HRT 310 Nursery Management pt2

1/71

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

72 Terms

Describe the 5 environmental factors to consider when selecting a site and why they are

important. Same for the 6 economic factors, same for the 4 biological factors

Environmental Factors

1• Climate (Rainfall, Temperature, Wind, Hail & Ice)

2• Topography

3• Soils

4• Water

5• Air

Economic Factors

1• Land Cost

2• Labor Availability & Cost

3• Facilities, Utilities

4• Competition

5• Transportation

6• Local Taxes, Permits, Zoning

Biological Factors

1• Insects & Related Pests

2• Disease

3• Weeds

4• Mammals

If you were starting a new nursery and planned to have field propagation using seed and liner beds, container production, and field production of larger plants, what would be your allocation priority for these operations?

Don’t forget your buildings, greenhouses, shipping/receiving areas. What guided your decision on allocation priority and why?

Allocation Priorities

• Field Production of Larger Plants

• Seed Beds / Liner Beds

• Container Production

• Buildings, Greenhouses & Access

How do you determine spacing in a planting design for seed and liner beds? For field grown crops? For container grown crops?

Factors that affect spacing?

Seed Beds

Width usually between 3 to 5 ft Spacing of seeds is determined by germination rate. Thin seedlings after germination and emergence of first true

leaves to between 2 to 5 inches apart.

Liner Beds

Liners are either planted in individual rows (3 to 12 inches apart) or in beds similar to seed beds in bed width but wider spacing between plants. Spacing depends upon desired final size of liner

Factors Affecting Spacing

1. Land cost

• The more expensive the more need to use efficiently.

2. Equipment size and cultural practices

• Need enough space for operation of equipment and culture operations

3. Plant size desired

• smaller plants = closer spacing

• larger plants need more room to grow

Determining Row Spacing

• In-row spacing = final width of crop

• Between-row spacing = Final width of crop + minimum equipment operating width

What factors affect selection of a particular planting design?

What are the 3 planting designs discussed in class? What is the most efficient?

What is harvesting on the diagonal, what planting design is it used for and why is it used?

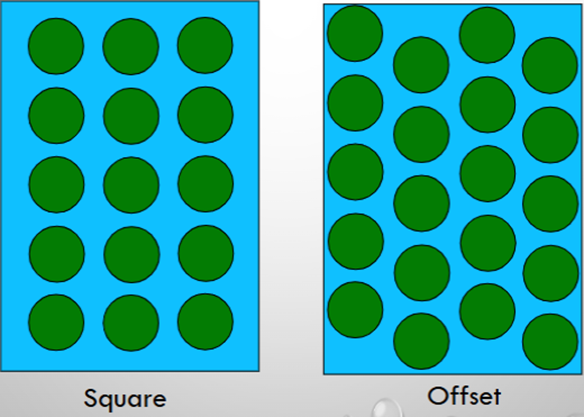

Square In-row= Between-row

-Harvest on diagonal keeps Square spacing

-harvested multiple times at different sizes, especially shapped trees

Rectangular Design / offset spacing

In-row < Between-row

Rectangle-Square Design- can have more than 2 rows tightly spaced

-common in larger plants needing wider spacing and easier equipment acess

Equilateral Triangle-Hexagon

In-row = x

Between-row = 0.85 x

-allows tighter spacing and is ideal for smaller plants or container nurseries.

Harvesting on the diaginal: Used with sqaure spacing. This method takes advantage of the layout by harvesting planta along diaginal rows instead of straight. This will also create space for remaining plants to grow. This also allows for multiple harvests over time from the same planting. An advantage is it provides income before the final harvest.

Why do we irrigate?

• Necessary for container production

• Increase growth rate

• Improved transplant survival

• Consistent production schedule

• Ease of digging/planting

• Fertilizer Solvent

• Winter Protection – frost protection

• Seals in and activates fumigants and herbicides

What are the concerns when irrigating, especially for container production? Why are they important?

• Overhead: up to 80% misses target

• Over-irrigation = Leaching and/or runoff

• Leaching = loss of nutrients

• Loss of nutrients = Wasted $, slower growth, decreased quality and Nutrients and other chemicals in runoff

• Increased disease and other pest pressure = increased cost of managing

them and loss of plants

• Runoff = possible movement of nutrients and pesticides off-site

• Environmental concerns

• Water use regulations

Container:

-Water quality and alkilinity

-irrigation return flow

-uniformity of water distribution

-substrate and container size

-nutrient managment

-enviormental impact (runnoff, nutrient leaching)

What are the required irrigation reporting practices by MDARD?

• If a nursery is capable of pumping > 70 gallons/min or 100,000 gallons/ day it must keep track of monthly water use and report it to MDA annually.

Why is it important to know the infiltration rate? What can affect infiltration rate?

and Field capacity (FC)

Infiltration rate = rate water moves into the soil.

• Irrigation should not be supplied at a rate higher than the infiltration rate.

must take slope into account

Field Capacity (FC)- Amount of water a field will hold after drainage and runoff.

Water Quality Guidelines for Mature Nursery Crops (Bicard (ppm) and Solunle salts (dS/m) )

Bicard (ppm): good = <60, ok= 61-215, bad = >215

Solunle salts (dS/m) good = <.75, ok =.75-1.4, bad = >1.4

How do most backflow prevention devices work? Why should they be used?

They use a valve system to prevent contaminated water from flowing back into the potable water supply, protecting it from pollutants. These devices create a physical barrier that stops backflow and should be used to ensure safe drinking water and comply with health regulations.

What is the difference between Microsprinklers, Sprayers/Spray Stakes, and Drip irrigation emitters?

What are the advantages and disadvantages of each?

How do they compare with more traditional overhead irrigation systems?

Low Volume irrigation = drip emmiters, micro sprinkleers, sprayer / spray stakes

Advantages

• Use less water

• Delivers to target

• Less runoff

• Lower initial: smaller pump capacity needed

• Pressure compensated

• Better control

Disadvantages

• Higher initial cost: delivery to containers

• Higher maintenance cost

• Clogging

• Pump filters

• Water quality more important

Microsprinklers distribute water over a larger area than drip irrigation but less densely than spray stakes. Spray stakes provide a more targeted application than overhead systems but can be prone to wind drift. Drip irrigation delivers water directly to the root zone, which minimizes evaporation and runoff, making it efficient for water conservation. Each system has specific applications based on water needs, plant type, and topography

Be able to discuss the 7 water conservation techniques

• Schedule irrigation on plant demand, not a set daily amount

• Group plants by water demand

• Check irrigation pattern uniformity regularly

• Rain shut off device

• Use maximum pot spacing efficiency

• Reclaim and recycle runoff

• Cyclic or Pulse Irrigate

Describe capillary irrigation; subirrigation (flood or ebb and flow).

capillary irrigation:

-uses the principle of capillary action, where water moves upward from a water source to the rootzone through small pores in the soil or sunstrate.

-efficent water use with minimal evaporation loss

-provides consistant moisture to plants, reducing over or under watering

-comon where gh or container nurseries have pots sit on wet mats

-typically smaller plants or seedlings in controlled enviorments

Subirriagtion:

-involves watering plants from below either by flooding bench or tray or by cyclially filling and draining the water resvoir (ebb and flow)

-flood system: entire growing area or bench is flooded with water staerating the rootzone before the water drains away

-Ebb and Flow system: water is periodically pumped into the grow tray to flood it and then allowed to drain back into reservoir, creating cycles if wetting and drying

-conserves water by recirculating unused water

-requires carful managment to avoid overwatering or salt build up.

-effective drainage is essential to prevent root disease

What is the lowest irrigation distribution uniformity acceptable for overhead irrigation?

Individual plant irrigation?

Why is it important to have high irrigation DU?

What are some causes of low DU?

Irrigation Distribution Uniformity (DU)

• Uniform irrigation distribution ensures that all plants in an irrigation area receive approximately the same amount of water.

• Important for maximizing efficient use of water.

• Desire a distribution uniformity greater than 80%.

Causes of Low Uniformity

• Improper irrigation pipe selection

• Improper operating pressure

• Inadequate selection of irrigation sprinklers or emitters

• Inadequate sprinkler overlap

• Wind effects

• Time- affects pump efficiency, pressure regulation, nozzles

• Blocking or damage of emitters

What basics should be considered when designing an overhead irrigation system for a rectangular bed with respect to overlap and arc of heads?

Better sprinkler overlap

-Best water use efficiency: 90 ̊ heads on corners 180 ̊ on sides 90° patterns will result in 2 times the water applied versus 180° patterns

-To improve efficiency more, use lower output nozzles on corners.

Best sprinkler overlap without going insane

-Select nozzles with lower output for 90º and 180º patterns than 360º patterns.

Describe the steps involved in determining DU for an overhead irrigation system. Same for an irrigation system delivering water to individual plants like Micro irrigation (drip, spray stake). Why should you keep track of catch can or emitter location?

Calculating Distribution Uniformity for Overhead Irrigation

• Place collection cans (straight sided) in a grid in irrigation block to be tested.

• Run irrigation system for at least 15 minutes, regular irrigation cycle recommended.

• Measure depth of water in each can.

• Determine average of depths in each can.

• Determine average of lowest 25% of cans.

• Divide average of the lowest by the overall average to get DU.

Calculating Distribution Uniformity for Micro-Irrigation

• Measure time to fill identical bottles from at least 18 emitters per irrigation

zone.

• Sum the lowest 1/6 of the measurements.

• Sum the highest 1/6 of the measurements.

• Plot the point on the following nomograph.

• Nomograph will show DU range, want greater than 80%.

What daily, weekly and 6 month irrigation checks should you conduct?

Six Month Irrigation Checks

• Nozzle pressure with pitot tube

• Wear of nozzles with drill bit or other item

• Risers are vertical

• DU in several locations

• Water penetrating canopies of representative plants

• Sprinkler heads and nozzles are uniform in each zone

• Rain shut-off

• Water holding capacity of substrate for container sizes

• Pump performance- flow, pressure

• Check if zones are running according to controller

Weekly Irrigation Checks

• Flow rate and pressure at pump outlet and inlets to each zone

• Plants grouped in zones according to water requirement

• Plants spaced so canopies just touch

• Read all flow meters

Additional for low volume systems:

• Emitter placement and clogging

• Filters cleaned and checked

• Lateral lines flushed

• Cleaning agent injected

Daily Irrigation Checks

• Amount applied is appropriate for container size and plant type

• Operation of nozzles (rotation, pattern, fogging)

• Moisture content of substrate before watering

• Drainage from containers

• Rain gauge to check if system ran

What are common causes for loss of irrigation system efficiency?

Irrigation efficiency

• Volume of water delivered to the target (pot) divided by volume of water input into the system

• Increase in crop yield over non-irrigated yield divided by water applied through irrigation

• Crop water use efficiency- crop yield divided by volume of water to produce the crop

• Pumping efficiency- volume of water beneficially used divided by the volume of water input to the irrigation system

Losses in Efficiency

• Non-uniform application

• Poor system design

• Improper installation

• Poor management

• Equipment failures

• Excessive or inadequate application

• Evaporation/drift

• Runoff (surface or subsurface)

• Leaks in pipes

What is the relation between pot spacing and irrigation efficiency?

Higher percent of surface area is covered with offest pattern compared to square pattern.

Define water quality.

The concentration and load of chemical elements and compounds and organic and biological contaminants in water that make it suitable or unsuitable for growing plants.

• Chemical elements include elements commonly from natural sources such as Fe, Na, Cl, Mg, Ca, F, B, As, Al, but also from industrial pollution such as Cr, Pd, Hg.

• Compounds can include pesticides, plant growth regulators, industrial chemicals (TCE, PABs, PCBs, SO 2 & NOs → acid rain)

• Organic contaminants include plant litter, spilt potting substrates, other formerly living things

• Biological contaminants include insects including eggs, pathogens, nematodes, weed seeds/propagules

Concentration is the mass or volume of contaminant per volume of water: mg/L, ppm

Load is cumulative mass or volume of the contaminant delivered to the same location over a period of time: tons/week, kg/day, lbs/hr

What are the 3 main sources of irrigation water? What are advantages and disadvantages of each?

Well (Groundwater)

• Often (not always) best quality, less disease

• Expense (installation), quantity, rights/regulations

Surface Water

• Disease, contamination, algae, soluble salts, land

• Recycling, rights/regulations

Municipal water

• Low soluble salts

• Unreliable, expensive, possibly unavailable

• Insufficient quantity for most wholesale nurseries

Explain riparian and reasonable use water rights.

Riparian & Reasonable Use:

Water rights belong to property owner adjacent to or above water source. Upstream owners can notunreasonably interfere with rights of downstream owners. Can be modified by legislation

Prior Appropriation:

Rights allocated to first in use Transfer of water rights by first user is possible.

What is the relationship between drawdown, transmissivity and yield of an aquifer and suitability of a high capacity well? How does this relate to site selection?

Transmissivity

is a measure of an aquifers ability to transmit water horizonatlly. I depends on hydraulic conductivity (ease of water flow through aquifer material) and the Thickness of the aquifer. Higher transmissivity means the aquifer can deliver greater volumes of water to a well over time.

Drawdown

Is the Lowering of the water levell in the aquifer (or well) when pumping occurs. It represents how much the water table or potentiometric surface drops near the well. Drawdown increases with pumping rate and duration, but the amount depends on aquifer properties inculuding transmissivity and storativity.

Yield

Refers to the suitable amount of water a well can pump over time without causing unaccceptable drawdown or depletion of the aquifer. A well with a high yield can withdraw water at a high rate while maintaining an acceptable drawdown level.

How are these realted

-for a high capacity well you want to pull large volumes of water without causing excessive drawdown that would de-water the well or damage the aquifer’s long term sustainablity

-high transmissivity aquifers can sustain high pumping rates with lower drawdown because water moves more freely towards a well.

-if transmissivity is low pumping water rapidly results in significant drawdown reducing well yield and possibly causing the well to fail or cause envirormental harm

Site Selection

you are looking for a site for your high capacity well look fro areas where the aquifer has:

-high transmissivity indicating good flow properties and thick saturated zones

-Adequate storativity so the aquifer can supply water without execessive drawdown

-with low tramsmissivity or thickness will have large drawdown for the same pumping rate, reducing the sustanable yield.

-site investigations typically include aquifer tests ( pumping tests) measuring drawdown over time to estimate transmissivity and yield before deciding on well location or design.

Draw a simple diagram through the soil profile that shows the water table, glacial aquifer and 2 confined aquifers. What is the difference between these water sources?

water quality 8

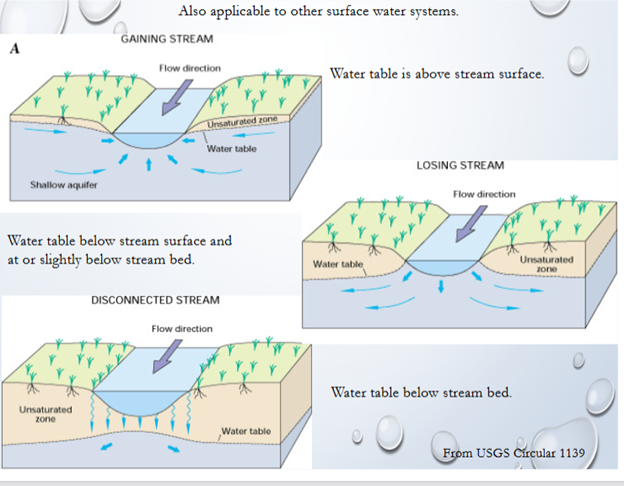

Contrast gaining streams, losing streams and disconnected streams. Are these terms applicable to lakes and ponds? Why is it important to understand water flow in these systems for irrigated agriculture?

Gaining; water table is above stream surface

Loosing; water table is below stream surface and at or is slightly below stream bed.

Dissconnected: water table below stream bed.

Diagram a gaining, losing, disconnected surface water source. What happens if you install a very high capacity well near the water source that redirects water away from that source?

What are the ramifications of the change in water movement as it progresses from mild to extreme in diversion?

water quality 8

List in order of importance for container production the water quality considerations discussed in class. What are the water quality guidelines ranges for good, some problem and problem needing management for bicarbonates and soluble salts (include the unit of measure)?

water quality 8

Physical and chemical characteristics of potting conatiner substrate

Bark: WHC, porosity, CEC, and C:N = medium, Bulk density =Low

peat moss: WHC, porosity, CEC = high, C:N = med, Bulk density = Low

coconut coir: WHC, porosity = High, CEC = Med, Bulk density, C:N = Low

sawdust: WHC, CEC, C:N = High, Porosity = Med, Bulk density = Low

rice hulls: Porosity = High, CEC, C:N = Med, Bulk density, WHC = Low

vermiculie: WHC, ECE = High, Porosity = Med, Bulkdenisty, C:N = Low

perilite: Porosity = High, WHC = Med, Bulk density, CEC, C:N = Low

sand: Bulk Density = High, Porosity = Med, WHC, CEC, C:N = Low

In relation to the terms used for irrigation water quality, what is the difference between pH and alkalinity?

Alkalinity is much more important than pH

A measure of the ability of a solution to neutralize acids to the equivalence point of carbonate or bicarbonate

Alkalinity relates to the ability of water to raise substrate pH

pH is an indication of alkalinity

- water with relatively high pH and low alkalinity may not affect substrate pH

- Water with relatively high pH and high alkalinity will increase substrate pH

Four crop factors that affect tolerable water alkalinity levels

1. Length of production cycle

2. Plant-to-substrate ratio

3. pH requirements of the crops

4. Plant water use

Level of Importance of Production Components

- Water Alkalinity

- Liming Material

- Crop Requirement/Tolerance

- Substrate

- Fertilizer

- Container Volume

How would you manage irrigation water with an alkalinity value of

45 ppm? 190 ppm? 550 ppm?

Defend your management choices.

Managing Alkalinity

Alkalinity < 60 ppm no action necessary

Alkalinity of 60 - 215 ppm

- Monitor substrate pH regularly (also for higher alkalinity levels)

- Reduce amount of lime used (the water will supply the lime)

- Irrigate more efficiently

- Use acid forming fertilizersAlkalinity > 215 ppm

- As pH of substrate edges out of ideal range, incorporate or top-dress with S, Fe2(SO4)3, Al2(SO4)3Alkalinity > 600 ppm

- Acidification (acid converts carbonates to CO 2 )

- Adjust water to pH near 5.8 - 6.0

Liquids:

- Nitric available at 61.4% or 67%

- Sulfuric available at 93% and 35%

- Phosphoric available at 75% and 85%

Solid:

- Citric- more expensive but does not change nutrition program

Solid/Gas:

- Sulfur

In what situations would you inject acid to manage water quality?

What types of acid are typically used?

Which ones are important for production (other than water quality) and environmental considerations?

Acids need to be taken into consideration in nutrition program:

Phosphoric acid- generally adds much more P than needed in nutrition program- problem from runoff/contamination aspect

Nitric acid- adds N which should be taken into account in nutrition program

Sulfuric acid- generally adds much more S than needed in nutrition program

Acid Injection - Safety

Phosphoric- safest, if washed off quickly usually no burning

of skin

Sulfuric- if washed off immediately usually minor burning

Nitric- burning occurs very quickly

Always add acid to water, Never water to acid

Management Strategies for Poor Water Quality Alkalinity (Bicarbonates):

- Irrigate as efficiently as possible, minimize leaching

- Use acid or acid forming substrate components

- Reduce lime addition

-Use acid forming fertilizers

- Top-dress/incorporate S compounds

- Inject acid

Why is electrical conductivity used to measure total soluble salt content?

Describe how to conduct the Virginia Tech Extraction Method (or Pour-Through Method) for determining substrate leaching quality. What 2 quality parameters are measured?

Why is it important to know these for container substrates?

Total Soluble Salts Electrical Conductivity (EC)

- Measure of total soluble salts

- Expressed as deciSiemens/m (dS/m) or milliSiemens/cm (mS/cm)

- EC < 0.25 dS/m best

- EC > 1.00 dS/m can lead to problems

Pour-Through or VTEM Procedure

•Irrigate Wait: 30 min- 2 hrs then Collect Sample

•Collect Drippings from Container OR

• Pour Water through Container

•1 - 3 Gallon= 1/4 - 1/2 Cup

•Collect Leachate & Check pH, EC

•Mid / Late Season- Check nutrients (lab)

•Smart to Check soluble salts before winterizing

Soluble Salt Levels for VTEM Pour Through

Nursery crops (CRF) = 0.5 - 1.25

What are the management strategies for water with high soluble salts?

With high sodium? With high chloride?

What is the difference between chloride and chlorine?

Soluble Salt Levels for VTEM Pour Through

Nursery crops (CRF) = 0.5- 1.25 ds/m

Management Strategies for Poor Water Quality High Soluble Salts:

Water with high soluble salts will add to salts present due to fertilizer

Acid injection will increase soluble salts

Management for high soluble salts include

- Monitor EC regularly, at least 1X per month

- Increase watering when EC levels are too high (leach out salts)

- Reduce rate & split application of fertilizers

- Use controlled release fertilizer (CRF)

- Plant selection

Sodium

- Critical level is 50 - 100 ppm

- Not an essential element, presence only contributes to higher EC

- Sodium interferes with uptake of N, P, Ca, Mg

Sodium Absorption Ratio

- Na, Ca and Mg compete for uptake

- Ratio determines level of problem

- SAR = [Na+] / (([Ca2+] + [Mg2+])/2)0.5

- SAR < 10 safe for most field crops

- SAR < 3 for container production

Management Strategies for Poor Water Quality Sodium Problems:

- Increase N, K, Ca, Mg but watch EC!

- If Ca & Mg in water:

- Leach containers (Do not under water)

- Under-canopy irrigation (eliminate foliar absorption)

- Dilute bad with good

- Use gypsum (no Δ in alkalinity) or lime (watch alkalinity) to flush Na

Management Strategies for Poor Water Quality High Chloride:

- Critical level 70 ppm

- Leach containers (Do not under water)

- Under-canopy irrigation (eliminate foliar absorption)

- Dilute bad with good

Chlorine vs Chloride

- Chloride is an ion, essential micronutrient

- Chlorine is an oxidizing sanitizer

- Critical levels of chlorine in irrigation water are much lower- should be < 2 ppm when leaving irrigation head furthest from source or will damage/kill plants

What are the management strategies for water with compounds that can result in leaf residues?

Management Strategies for Poor Water Quality Leaf Residues:

- Irrigate less frequently

- Irrigate when evaporation is slow

- Under canopy irrigation

- Acid Injection (for some)

Why are there additional water quality considerations for microirrigation systems?

maintaining good water quality is essential to prevent clogging and ensure unform water delivery.

Particulate matter / suspended solids

-even in small amounts of suspended solids can clog tiny emiter openings.

-water should be filtered well, often using sand filters, screen silters, or disc filters with fine mesh

Dissolved soilds

-high levels of total dissolved solids (TDS) can lead to mineral precipitaion inside emitters

-monitor electrical conductivity (EC) to keep salts at manageable levels

iron and manganese

-iron oxides to form rust or iron oxide precipiates that clog nozzles

-manganese can form dark deposits as it oxidizes

-keep iron below 5 ppm and manganese low, use chelating agents or acid injection to keep these in solution if needed

hydrogen sulfide

-presence causes rotten egg smell and can corrode pipes or react with metals inside emittres

-avoid water sources high in hydrogen sulfide or treat accordingly

Tannins and phenolics

-Organic compounds like tannis and phenolics can cause staining and sticky deposits thta clog systems

-often found in surface water or water with decaying organic matter

water pH

-extreme pH values can cause mineral precipitaion (high pH) or corrosion (low pH)

-keep pH in range suitable to minimize buildup and system drainage, typically near neutral (6.5-7.5)

microbial growth and biofilms

-biological growth can create slime or biofilms insidepipes and emitters that restrict flow

-Regular maintence and sanitaion protocols are needed to control microbes

Five main methods of water sanitation were discussed. What are they and how do they work?

What is the most commonly used sanitizer type?

Chlorine sanitizers: Oxidizer- strips electrons from molecules. Most commonly used, generally least expensive. Proven to control widest range of organisms, as well as vegetative, reproductive and cysts cells. Long residual effect, ~48 hrs

Ozone: Oxidizer. Kills most vegetative/thin-walled bacteria, fungi and algae but not viruses. Very short residual.

Hydrogen Peroxide: Oxidizer. Kills most vegetative/thin-walled bacteria, fungi and algae but not viruses. Short residual. Stabilizing agents can increase effectiveness but also cause phytotoxicity.

UV Light: disrupts DNA killing pathogens. Particulates in water decrease effectiveness. Contact time is critical

Cu and Cu/Ag ionization systems: Cu disrupts cell wall and membrane functions resulting in poor nutrient uptake by organisms. It also increases Ag transmission through cell walls/membranes. Ag binds to proteins,

RNA, DNA, enzymes and disrupts multiple cell functions. Organic matter in water reduces effectiveness.

Slow Sand Filtration: eliminates phytophthora, bacteria, virus. Slow process may not keep up with water demands. Typical treatment rate is 0.05 to 0.1 gpm per ft 2

pH is important when using chlorine sanitizers. In general, what pH is best for chlorine sanitizers? Why?

pH directly affects the form and effectivness of chlorine in the water.

Chlorine in water exists mainly as hypocholorous acid (HOCI) and hypochlorous acid (OCI-)

Hypochlorous acid is the more effective sanitizer with stronger antimicrobial properties

Balance between HOCI and OCI- depends on pH

-lower pH (6-7.5) most chlorine HOCI most effective. too low can be corrosive and damage irrigation equipment or plants.

-higher pH (7.5) chlorine converts to OCI- and is less effective ( baility to kill pathogens dramatically decreses.

When injecting sanitizers, especially chlorine types, what are the injection considerations to remember? Why are they important?

Injection Considerations

• Always add chlorine to water, not vice-versa

• Filter before injection to remove organic material

• Also filter after injection especially if high Fe or Mn in water

• If high water alkalinity and pH, inject acid to decrease pH to between 6 and 7

• Use separate injector for acid injection, inject acid first then chlorine

• Do not use sulfur burner to acidify water when using chlorine, it will deactivate the chlorine

• Effective contact time is the combination of the initial concentration of chlorine and time needed to sanitize the water. It is higher for\ water with high amounts of organic matter, Fe, Mn

What free chlorine concentration is desired at the end of irrigation lines for continuous injection with water pH > 7? With water pH < 7?

What is it for periodic injection to clean irrigation lines?

What is it for shock treatments to remove biofilms?

What happens if water from periodic cleaning injections or shock treatments contacts plants?

How should you handle this water?

Free Chlorine Concentration

At furthest end of irrigation lines:

• Continuous injection for sanitation: 1 ppm for water pH < 7; 2 ppm for water pH > 7

• Periodic injection to keep irrigation lines clean: 10-20 ppm

• Shock treatments to remove biofilms: 500-1,000 ppm

-Chlorine can be phytotoxic at high concentrations, some plants are sensitive when > 2 ppm.

-When doing periodic injections or shock treatments, lines need to be flushed afterwards so that flushed water does not contact plants.

-Active chlorine solutions are dangerous to humans and animals

Is reverse osmosis a viable treatment for wholesale production nurseries?

In what situations might a wholesale nursery use reverse osmosis water?

Reverse Osmosis

- Very Expensive

- Used for specialty operations (e.g. propagation)

- Used for high value crops

- Volume limited

Advagtages: water purity (RO removes most salts, ions, and comtainates to help manage alkilinity and soulable sal issues.) and there is more control with RO (reduce problems such as salt build up, sodium toxicity, and pH inblances)

Challenges: cost especially with large scale (initial high investment and ongoing maintence), water waste (3-4x more water flushed out as waste), volume requirments (RO systems struggle to keep up or require multiple/ larger units), and mineral rebalancing (RO often too clean may need to reintrodice minerals)

Large scale opperation: while typically not used for full scale lard wholesale nurseries due to the cost and volume challenges. RO is valuable in certain situation such as: for water purifiction for sensitive areas, or when facing sever water quality issues that other treatments can’t resolve, or if when precise water quality control is critiacal to crop sucess.

Define Irrigation Return Flow

portion of aplied irrigation that is not absorbed or used by the plants or soil and instead runs off or percolates beyond the root zone eventually returning to surface water bodies (river, lakes, streams, groundwater aquifers) or entering dranage systems.

this water can carry nutrients, salts, pesticides or sediments from the site. Potentially causing enviormental harm as water pollutuion

What are the advantages and disadvantages of using recycled irrigation water?

What are some things that can be done to improve recycled irrigation water quality?

How is handling recycled irrigation water different from handling irrigation return flow?

Recycling Irrigation Water

- Restricts movement of contaminated (fertilizers, pesticides) runoff

- Affects water quality both good and bad

- Conserves water resources

- Requires improved management

Definition: captured irrigation return flow that is treated and reused

Envirorment role: managed resourse to conserve water and reduce discharge

Management: Activiely collected treated and monitored

Purpose: water conservation and resource recycling

VS Irrigation return flow:

Definition: excess irrigation water that leaves the root zone and site

Envirormenatal role: Potential source of pollution if unmnaaged

Mnagment: often uncontrolled or simply drained off

Purpose: waste water or runoff

Soil/substrate infiltration rate

Infiltration rate- rate water moves into the soil.

• Irrigation should not be supplied at a rate higher than the infiltration rate

Pulse or Cyclic Irrigation

• Defined as a sequence of time cycles composed of an irrigation phase and a resting phase.

• Cycled irrigation reduced effluent volume and decreased NH4-N losses.

Irrigation Distribution Uniformity

• Uniform irrigation distribution ensures that all plants in an irrigation area receive approximately the same amount of water.

• Important for maximizing efficient use of water.

• Desire a distribution uniformity greater than 80%.

Irrigation Efficiency (in relation to water delivery)

vs

Irrigation Efficiency (in relation to crop yield)

• Volume of water delivered to the target (pot) divided by volume of water input into the system

• Increase in crop yield over non-irrigated yield divided by water applied through irrigation

Crop Water Use Efficiency

• Crop water use efficiency- crop yield divided by

volume of water to produce the crop

• Pumping efficiency- volume of water beneficially used

divided by the volume of water input to the irrigation

system

Why do we irrigate? (8)

• Necessary for container production

• Increase growth rate

• Improved transplant survival

• Consistent production schedule

• Ease of digging/planting

• Fertilizer Solvent

• Winter Protection – frost protection

• Seals in and activates fumigants and herbicides

Total porosity

(TP) - amount of pore space in substrates

Container capacity

(CC) - pores occupied by water after gravitational drainage

Available water

(AP) - pores occupied by air at container capacity

Readily available water

(AW) - Amount of water that can be taken up by plants

Unavailable water

Water bound tightly to substrates that can not be taken up by plants

Water Holding Capacity

(WHC) ~ usually higher for organic substrates than soils

Finer particled substrate increases WHC but decreases aeration, while large particled media decreases WHC but increases aeration.

Physical Properties of Container Substrate %

• Total Porosity (φ): TP 50% to 85%.

• Aeration Porosity: 10% – 30%

• Container Capacity: 45% – 65%

Container Size and Shape?

Affected Properties

• Water Holding Capacity

• Aeration Porosity

Unaffected properties

• Total Porosity

• Bulk Density

-The water-holding capacity of a container is influenced by its height, with a certain amount of water always remaining in the bottom of the container

Why is it important to know the pH and EC of a substrate?

What is the ideal range for substrate pH for most nursery crops?

pH ~ optimum for most plants 5 to 6.

pH above 6 will create deficiencies of P, Mn, B, Cu, Zn.

pH below 5 will create deficiencies in many essential elements

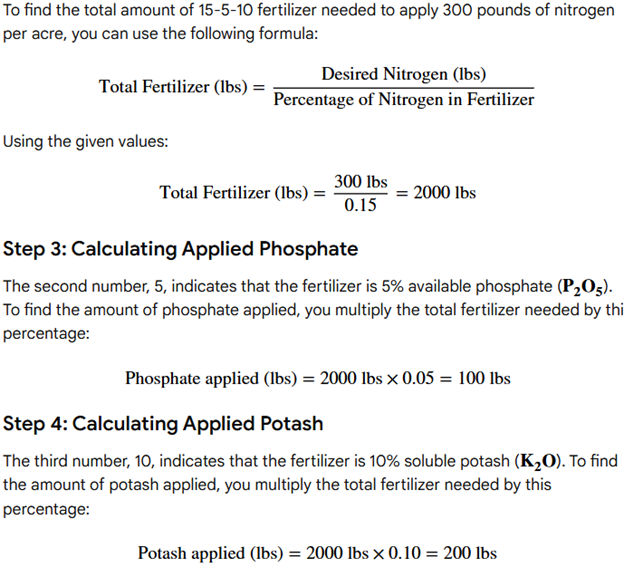

You are told to apply 300 pounds of nitrogen per acre using a 15-5-10 fertilizer. What do each of the numbers refer to (include unit of measure)?

How much of this fertilizer will you need to apply?

How much of the nutrient represented by the second number is applied?

How much of the nutrient represented by the third number is applied?

15-5-10 = 15%N 5%P2O5 10%K2O

-nitrogen expressed on an acutual elemental basis

-Phosphorous and Potassium expressed on an oxide basis

%P x 2.29 = %P2O5

%K x 1.2 = %K2O

you have to add 300 lbs N per acer using 15-5-10 fertilizer

how much P2O5 → 300/

Describe an ideal substrate storage area.

Do not store media that contains fertilizer – especially if moist. Fertilizer will speed up composting and increase soluble salts

What is the relationship between irrigation, container substrates and fertilization for container- grown plants?

• Container crop production generally relies on frequent overhead irrigation at high rates.

• The use of highly porous media and frequent overhead irrigation result in the leaching and loss of the applied nutrients.

• Substrate composition and irrigation practices can influence nutrient retention and leaching. The reduction in phosphate and nitrate load in the Strat and Strat+Fe treatments, particularly under reduced irrigation conditions, indicates the advantage of

substrate stratification in water and nutrient retention.

What characteristics should a container substrate provide? Know at least 6

• Good aeration and drainage

• Good water holding capacity

• Sterile

• Ability to hold nutrients (pH and CEC)

• Functionality

• Durability

What is the primary component of nursery substrates in the eastern U.S.?

Why is this component so popular?

What other components are often blended with it? Why?

eastern us = Pine bark

due to the physical and chemical properties suitable for container production. Provides good aeration and drainage. It is the standard organic substrate material in nursery production in that region.

Often mixed with peat moss ( adds water retention and lowers pH), other organic materials they might add are coconut coir, rice hulls, peanut husks ( org material may casue shrinkage), or they’ll add Inorganic material such as coarse sand, perilite, vermicultie, or pumice ( improved drainage, aeration, adds weight)

What are the important substrate physical and chemical properties?

Why are each important?

Physical Properties of Container Substrate

• Water Holding Capacity (WHC) ~ usually higher for organic substrates than soils.

• Finer particled substrate increases WHC but decreases aeration, while large particled media decreases WHC but increases aeration.

• Total Porosity (φ): TP 50% to 85%.

• Aeration Porosity: 10% – 30%

• Container Capacity: 45% – 65%

• Bulk Density (ρb) ~ 0.19 to 0.52 g/cc.

-A good growing media is composed of micropores (most responsible for holding hold water), and macropores (most responsible for holding air). Containers also have a perched water table (PWT)

Chemical Properties of Container Substrate

pH ~ optimum for most plants 5 to 6.

pH above 6 will create deficiencies of P, Mn, B, Cu, Zn. pH below 5 will create deficiencies in many essential elements

To raise soil pH.

• Ground limestone (CaCO3).

• Dolomitic lime (mixture of CaCO3 + MgCO3).

• Gypsum (CaSO4).

To lower soil pH.

• Sulfur powder (S).

• Aluminum sulfate [Al2(SO4)3].

• Iron Sulfate (FeSO4)

Cation Exchange Capacity (CEC).

• In soils reported as mEq/100 g of soil, CEC of substrates reported as mEq/100 cc of substrate ~ basically the same!

• Loamy sand to sand 2-4, Sandy loam 5-10, silt loam to loam 12-16.

• CEC of most media is high (8-18 mEq/100 cc)

Soluble Salts.

• Naturally occurring in substrates.

• Irrigation water and fertilizer as well as soil and water amendments add up to the container system. Salinity affects the development and health of plants

What is the trade-off between a high versus low bulk density substrate?

High bulk density = heavy containers = wont tip over = $$$ shipping costs

How do you measure EC and pH using the Virginia Tech Extraction Method (aka the Pour- through Method)?

What are the desired ranges for EC and pH using this method?

When/how often would you measure EC and pH? Why?

1. Turn on meters, let warm up for 2 minutes, calibrate

2. Place a recently irrigated (~1 hour prior) to container capacity but no longer draining container plant over a drip pan. Test at least 5 plants.

3. Add enough water over the substrate surface so that 2 ounces of solution (leachate) drains from the container (do not pour water so that it drains down sidewalls).

4. Test the leachate for pH and EC by using a pipette or eyedropper to transfer the required volume of sample from the drip pan to the meter.

5. A soluble salts (EC) reading of

a. 0 – 0.7 is low for greenhouse plants

b. 0.8 – 1.5 is very low for greenhouse plants

c. 1.6 – 3.5 is suitable for most greenhouse plants

d. > 3.5 is high for greenhouse plants and may require leaching

e. 0.8 – 1.5 mS/cm (or dS/m) is the acceptable range for outdoor nursery plants fertilized with liquid or liquid and control release fertilizers

f. 0.5 – 1.0 mS/cm for outdoor nursery plants fertilized only with control release fertilizers.

pH ~ optimum for most plants 5 to 6.

pH above 6 will create deficiencies of P, Mn, B, Cu, Zn.

pH below 5 will create deficiencies in many essential elements

Quality Control – Ideally before unloading sunstrate

• Always check pH and soluble salts before using stored supplies

• Visually check for color, mycelium, spore cloud

• If poor but manageable quality, consider blending old inventory and new inventory (50:50) Adapted from Bilderback (2017).

If you have dry bark; a haze; or mycelium web just beneath the surface of an inventory pile: DON’T POT IN IT

What results from the addition of fine (or coarse) particles to container substrates?

Finer particled substrate increases WHC but decreases aeration, while large particled media decreases WHC but increases aeration.

What does sulfur, iron sulfate and aluminum sulfate do to container substrates?

To lower soil pH.

• Sulfur powder (S).

• Aluminum sulfate [Al2(SO4)3].

• Iron Sulfate (FeSO4).

What does calcium carbonate, magnesium carbonate, calcium hydroxide do to container substrates?

To raise soil pH.

• Ground limestone (CaCO3).

• Dolomitic lime (mixture of CaCO3 + MgCO3).

• Gypsum (CaSO4

CaCO = Calcium Carbonate

MgCo = Magnesium carbonate

CaSO = Calcium hydroxide

CONCLUSIONS: for guest speaker research project

• FeSO4 did not influence phosphate leachate concentration.

• Substrate stratification was crucial in improved substrate water retention.

• Substrate composition and irrigation practices can influence nutrient retention and leaching. The reduction in phosphate and nitrate load in the Strat and Strat+Fe treatments, particularly under reduced irrigation conditions, indicates the advantage of substrate stratification in water and nutrient retention.

• Cotinus coggygria ‘MINCOJAU3’, Cornus sericea ‘SMNCSBD,’ Hydrangea paniculata ‘Limelight,’ and Ilex crenata ‘FARROWSK6’ can be produced in stratified systems and have similar growth performance than those grown in conventional containerized crops.

• There can be limitations of stratified substrates in supporting certain ornamental species (Buddleja x ‘Miss Violet’, Rosa x ‘ChewDelight’, Physocarpus opulifolius ‘Seward’). The specific needs of different plant types must be considered when selecting substrates