SCM Class 15 - Issues in Scheduling and Coordination

1/9

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

10 Terms

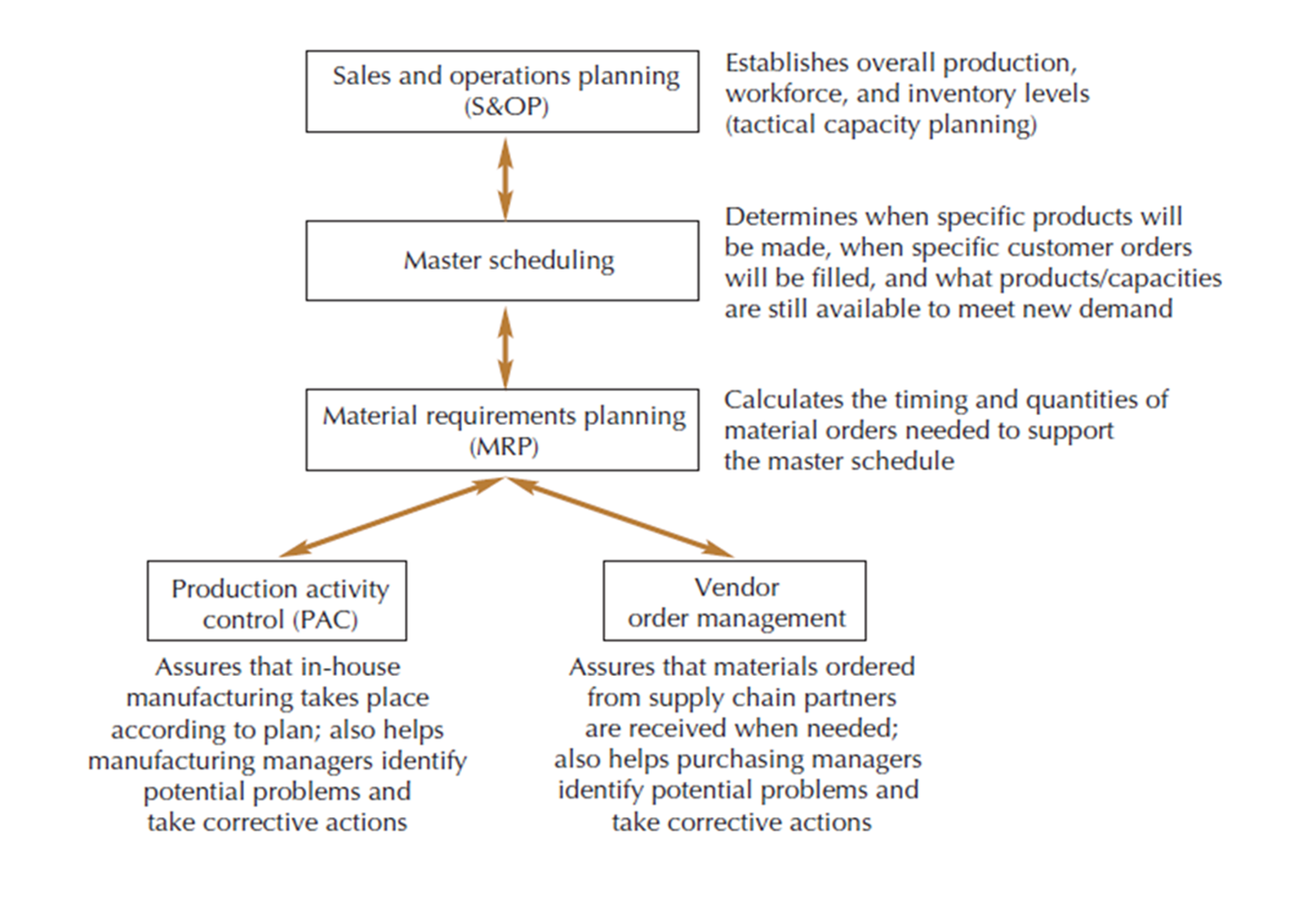

Planning and control:

A set of tactical and execution-level business activities that includes:

master scheduling

material requirements planning

production activity control

vendor order management

Master Schedule

a detailed planning process that tracks production output and matches this output to actual customer orders

TRACKS PRODUCTION OUTPUT AND MATCHES IT TO CUSTOMER ORDERS

makes specific the overall resource levels established by S&OP

states when and quantities products

links production with specific customer orders

Purpose:

maximize labor and equipment utilization

minimize costs

ensure adequate finished goods inventories to fill customer orders on time

match the average production rate with the average sales rate over planning horizon

Master Schedule Record

Forecasted demand: Estimate of future demand during the planning period

Booked orders: Confirmed customer orders for shipment

Projected inventory levels: Calculation of future inventory levels

Production quantities: Master Production Schedule (MPS): Planned quantity of products to be produced

Units still available to meet customer needs (Available to Promise) after filling Booked orders

Master Production Schedule (MPS)

The amount of product that will be finished and available for sale at the beginning of each week.

The MPS drives more detailed planning activities, such as Material Requirements Planning (MRP)

Planning Horizon

the amount of time the master schedule record or MRP record extends into the future

the longer the production and supplier lead times, the longer the planning horizon must be

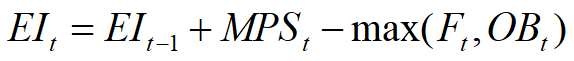

projected ending inventory

best estimate of what inventory levels will look like at the end of each planning period

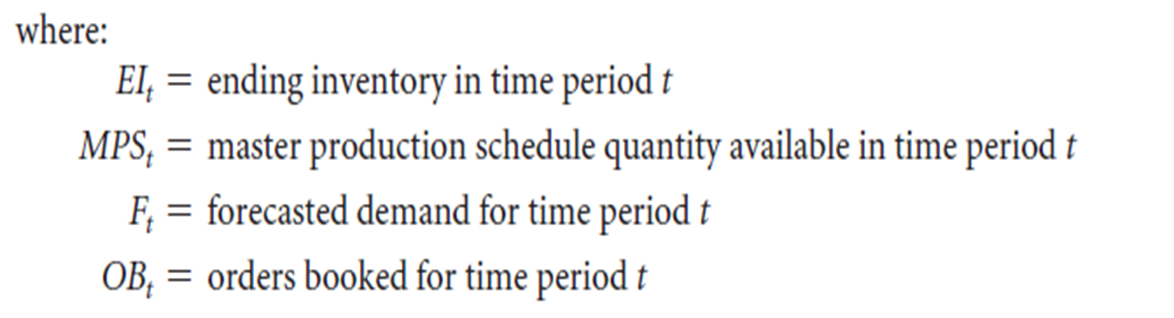

available to promise

a field in the master schedule record that indicates the number of units that are available for sale each week, given those that have already been promised to customers

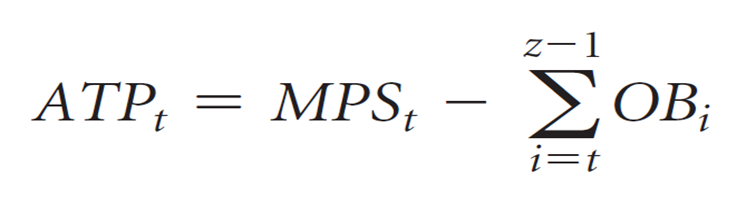

First Week ATP

Subsequent week atp

if mps=0, then there is NO ATP

Material Requirements Planning (MRP)

A planning process that translates the master production schedule (Independent Demand Items) into planned orders for the actual parts and components needed (Dependent Demand Items) to produce the master schedule.

independent demand: for finished goods - products made up of purchased or produced components and materials

dependent demand: raw materials and work in progress - components and materials used to create independent demand items

bill of materials: recipe for an independent demand item - a list of all the dependent demand items used to create the finished product

product tree structure: graphical or outline representation of all components involved in building the independent demand item

calculates future needs for components and raw materials by exploding the bill of material

planning lead time

backward scheduling

Planning Lead Time

the time from when a component is ordered (produced) until it arrives and is ready to use

Backward Scheduling

MRP calculates when dependent demand items must be ordered and when sub assembly stuff needs to be produced to complete independent demand item on schedule