Product design process and management

1/39

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

40 Terms

Product design process

Companies continuously bring new product to market

Product design is integral to success

Product design differs significantly depending on the industry

Companies often outsource major functions

Contract manufacturer

An organization that performs manufacturing and/or purchasing needed to produce a product or device not for itself but as a service to another firm.

Core competence: the one thing a company can better than its competitors

It provides potential access to a wide variety of markets

It increases perceived customer benefits

It is hard for competitors to imitate

6 phases of the generic development process

Planning

Concept development

System level design

Design detail

Testing and refinement

Production ramp up

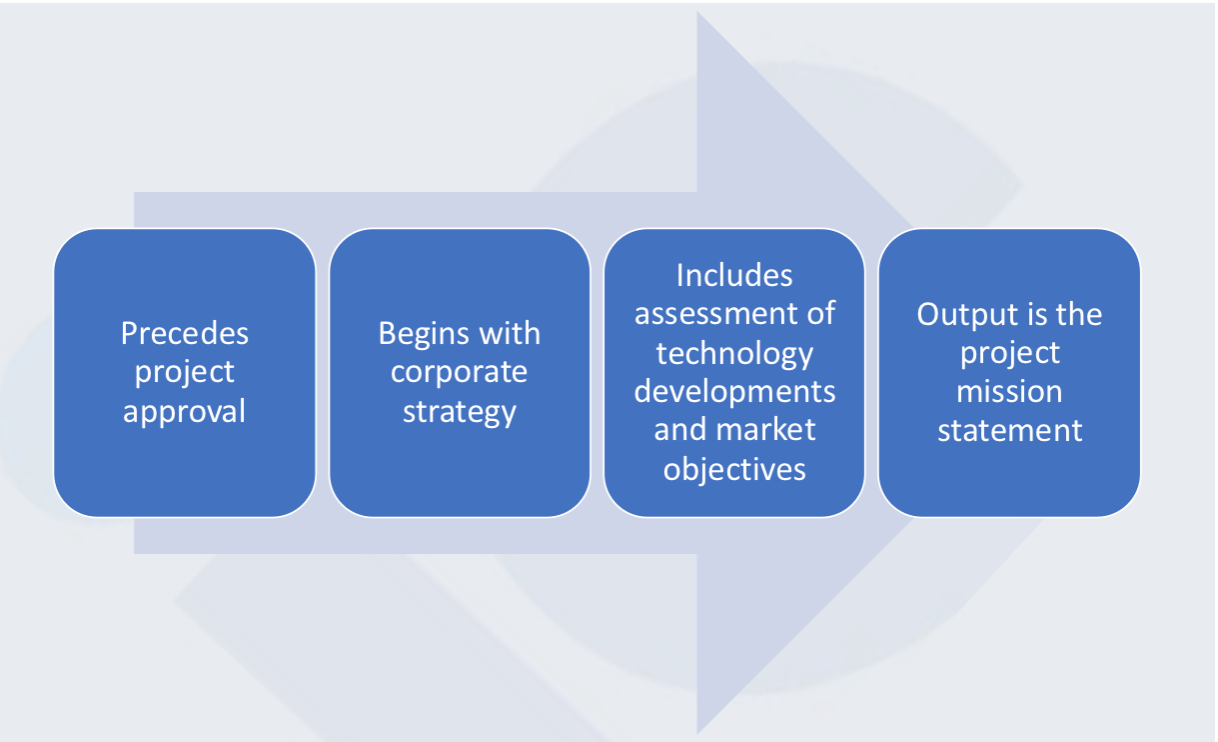

0. Planning

1. Concept Development

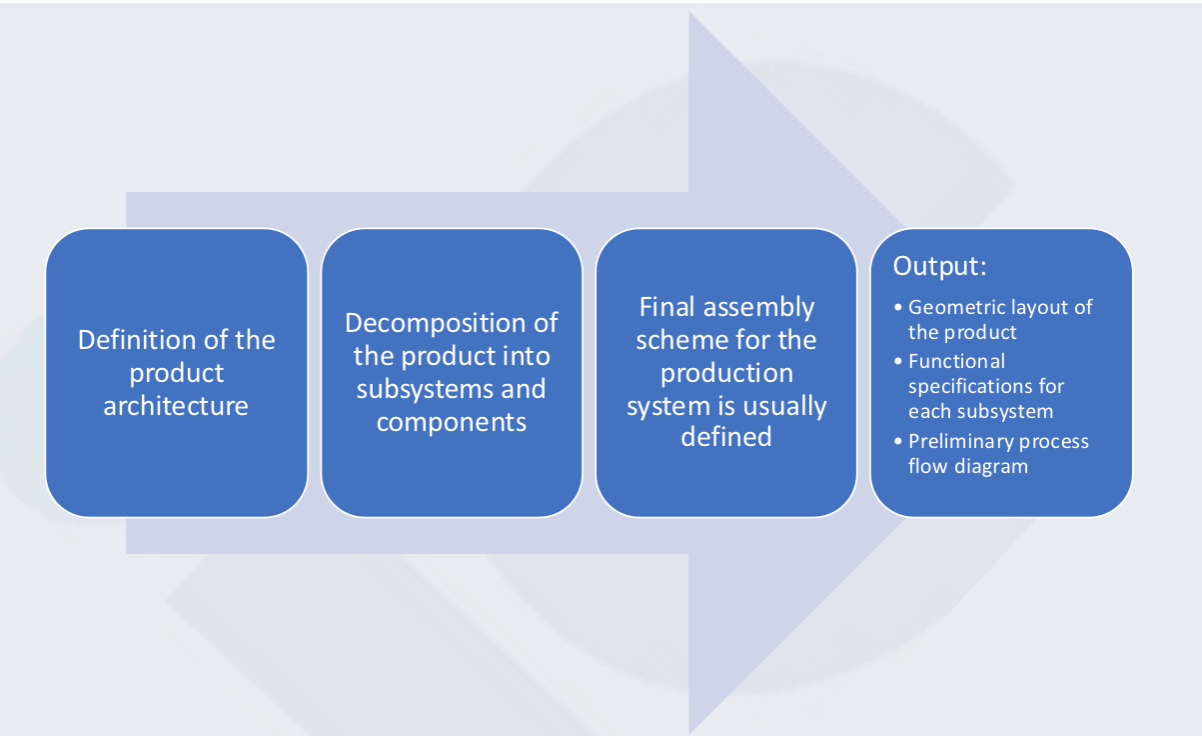

2. System Level Design

3. Design Detail

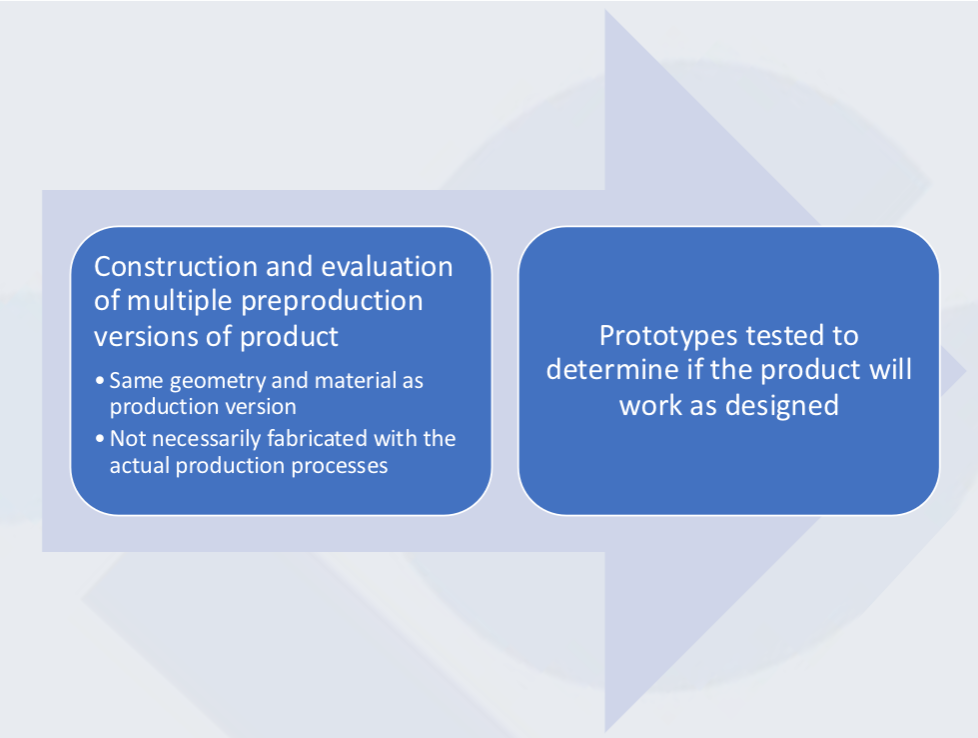

4.Testing and Refinement

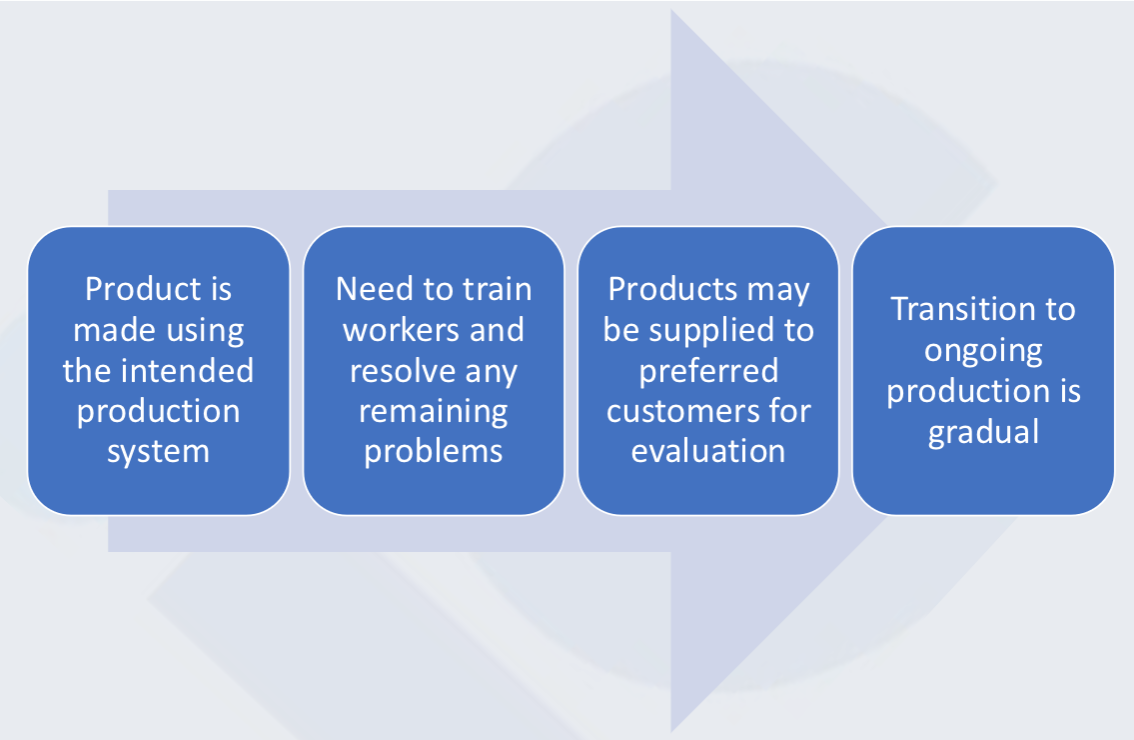

5.Production Ramp Up

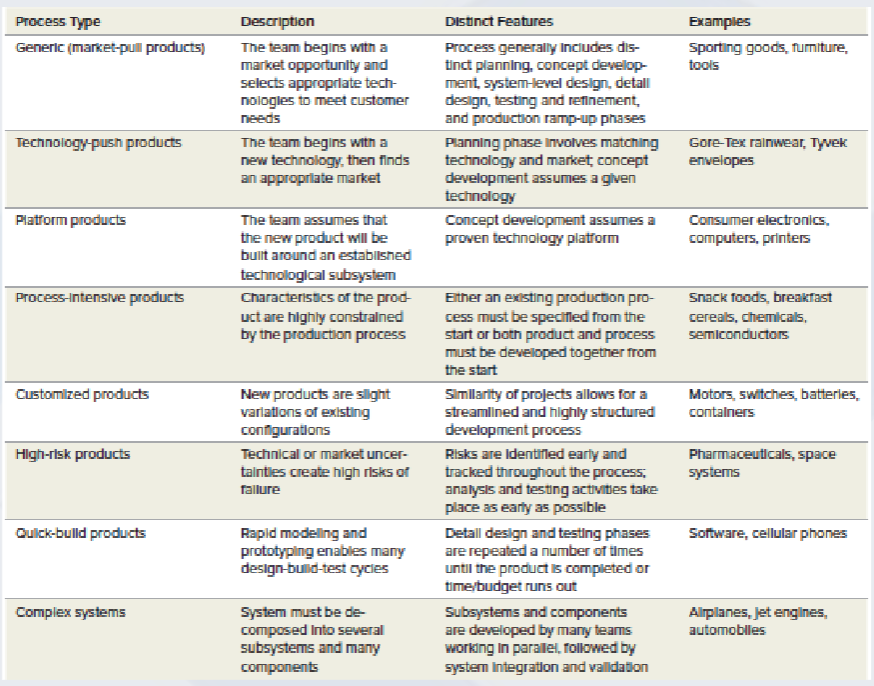

Variants of generic product development process

Technology push products

Platform products

Process intensive products

Customised products

High risk products

Quick build products

Complex systems

Technology push products

Firms begins with new technology and looks for a market

Platform products

Built around a preexistent technological subsystem

Process intensive products

Production process has an impact on the properties of the product

Product design cannot be separated from process design

Customised products

New products are slight variations of existing configuration

High risk products

Technical or market uncertainties create high risks of failure

Quick build products

Rapid modeling and prototyping enables may design build test cycle

Complex systems

Systems must decomposed into several subsystems and many components

Variant of Generic Product Development Process

Quality Function Deployment

Interfunctional teams from marketing, design engineering, and

manufacturingBegins with listening to the customer

Uses market research

Converts the expectations and demands of customers into clear

objectivesThese are then translated into specifications

Customer requirements forms the basis for the house of quality

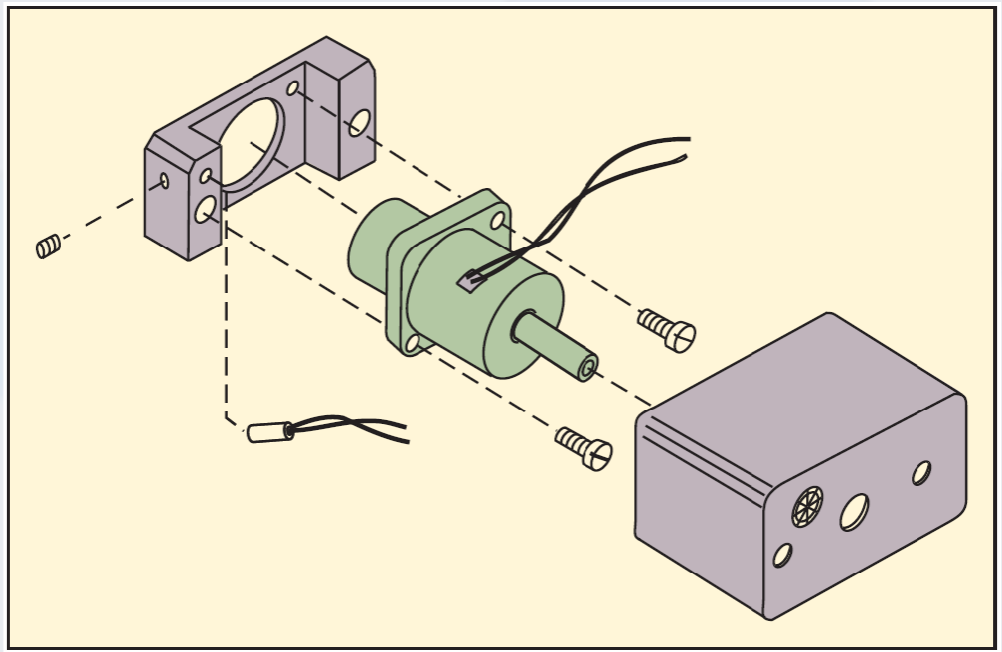

Value Analysis/ Value Engineering (VA/VE)

Purpose is to simplify products and processes

Objective is to achieve better performance at a lower cost while

maintaining all functional requirements defined by the customerInvolves brainstorming such questions as:

Does the item have any design features that are not necessary

Can two or more parts be combined into one?

How can we cut down the weight?

Are there nonstandard parts that can be eliminated?

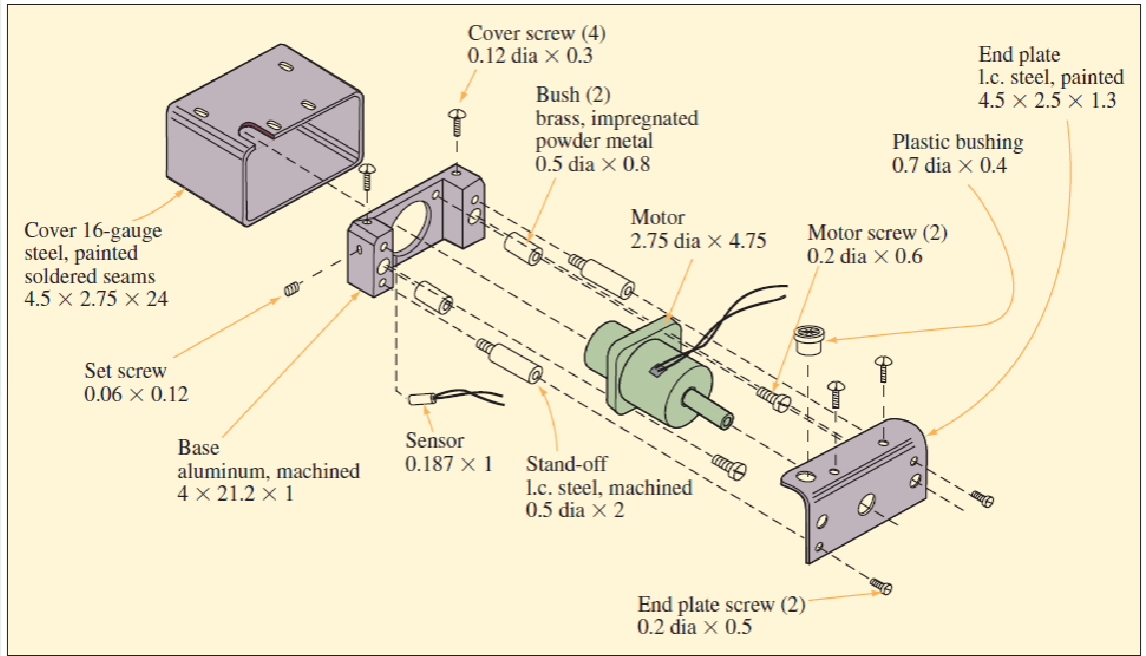

Designing Products for Manufacture and Assembly

Traditional approach

“We design it, you build it” or “over-the-wall”

Concurrent engineering

“Let’s work together simultaneously”

3 Criteria Against which each part must be examined

1. During the operation of the product, does the part move relative to all other parts already assembled?

2. Must the part be of a different material than, or be isolated from,

other parts already assembled?

3. Must the part be separate from all other parts to allow the

disassembly of the product for adjustment or maintenance?

Ecodesign

Ecodesign: the incorporation of environmental considerations in the design and development of products or services

The whole life cycle is considered

The product is considered as a system

A multi-criteria approach is used

An extension of other important requirements such as quality, costs,manufacturability, functionality, and so on

Application of ecodesign can benefit business

Services

Why ? Because services are unique each time as they depend on customer interaction.

What ? Co production.

How ? By understanding what makes a good customer journey.

Designing Service Products

Service products are very different

Direct customer involvement introduces significant variability in the

processQuestions to address:

How will this variability be addressed?

What are the implications for operational cost and the customer service

experience?

Similarity to current services

New service should fit into the current service experience for the customer

Similarity to current process

Even the greatest service ideas require operational support to execute

The more similar they are to the current process, the more of that support is already in place

Financial justification

New services are costly and should be financially justified

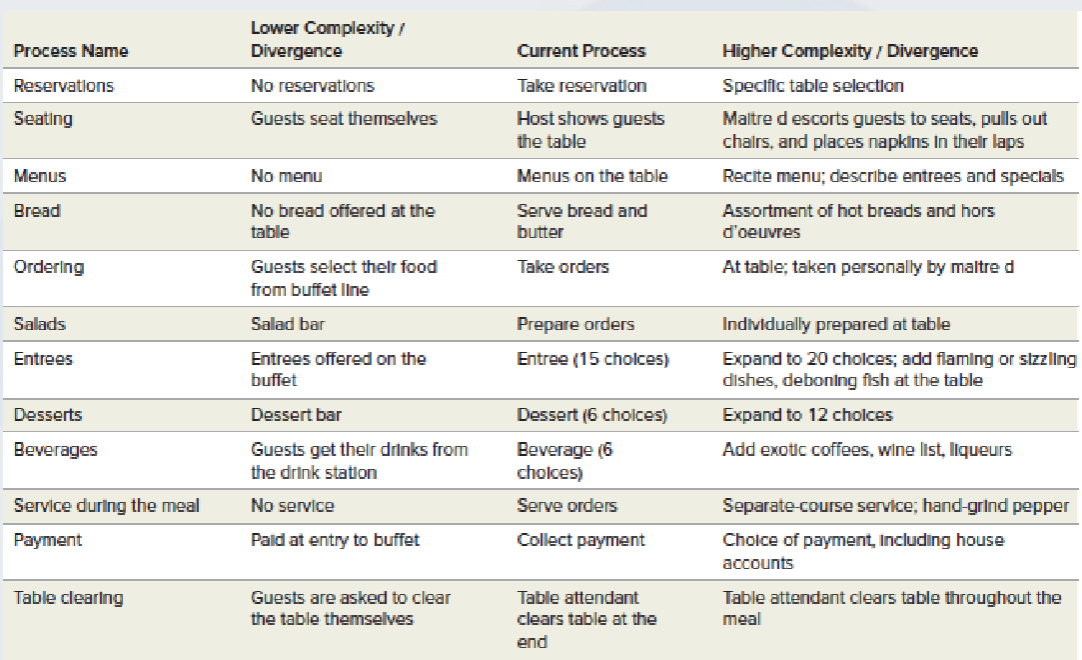

Complexity

the number of steps involved in a service and the possible actions that can taken at each step

Divergence

the number of ways a customer/ service provider interaction

The result may be a combination of higher complexity/divergence on some steps and lower complexity/divergence on others

Can be used to determine ≠ resource requirements such as worker skills, layout, and process controls.

Process Alternatives for a Family Restaurant

Economic Analysis of Project Development Costs

Economic analysis is useful in at least two different circumstances

1. Go/no-go milestones

2. Operational design and development decisionsBuilding a base-case financial model

Compute net present value

Good estimates of cash flows

Sensitivity analysis for “what if” questions

Calculates change in NPV corresponding to a change in the factors included in the model

Can be used to model different scenarios

Possible Sensitivity Analysis Scenarios

Longer product development time

Higher/lower sales volume

Higher/lower sales price

Higher/lower development costs

Measuring product development performance

• A steady stream of new products is important to competitiveness

• Firms must respond to changing customer needs and competitor

moves

• Ability to identify opportunities and bring new products to market is

critical and Must also be efficient

Time to market

There are two aspects to this, the frequency of new product

introductions and the time from initial concept to market introduction

Productivity

Such measures as the number of engineering hours, the cost

of materials, and tooling costs are used in these measures

Quality

Measures that relate to the reliability of the product in use,

the product's performance features compared to customer

expectations, and the ability of a factory or service process

to produce the product

Summary

Product development is a major challenge that directly impacts the

long-range success of a firmMany companies today outsource product design to companies that specialize in different industries

Product development is a multistep process that is unique to each organization

Different sets of criteria drive the design of a product

Criteria that relate to customer wants are fundamental

Criteria related to cost, manufacturability, and impact on the environment are also important

Service products are different because direct customer involvement in the process introduces variability

Summary continued

Financial justification of service features ensure that customers can be retained while the company is making a profit

Economic analysis that consists of estimating the timing and magnitude of future cash flows is used to understand the financial implications of a product development project

Sensitivity analysis can be used to answer “what if” questions that relate to project timing and costs

Generating a steady stream of new products to market is important to the competitiveness of the firm

Measures that relate to time to market, costs, and quality be used to evaluate product development success