Metal Alloys for Removable Partial Dentures (RPDs) and Clasps

1/63

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

64 Terms

For the last lecture

Dentures rely on soft tissues while fixed pros don’t so it doesn’t matter if you use a viscous muco/compressive impression material

immediate casting for alginates

Elastomers vary on whether they are compressive or static based on high viscosity and low viscosity respectively

might use putty instead of green stick for border moulding

Polyether - hydrophilic

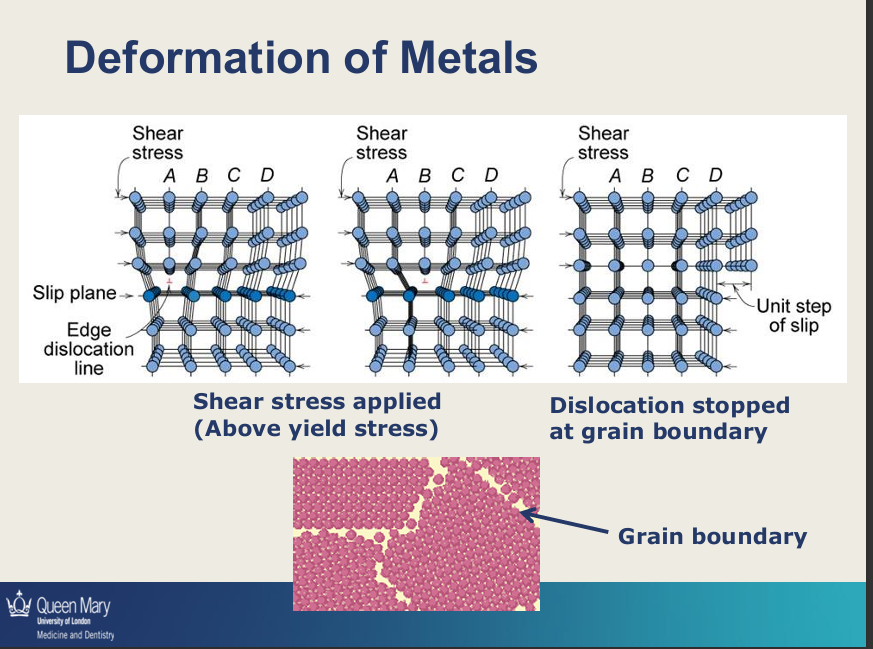

Deformation of metals requires what?

what happens in the metal in permanent deformations?

to deform metals you apply stress above yield stress

if it is lower than the yield stress, you get no deformation

you get movements of dislocations which then stop at the grain boundary

in the image there is an extra plane of atoms moving from A to B to D and keeps moving due to application of stress above the yield stress - as it moves it will eventually stop at the grain boundary - as between grain boundaries structure is amorphous where atoms are arranged randomly so cannot move beyond the crystalline structures (where atoms are arranged in organised structure).

next time you deform the metal you require higher forces

when you bend/apply force the metal more dislocations are also made

eventually it will fracture

What is work (strain hardening)?

Application of shear stresses produces more dislocations, hinders the movement of dislocations, more difficult to deform the metal

What are other strengthening mechanisms? (6)

Forging - drawing wire/rolling sheets

Bending - denture clasp, orthodontic appliances

burnishing - amalgam or Gold Inlay

Solution hardening - different atomic radii of atoms within same crystalline structure limit the movement of slip planes (alloys)

order hardening - super lattice (ordered structure) formation (in a solid solution)

precipitation hardening - partial solubility varying with temperature Ag-Cu

in a solid solution the metals are completely soluble

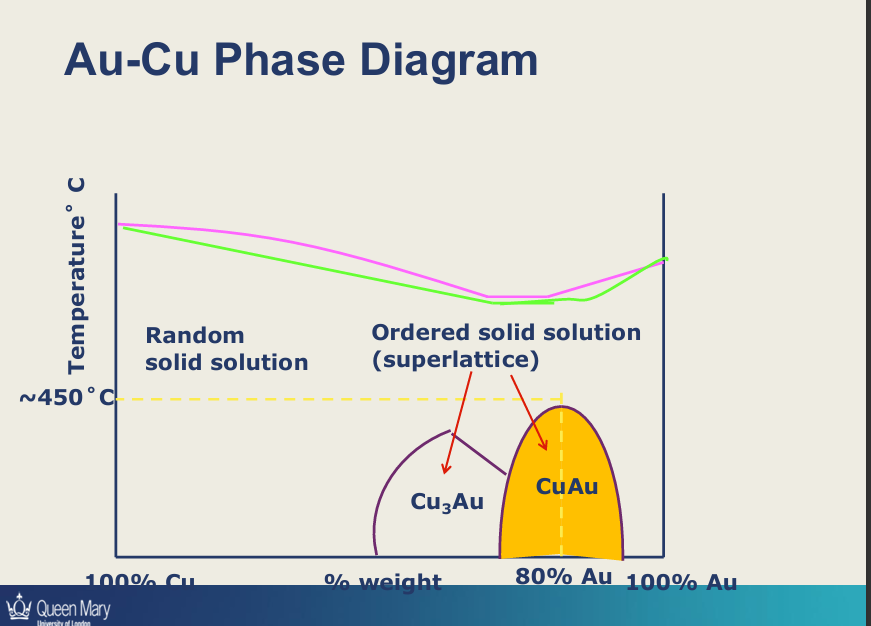

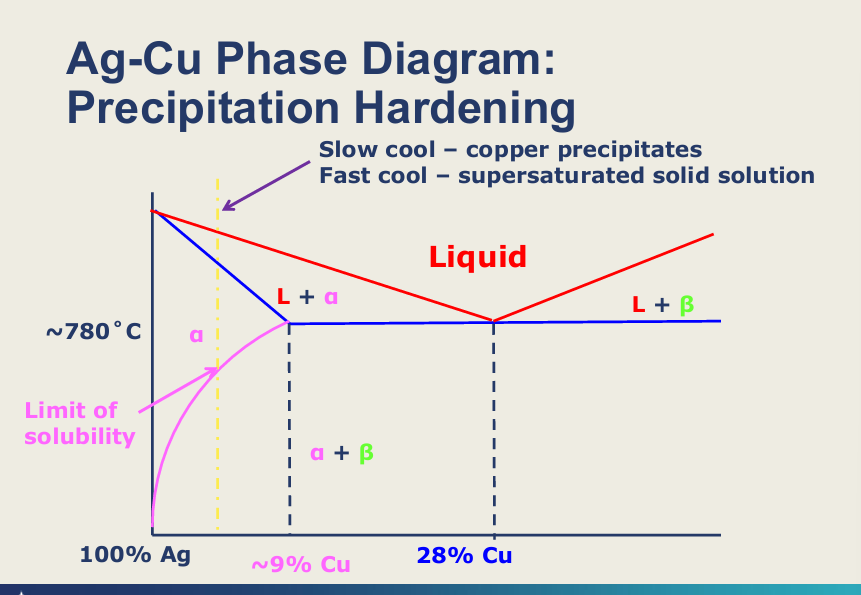

Describe this diagram

heat above the pink line - liquid

fast cooling/quench/solid solution - 1 phase of metal in a random state (organised/ordered/crystalline structure but atoms in random structure) (atom position is disordered)

put the metal under heat treatment - not melting the metal - giving atoms energy and time to form ordered structure within the crystal = super lattice (atoms occupy specific repeating positions)

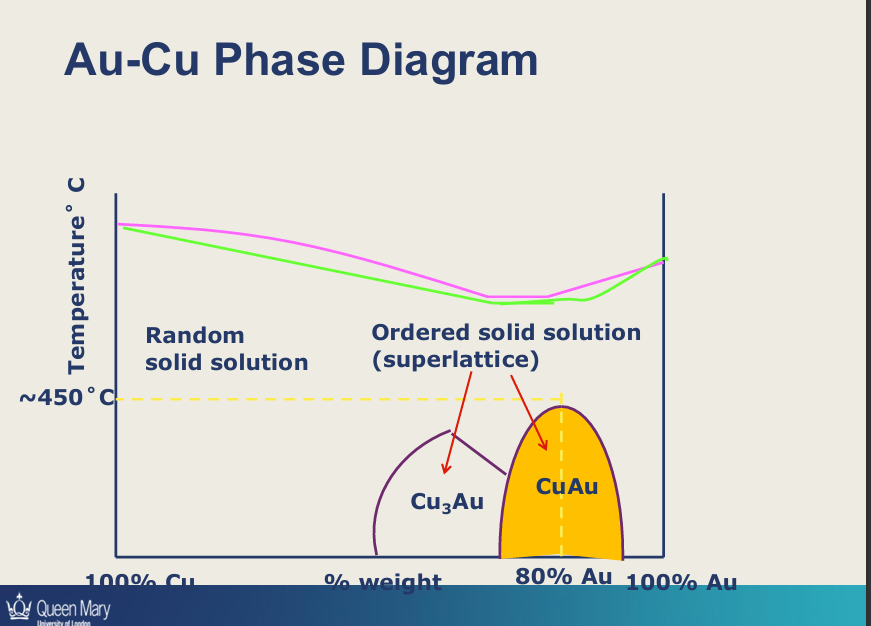

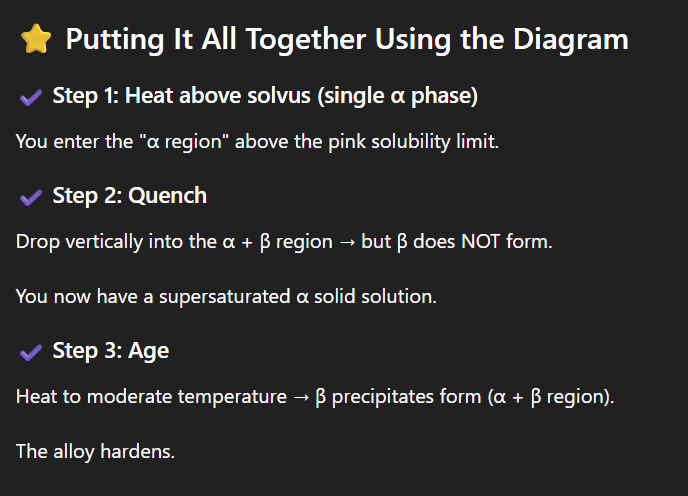

Explain this diagram?

Solid solution - 2 metals are completely soluble in each other so one phase

limit of solubility, if you cool metal you freeze structure in place (alpha) - supersaturated solution

if you slow cool and below limit of solubility - you get a phase rich in copper will start precipitating within the alloy - so you create obstacles that dislocations can’t move beyond that second phase

slow cooling allows the Cu to diffuse when the solubility decreases

What are the 3 classifications of dental alloys? (3)

High noble

Noble

predominantly base metal

What is a Noble Metal?

Must contain a Noble metal

Containing least 60% noble metal of which 40% must be gold Au

Other metals - Pt, Pd, Rh, Ru, Ir, Os

platinum, palladium, rhodium, ruthenium, iridium, osmium

Noble metals?

Must contain at least 25% noble metals

Predominantly base metals?

Contain <25% noble metal

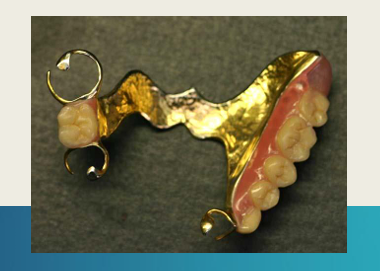

What are the alloys used for removable partial dentures?

Initially

1930’s

1970’s

other alloys (3)

Gold alloys

chrome-based developed

cobalt-chrome alloys

nickel chrome, type IV gold, titanium-based alloys

3 main categories for ideal requirements of Removable partial dentures alloys?

Handling and fabrication

Mechanical properties

Biological and clinical

Handling and fabrication requirements includes: (7)

Easy to cast (low melting point, high density)

High density = easier to fill mould completely and force air out of the mould

Easily soldered or laser-welded

Low shrinkage

Easy to finish, polish and adjust

Mechanical properties requirements includes: (4)

High rigidity (high modulus) - support and stability

High yield stress and fatigue stress - avoids permanent deformations during function

Good wear resistance

Biological and clinical ideal requirements include? (4)

Biocompatible and corrosion resistant

Comfortable (light weight thin sections)

Aesthetic compatibility with acrylics and tissues

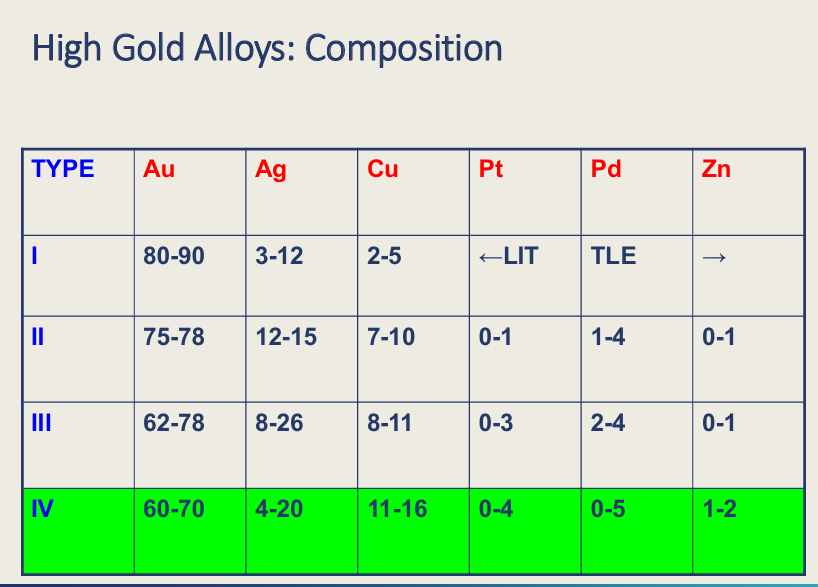

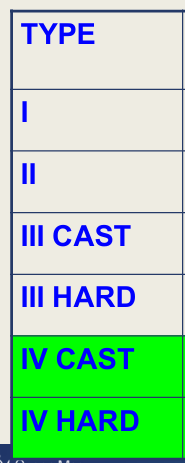

What type is high gold alloy? 1-4?

Type 4 (IV)

3 and 4 further divided into?

cast and hard

Which have the better property?

hard is more hard and higher tensile strength the 4 has better properties Don’t have hard type 1 and type 2 - hard - not enough copper in the system for ordered structure

Properties of type IV gold for removable partial dentures (not used anymore): adv(7) dis(4)

Adv:

Low melting point

Easy to cast

easy to solder

can be heat hardened (order hardened)

easy to finish/polish

biocompatible

corrosion resistant

dis:

High density

Low yield stress

low modulus

expensive

high density and low modulus - needs to be in thick cross sections - not comfortable for patient

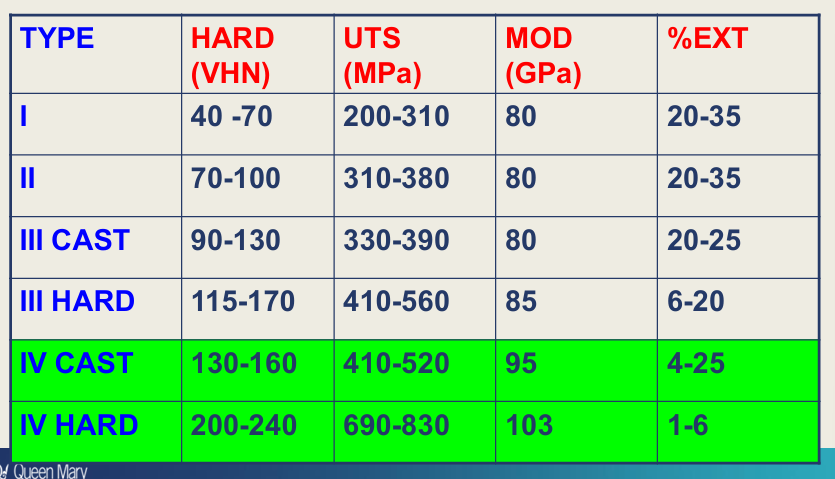

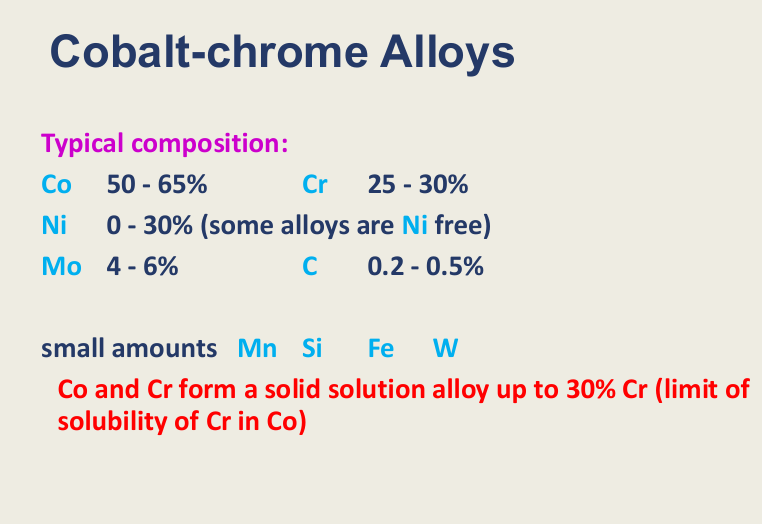

Typical composition of Co-Cr alloys

what is the maximum amount of Chrome?

other metals that can be involved? (3 main and 4 others)

Co - 50-65%, Cr - 25-30%

Ni 0-30% (some without) (replaces some of the Cr)

Mo 4-6% or C 0.2-0.5%

Small amounts of: Mn, Si,Fe,W

Co and Cr forma a solid solution alloy up to 30% Cr - limit of solubility of Cr in Co

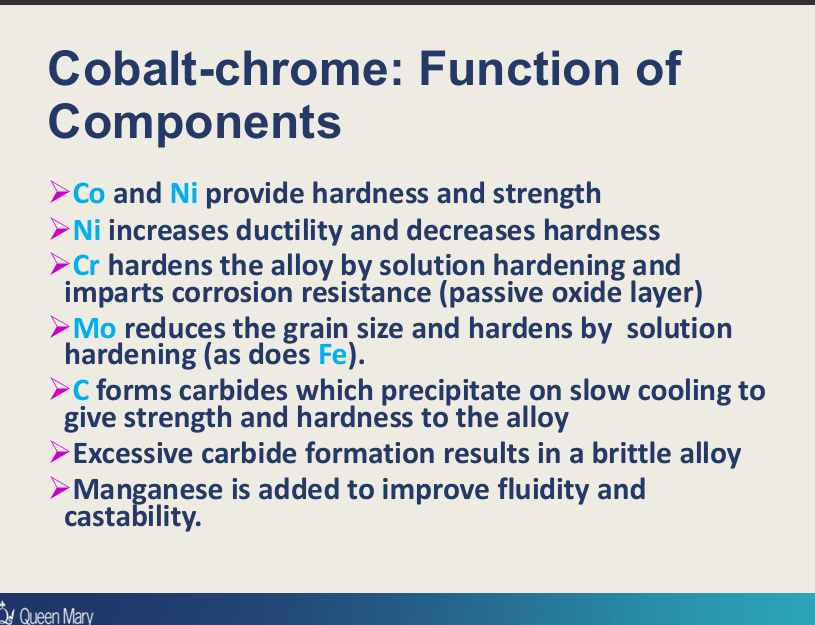

What are the functions of Co, Ni, Cr, Mo, Fe, C, Mn in the Co-Cr metal framework?

Cobalt:

hardness and strength

Ni:

hardness and strength (in Ni-Cr)

increases ductility and decreases hardness (C to Co in Ni-Cr alloys)?

Cr:

hardens the alloy by solution hardening,

corrosion resistance by passive oxide layer

Mo+Fe:

reduce grain sizes

hardens by solution hardening

C:

forms carbides which precipitates on slow cooling to give strength and hardness (excesses results in brittle alloy - therefore added in small amounts)

Mn:

improve fluidity and castability

Adv of Co-Cr? (7)

Low cost compared to gold alloys

hard

abrasion resistant

High modulus - can be used in thinner sections

low density - light weight

high yield stress - less likely to become permanently deformed

Ni free are biocompatible

Dis of Co-Cr ? (5)

High casting temperature

casting shrinkage - 2%

Limited ductility - clasps may fracture if adjusted

rapid work hardening - limited chairside adjustment

Ni sensitivity

difficult to finish/polish

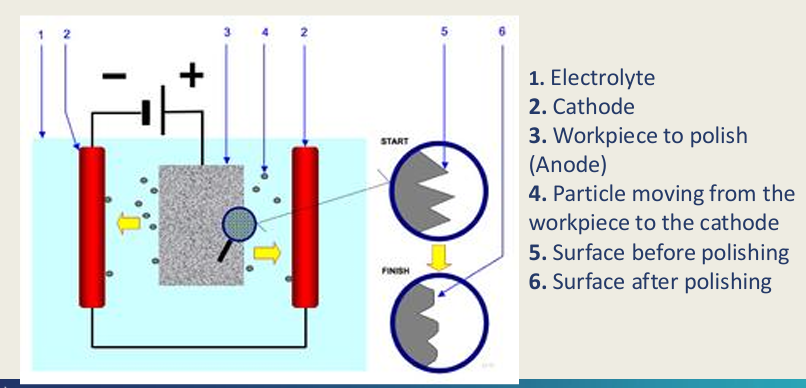

Electroyle polishing of fit surface?

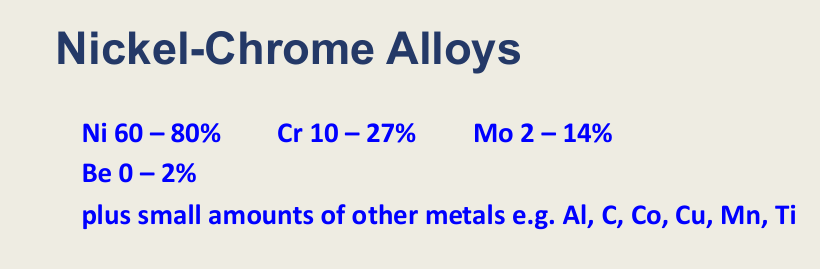

Ni-Cr alloys composition (4 main) small amounts of other metals? (6)

Ni, Cr, Mo, Be

Al, C, Co, Cu, Mn, Ti

The purpose of Ni?

Cr?

what to note about C addition?

Ni:

Strength and hardness

Cr:

Hardens solution by solution hardening

Corrosion resistance - passive oxide layer

must also limit carbide precipitation for strength

Properties of Ni-Cr alloys similar to those of?

CO-Cr

Ni-Cr has largely been replaced by Co-Cr and Ti alloys

Titanium and alloys 2 types?

Commercially pure and alloys

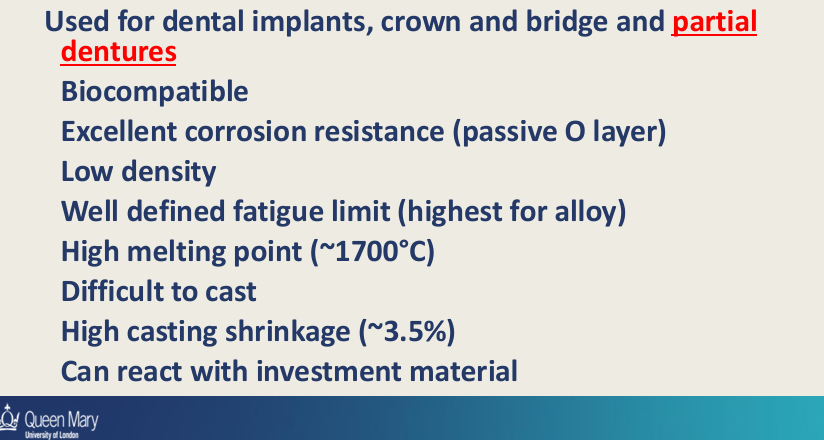

What can titanium and alloys be used for? (4)

Dental implants

Crown

Bridges

Partial dentures

Generally:

High density - low MP

Difficult to cast - high MP - low density - high shrinkage

Titanium and alloys properties? (8)

Biocompatible

Low density

Excellent corrosion resistance - passive O layer

High melting point

Well defined fatigue limit - highest for alloys

difficult to cast

high casting shrinkage - 3.5%

can react with investment material

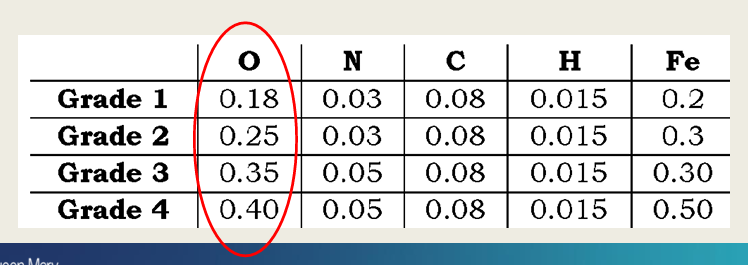

How can commercially pure titanium be classified, what elements might be included (5) and % of titanium in CpTi?

4 grades containing +99% Ti, N, C, H, Fe, and O

Grade 1 - 4

How does increasing O affect the titanium material?

increases X and decreases Y?

Increasing O increases strength and decreases ductility

Titanium alloys:

alloyed with what metals?

Al or Nb (niobium) or V (vanadium)

2 forms of Ti?

alpha - low temp

Beta - high temp form

What is the form found in Cp titanium? what elements are need to stabilise this form?

Cp titanium alpha form is stabilised by O, C,N

What forms are found in Ti6AL4V alloys and what stabilises it?

Alpha and beta - V stabilises the beta form, Nb in TiAL7Nb will stabilise the beta

What is the problem with V?

vanadium is toxic in elemental form, can be replaced by Nb - Ti6Al7Nb

Titanium framework are now made by what methods ? (2)

Digital dentistry:

Computer numerical control (CNC) milling

Laser sintering SLM for RPDs

Properties similar to ?

CpTi

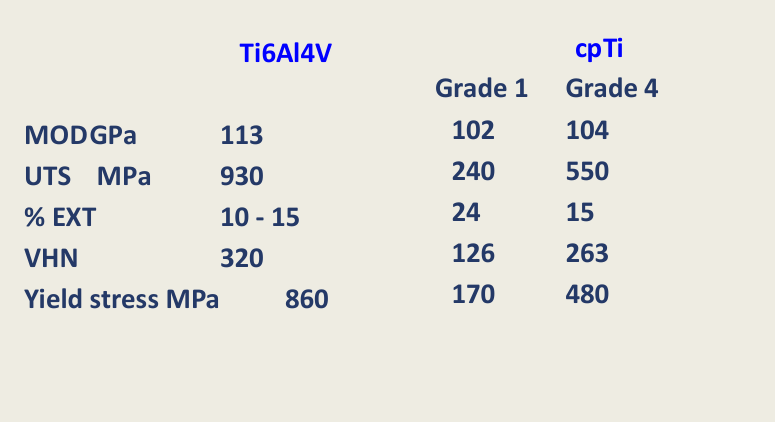

Which has better properties, the titanium alloy or the commercially pure titanium

Improved properties in titanium alloys comparedto CpTi

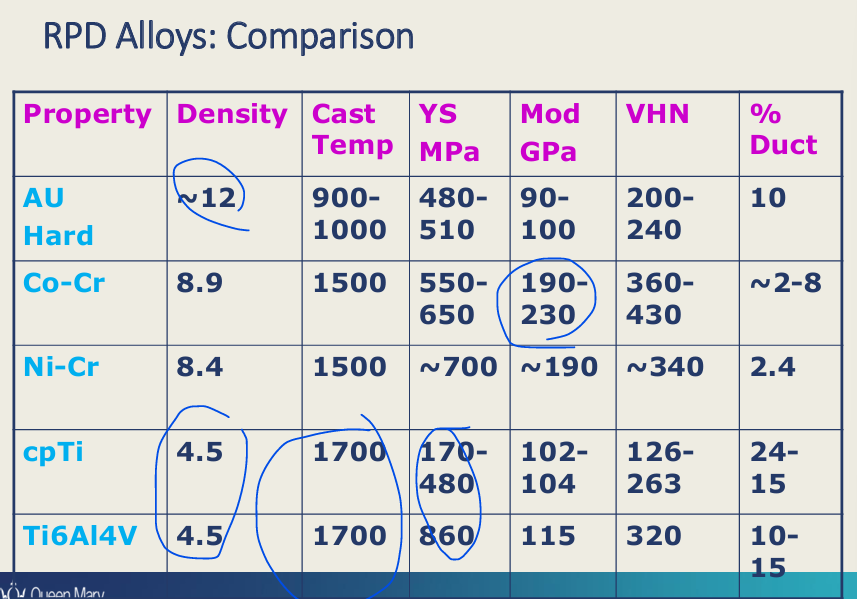

comparison of alloys used for RPDs

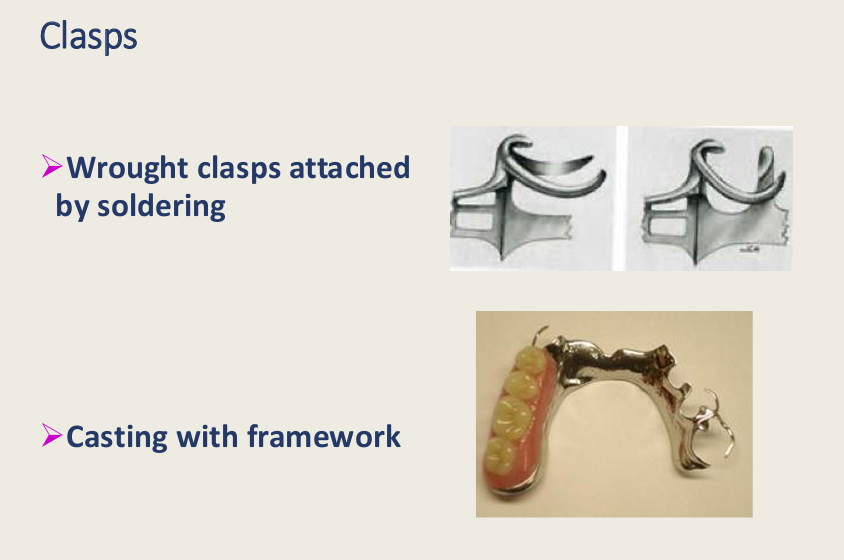

2 methods of making clasps?

Wrought clasps attached by soldering

Casting with framework

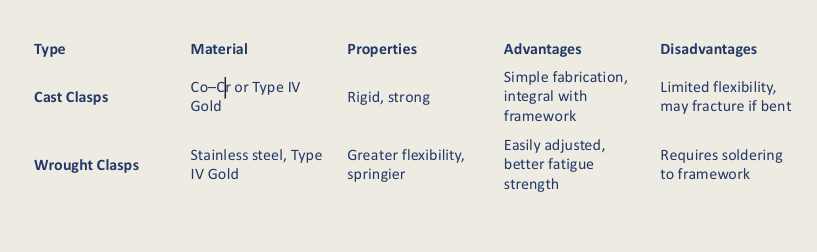

Which materials are used for cast clasps and wrought clasps (attached by soldering?), properties of each, 1 adv and 1 dis for each?

Rapid work hardening in Co-Cr - hence fracture if bent

Easily adjusted so better fatigue

flexible - better for undercuts

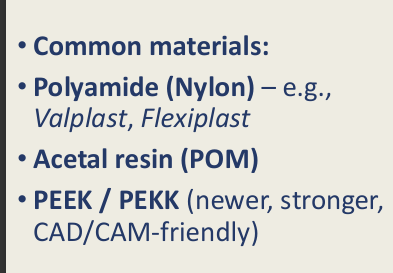

Aesthetic and tooth-coloured clasps - use which materials? (3)

Acetal resin (Polyoxymethylene)

Polyamide (Nylon)

PEEK/PEKK (polyetheretherketone polymers)

What are the adv of aesthetic and tooth-coloured clasps?

tooth coloured - improved aesthetic

Flexible - engage deeper undercuts

Biocompatible - metal-free

can be used with metal or acrylic frameworks

3 dis of aesthetic and tooth-coloured clasps?

lower rigidity - limited support

may discolour over time

harder to polish than metal

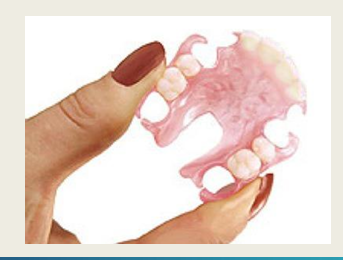

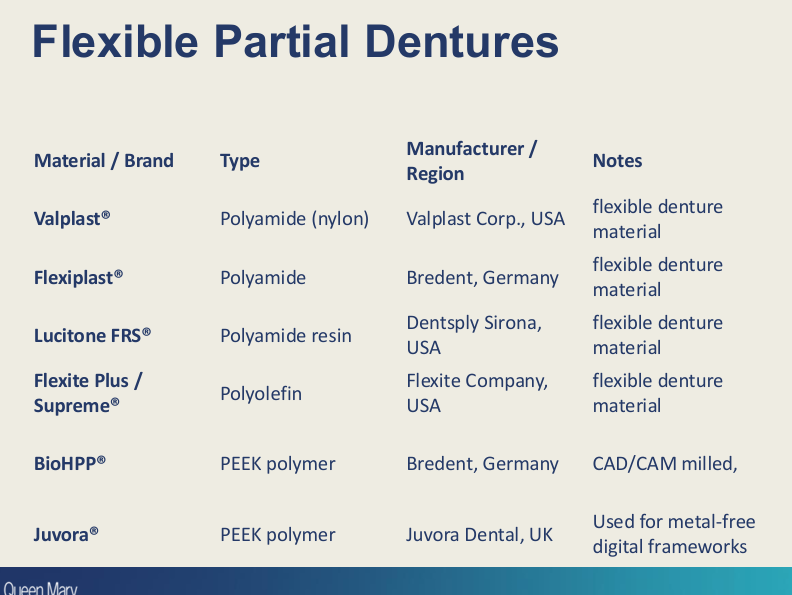

Flexible partial dentures:

what materials are commonly used?

Polyamide (Nylon) - e.g valplast

Acetal resin - polyoxymethelene

Peek/pekk - polyetheretherketone

Fabrication method? (2)

Injection moulding - traditional

CAD/CAM milling or 3D printing (modern)

Adv of flexible partial dentures? (4)

Flexible - engage undercuts without stress

lightweight and comfortable

aesthetic - no visible metal

biocompatible - no residual monomer

Dis of flexible partial dentures? (3)

usually used as what?

Not as rigid - limited support and stability

Prone to staining or warping overtime

Difficult to repair or reline

Usually used as interim or provisional solution

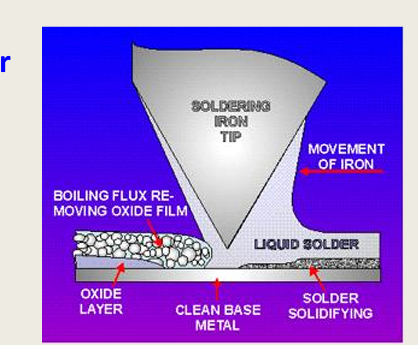

What is soldering How does it work?

The joining of metals by a filler metal (solder)

solder melts and wets the surface and joins 2 metals together

What must be used first before the solder?

Flux, as it dissolved the surface oxides

it wets the surface

and solder displaces the flux

what happens to the metal once passive oxide layer is removed?

metals have high surface energies

attract the molten solder to form bonds

Fluxes are commonly what?

give examples used with gold alloys (4)

and one example used with base metals alloys (1)

Borates

gold alloys: borax/sodium tetraborate/borax glass, sodium pyroborate

fluoride fluxes are used with base metal alloys

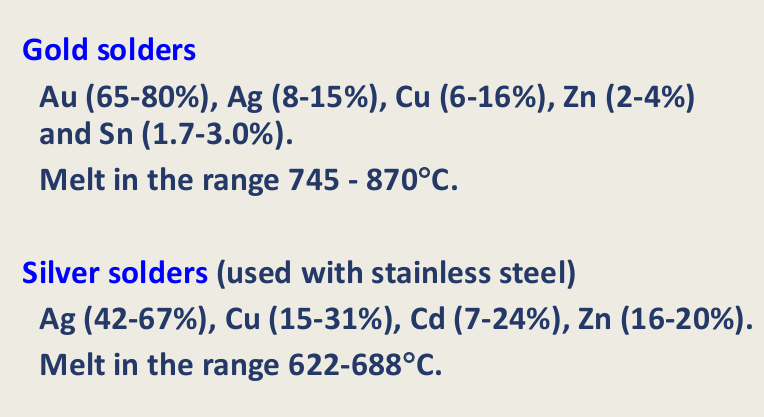

Hard dental solders need to be (4)

Corrosion resistant

Have a high fusion temp - 50 degrees less than alloy (Don’t want it to change shape/melt)

be as strong as the alloy

have good flow

2 types of Solder

what is one of them typically used with?

which has the higher melting range?

Gold solders

Silver solders - stainless steel

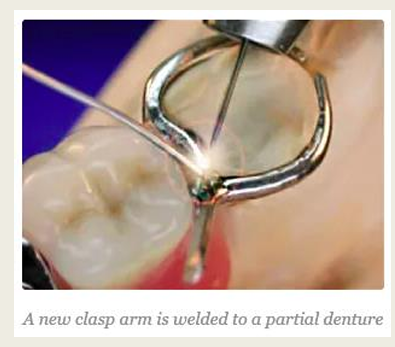

What is welding?

Joining metals without the use of a solder

3 types of welding?

Pressure welding - metals are heated to recrystallisation temperature under pressure

Electric spot welding - electric current generates heat at contact points

laser welding (modern technique)- uses a focused laser beam to melt and fuse metals precisely

Pressure welding is used for and not used for?

used for orthodontic wires not RPD frameworks

Electric spot welding is limited to?

thin metal sheets or wires

Laser welding is suitable for which materials used for RPD, 2 adv?

gold, Co-Cr, SS, Ti

minimal heat distortion and high accuracy

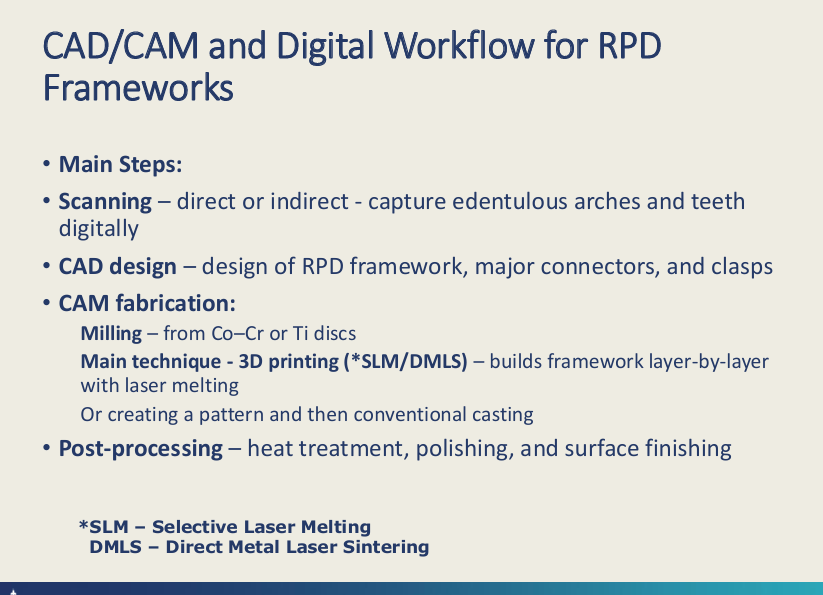

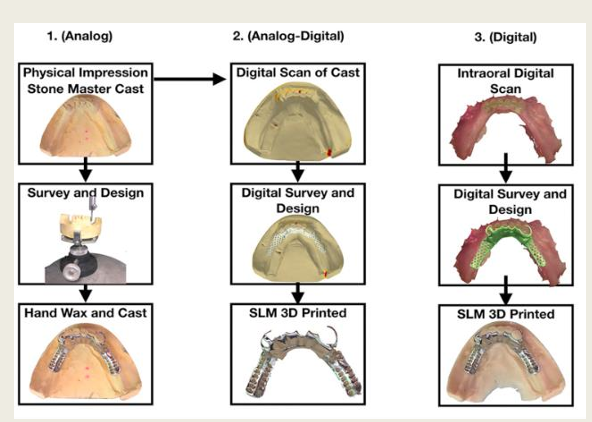

CAD/CAM workflow for RPD frameworks: main steps? (4 main)

Scanning

CAD

CAM:

- milling

-SLM/DMLS selective laser melting or direct melting laser sintering

creating pattern then conv casting

Post-processing - heat tx, polishing and surface finish

ADV of CAD/CAM? (3)

short time production

digital storage and easy remakes

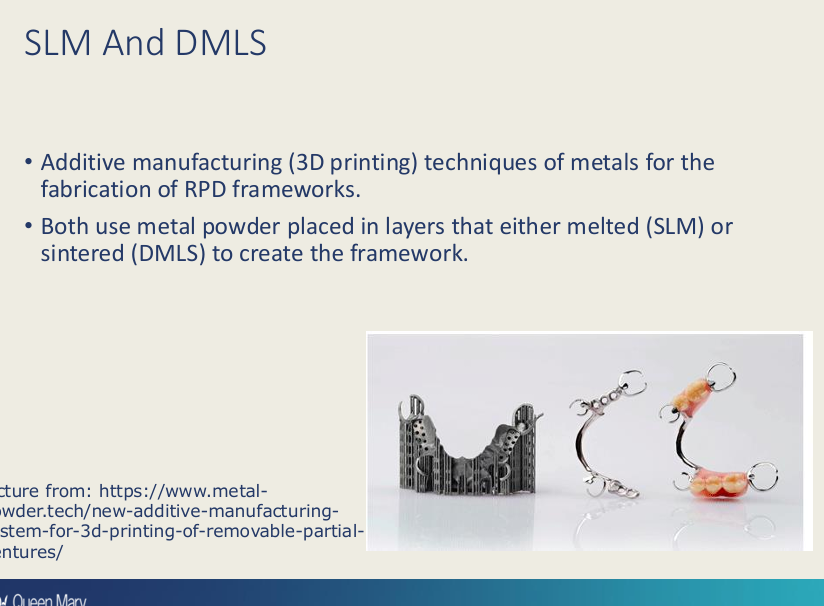

Difference between selective laser melting and direct metal laser sintering?

what type of manufacturing technique are they?

both use what?

main difference

additive

metal powder in layers

In SLM - melted

In DMLS - sintered