Composites

1/103

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

104 Terms

how many phases are in a composite microstructure?

2, the matrix and the dispersed phase

are composite microstructures continuous or discontinuous?

discontinuous

what are the two phases in the composite microstructure?

dispersed and the matrix

what is the role of the matrix?

binding together

what is the dispersed phase?

surrounded my the matrix, usually particles

name three composite properties that effects the material properties

amount of phases

phase properties

geometry

orientation

distribution

what are particle reinforced composites?

defined by their strengthening mechanism

what is the particulate phase?

harder and stiffer than the matrix which creates a barrier to stop matrix deformation

how does the particulate phase transfer loads?

particles restrain matrix movement resulting in a transfer of load

what is the degree of reinforcement dependant on? (in terms of the composite microstructure)

a high degree of reinforcement is dependant on strong bonding at the matrix particle phase

how should particles be distributed and orientated for effective reinforcement?

for effective reinforcement particles should be in the same direction and evenly distributed throughout the matrix

what is the effect of the material volume fraction?

volume fraction influences behaviour, mechanical properties increase with particulate content

what is the rule of mixtures equation?

shows the upper and lower bounds for the dependence of the elastic modulus on the volume fraction of the phases

what is the equation for the upper bound?

Ec(U) = EmVm+EpVP

where:

E = elastic modulus

V = volume fraction

C = composite

M = matrix

U just refers to upper

what is the equation of the lower bound?

Ec(L) = EmVm / VmEp + VpEm

where:

E = elastic modulus

V = volume fraction

C = composite

M = matrix

L just refers to upper

what does this equation stand for?

Ec(L) = EmVm / VmEp + VpEm

elastic modulus of the lower bound

where:

E = elastic modulus

V = volume fraction

C = composite

M = matrix

L just refers to upper

what are 2 properties of tungsten particles in a copper matrix?

high heat resistance

low thermal expansion

what is cermet and 1 one of its properties?

hard ceramics in a metal matrix

prevents crack propagation

what is carbon black and what are two properties?

carbon black is small particles added to rubber

enhances toughness and abrasion

what is concrete and what is a disadvantage of it?

concrete is a mix of coarse aggregates, water and cement

weak and brittle

what is an advantage of reinforced concrete?

better maintains stresses as well as reduced corrosion

what is a dispersed strength composite?

small particles, strengthened at atomic levels

what is are two advantages of a dispersed strength composite?

particles hinder dislocations as well as restricting plastic deformation improving yield and tensile strength

what is a fibre reinforced composite?

within a fibre reinforced composite, the dispersed phase is a fibre that is either continuous or discontinues

what is the difference between continuous and discontinuous fibres?

continuous fibres - aligned

discontinuous fibres - short, aligned and randomly orientated

what do mechanical properties depend on within fibre-reinforced composites?

mechanical properties depend on fibre properties, and the degree in which load is transmitted to the fibres

what happens to the matrix bond when under applied stress?

the fibre matrix bond creases at the fibre ends when under applied stress, yielding a a matrix deformation pattern

what is needed for effective strengthening

critical fibre length

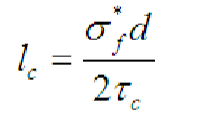

what is the equation for critical length?

where:

lc = critical length

σ*f = fibre ultimate strength

d = fibre diameter

τc = fibre matrix bond strength

what does it mean if fibres are l > lc?

the fibre is continuous

what does it mean if fibres are l < lc?

the fibre is discontinuous

name 2 factors that have a strong influence on fibre strength

fibre arrangement

fibre concentration

distrubution

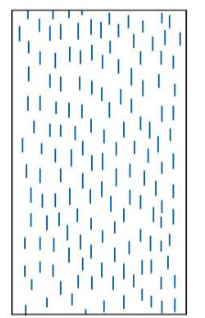

what is this arrangement?

discontinuous but aligned, short

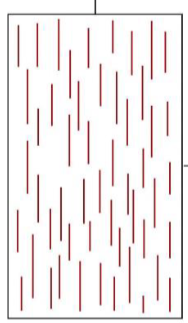

what is this arrangement?

continuous

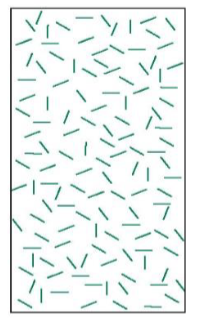

what is this arrangement?

discontinuous, randomly aligned

what does tensile stress strain behaviour in longitudinal loading depend on? (give 2)

stress strain behaviour of the fibre and matrix phases

phase volume fractions

direction of stress

are composites generally anisotropic or isotropic?

anisotropic

what happens in stage 1 of a stress strain diagram of a composite material?

fibres and matrix deform elastically (curve is usually linear)

what happens in stage 2 of a stress strain diagram of a composite material?

matrix yields and deforms plastically

fibres continue to stretch

failure begins once fibres start to fracture

generally, does the matrix or fibres have higher tensile strength?

the fibres have higher tensile strength

why is composite failure not catastrophic?

no all fibres fail at the same time. Once they have failed they are still embedded in the matrix which means they can still support a diminishing load

how does the fibre matrix bond react to longitudinal loading

the fibre matrix bond is good, meaning that deformation in the matrix and fibre is the same

what does this represent: εc = εm = εf

deformation is the matrix and fibres are the same (iso-strain)

what is the equation for the elastic modulus of a continuous and eloigned fibrous composited in the direction of the alignment.

Ecl = EmVm + EfVf

what is the ratio of the load carried by the fibres to that of the matrix?

Ff / Fm = EfVf / EmVm

what is iso- stress?

the composite and both phases are exposed to same amount of stress

what is the equation for iso-stress?

σc= σm = σf = σ

what is the equation for the modulus of elasticity in a continuous and aligned fibre-reinforced composite in the longitudinal direction?

1 / Ect = Vm / Em + Vf / Ef

what is transverse stress influenced by in fibre reinforced composites? (name 2)

properties of the matrix of the fibres

bond strength

presence of voids

do discontinuous or continuous composites have a higher reinforcement efficiency?

continuous

what is the modulus of elasticity of short composites?

short fibre composites have an elastic modulus of about 90% of continuous fibre composition

why are smaller diameter fibres stronger than the bulk material?

lower probability of a critical surface flaw

name 2 example of fibres

whiskers

fibres

wires

what are whiskers?

thin crystal strands with a high length to diameter ratio

what is an advantage of whiskers?

high degree of crystalline perfection creating high strength due to less flaws

why are whiskers not used

impractical and expensive

what type of structure can fibres have?

polycrystalline or amorphous

are fibres or wires larger in diameter?

wires

what are wires used for?

reinforcement

what can the matrix phase be made from

either polymer, metal or ceramic

give two functions of the matrix

binds fibres together

acts as a medium of stress

protects fibres from surface damage

separates fibres stopping propagation

is the matrix brittle of ductile?

ductile

the elastic modulus higher in fibres or the matrix?

fibres

what does the UTS of the composite depend on?

the bond between the matrix and fibres

name 2 advantages of glass fibre

easily fabricated

economical

strong

what is an advantage of carbon fibre reinforced polymers? (give 2)

high modulus to density ratio

high specific strength

retains strength at high temps

name a limitation of glass fibre reinforced polymer composites

not very stiff

limited applications

describe the carbon fibre structure

composed of graphitic and non-crystalline regions

coated carbon fibres

what are three advantages of aramid fibre reinforced polymer composites

high strength

high modulus

high strength to weight ratio

what is pultrusion used for?

used for continuous lengths and constant cross sectional shapes

describe the process of pultrusion

fibres are drawn together as strands

strands are impregnated with a thermosetting resin

fibres are pulled through a steel die to preform to a desired shape

die is heated to initiate the curing of the resin matrix

pulling device draws the stock through the dies

tubes are created by inserting hollow cores

what is filament winding

process of fibres are positioned in a predetermined pattern to form a hollow shape

what is the process of filament winding

fibres are fed through a resin bath

fibres are wound onto a mandrel using automated winding equipment

curing occurs and mandrel is removed

what is prepreg production

fibre is pre-impregnated with a polymer resin that is only partially cured

what is the pre-preg production process

delivered in a tape form

directly moulds and fully cures the product without needing to add resin

what is the process of creating a prepreg tape

spool wound fibres tows are sandwiched and pressed between sheets of papers using heated rollers

a doctor blade spreads resin into a film

final product is a thin tape of fibres in partially cured resin

what does final curing require during the pre preg process

heat and pressure

what are structural composites usually composed of?

homogenous and composite materials

what are properties dependant on in structural composites

material used

geometrical design

what are sandwich panels

lightweight beams of panels with high stiffness and strength

what are laminar composites?

composed of 2D shapes that have a preferred strength orientation

how do laminar composites create balance?

each board has a different direction of high strength, therefore they are swapped on each layer in order to balance out

what are sandwich boards made up of?

two beams that are separated by a adhesively bonded thicker core

what are the main properties of the core within sandwich boards? (give 2)

continuous support

must have shear strength to withstand transverse stresses

variety of applications