Abrasives polishing

1/125

Earn XP

Description and Tags

not done yet

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

126 Terms

surface irregularities can include fine surface roughness, this means

inherent particle size of investment

fine surface roughness have a high W/P ratio that _________ (inc/dec) surface roughness

inc

fine surface roughness with a low W/P ratio that _________ (inc/dec) investment adaptation or flow

dec

when thinking about fine surface roughness, what can encourage investment decomposition

prolonged burnout and overheating alloy

when thinking about fine surface roughness, what encourages rxn w investment

overheating alloy

definition of finishing

to put a final surface on; the refinement of form prior to polishing

definition of polishing

to make smooth and glossy, usually by abrasion

w an interim prothesis, would you do finishing or polishing

finishing

w a definitive prosthesis, would you do finishing or polishing

polishing

what are the general steps of “the direct restoration armamentarium” (12)

diagnostic

tissue management

isolation

decay removal

cavity preparation

sectional matrix

lingual matrix

bonding

composite

placing, shaping, bending, and curing

finishing

procedure systems

polishing

what is the diagnostic step of direct restoration armamentarium

where dentistry and tx begin using high quality hand-instruments, x-ray sensors, and headlight systems

what is the tissue management step of direct restoration armamentarium

a soft-tissue diode dental laser can make dentistry easier and more painless

what is the isolation step of direct restoration armamentarium

help control the oral environment of a procedure by isolating the effected tooth: a dental dam is commonly used to ensure protection from saliva, blood, and debri; can help clinician focus too

what is the decay removal step of direct restoration armamentarium

removing decay with high quality diamonds, carbides, and handpieces

what is the cavity preperation step of direct restoration armamentarium

using high-quality burs is essential for this step- preparation is key for restorative success

what is the sectional matrix step of direct restoration armamentarium

improves restorative success, an advanced sectional matrix system is used for CII composite restorations and provides a consistently tight posterior contact and delivers inc separation force to reduce flash

what is the lingual matrix step of direct restoration armamentarium

used to build up layers of composite during a CIV restoration; an effective fast set impression material can be used for anterior restorations that can lead to highly esthetic and efficient results

what is the bonding step of direct restoration armamentarium

bond to the enamel is the most important and determines the longevity of your restoration and the integrity of of the composite-enamel margin; the total etch technique provides the highest bond strength to enamel while demineralized the dentin and removing the smear layer

what is the composite step of direct restoration armamentarium

the right composite will provide pts w beautiful dental restorations that will last; an ideal composite will come in various shades and opacities and polish quickly while maintaining high gloss retention

what is the placing, shaping, blending , and curing step of direct restoration armamentarium

shaping and contouring before light-curing results in dec finishing time and equals efficiency and esthetically pleasing restorations

what is the finishing step of direct restoration armamentarium

trimming and finishing carbides and finishing diamonds are used to shape, strip, contour, and add texture to composite

what is the procedure systems step of direct restoration armamentarium

procedure kit can help w predictability, practicality, and repeatability in contouring, finishing, and polishing

what is the polishing step of direct restoration armamentarium

this can require a series of polishers, brushes, discs, strips, and paste

definition of abrasion

wear or material loss from a surface as a result of scratching or other mechanical means

when thinking of dental abrasion, what is the substrate

material being abraded

when thinking about dental abrasion, what is the abrasive

material that causes wear

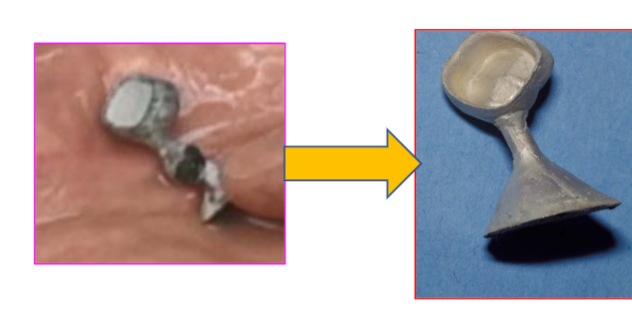

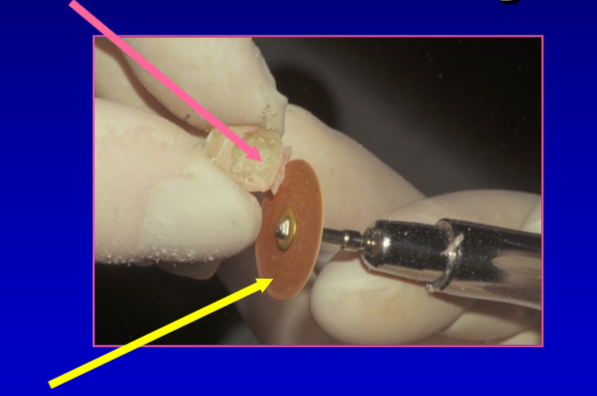

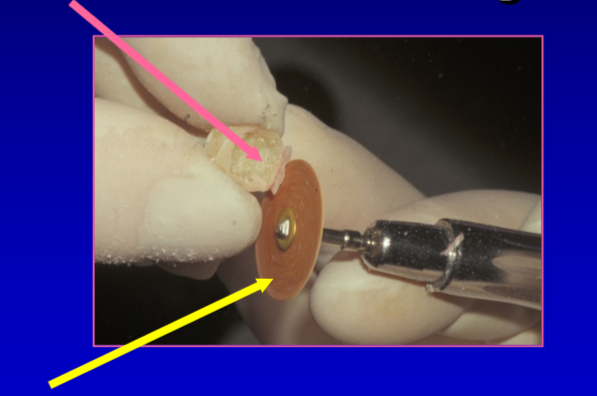

pink arrow

substrate

yellow arrow

abrasive

what are the three dental abrasion procedures

two-body abrasion

three-body abrasion

airborne particle abrasion

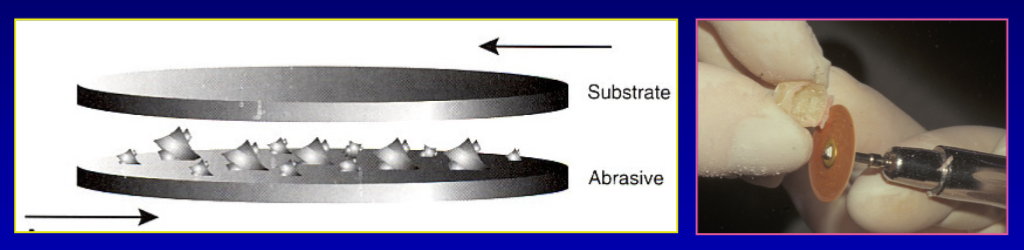

what is two-body abrasion

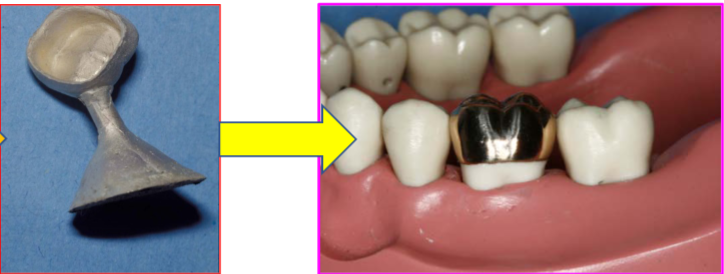

abrasive particles are tightly bonded to the abrasive instrument that is removing material from the substrate surface

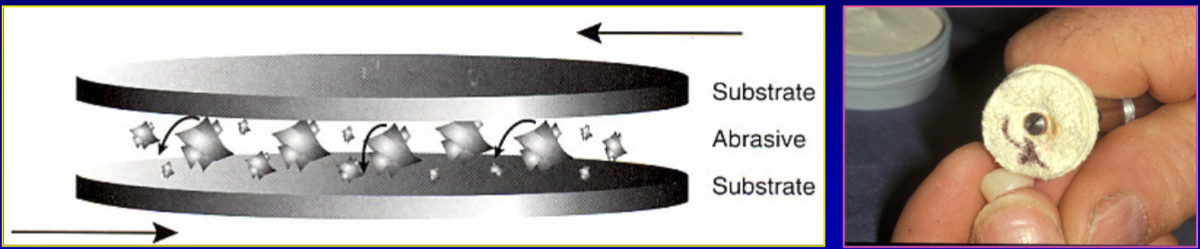

what is three-body abrasion

involves the use of non-bonded abrasives, abrasive particles are free to translate and rotate between two surfaces

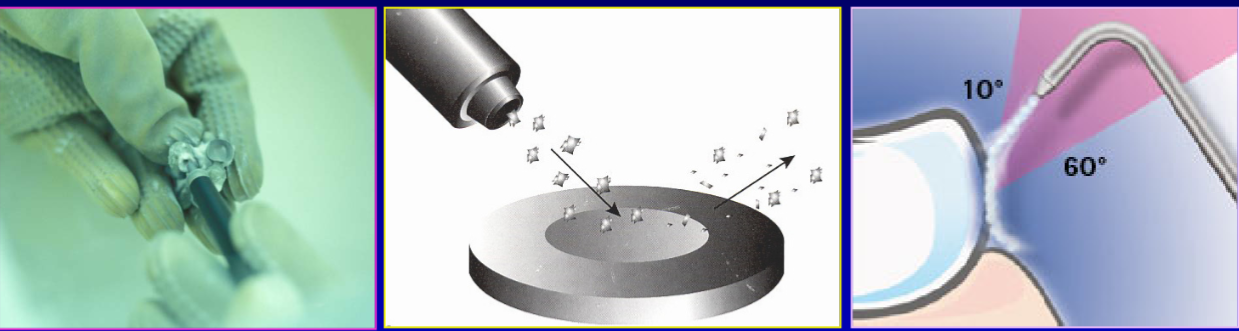

what is airborne particle abrasion

abrasive particles are propelled (sandblasted) against a substrate by air pressure to remove surface material

what are the 5 factors that affect the rate of abrasion

hardness between the abrasive and the substrate

particle size of abrasive

particle shape of abrasive

speed and pressure

lubrication

one of the factors that affect the rate of abrasion is hardness between the abrasive and the substrate, how can we assess hardness

the relative hardness of minerals using a scale established by Dr. Mohs (1812) and an indentation hardness test

what is the Mohs hardness test

the test compares the resistance of a mineral by scratching w ten reference minerals known as Mohs scale materials

what are the 10 materials used in Mohs hardness test

Talc

gypsum

calcite

fluorite

apatite

orthoclase

quartz

topaz

corundum

diamond

what is Mohs Hardness Scale

determined by scratching the surface of the tile w different mineral and subjectively assigning a “Mohs” number

pumice is created when…

super-heated, highly pressurized rock is violently ejected from a volcano

what is included in an indentation hardness test

test surface harness- Brinell, Knoop, Vickers hardness tests

what is an indentation hardness test

the size or the depth of the indentation and the amount of force are used to calculate a hardness value

one of the factors that affect the rate of abrasion is particle size of abrasive, explain this between large and small particles

for the same applied pressure: larger particles leave larger scratches in the substrate while smaller particles leave smaller scratches in the substrate

what color is superfine

white

what color is fine

red

what color is medium

blue

what color is coarse

black

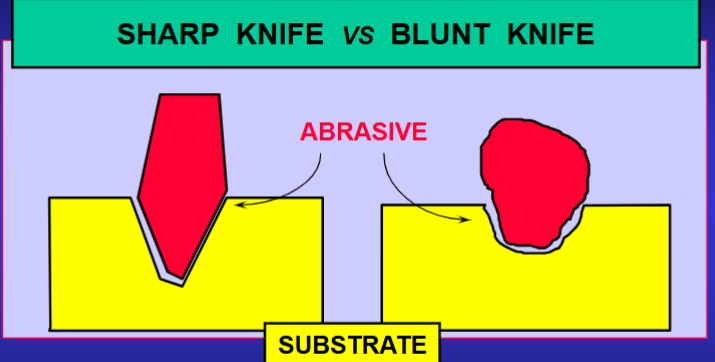

one of the factors that affect the rate of abrasion is particle shape of abrasive, explain the difference of a sharp vs rounder particle

a sharp particle produces a deeper abrasion than a rounder particle under the same applied force

one of the factors that affect the rate of abrasion is abrasive speed and pressure, explain this

deeper and wider scratches are produced by inc the applied force, equivalent sized scratches can be produced by different size of particles by varying the applied pressure

one of the factors that affect the rate of abrasion is lubrication, explain this

reduce heat-buildup, to wash away debris to prevent clogging of the abrasive instrument (ex: wear in engines is reduced using oil or maintenance fluid as a lubricant→ stops metal to metal contact)

the most efficient abrasion occurs when the difference is __________ (larger or smaller) in hardness between the abrasive and substrate

larger

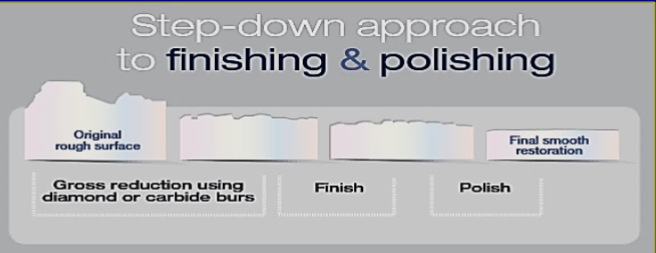

step-down approach to finishing and polishing

finishing: refinement procedure of substrate surface

polishing: makes smooth and glossy surface by abrasion

what are the three types of rotary grinding instruments

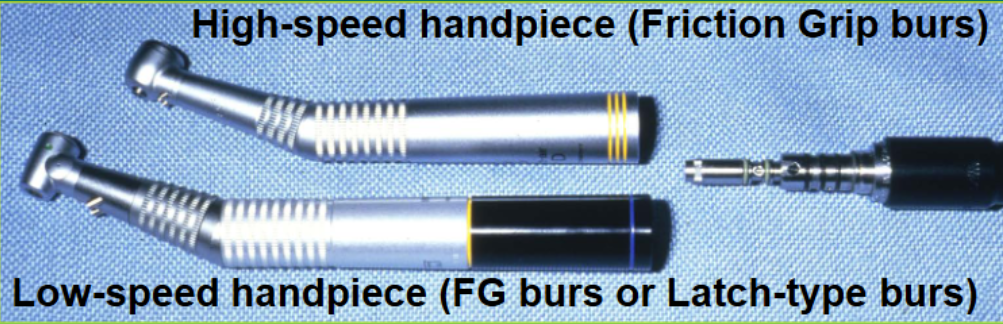

low speed, medium speed, high speed

a high speed rotary instrument is ______-driven

air

air turbine characteristics

balance between speed and torque, faster and consistent cutting and grinding

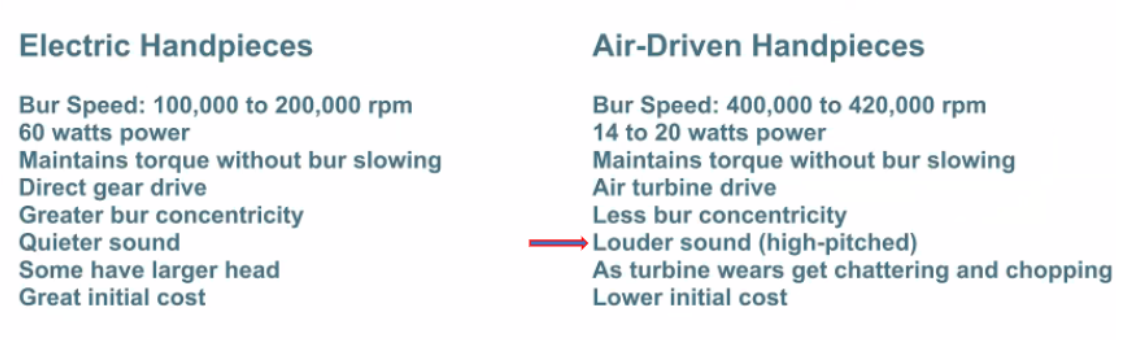

comparison or electric and air-driven handpieces

air-driven: faster, air turbine drive, less bur concentricity, louder sound, cheaper

what are the 5 finishing and polishing instruments

carbide burs, diamond burs, dental stones, rubber wheels, disks and strips

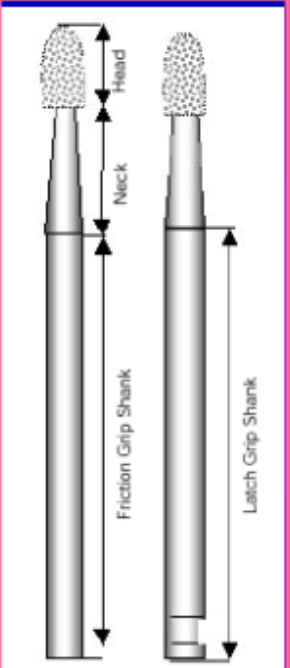

what are the three basic parts of a dental burs - carbide and diamond

the shank, the neck, and the head

what are the two types of shanks in dental burs

friction grip (high speed) and latch-type (slow speed)

what is the purpose having different types of shanks in dental burs

to accommodate either contra-angles or straight handpieces

what are the different head types of carbide burs

barrel, cone, egg, taper, flame, cylinder

in carbide burs, the bur shank is made of ___________ while the cutting blades are made of ________________

stainless steel; tungsten carbide

carbide burs are primarily used for…

contouring and finishing

the most commonly used carbide burs range from 8 to 30 _________ blades which can be __________ or _________

fluted; straight or twisted

what is the straight blade design

one blade on tooth

what is the spiral blade design

several blades on the tooth

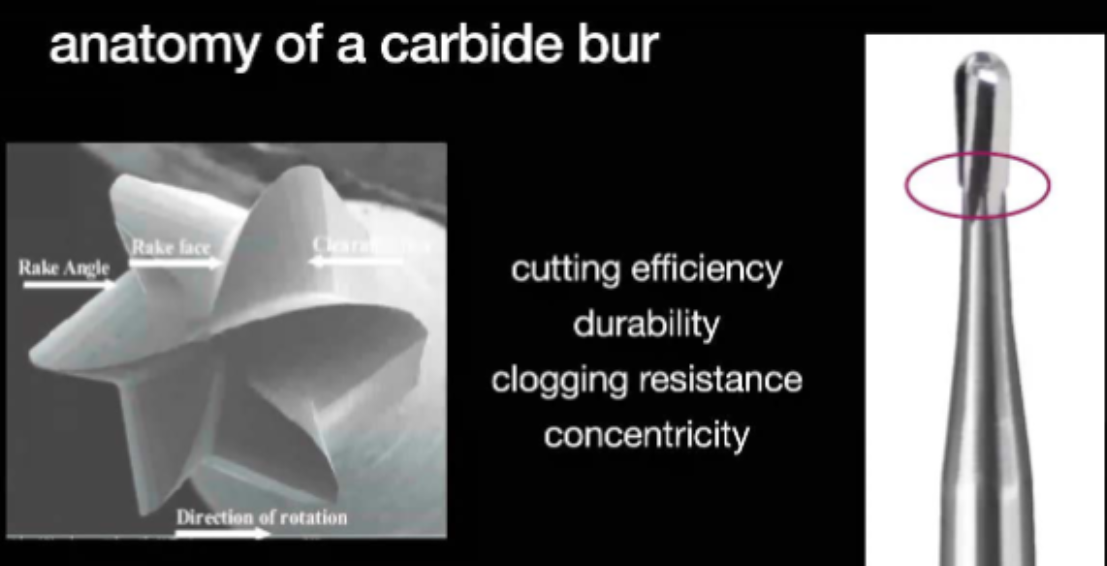

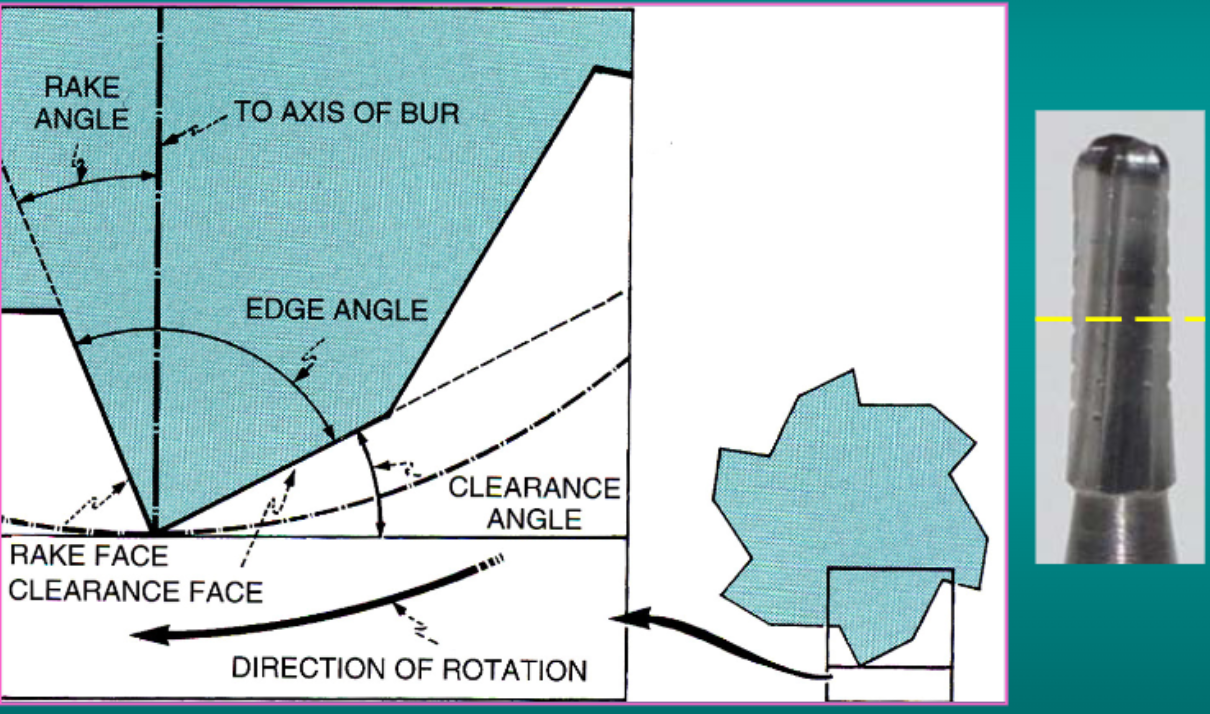

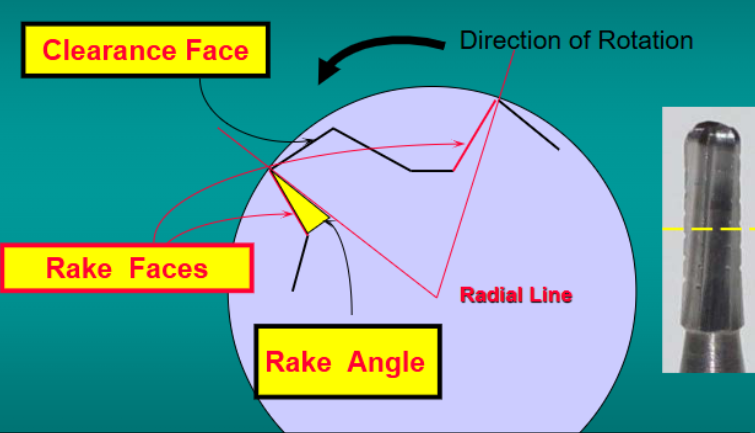

anatomy of a carbide bur

rake angle, rake, face clearance face

carbide bur blade design has ____ angles + ____ faces

3 angles, 2 faces

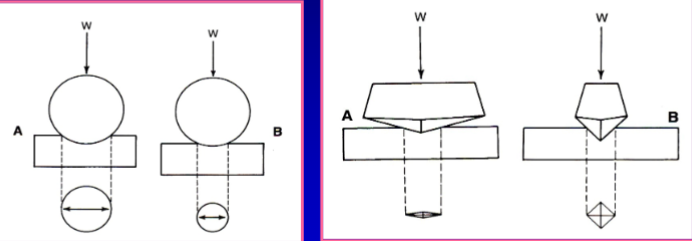

what is the rake angle

the angle made between the rake face and the line connecting the edge to the axis of the bur- cutting edge strength

you want a positive rake angle for what type of materials

soft and weak materials

you want a negative rake angle for…

hard and brittle materials

what is a negative rake angle

the radial line lies behind the rake face and entirely within the blade

what is a positive rake angle

the radius lies outside the blade

the larger the rake angle means ____________ (higher/lower) strength of the cutting edge

lower

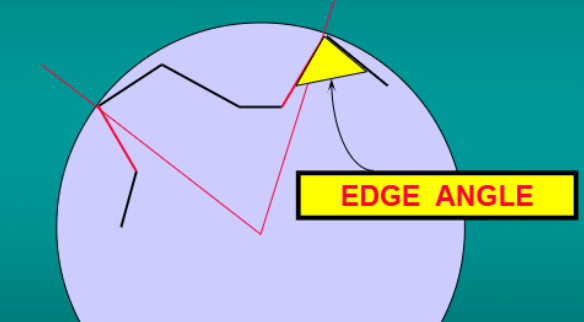

what is the edge angle

internal angle at the edge formed by the two faces of the bur blade, related to the resistance of the blade to fracture- blade strength

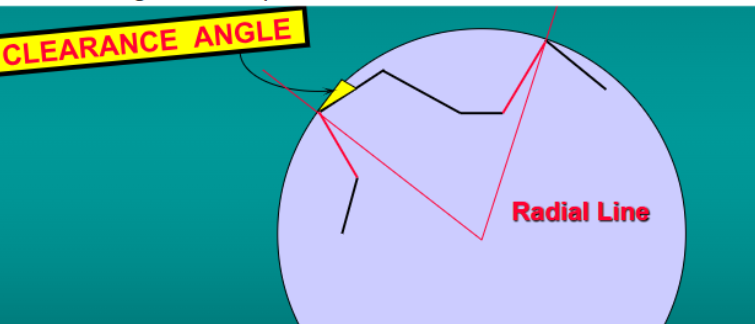

what is the clearance angle

angle between the clearance face immediately behind the edge and a tangent to the path of rotation- provides stop and space

the clearance angle helps eliminate…

rubbing friction of the clearance face of the blade against the new tooth surface

the clearance angle provides a stop to prevent…

the bur edge from digging into the tooth structure excessively

the clearance angle helps to provide an adequate clearance space for…

the chips formed ahead of the following blade

what are diamond instrument primarily used for

finishing ones are used for contour, adjust, and smooth composites or porcelain

diamond bur characteristics (3)

stainless steel shank

the powdered diamond abrasive

a metallic bonding material that holds diamond powder onto the shank

the diamond bur shank is made of…

stainless steel

the diamond bur cutting end is made of…

stainless steel with diamond particles cemented

diamond burs can also come in a disk form where the metal disk is made up of…

stainless steel w diamond particles cemented→ diamond grit

in most cases, diamond particle sizes are applied in a sequence, you start w a ________ (finer/coarser) grit and progress to a _________ (finer/coarser) grit

coarser; finer

diamond burs should always be utilized with…

water spray

polishing instruments, like rubber polishing instruments or pastes, will usually follow the use of…

diamonds

carbide burs are better for…

end-cutting procedures, they produce lower heat and have more blade edges for cutting

diamond burs are better for…

tooth preparation, braveling enamel margins and enameloplasty

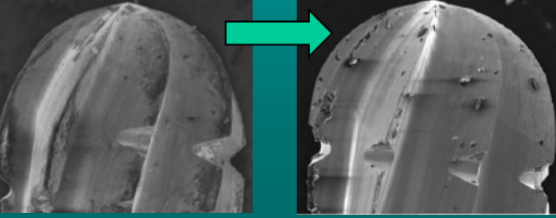

what is happening here

the left is an unused bur and the right is a used bur

what are the 5 cutting recommendations

using a contra-angle handpiece

air-water coolant system

high-operating speed

light pressure

a carbide bur or diamond bur

dental stones consists of what kind of particles

abrasive particles that have been sintered together or bound w an organic resin to form a cohesive mass

dental stones are available in what variety of grade

fine, medium, and coarse grades

what are the three types of dental stones

silicon carbide (carborundum)

aluminum oxide

diamond stone

what are dental stones primarily used for

contouring and finishing restorations, and where maximum abrasion is needed

what are rubber wheels used for

fine grinding to remove coarse scratches from rough grinding

rubber wheels are made by…

molding the fine abrasives in a rubber matrix

what are the fine abrasives that are used in a rubber matrix to make rubber wheels

aluminum oxide, silicon carbide, chromium oxide

what are rubber polishers used for

for adjusting and polishing acrylic material

rubber polishers are often sold as kits, why

have a variety if shapes and grits since the wheel instruments are not flexible enough to reach all tooth surfaces

________ shape instruments are used for occlusal fine finishing and polishing

point

what do you not want to do when using rubber polishers

you do not want to apply heavy pressure, will produce excessive friction heat which can have a negative effect on the restoration, the rubber instrument, and the tooth itself