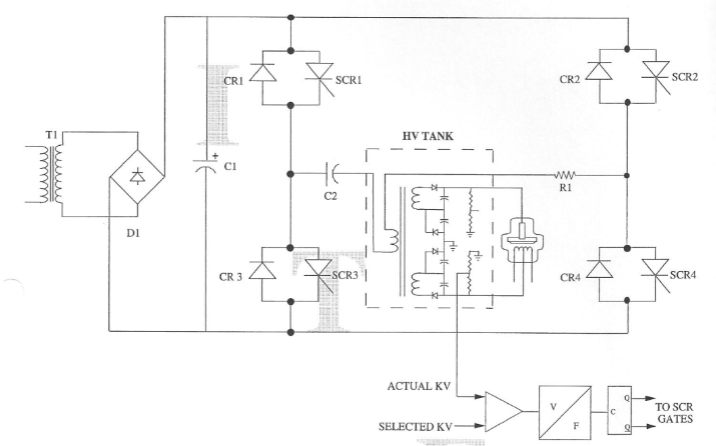

Line Match

Selectable taps allow the installer to program

the input circuitry to produce the required

operating voltages based on the measured

value of the incoming line voltage

KV Selection Device

The component that delivers voltage to the primary of the

HV transformer

Pre reading KV meter

measures the

selected output of the KV control device and

displays the KV value that should be

produced when that voltage is delivered to

the high voltage transformer

Load Compensation

Compensates for the I2R load loss that occur

in the HV transformer

Usually done by increasing the primary

voltage to the HV transformer when mA is

increased

Primary Contacting

Method of controlling exposure time

Primary contactors are usually SCRs

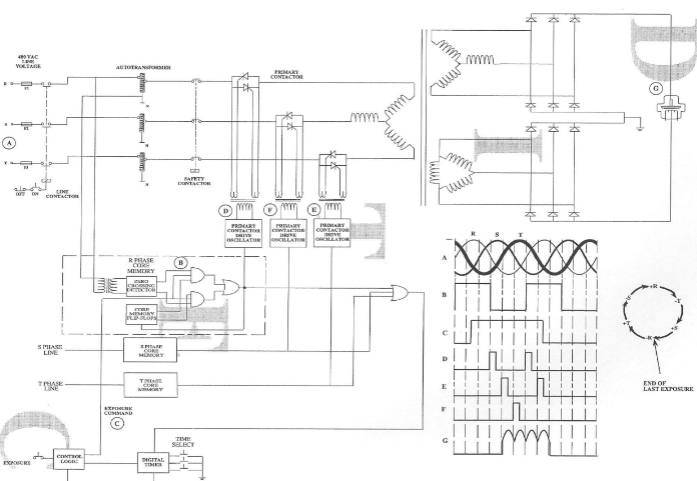

Single Phase, Self Commutation

SCR is the primary contactor

Three phase self commutation

Self Commutation

removes the gate pulse and waits for the incoming voltage

to hit the zero crossover point. The SCR current will drop below the holding current and shut off

This method requires two SCRs for each phase of

incoming voltage

3 phased 12 pulsed

forced commutation

Forced Commutation

This method removes the SCR gate pulse and

applies a reverse voltage across the SCR.

The reverse bias is usually supplied by a bank

of capacitors that were charged prior to

exposure

Requires only two SCRs

Pre charge circuit

Used to charge the commutation capacitors prior

to exposure

Soft Start SCR (pre-contacting

SCR)

An SCR in series with a resistor is placed in

parallel with the contacting SCR and fired a

few milliseconds before the make SCR

Reduces KV overshoot

Maximum Filament Current

Limiter

limits the absolute value of filament

current, 5.0 to 6.5 amps

Standby Adjust

Sets the continuous filament current, while the

machine is in standby mode, 2.0-3.0 amps

Baseline Adjust

Sets the starting filament current values that will

produce the desired mA

Spacecharge Compensation

Makes electrons ready to shoot x rays

ma Sensing

monitors the current flowing form the

cathode to the anode

mA Stabilizer

Compares the actual mA to selected mA and

increases or decreases the filament mA to correct

for any differences

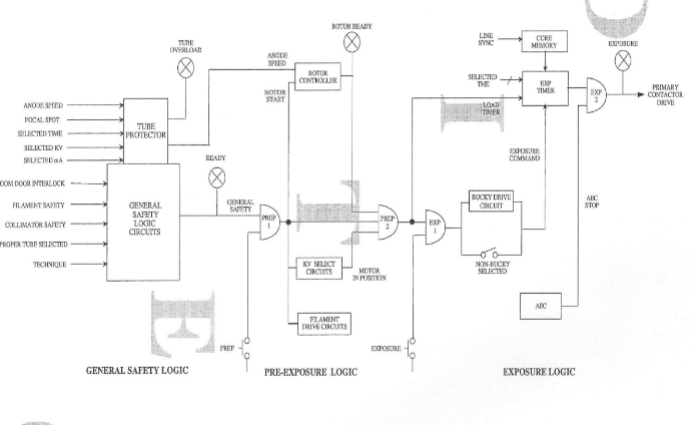

Tube Protector

Tube Protector 2 functions

Prevents exceeding maximum

Limit maximum generator output

Types of radiation sensors

Photo multiplier

Ionization Chamber

Control Logic

Control Logic

3 major areas

General safety

pre exposure

exposure

General Safety

This area of control logic monitors the

condition of the x-ray system at turn on

Pre Exposure 1

boosting of filaments, starting anode

rotation, driving KV motor and charging commutation

capacitors

Pre exposure 2

feedback from the circuits in Pre-exposure

1 are added and sent to exposure area

Exposure

Bucky mechanism is started

Primary drive pulses are generated at

appropriate zero crossover of incoming line

voltage (core memory)