GCSE Mocs Design Technology

1/51

Earn XP

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

52 Terms

Softwood

Come from Coniferous trees so they grow quickly

Hardwood

Come from Deciduous Trees so they grow slow

Property’s of Softwoods

Typically easy to work with and less dense

Property’s of Hardwoods

Typically hard to work with and very dense

Pine

Softwood

Pine advantages

Durable, Easy to work with, Cheap and Lightweight

Pine disadvantages

Can warp, crack and splinter

Pine uses

Construction and furniture

Cedar

Softwood

Cedar Advantages

Natural oils make it resistant to water and fungal growth

Cedar disadvantages

More expensive than pine but not as strong

Cedar uses

Outdoor furniture, fences, sheds boats

Larch

Softwood

Larch Advantages

Tough, durable and resistant to water

Larch Disadvantages

Costs more than other softwoods

Larch uses

Structural components and boats

Oak

Hardwood

Oak advantages

Strong, durable and has a attractive grain when finished well

Oak disadvantages

Expensive, becoming rarer, Harder to work with, corrodes iron and steel

Oak uses

High end furniture and alcohol barrels

Mahogany

Hardwood

Mahogany Advantages

Attractive finish and easy to work with

Mahogany disadvantages

Very Expensive, Environmental issues, Can cause skin rash and breathing problems

Mahogany uses

High quality furniture and jewellery boxes

Beech

Hardwood

Beach advantages

Tough, does not crack or splinter easy and good for children

Beech disadvantages

Expensive, not resistant to moisture, not suitable for exterior use

Beech uses

Toys, Cooking implements and furniture

Balsa

Hardwood

Balsa advantages

Extremely light weight and easy to cut

Balsa disadvantages

Easily damaged due to it being soft and weak

Balsa uses

Model making, surfboard cores and historically used to make rafts

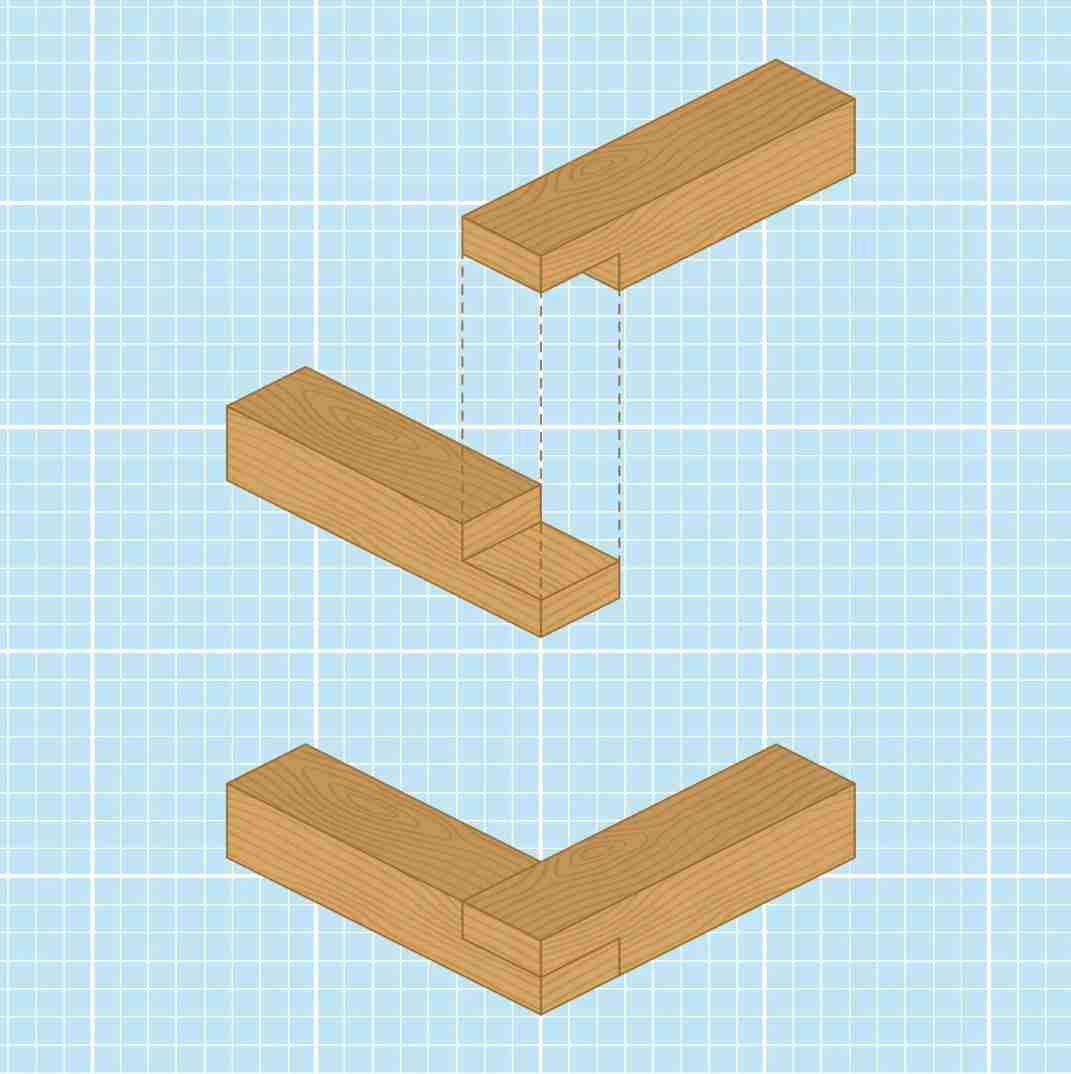

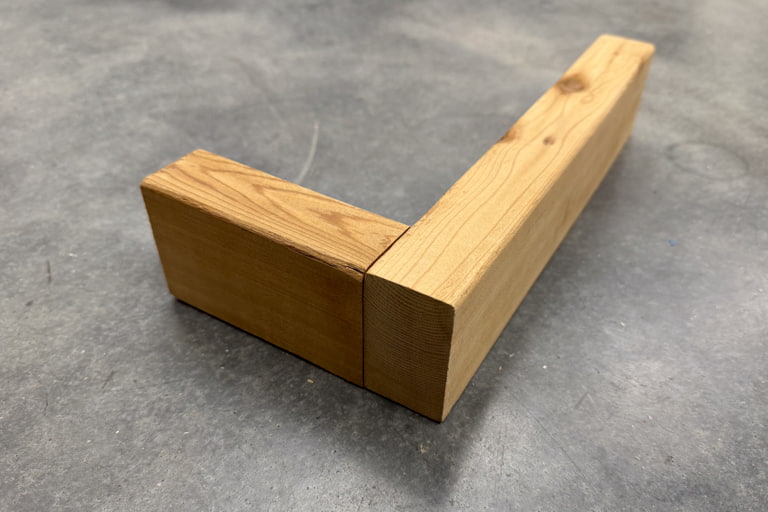

What is this joint

Half lap joint

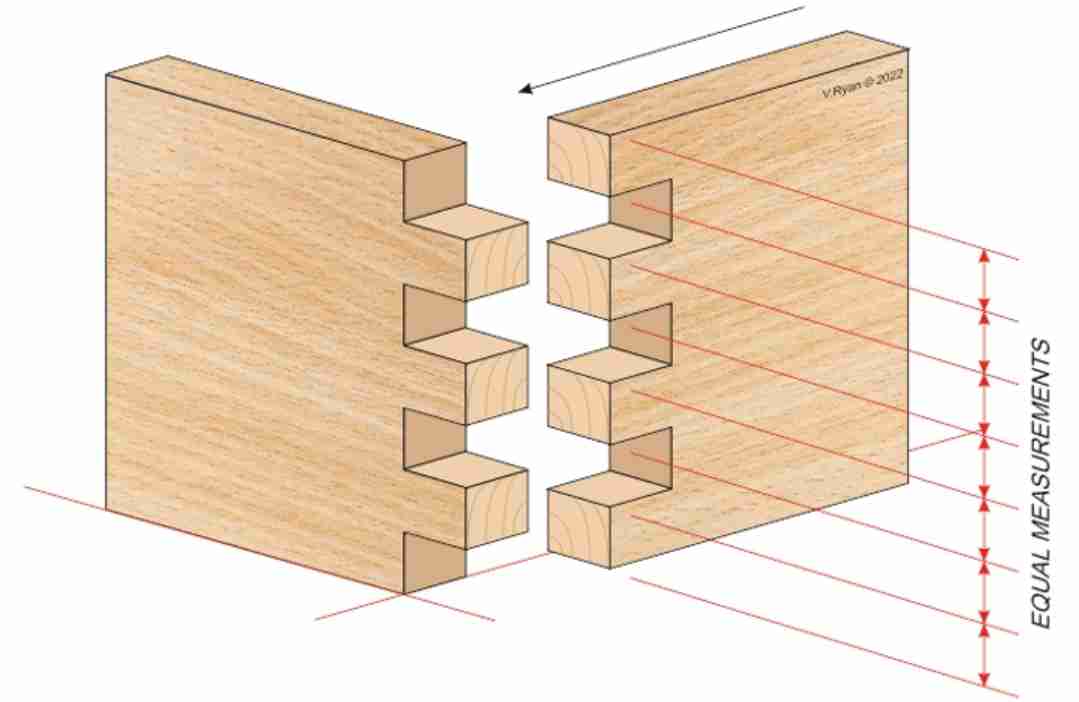

What is this joint

Comb joint

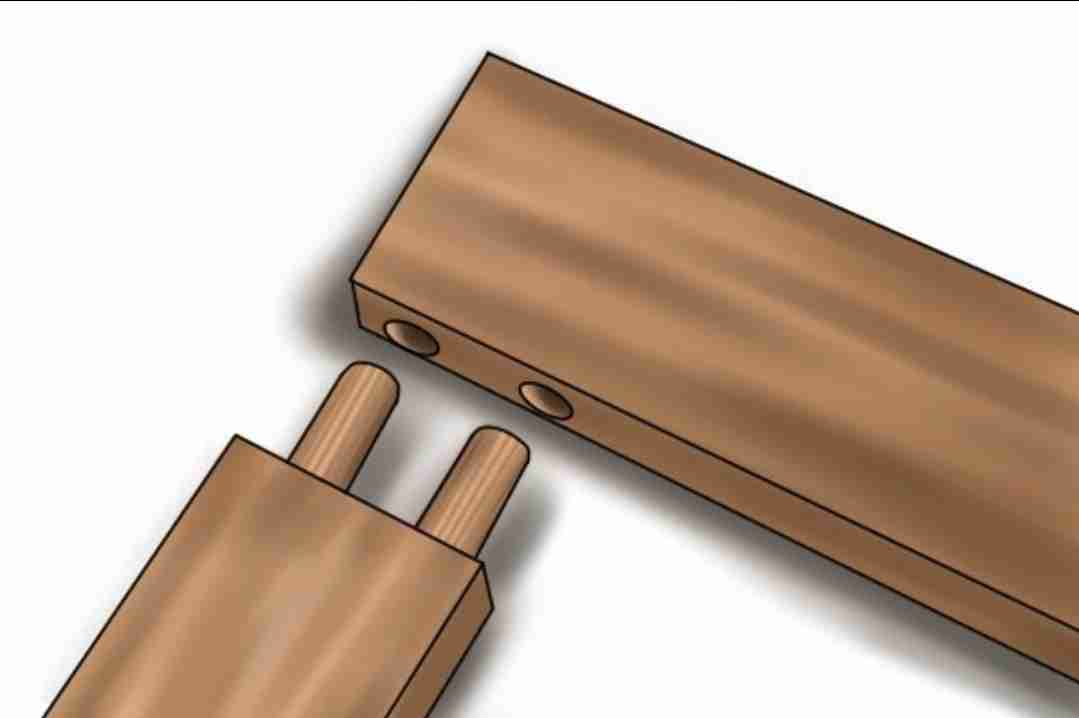

What is this joint

Dowel joint

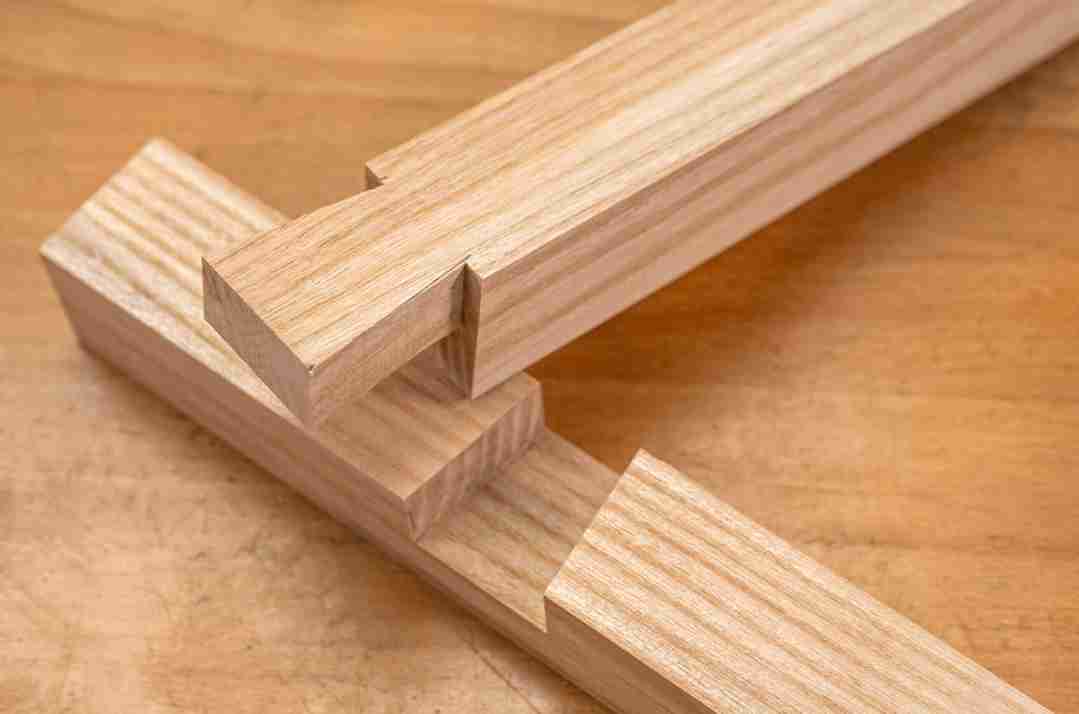

What is this joint

Dove tail Joint

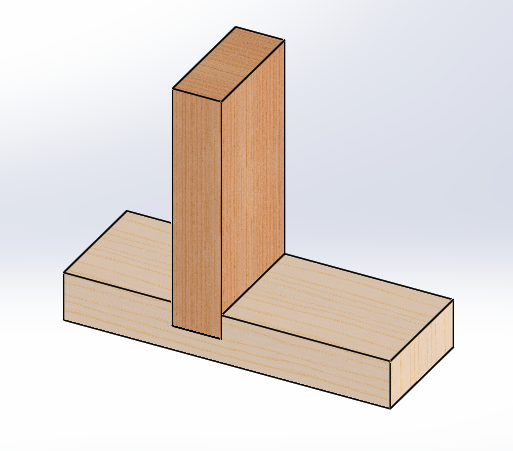

What is this joint

Mortise and tenon Joint

What is this joint

Butt joint

What is this joint

Housing Joint

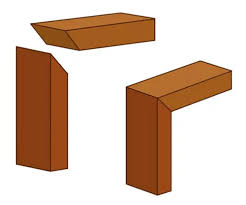

What is this joint

Mitre joint

What is a man made board?

A type of manufactured wood made from waste materials made of wood compressed back into new man made wood boards.

What makes man made boards better than natural timbers?

They are not limited by size, have different properties and are cheaper

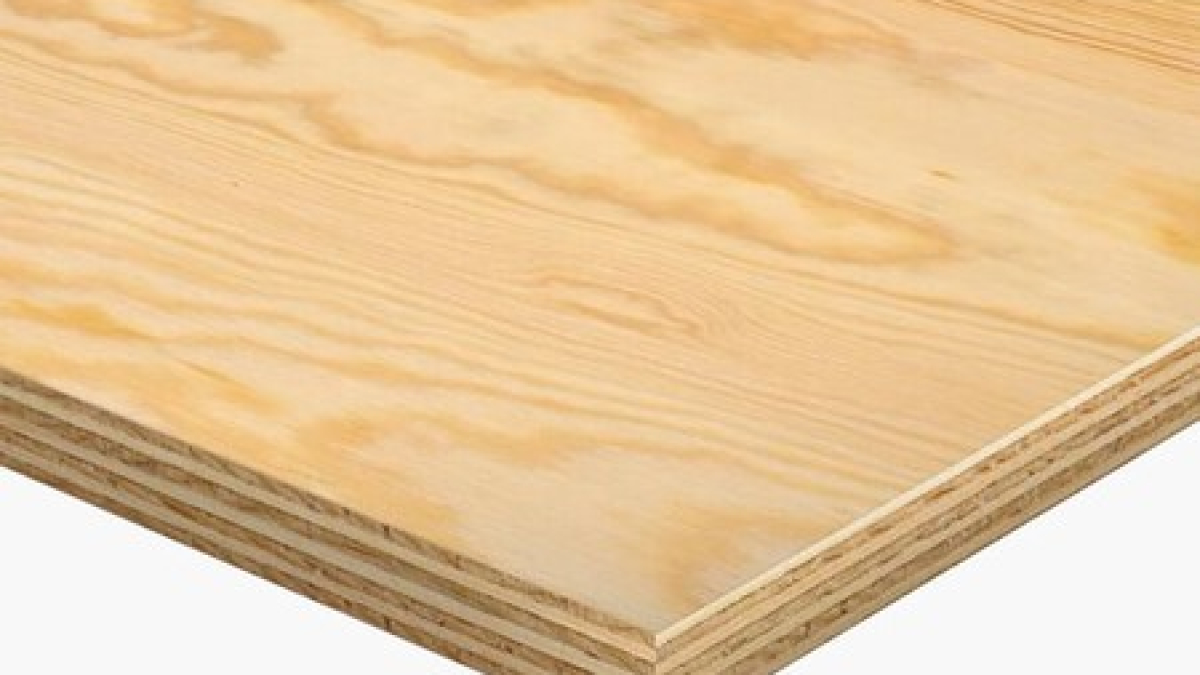

How is plywood made?

Plywood is made by gluing together thin layers of wood veneers, with the grain of each layer oriented in alternating directions

Advantages of plywood

Flat, structurally strong, and resistance to warping. Versatile for construction and furniture.

Disadvantages of plywood

Quite expensive, edges can look rough, susceptible to water damage if wrong grade is used

How is MDF made?

Wood dust and fiber are mixed with glue and pressed into flat sheets under extreme heat and pressure.

Advantages of MDF

Cheap to produce, smooth, ungrained surface is good for staining or painting and easy to machine making it good for flat pack furnature and storage units

Disadvantages of MDF

Does not look good so needs coating, weak compared to real wood or plywood

how is chipboard made?

Wood chips are mixed with glue and pressed into flat sheets

Advantages of chipboard

Use waste materials so is cheap to produce making it good for Desktops, kitchen worktops, cheap, flat pack furniture

Disadvantages of chipboard

Not much structural strength, especially in damp conditions, Surface is very rough, so usually plastic coated