Westgard, Evaluation Methods, and Reference Values

1/224

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

225 Terms

Who developed Westgard rules

James Westgard

What does Multi rule Quality Control use

a combo of decision criteria and or a combo of control rules sequentially

What type of control materials are used in Westgard rules

Level 1 and Level 2

How are decisions made in Westgard Rules

they are made in a sequential fashion

What is the main purpose of using Westgard Rules

its allows the determination of whether an analytical run is in control or out of control

How does the accuracy of Westgard Rules compare to a L-J Chart

Westgard provides better accuracy when used with single control rules

How are most quality control rules expressed in Westgard rules

they are expressed as N^L

What does N represent in Westgard Rules

the number of control observations or runs to be evaluated

What does L represent in Westgard rules

the statistical limit for evaluating the control observations

When are Multirule quality control used

when there are 2 levels of control material are being analyzed per run

What are Westgard rules designed to do

minimize false alarms or false rejections and increase error detection

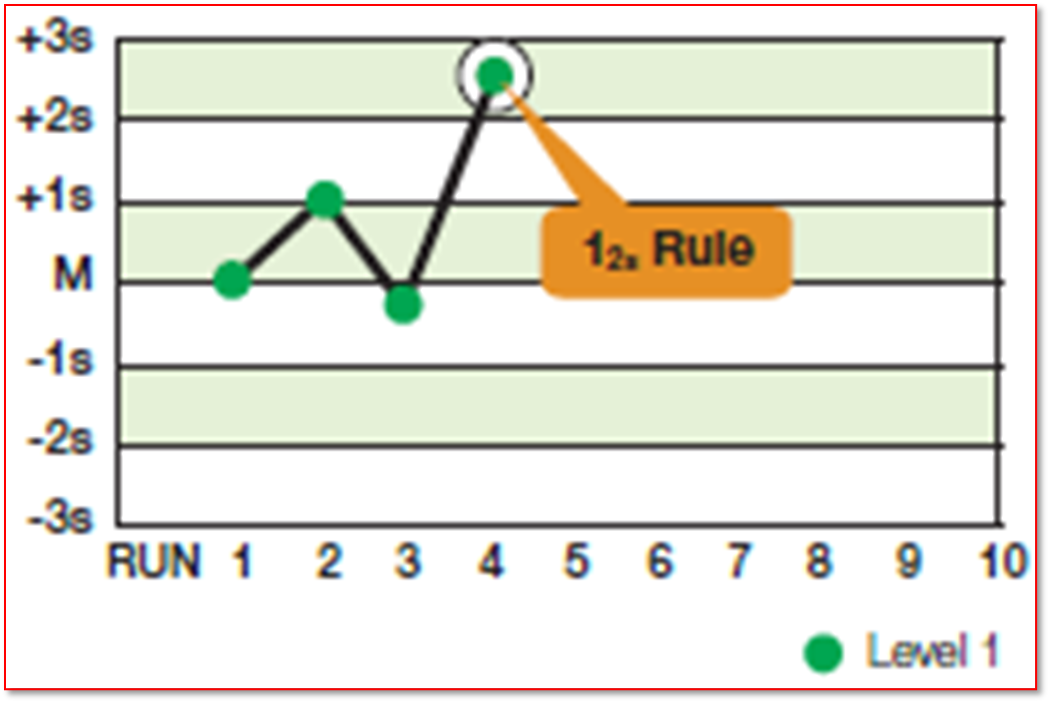

What is Westgard 12S rule

The warning rule where one of the two controls results falls outside ± 2SD

What is the purpose of the 12S warning rule

it alerts techs to possible problems

Does the 12S rule automatically reject a run

No, because this deviation can happen by chance

What must be done after an 12S rule alert

The 13s rule must then be evaluated and the process of evaluation must continue sequentially

Which Westgard Rule is this

12S or Warning rule

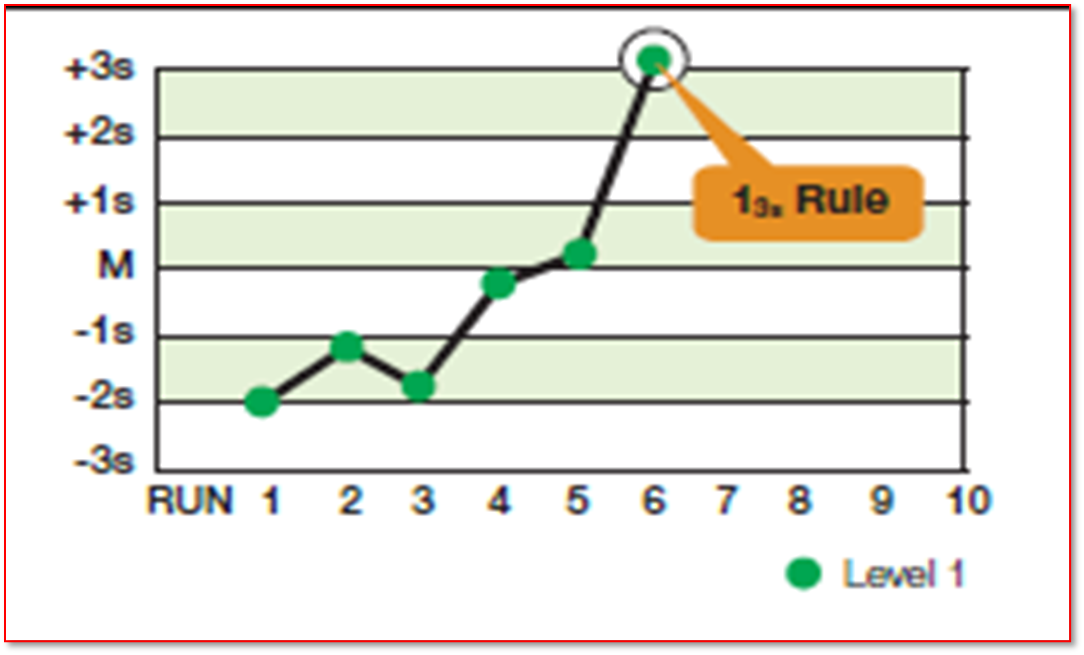

What is the Westgard 13S rule

when either of the two control material fall outside of ± 3SD

What does a violation of rule 13S indicate

it is an indication of a random error

What should be done if rule 13S is violated

the run must be rejected

What is done if rule 13S is not violated

the next rule 22S should be checked and the evaluation should continue in a sequential order

Which rule is this

13S

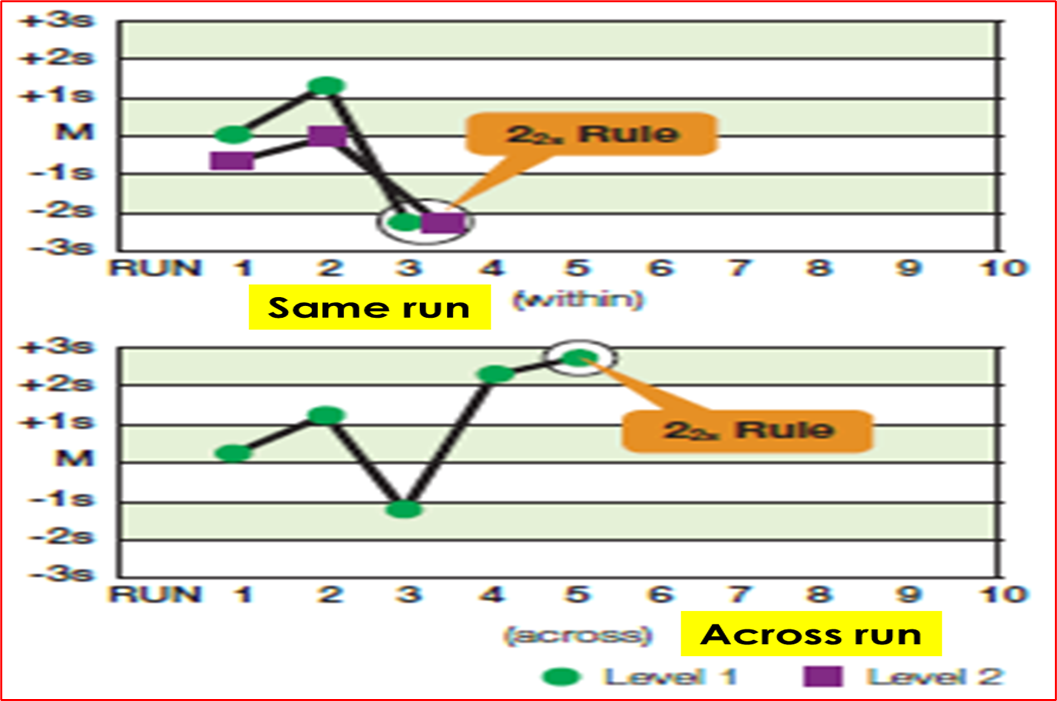

What is the Westgard rule 22S

when two consecutive quality control results exceed ± 2SD on same side of the mean

When can 22S rule be violated

Within the same run or across consecutive runs

Can the patient results be reported if rule 22S is violated

NO

What is required if 22S rule is violated

Corrective action must be taken

What rule is being violated

22S, the mean of level 1 and 2 are below -2SD on graph 1 and the run on the second graph exceeds +2SD across run day 4&5

What does a violation of the 22S rule indicate

a systemic error

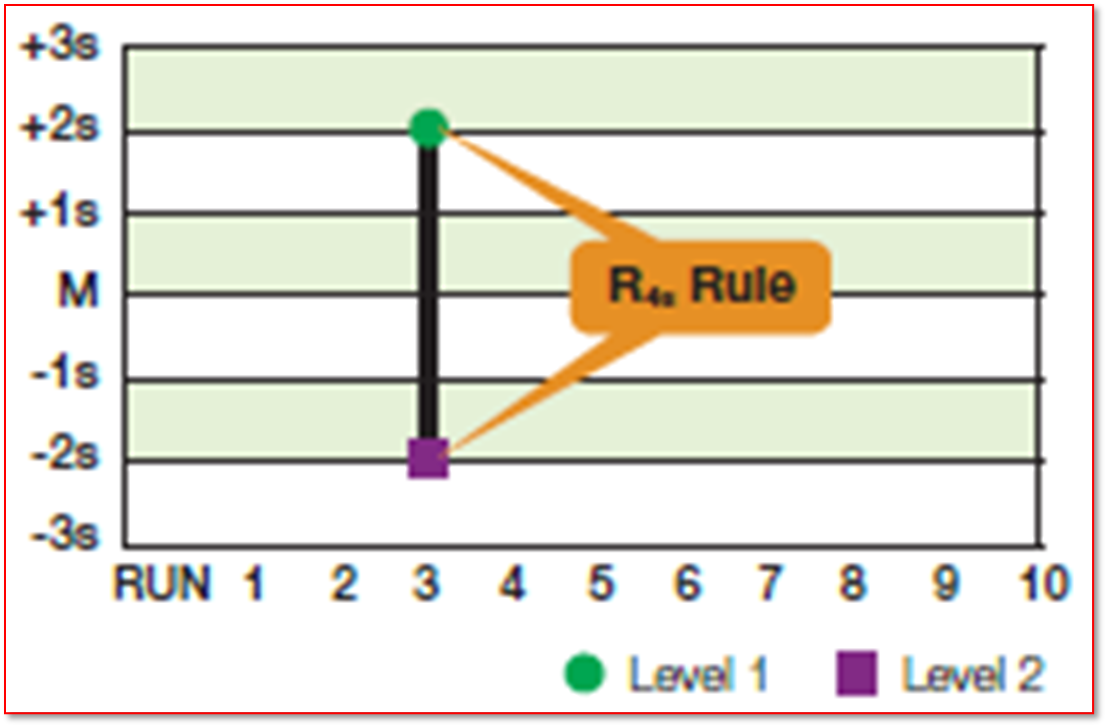

What is the Westgard rule R4S

a range rule when one control exceeds the mean by -2SD and the other control exceeds the mean +2SD the range between the two results will exceed 4SD

What does a violation of the R4S rule indicate

a random error within the current run and not across run

Which rule is being violated

rule R4S

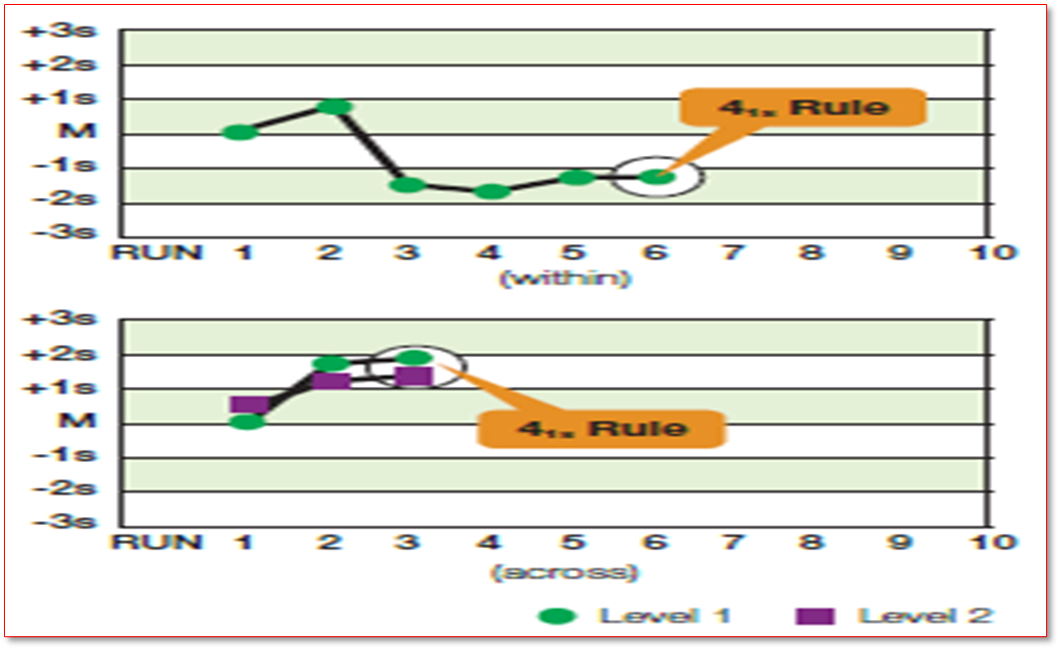

What is the Westgard 41S rule

when four consecutive control rules are greater than ± 1SD on the same side of the mean

What does the 41S rule require for evaluation

control data from previous runs

How does the 41S rule apply within a single control material

it indicates systemic bias within level one control results in a single area of the method curve

How does the 41S rule apply across control materials

when applied across level one and two in combination with each showing two consecutive results greater than ± 1SD on the same side of the mean it indicates systemic error over a greater concentration

Which rule is being violated

41S where on the first graph there are 4 consecutive rules being violated only on one level indicating systemic error in one error, whereas the second graph shows 4 consecutive rules being violated in two levels which indicates systemic error in greater broad concentration

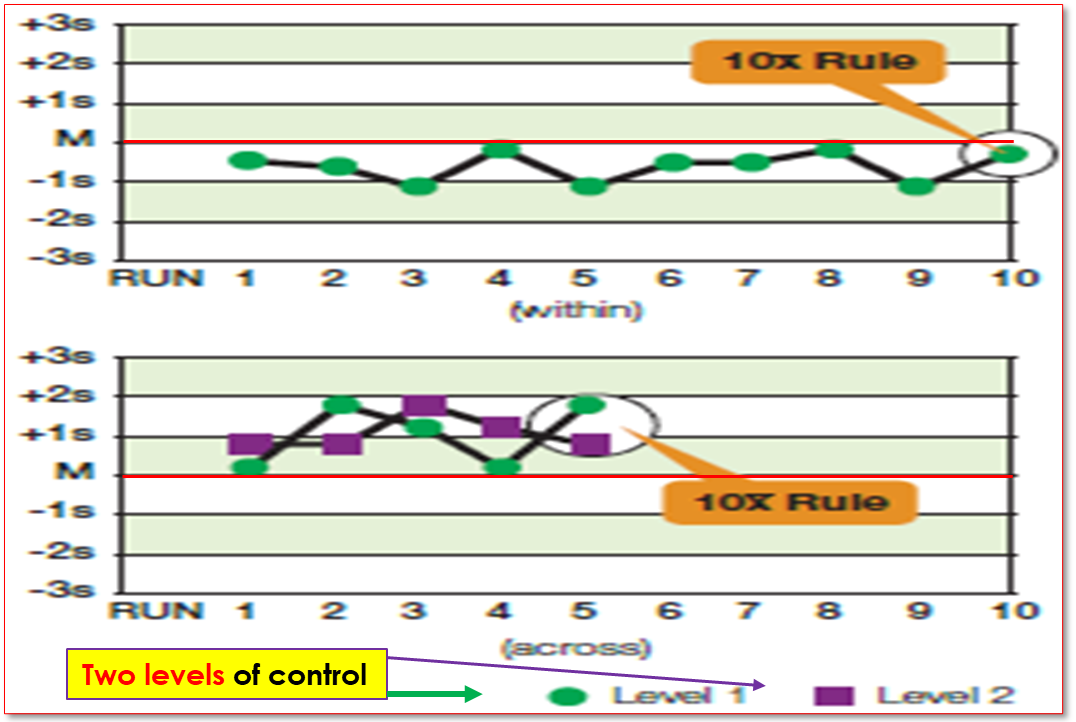

What is the Westgard 10X rule

when 10 consecutive QC results for one level of control are on one side of the mean

How does the 10X rules apply to one level of control

a violation occurs if all 10 consecutive results from that level fall on the same side of the mean

How does 10X apply to two levels of control

a violation occurs if five consecutive results from each level are on the same side of the mean

What does the 10X rule require for evaluation

it requires control data from previous runs

What rule is being violated

10X rule where graph one shows that all 10 consecutive runs are all on the same side of the mean on one level, and the second graph shows two levels running 5 consecutive runs each on the same side of the mean

What are indicators of systemic error in quality control

the two main indicators are Trends and Shifts in control data

What are trends in systematic errors

they are gradual increase or decrease in control values over time similar to a chronic condition

What are causes of trends in systematic errors

Reagent of standard deterioration

Gradual accumulation of debris in the sample or reagent delivery system

Deterioration of the instrument light source or performance

Aging or deterioration of QC materials

What direction can trends take

upward or downward

What are shifts in systematic errors

a sudden change in values in one direction, similar to an acute condition

What are some causes of shifts in systematic errors

Use of new reagents

Malfunction in the instrument or major maintenance

Inaccurate calibration or recalibration

Failure in sample/reagent delivery system

What direction can shifts take

negative or positive deviation

What is the traffic light rule

warning rule means to use other rules to inspect control points for further evaluation, and rejection rule indicates that the process is out of control, requiring immediate corrective action

What should be done if a rejection rule is violated

stop testing immediate

Identify, correct and document the problem

Repeat testing on patient samples and controls

Do not report results

When can you report results when a rule is rejected

until the problem is solved

until controls indicate proper performance

When should you follow policies and procedures

for remedial action and troubleshooting

What does solving “out of control” problems include

Retest the same control

Retest a fresh aliquot of the same control material

Reconstitute/thaw a new vial of control material and retest

Replace faulty reagents/ check reagent lot

Look for instrument - related mechanical faults

Recalibrate the assay ( asses linear response which is the signal or absorbance/concentration)

Consult the QC officer and/ or supervisor for further direction

What organizations set quality control standards

JCAHO, CLIA, and CAP

What do JCAHO, CLIA, and CAP stand for

Joint Commission on Accreditation of Health Organizations

Clinical Laboratory Improvement Amendments

College of American Pathologist

What QC requirements are set by JCAHO, CLIA, and CAP

The number of control value run/day (CLIA guidelines)

Documentation of QC results

Proficiency testing as part of quality assessment

Standard operating procedures (SOPs) for testing

Training and refresher courses for staff

What is the minimum number of control materials that must be run each day according to CLIA guidelines

according to CLIA 88’ at least two control samples of different concentrations must be tested every 24 hours

What are examples of QC guideline for blood gas testing

Test both high/low blood gas control materials

This must be tested every 24 hours

At least one blood gas control sample must be tested every 8 hours

At least one control must be tested each time a patient sample is tested

What should be included in QC documentation

Record all information good/bad

Record all corrective action

What is proficiency testing

a QC requirement process by which stimulated patient specimens made from a common pool are used to validate a laboratory performance in testing process

Who requires proficiency testng

CAP, CLIA, and JCAHO

What is the purpose of proficiency testing

to maintain lab accreditation

What are the steps for proficiency testing

A series of unknown samples is sent to lab from program

Samples are analyzed in the same manner as patient samples

Results are reported to program

Results are complied with results from all other labs participating in survey

Performance report is sent back to each participating lab

What are strict requirements for proficiency testing

Labs must incorporate PT into its routine workflow as much as possible

Test values/samples must not be shared with other labs at any time

PT samples are tested by bench technical staff only who normally do patient testing and should be completed within usual time

What is personnel competency and training apart of

QC requirement

What do personnel competency and training address

the importance of people training and education

What are CLIA’S components for laboratory competency assessment

Timing of training and guidelines for competence assessment (frequency/Interval)

Design of in service training program (workshop) via internet/ zoom conferencing

Needs assessment of gap analysis (area of defect)

Utility and economy of internet based in service training

What is the purpose of a CLSI (clinical and lab standards institute) defined procedure document

it is a QC requirement document of an analytical procedure and promotes development and use of consensus standards

What should a SOP document include

Test name

Method principal

Significance of test

Patient preparation

Test specimen requirements

Equipment and materials needed

Reagent preperation

Test procedure

Calculations

Quality control procedures

Reference intervals

Panic values

Limitations of the procedure

References (including the instrument user’s manual)

How often should the procedure be reviewed, signed, and dated

annually

What are new quality initiatives

programs used to ensure incorporation of QM and QA principals into daily operations

What is the purpose of New Quality initiatives

eliminate defects and improve processes

What is the relationship between QM and QA in these initiatives

they are a continuous improvement process

What is SIX SIGMA

a QC process that business use to eliminate defects and improve processes

What are other examples of New Quality intiaitve

Lean Production -used in manufacturing to eliminate defects and improve processes

International Organization for Standardization (ISO) 9000

Joint Committee for Traceability in Laboratory Medicine

Why do we evaluate method performance in clinical laboratories

to assess how well new methods compare to existing methods

Why is it important to evaluate method performance

because the agreement between clinical lab test results and the clinical diagnosis is indispensable

Why do we evaluate laboratory test methods

To assess clinical performance of methods

To assess characteristics of the test methods

How well they detect disease when disease is present (Sensitivity)'

How well they do not detect when disease is absent (specifically)

What does the agreement between clinical lab test result and clinical diagnosis ultimately establish

definitive diagnosis

What is an important consideration during evaluation of test methods

it will ensure achievement of definitive diagnosis using reliable clinical methods

What do evaluation of test methods provide

an indication of test performance

What is the “million dollar question” in clinical testing

What are the tools for representing extent of agreement

The extent of agreement of test results with patient diagnosis or clinical diagnosis is represented in which ways or how well does the test results agree with the doctors diagnosis

Clinical sensitivity

Clinical specificity

Efficiency

Predictive values

Positive Predictive Value

Negative Predicative Value

Receiver operating characteristics (ROC) charts

Odds ratio

Likelihood ratios (LH)

Positive LH

Negative LH

What does sensitivity measure in clinical testing

how well a test detects the presence of disease in people who actually have it.

How is sensitivity related to disease

it is the percentage of people with a disease

What does sensitivity detect

the true positive or TP

What is FPR

the quantity 1-specficity

What is FNR

the quantity 1-sensitivity

What is the formula for Specificity

TRUE NEG/ TRUE NEG + FALSE POS

What is the formula for Sensitivity

TRUE POS/ TRUE POS+ FALSE NEG

What is a sensitive test (method)

one that rarely miss people who have the disease which means it will have few false negatives

Why is sensitive testing important in Cushing Syndrome

because the syndrome is caused by excess cortisol it can be fatal if misdiagnosed

Therefore, in order to avoid misdiagnosis the sensitive test method must have …

high sensitivity with few false negatives

How is specificity related to health

it is the percentage of people without the disease when correctly predicted by the test

What does specificity measure

how well the test is at calling uninfected people negative

What does specificity detect

it detects true negative or TP

A specific test will…

rarely misclassify people without the disease and will have few false positives

Why is specificity important in cystic fibrosis

the disease is serious and is not curable (affects babies) and if a FP is obtained it can lead to psychological and economic trauma to the patient and parents

Therefore, in order to avoid misdiagnosis the specific test method must have …

the highest specificity with few false positives

Clinical sensitivity and specificity test can be

Dichotomous (qualitative or binary, descriptive) or Continuous (quantitative data)

What is a dichotomous test

a type of test that has defined variables (two possible outcomes or results), such as pos/neg, 1 or 0, or present or absent