TOPIC 3.2: Filtration (API Isolation)

1/10

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No study sessions yet.

11 Terms

What is filtration?

The desired drug substance (ie. API) is synthesized via chemical reaction and remains in a dissolved state within a solution in the batch reactor

FIltration is the separation of solids from a solid-liquid mixture (slurry) by means of a porous medium or screen which retains the solids while allowing the liquid to pass

In Pharmaceutical application, solid is the valuable product (ie. API) and liquid is the waste (ie. mother liquor)

Results in separation of the solids as wet cake → need to wash and dry to yield high purity API

What is cake filtration?

A solid-liquid process where slurry is forced through a filter medium with pores smaller than the slurry’s solid’s particle size

The liquid (ie. filtrate) passes through while the solids get retained, accumulating as cake on the medium

Cake Filtration — Key Characteristics

Used for slurries with a high proportion of solids.

Solids build up as a cake, increasing thickness and flow resistance over time.

Lab equipment: Büchner funnel and flask.

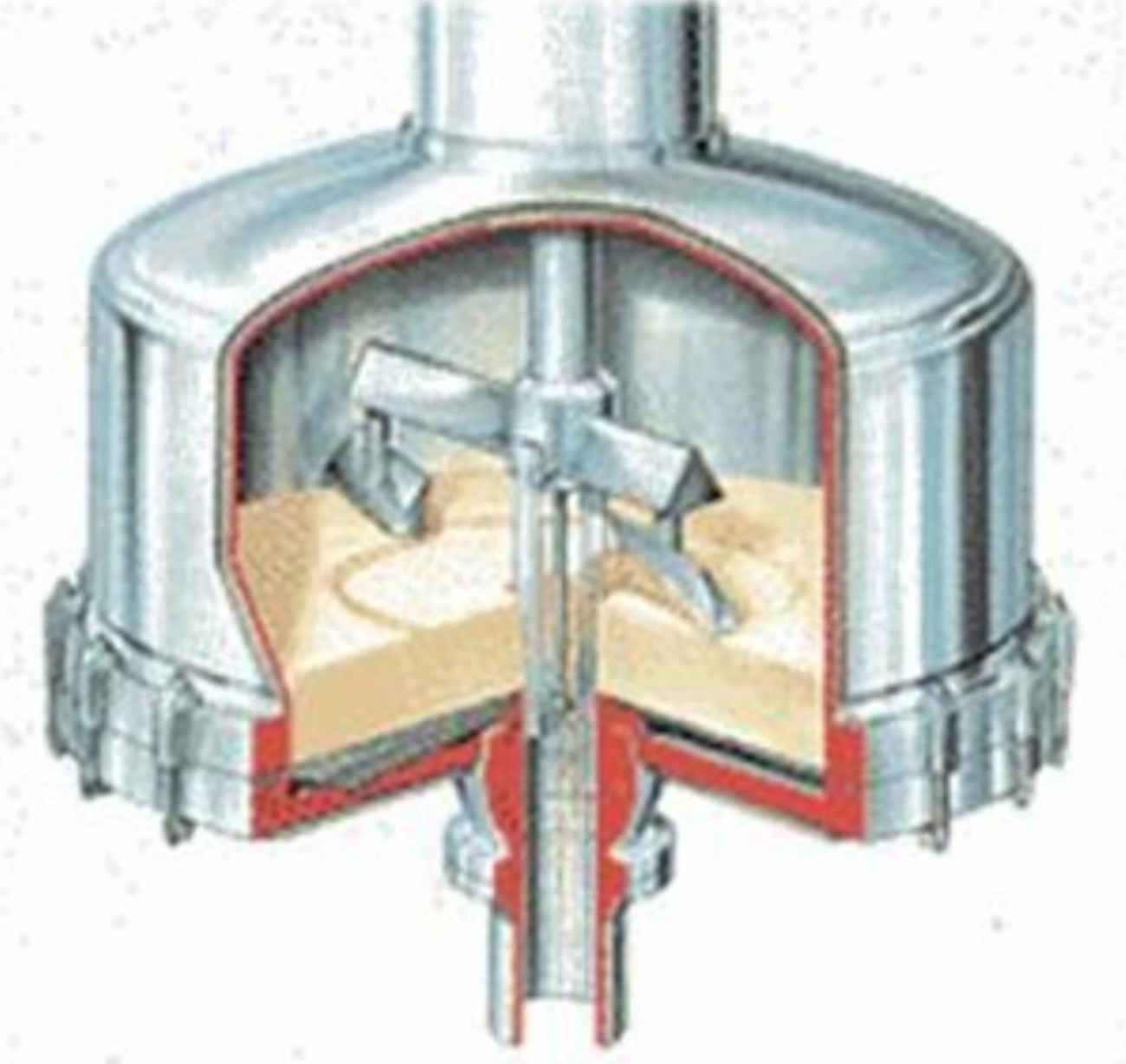

Industrial equipment: Agitated Nutsche Filter.

Cake Filtration — Principle (Why is the initial stage critical?)

The initial stage is critical as:

Flow rate is highest at the start since the resistance is minimum

Too-high initial flow can plug filter pores → greatly increasing resistance

The arrangement of the first particle layers greatly influences the entire cake structure

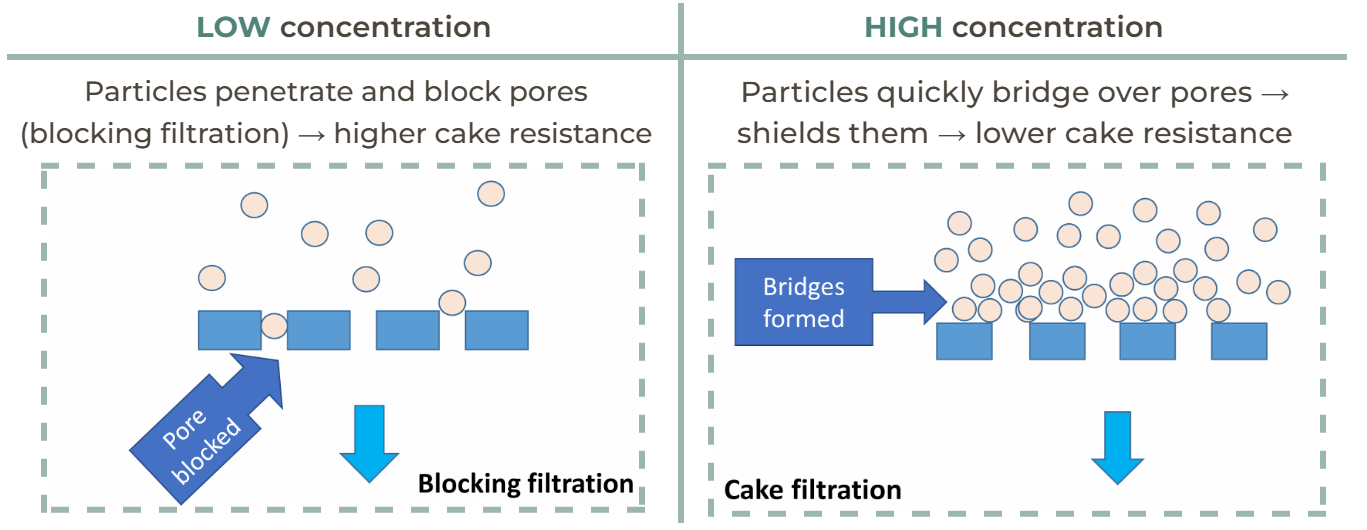

Cake Filtration — Principle (Effects of solids concentration)

LOW concentration | HIGH concentration |

Particles penetrate and block pores (blocking filtration) → higher cake resistance | Particles quickly bridge over pores → shields them → lower cake resistance |

Delayed cake filtration

During regular filtration, resistance to filter cake progressively increases → reduces rate of filtrate flow

Delayed cake filtration delays / reduces build-up of cake by limiting cake thickness

Cake thickness remains constant → allows constant filtrate flow

Agitated Nutsche filter is needed

Comes with an agitator → thickness is limited to the clearance between agitator blades and filter medium

Filtrate flows through cake at a constant rate BUT solids are retained in the suspension

BUT if solid concentration starts to increase, particles will start to make permanent physical contact with each other → ↑ resistance to flow → ↓ filtrate flow

Rate of Filtration — Formula

dV/dt ∝ (A △P) / (rμL)

Rate of Filtration — Constant Pressure vs Constant Rate

PARAMETER | CONSTANT PRESSURE FILTRATION | CONSTANT RATE FILTRATION |

Filtration Area (A) | Constant | |

Resistance (r) & Filtrate Viscosity (µ) | Constant | |

Thickness (L) | Increases | |

Differential pressure (ΔP) | Kept constant | Increases to keep dV/dt constant |

Flow rate dV/dt | Decreases eventually | Kept constant |

More frequently adopted for practical reasons → easier to operate | ||

Factors Affecting Rate of Filtration (Cycle Time)

FACTOR | EFFECT(S) |

Resistance, r |

↓ Resistance = ↑ rate of filtration |

Thickness, L |

↓ Thickness = ↑ rate of filtration |

Filtration Area, A | ↑ Filtration Area = ↑ rate of filtration |

Filtrate Viscosity, µ | ↓ Viscosity of filtrate = ↑ rate of filtration |

Pressure difference across cake and filter medium, ∆P |

↑ Differential pressure = ↑ rate of filtration |

Filter Medium

Acts as a support for the filter cake while the initial layer of cake is the true filter

MUST satisfy cGMP requirements:

Sintered stainless steel, polypropylene, or 100% cellulose material (Non shedding type)

High mechanical strength, and chemical resistance

Able to withstand sanitization temperatures of 80 °C during Cleaning-in-place (CIP)

“Equipment used in the manufacture, processing, packing, or holding of a drug product shall be of appropriate design, adequate size, and suitably located to facilitate operations for its intended use and for its cleaning and maintenance” |

Should offer minimum resistance to filtrate flow

Easy cake removal is essential for maximizing product yield recovered

Washing of Filter Cake

To remove traces of mother liquor, unreacted starting material, by-product or impurities from the cake

Directly reduces the impurity level in the final drug substance

Prevents the crystals from re-dissolving in the residual mother liquor during drying

Washing liquid MUST have:

Maximum solubility of the unwanted impurities (to prevent crystallization of the impurities)

Minimum solubility of the product (to prevent product loss to the washes)

Low boiling point and inert to cake (improves drying productivity)

Washing is done in 2 stages:

Displacement washing – Mother liquor is directly displaced from cake surface by washing liquid (removes 90% of filtrate)

Diffusion washing – Remaining mother liquor diffuses into the washing liquid from the less accessible voids

Re-slurry washing – Cake is re-suspended in fresh washing liquid to form a slurry → filter again

Channeling is the main problem encountered during cake washing

Washing liquid forms preferred paths ("channels") through the cake, leaving some areas unwashed → incomplete washing

Can use lower pressure during washing than during filtration OR use an agitator to smooth the surface