Chapter 7

1/41

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

42 Terms

Fiber-reinforced

Composite in which the one material forms the outer matrix and transfers any loads applied to the stronger, more brittle fibers (e.g. kevlar-epoxy)

Particulate

Composite that contains large numbers of coarse particles to reinforce the matrix (e.g. concrete)

Laminar

composite that is made by alternating the layering of different materials affixed together with an adhesive (e.g. plywood)

Hybrid

composite made of other composite materials (e.g. rebar-reinforced concrete)

Fibers

withstands tensile loads in the direction of alignment; thinner and longer is better

Aligned fibers

handle loads in the longitudinal direction but contribute nothing to handling transverse loads

Transverse fibers

perpendicular to composites and handle loads in transverse direction

Matrix

surrounds and orients the fiber. Protects fibers from environment and transfers load

Aspect ratio

is the ratio of fiber length to diameter

(l/d). Large aspect ratios result in stronger composites, but they are more difficult to orient and are often limited by the size of the composite itself

critical length (lc)

above which the fiber behaves roughly as if it were infinitely long lc = sfd/2ti

isostrain condition

If the quality of bonding between the fiber and matrix is sufficient, they elongate at the same rate under stress and experience the same strain

Fiber Pull-out

When the bonding is less strong, the bonds between the fiber and matrix break

isostress condition

When the load is applied in the transverse direction, the fibers provide essentially no reinforcing benefit to the matrix. All the stresses experienced by the fibers and matrix are the same

Uniaxial

Fibers aligned along a single axis in almost perfect alignment. Composite is much stronger in the longitudinal direction than

the transverse

Chopped

The random orientation of small chopped fibers provides essentially isotropic properties in all directions. Because the fibers are smaller and only a fraction are oriented in any specific direction they are much less strong than

uniaxial composites

Resin formulation

Bits of chopped fiber and poured or blown into the matrix material (often already in the desired mould) Curing agents, accelerators, diluents, fillers, and pigments are added as well. The matrix material hardens into the shape of the mold

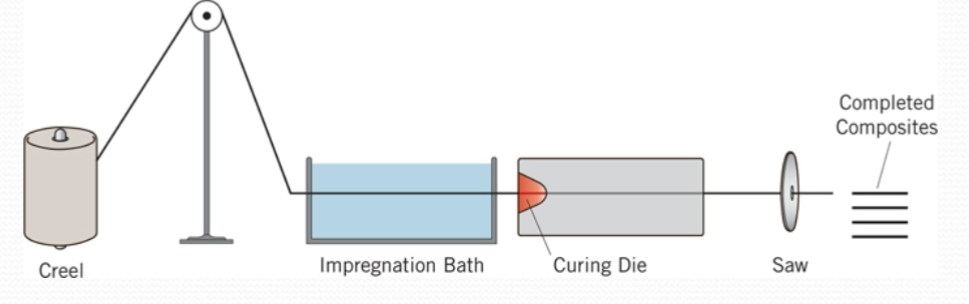

Pultrusion

Large numbers of single strands are wound in

parallel to form a roving. Many rovings are connected into a device called a creel that lets fibers to be pulled together. Fibers are coated with matrix material and are cured in a heated die then cut into shape

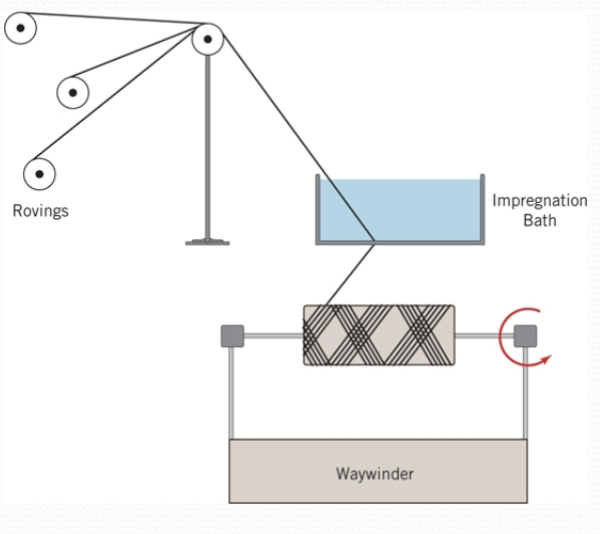

Wet filament winding

Continuous fibers from rovings are pulled through a resin impregnation bath then wound

into the desired shape. When enough wet filaments are wound around the part, it is

taken to a curing oven to complete a composite of the desired shape

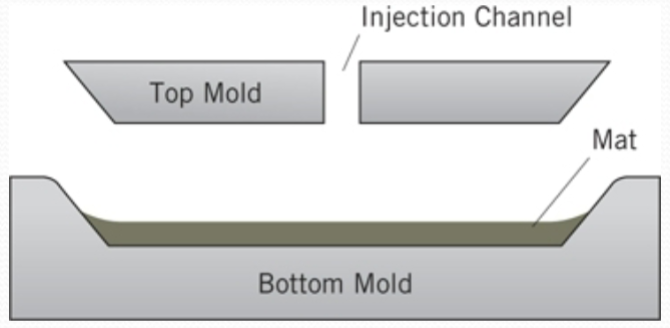

Resin Transfer Molding

Woven fiber mats are placed into a space between the top and bottom mold. Resin is injected through the top cavity under sufficient

pressure to ensure that it penetrates and surrounds the mat. The molds are cured using heat and pressure to create a composite part in the shape of the mold

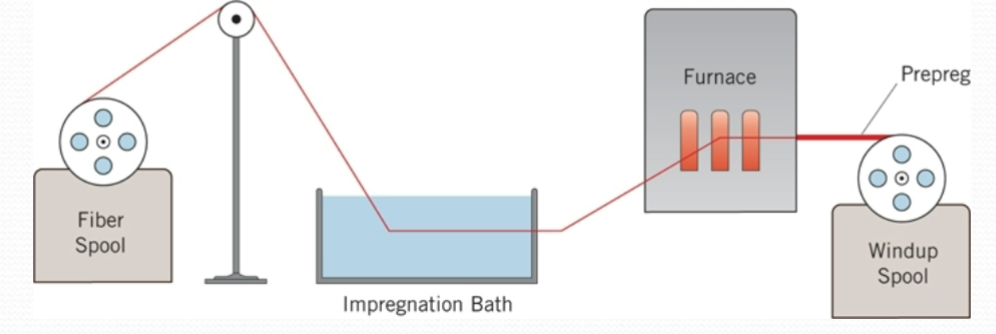

Prepregging

Fibers are passed through an impregnation bath that coats them with small quantities of resin. They are then passed through a furnace and heated slightly to ensure that the resin sticks to the fiber. The resulting coated fibers can be used later to form composites

Specific strength

tensile strength divided by density

Tradeoffs

Ceramic fibers tend to be strong and stiff, but dense. Glass fibers offer chemical resistance and blend of properties but are easily broken during processing. Metals are strong but are also heavy. High performance polymers are strong and light, but have trouble withstanding compressive forces

Polyester Resins

most common and economical resin

Isophthalic Polyester Resins

used when water resistance is needed

Epoxy Resins

more expensive but provide improved

mechanical properties and exceptional environmental resistance

Vinyl Ester Resins

compromise between the economic advantages of polyester and the properties of epoxy

Phenolic Resins

Poor mechanical properties but excellent fire resistance

Polyimide Resins

expensive and used only for high-end applications such as missiles and military aircraft

Metal Matrix Composites

High strength. Excellent environmental resistance. Greater thermal conductivity and abrasion resistance

Ceramic Matrix Composites

Increased fracture toughness. Ability to withstand extremely high temperatures. Corrosion resistance

Particulate Composites

Contain a large number of randomly oriented particles called aggregate that help the composite withstand compressive loads. Tend to be isotropic and are free from orientation issues. Include the most important commercial composite (e.g. concrete is mix of gravel and Portland Cement)

Hydration Catalysts

alter the rate of hydration in the Portland Cement. Accelerators speed up the reactions, while retarders slow them down

Air-Entrainers

cause tiny air bubbles to form and distribute throughout the concrete to withstand the freeze-thaw expansion cycles without failing

Plasticizers

reduce the viscosity of the cement paste, making it easier to flow the concrete mixture into its final form

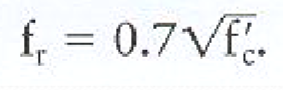

Modulus of Rupture

The maximum tensile strength at the bottom of the test beam

Rebar

Steel-deformed reinforcing bars that add strength to concrete. The result is a hybrid composite with the concrete serving as the matrix and the rebar handling tensile loads

Asphalt

blend of a mineral aggregate in an asphalt binder. Costs much less than concrete, but lasts only half as long

Hot-Mix Asphalt Concrete (HMAC) Process

uses asphalt softened at 160°C before mixing the aggregate then the road is compacted at 140°C. Significant amount of organic vapors are released

Warm-Mix Asphalt Concrete (WAM) Process

uses zeolites to reduce the softening temperature by as much as 25°C, resulting in reduced emissions and lower costs

Cold-Mix Asphalt Process

adds water and surfactant molecules to the asphalt before mixing it with the aggregate.

When the water evaporates, the properties are similar to asphalt produced by the HMAC process. Used for patches

Plywood

layers of wood veneers bonded together

by adhesives. More resistant to shrinking and warping than regular wood because of crossbanding

Sandwich composites

Used to increase strength with little weight. the honeycomb can be made of cardboard, but high-performance polymers are used for higher-end applications