Topic 3 - Polymers

1/41

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

42 Terms

Define polymer

Long chain organic macromolecules

Macromolecules formed by the chemical bonding of large numbers of smaller molecules

Define monomer

A molecule which each can be linked to other monomers to form polymer chain

What are some naturally occuring polymers?

Hair

DNA

Spider silk

How are synthetic polymers produced?

They are produced by a polymerization reaction

What happens during polymerisation

C=C breaks apart

2 free electrons from the broken double bond combine with 2 other ethene molecules to form a chain

As it progresses, more and more ethene molecules are added to the chain resulting in a macro-molecule

Define polymeric materials

combination of carbon with oxygen, hydrogen, nitrogen and other organic/ inorganic elements.

Easily shaped into forms under heat and pressure

Define plastic and the two main types of plastic

Plastic: Large and varied group of synthetic materials formed or molded into shape

Thermoplastic: Polymer that can be melted

Thermoset: Cross-linked polymer that cannot be melted [silicone,, phenolics]

Define elastomers

Lightly crossed-linked macromolecules with rubbery viscoelastic properties [extremely flexible] [eg: Butyl, natural rubber, EPDM, neoprene, nitrile]

Thermoplastic

Soften when heated and harden when cooled [Reversible]

Melt and solidify without chemical changes and significant loss in mechanical properties

FOA between polymer chains can be overcome by heating thereby allowing the chain to slide over one another

Most linear polymers and some branched polymers are thermoplastics

Support hot-forming methods such as injection-moulding and FDM

Poor resistance to high temperature

Low strength but ductile

Thermosets

Harden the first time they are heated, do not soften after subsequent heating

During the initial heat treatment, covalent linkages are formed between chains [chains become cross-linked]

Do not melt with heating but will degrade at high enough temperatures

Networked/crosslinked polymers are typically thermosets

High thermal stability

Strong, rigid, hard, somewhat brittle

Name a few examples of thermoplastics

Polyethene (PE)

Polypropene(PP)

Polyvinyl chloride (PVC)

Polymethyl methacrylate (PMMA)

Polystyrene (PS)

Polyamide (PA-nylon)

Name a few examples of thermoset plastic

Epoxy

Silicone rubber

Polymelamin

Polyurethanes

What is a homopolymer?

polymer formed from one monomer [All repeating units are the same]

What is a copolymer?

Polymer made of 2 or more monomers

What are the 4 main structures of polymers?

Linear polymers [HDPE, PVC, Nylon]

Branched polymers [LDPE]

Crosslinked polymers [Rubber]

Network polymers [Kevlar, Epoxy]

![<ol><li><p>Linear polymers [HDPE, PVC, Nylon]</p></li><li><p>Branched polymers [LDPE]</p></li><li><p>Crosslinked polymers [Rubber]</p></li><li><p>Network polymers [Kevlar, Epoxy]</p></li></ol><p></p>](https://knowt-user-attachments.s3.amazonaws.com/a0996c91-70a5-4ae1-aa41-4908b765c592.png)

Describe the layout of an amorphous structure

No orderly arrangement of molecular chain in the solid state

When heated, shows no definite melting temp, but progressively becomes less rigid

Describe the layout of a crystalline structure

Ordered arrangement of the molecules in the solid state

distinct melting point, higher melting point

What are the effects of crystallinity on the mechanical properties and physical properties of a polymer?

The higher the crystallinity of polymer, the higher the melting point, the higher the tensile strength and modules of elasticity [resistance to deformation] of polymer

Define molecular weight

The mass of 1 mole of molecular chain [1 mole = 6.02×1023]

What are the effects of a higher molecular weight on properties of polymers?

Increases ductility

The higher degree of entanglement allows the material to be pulled further before the chains break

Increases the tensile & impact strength of the material

The higher degree of entanglement means that in order to rupture, more polymer bonds need to be broken, this means that the polymer can absorb more energy before failing

Increases the viscosity of the material

Harder to process the material using conventional methods. The longer the chains, the harder it is ti get them to flow because they are more tangled

Increases the chemical resistance

Takes more damage to the main chains of the molecules before it will affect the strength of the material

Explain what is glass transition temperature [Tg]

When an amorphous polymer is heated, the temperature at which it changes from a glass to the rubbery form is called Tg. This is the temp below which an amorphous soild (such as glass, polymers, tire rubber or cotton candy) goes from being ductile to brittle

Explain what is melting temperature [Tm]

For Crystalline or Semi-Crystalline materials, the melting temperature (Tm) is the temperature at which the crystals melt. Amorphous materials don’t truly have a Tm. They just continue to soften more until they behave more like a liquid. When we refer to the melt temperature for amorphous materials, it is usually the temperature at which we can process it.

What are the additives added to polymers to change the mechanical, chemical and physical properties?

Filler

Increases bulk and reduce cost

improve properties such as heat and chemical resistance

Plasticiser

Lowers Tg to improve ductility and softness

Stabiliser

Prevent degradation by heat and light

Colarant

Organic dye or inorganic pigment to form color

Lubricant

Reduce friction during processing or prevent sticking to molds

Flame retardant

Reduces the flammability of plastic

State the properties and applications of polyethylene

Properties:

Cheap

tough

flexible

Good chemical resistance

Applications:

LDPE: Bread bags, frozen food bags, grocery bags

HDPE: Milk, water and juice containers, toys, liquid detergent bottles

State the properties and applications of polypropylene

Properties:

Strength similar to HDPE, but easier to injection mold

Good fatigue properties

Excellent chemical resistance

Applications:

Gasoline tanks, chemical tanks, luggage, battery cases, ropes, fibers or filaments

Consumer products: Ketchup bottles, yogurt containers and margarine tubs, medicine bottles

State the properties and applications of Polyvinyl Chloride

Plasticised — low strength

Applications: decorative coatings, wire coating, imitation leather

Rigid — much stronger, tough resistance to grease/oil, resistance to chemicals, clarity, low cost

Applications: Chemical storage tank, piping, ducting

State the properties and application of polystyrene

Properties:

Brittle transparent material

Excellent electrical insulator

Application:

toy boxes, casing, radios

State the properties and application of polyamide

Properties:

strong and tough

relatively high melting point

low friction

Applications:

Gears, bearings, toothbrush bristles

State the properties and application of acrylonitrile-butadiene-styrene

Properties:

Tough, stiff, and abrasion resistance

Moderate rensile and compressive strengths

Remarkable dimensional stability

Applications:

Instrument panels

safety helmets

State the properties and application of acrylics

Properties:

Completely transparent themoplastics

Stiff strong with outstanding weather resistance

Applications:

Lenses for car lights, signs and nameplates

State the properties and application of Alkyds

Properties:

Hard and stiff

Good mechanical and electrical properties, dimensional stability

Applications:

Encapsulation of small electronic parts

State the properties and application of Phenolics

Properties:

High stiffness, impact, and heat resistance

Applications:

electrical plugs, sockets, switches

State the properties and application of Silicones

Properties:

excellent chemical inertness

low toxicity

Applications:

Water repellent properties

What are the differences between the processing of thermoplastic and thermoset?

Thermoplastic:

Raw polymeric materials are often in the form of pellets, granules, flakes or powders

Easily remelted and formed to the desired shapes

Examples: Injection Moulding, plastic extrusion

Thermoset:

Permanently set, with heat and catalysts, upon polymerization

Reheating will not change their shape aand heating at high temp will only cause disintegration and damage to the polymer

Raw material form monomer solutions or rod and sheet stocks

Examples: Compression Moulding, Transfer moulding

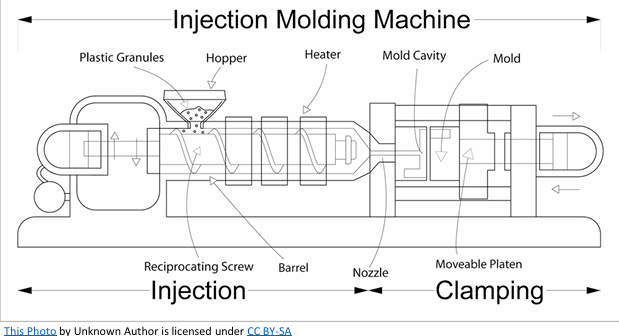

How does an injection mould work?

Polymer granules feed via hopper, polymer melts into molten state using heater bands and friction action of a reciprocating screw barrel

Heated plastic fills barrel, motorised screw pushes molten polymer into a mould

Injects molten polymer at high pressure into mould via gates and hot runners

The plastic product is allowed to cool and solidified before being ejected from the opened mould.

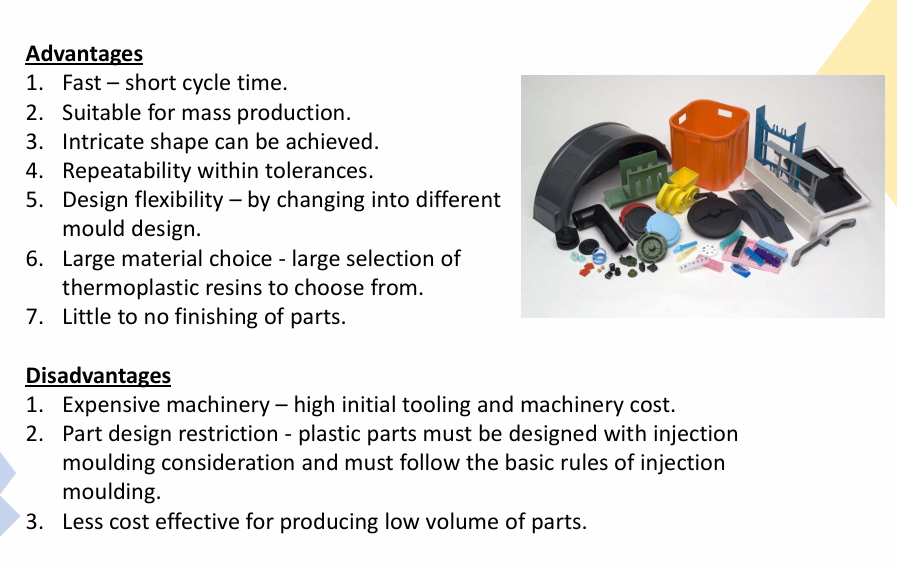

What are the advantages and disadvantages of injection moulding?

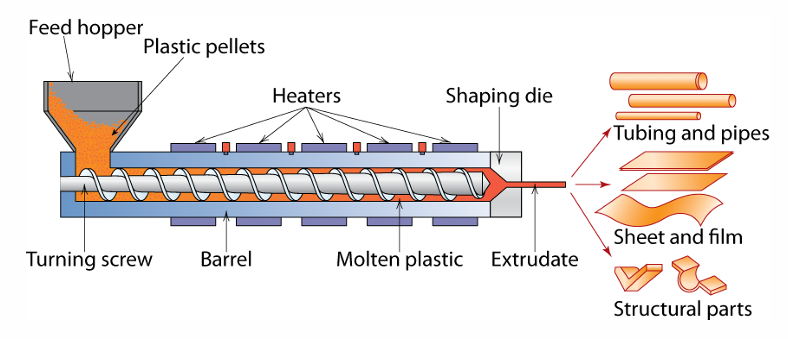

Explain the process of plastic extrusion

Plastic Extrusion Process is an operation for transforming a polymer using an extruder from the solid to the easily mouldable molten state, then discharging it through an extrusion die in a pre determined cross-sectional shape and re-solidifying by cooling.

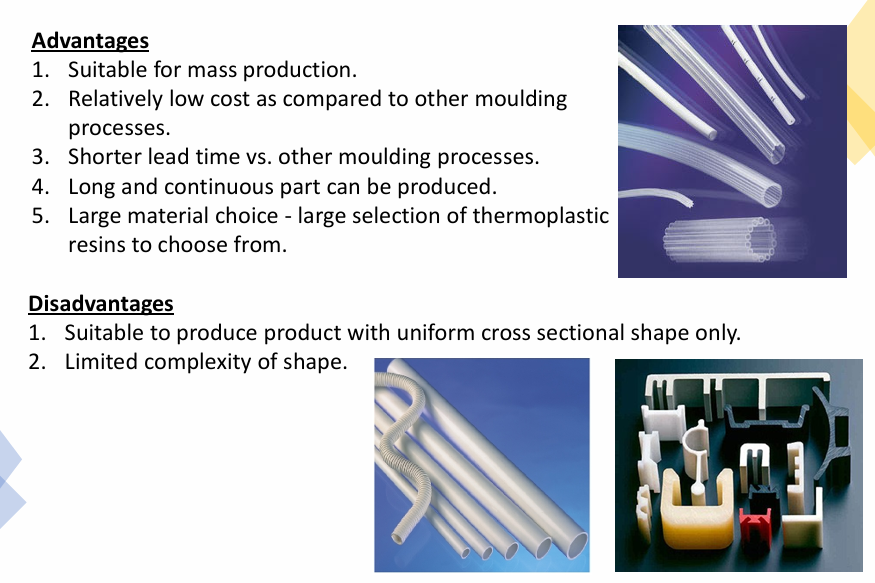

What are the advantages and disadvantages of plastic extrusion

Explain the process of compression moulding

Compression moulding is the simplest and most widely used process for making thermoset polymer products. Compound or blend is placed in mould and heated under pressure within the platens of a steam-heated press. When reaction is complete, product is cooled and ejected

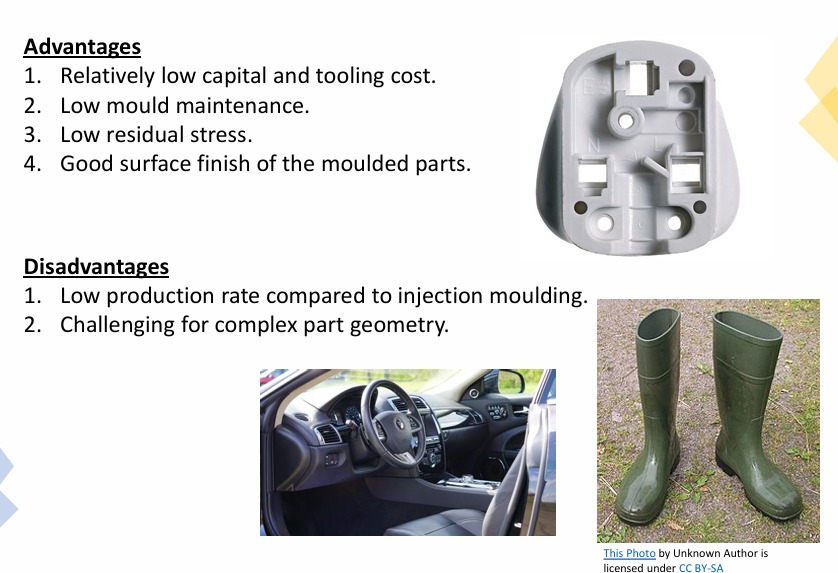

State the advantages and disadvantages of compression moulding

Explain the process of transfer moulding

Athermosetting charge (preform) is loaded and heated inside a chamber immediately ahead of the mould cavity

Pressure applied on the heated material using a plunger to force the softened polymer to flow into the heated mould

Pressure applied on the heated material using a plunger to force the softened polymer to flow into the heated mould

Athermosetting charge (preform) is loaded and heated inside a chamber immediately ahead of the mould cavity.

Pressure applied on the heated material using a plunger to force the softened polymer to flow into the heated mould.

The polymer within the mould cavities are permitted to cure before the final part is ejected from the mould.

State the advantages and disadvantages of transfer moulding