7. characteristics of metals

1/60

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

61 Terms

what kinds of stock form are more expensive?

more complex or containing more material

5 main metal stock forms

sheet

plate

bar

tube

structural angular

how thick are metal sheets?

from less than 1 mm up to 3mm

how thick are metal plates?

3 mm

4 types of metal bar

flat

square

round

hexagonal

4 types of metal tube

square

rectangular (AKA box section)

round

hexagonal

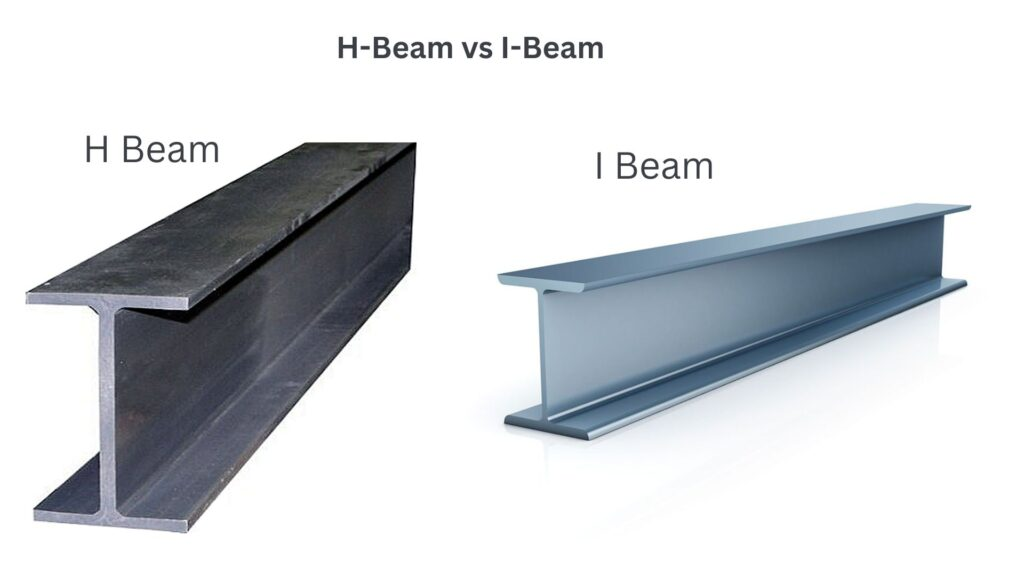

5 types of structural angular shapes

H beams

L beams (AKA angle)

I beams

tee bar

channel

how much of the Earth's crust is made of metal ore?

25%

what is the most common ore?

bauxite

how is raw metal extracted from ore?

crushing and smelting

with addition of chemicals and huge amounts of electrical energy

why are metals easy to recycle?

low melting point

copper ore name

chalcopyrite

iron ore name

haematite

aluminium ore name

bauxite

tin ore name

cassiterite

zinc ore name

zinc blende ✨

three main metal categories

ferrous, non-ferrous, alloy

what does ferrous mean?

containing iron

what is an alloy?

material made of two or more elements, at least one being a metal, to enhance properties

pewter melting temperature

170-230 degrees C

titanium melting temperature

1668 degrees C

low carbon steel carbon content

0.15-0.30%

medium carbon steel carbon content

0.30-0.70%

cast iron carbon content

2.5-4.0%

what is stainless steel made of?

iron, chromium, nickel

what is HSS made of?

iron, tungsten, chromium, vanadium, carbon

what is tool steel made of?

same as HSS

what is bronze made of?

copper and tin

what is brass made of?

copper and zinc

what is duralumin made of?

aluminium, copper, magnesium, manganese

what is pewter made of?

tin, copper, antimony

what is wrought iron forging used for?

decorative metalwork such as fencing

what material does wrought iron forging use?

wrought iron - carbon content less than 0.08%

in what two ways can wrought iron forging be done?

by hand

hydraulic press

advantages of hot rolling

uniform mechanical properties, no deformation or stresses

advantages of cold rolling

material with tighter tolerance and better surface finish

what is hot chamber pressure die casting?

same as gravity die casting but it uses a plunger in a chamber to force the molten metal into the die

what is cold chamber pressure die casting?

same as gravity die casting but it uses a ram to force the molten metal into the die through a shot chamber

it looks similar to injection moulding

what is investment casting used for?

intricate shapes that are difficult to mould with other casting processes

how does TIG welding differ from MIG?

uses filler rod and the electricity is provided by a tungsten electrode as opposed to the electrode being the weld metal

what is TIG welding used for?

stainless steel

what materials is MIG used for?

aluminium or medium carbon steel

what kind of task is oxy-acetylene welding used for?

quick or remote jobs

where arc welding processes are not available/there is no power supply

how does oxy-acetylene welding differ from MIG/TIG?

mixture of 2 high pressure gasses, oxygen and acetylene, to form an intense flame, melting base metal and filler rod

how does spot welding work?

mild steel sheet is welded together at points along a length, when charged copper electrodes make contact with the metal

what is soldering used for?

gold or silver jewellery or copper pipe in plumbing

how does soldering work?

uses a filler metal of a lower melting point than metals being joined

what is brazing used for?

mild steel tube or bar

dissimilar metals such as mild steel sheet to aluminium

how does brazing work?

brass filler rod, sometimes with oxy-acetylene - lower temp than welding

how does riveting work?

two pieces are overlapped and drilled

rivet is placed through and the end of the shaft is hammered over to join

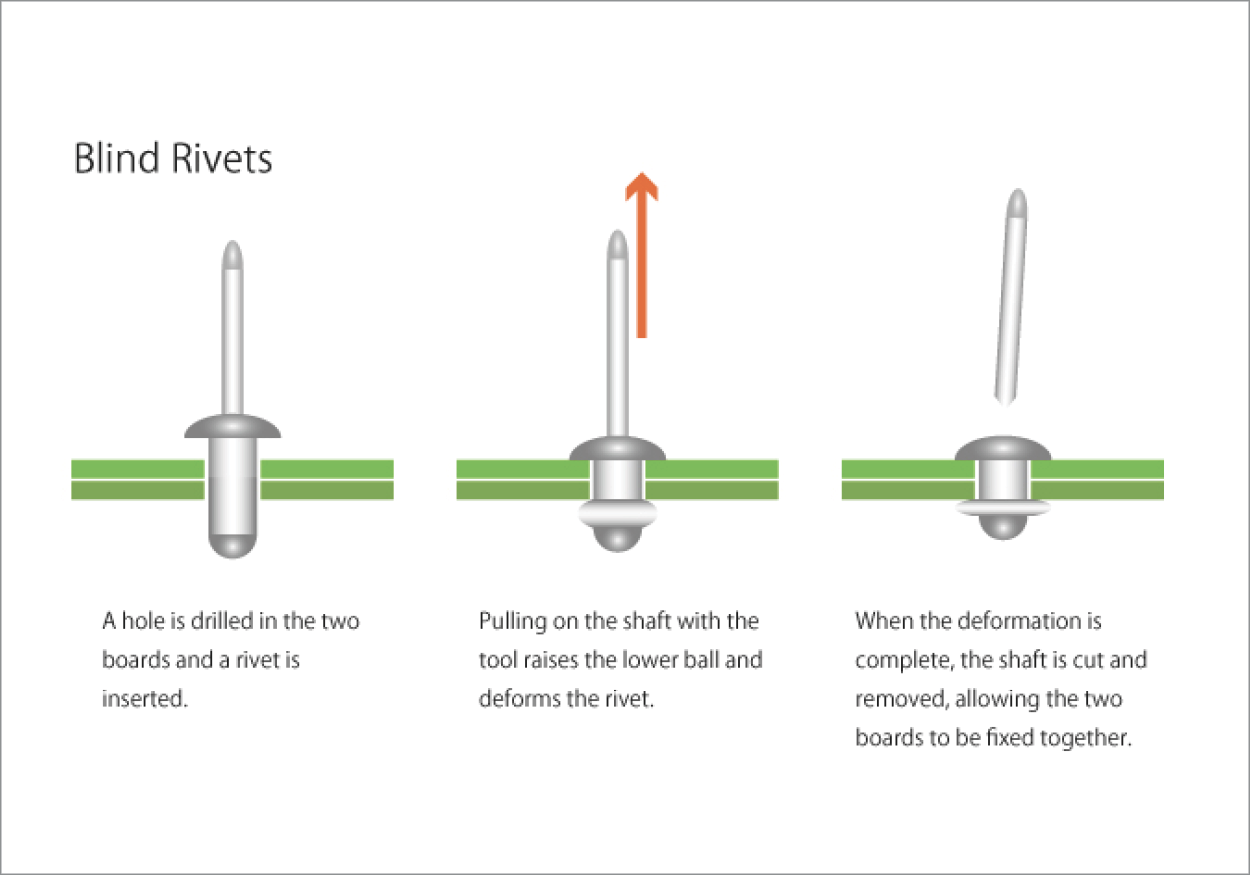

what is pop riveting used for?

when underside of joint is inaccessible

how does pop riveting work?

a steel pin is placed in the gun with a hollow rivet body. The gun breaks off the pin, completing the rivet

three types of temporary fasteners

self-tapping screws

machine screws

nut and bolt

how do self-tapping screws work?

pilot hole is drilled through and the screw is screwed in, cutting its own thread and keeping it in place

how do machine screws work?

top part to be joined has a clearance hole larger than the thread on the bolt, then the bolt is screwed into a threaded hole in the second piece

how is flame cutting done?

oxy-acetylene gas and flame-cutting torch deliver a very focused and intense flame to cut low carbon and alloy steel plates

flame cutting disadvantage

difficult to maintain parallel line with high levels of tolerance

what is plasma?

super-heated ionised gas that is electrically conductive

how is plasma cutting done?

the conductive plasma gas transfers energy from the power supply to a conductive material, quickly burning through the material and blowing it away

how is punching/stamping done?

CNC machine uses shearing on a sheet of metal placed between a punch and a die

what is redistribution?

material changes from one form to another