Inventory Management

1/32

Earn XP

Description and Tags

SCM 2160

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

33 Terms

what is inventory

stock of items including materials, orders, information, and people that flow through or are used in a process to satisfy eventual demand

what do inventory management policies must be aligned with

aligned with competitive priorities → there is an “appropriate” amount of inventory

decisions are about balancing inventory costs with the pressures to increase inventory

what are inventory holding costs

variable costs associated with keeping inventory

$ per unit cost (or % of a unit cost)

Costs over a period of time (usually one year)

E.g., rent, heating, cooling, lighting, security, interest on loans, depreciation

what is capital cost

opportunity cost of investing in inventory relative to the expected return if invested elsewhere

what is storage and handling cost

includes costs associated with renting and staffing storage space, opportunity cost associated with the use of space for storage

what is taxes, insurance, and shrinkage cost

includes cost of insuring inventory, theft of inventory, spoilage and obsolescence

what are ordering costs

the costs associated with the act of placing an order, transaction costs

fixed cost per order, regardless of the number of units ordered

In a production setting, there is also set-up costs (fixed cost per production of a set quantity)

E.g., requisition and purchase ordering, transportation and shipping, receiving and storage

what are stockouts

what are inventory pressures

Inventory can support quick delivery, avoid stockouts

Higher volume orders may optimize ordering costs from suppliers

Increasing inventory by producing in large batch sizes may decrease set-up costs

Producing inventory may increase productivity and resource utilization

Increase efficiency of transportation resources and reduce less-than- truckload shipments

what is safety stock

buffer to protect against uncertainties in demand, lead time, processing time, quality and supply

what is decoupling

work-in-process inventory waiting for the next step (can accommodate different rates of production in system)

what is pipeline inventory

inventory moving from point-to-point in the system, including materials on their way from the suppliers

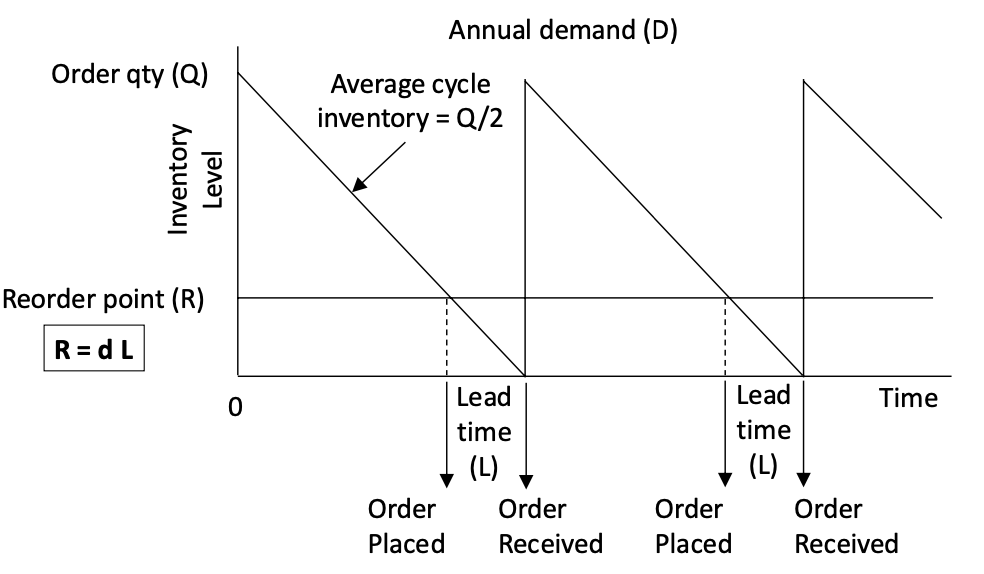

pipeline inventory (reorder point) = …

what is anticipation inventory

used to manage predictable variation in demand

what is cycle inventory

the portion of your total inventory that varies based on the size of an order or production batch (Q)

average cycle inventory: Q/2

what is economic order quantity (EOQ)

the value of Q that gives you the lowest total annual inventory costs

what are the assumptions of EOQ models

Demand is independent, known, and constant

Supply is certain and received all at once in a batch

Replenishment lead time is known and constant

Lead time: time between order placed and order received

Cost information is fixed and constant

No shortage and back orders

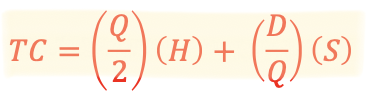

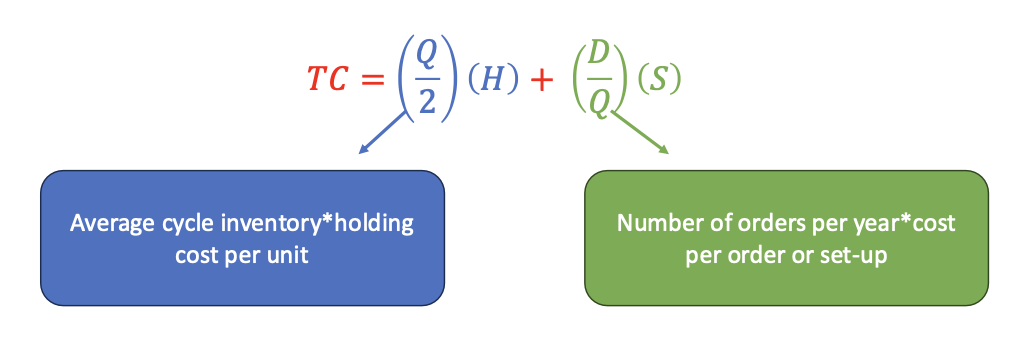

what is the equation for annual costs

annual holding cost + annual ordering (or setup) cost

𝑇𝐶 = 𝑡𝑜𝑡𝑎𝑙 𝑐𝑜𝑠𝑡 𝑝𝑒𝑟 𝑦𝑒𝑎𝑟

𝑄= 𝑜𝑟𝑑𝑒𝑟 𝑞𝑢𝑎𝑛𝑡𝑖𝑡𝑦 ,𝑙𝑜𝑡 𝑜𝑟 𝑏𝑎𝑡𝑐h 𝑠𝑖𝑧𝑒 𝑖𝑛 𝑢𝑛𝑖𝑡𝑠

𝐻= h𝑜𝑙𝑑𝑖𝑛𝑔 𝑐𝑜𝑠𝑡 𝑝𝑒𝑟 𝑢𝑛𝑖𝑡 𝑝𝑒𝑟 𝑜𝑛𝑒 𝑦𝑒𝑎𝑟 𝑜𝑓 𝑡𝑒𝑛 % 𝑜𝑓 𝑡h𝑒 𝑖𝑡𝑒𝑚′𝑠 𝑣𝑎𝑙𝑢𝑒

𝐷 = 𝑎𝑛𝑛𝑢𝑎𝑙 𝑑𝑒𝑚𝑎𝑛𝑑 𝑖𝑛 𝑢𝑛𝑖𝑡𝑠 𝑝𝑒𝑟 𝑦𝑒𝑎𝑟

S = cost per order or set-up (in dollars per batch)

This equation can be used to compare the costs of different inventory policies

what are the two factors that affect how many order you place per year

demand and order size → total ordering costs

what does large quantity values minimize

minimize the number of orders

what does small quantity value minimize

minimize average cycle inventory and holding costs

what is independent demand

demand which is influenced by market conditions and is not related to inventory decisions for other items in stock

what are the different ways to determine when and how many to order

Q system (continuous review – fixed quantity)

P system (periodic review – fixed time-period)

ABC system

what is the Q system (continuous review)

Replenish decisions made in real-time based on inventory level

System triggers a fixed order quantity (Q) when inventory reaches a set reorder point (R)

Time between orders varies

what is the P system (periodic review)

Replenishment decisions made based on time between orders

Inventory review happens at fixed time intervals (periodically)

Order quantity (Q) varies, and is determined by current inventory level

what is most important decision in continuous review system

setting your reorder point

inventory will hit 0 exactly when you receive your next order

safety stock can change your reorder point

what is most important decision in periodic review system

selecting the time between orders and target inventory level

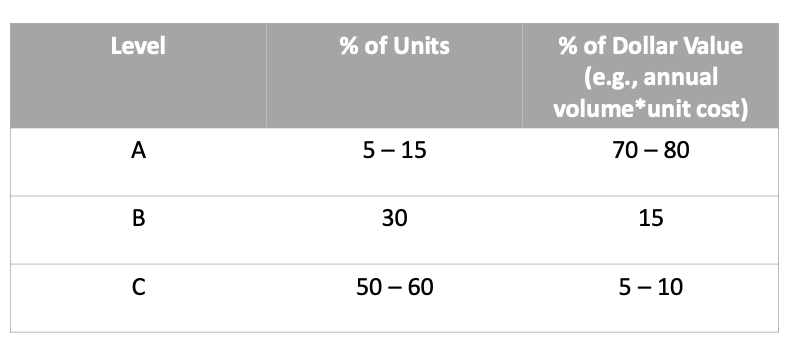

what is the ABC system

An inventory classification system in which a small percentage of items (A-level) account for most of the inventory value

what are A-items in the ABC system

High priority

Tight control with regular review

Carefully determined Q, frequent deliveries, continuous review

Very accurate and detailed inventory records, update monthly

what are B-items in the ABC system

Moderate priority

Moderate control with regular attention

Order quantities or order points reviewed quarterly

Batch updating of inventory records

what are C-items in the ABC system

Low priority

Simple control

Large inventories, visual review

Simplified counting, annual review

what are the benefits of the Q system

May reduce total holding and ordering costs by tailoring reorder point

Fixed order sizes may support quantity discounts

Requires less safety stock

what are the benefits of the P system

Supports standardization of deliveries, scheduling of inventory assessment

Opportunities to combine orders for multiple products from same suppliers

Does not require computerized inventory management system