Battery Technology (ACE)

1/33

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

34 Terms

Primary Batteries

Galvanic cells that produce electricity from sealed-in chemicals

Cannot be recharged; once equilibrium is reached, they are discharged

Example: dry cell, lithium copper sulfide cell

Requirements:

Economically and environmentally benign

Provide a constant voltage and a long discharge duration

High energy density and longer shelf life

Compact, lightweight and made from easily available materials

Secondary Batteries

Rechargeable cells that can be used through multiple charging and discharging cycles

External electricity reverses the spontaneous cell reaction during charging.

Ex: Nickel cadmium cell, lead acid battery, lithium ion battery

Requirements:

High power-to-weight ratio

Provide high voltage

Long cycle life and shelf life

Short recharge time

Galvanic Cells

Convert chemical to electrical energy

Produces electricity as a result of the spontaneous redox reaction occurring inside it

Anode (-):

Oxidation occurs

Electrons are produced

Desired characteristics: Low reduction/redox potential, high specific capacity, reversibility, and good conductivity.

Cathode (+):

Reduction occurs

Electrons are consumed

Desired characteristics: High reduction potential, high specific capacity, reversibility, and stability.

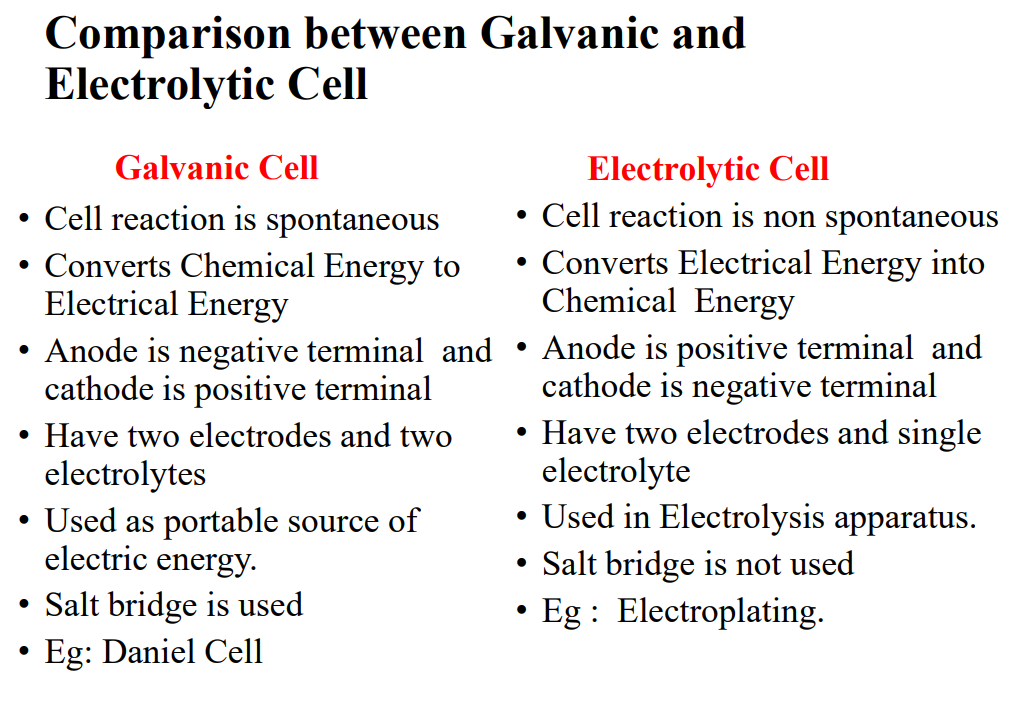

Galvanic vs Electrolytic Cells

Daniel Cell

The cell consists of a zinc electrode in a zinc sulfate solution and a copper electrode in a copper sulfate solution

Anode: Zn → Zn2+ +2e-

Cathode: Cu2+ + 2e- → Cu

Cell reaction: Zn + Cu2+ → Zn2+ + Cu

Key Battery Performance Metrics

Current

Capacity

C = (m x n x F)/M

m → mass of active material

M → molar mass

n → number of electrons transferred

Energy efficiency

% Energy efficiency = (Energy released on discharge / Energy required for charging) × 100

Cycle life

Number of charge-discharge cycles that can be achieved before failure occurs

Shelf life

Energy Density

Power density

Traditional Liquid Electrolyte

Low vicosity, high energy density

High discharge, charge rate

Operational temperature: -40 to 60

Low flammability

Polymetric Electrolytes

Solid or gel form

Solid: High flexibility, energy density, safety and stability

Gel: High ionic conductivity, multifunctional, chemically stable

Advantages of Solid Polymeric Electrolytes:

No leakage.

Non-flammable.

Non-volatile.

Thermal and mechanical stability.

Easy fabrication.

High achievable power density and cyclability.

Lead Acid Battery/Storage Battery

Anode: spongy lead (Pb)

Cathode: lead dioxide (PbO2)

Electrolyte: sulfuric acid solution (H2SO4)

Anode reaction:

Pb → Pb2+ + 2e-

Pb2+ + SO42- → PbSO4

Overall: Pb + SO42- → PbSO4 + 2e-

Cathode reaction:

PbO2 + 4H+ + 2e- → Pb2+ + 2H2O

Pb2+ + SO42- → PbSO4

Overall: PbO2 + 4H+ + 2e- + SO42- → PbSO4 + 2H2O

Overall reaction: Pb + PbO2 + 4H+ + 2SO42- → 2PbSO4 + 2H2O

Overcharging of Lead Acid Batteries

If charging is pushed beyond full capacity, electrolysis of water occurs.

Anode: 2H2O → O2 + 4H+ + 4e-

Cathode: 2H+ + 2e- → H2

Overall: 2H2O → O2 + 2H2

Consequences:

Lowers acid level → damages electrode grids.

Gas pressure may build up → risk of explosion.

Older batteries require topping up with water.

Solution:

Maintenance-free batteries

Pb-Ca alloy anode reduces water electrolysis

Catalysts (ceria + platinum) recombine gases into water; no maintenance is needed

Sealed design prevents leakage

Applications of Lead Acid

Automotive Batteries: Starting, Lighting, Ignition (SLI) for cars and trucks

Industrial Batteries: Motive and standby power for heavy-duty applications

Consumer Batteries: Emergency lighting, security systems, power tools, UPS

Advantages of Lead Acid

High Efficiency: Voltage efficiency ~80%

Longevity: 300–1500 recharge cycles (up to 2000 for sealed batteries)

Quick Recharging: Approximately 2–8 hours

Low Self-Discharge: Maintains charge when not in use

High Current Capability: 12 V car batteries can deliver over 10 A

Disadvantages of Lead Acid

Sulfation: Formation of large PbSO₄ crystals if left partially charged

Weight: Low energy-to-weight ratio (~35 Wh/kg)

Concentration Dependent: Cell potential drops as sulfuric acid is consumed

Temperature Sensitivity: Reduced efficiency at lower temperatures

Overcharging Risks: Potential electrode damage and explosion

Toxicity: Environmental and health concerns with lead

Corrosion: Lead grid corrosion at the lead dioxide electrode

Nickel-Metal Hydride (NiMH) battery

Anode: Hydrogen-absorbed alloys

Cathode: Nickel hydroxide

Electrolyte: Alkaline, mainly potassium hydroxide

Anode reaction:

MH + OH- → M + H2O + e-

Cathode reaction:

NiOOH + H2O + e- → Ni(OH)2

Overall Reaction:"

MH + NiOOH → M + Ni(OH)2

They have about twice the energy density of Ni-Cd batteries but a similar operating voltage

Advantages of NiMH battery

High Energy Density: Surpasses Ni-Cd batteries, with capacities ranging from 1000mAh to 3000mAh or higher

Long Cycle Life: Hundreds to thousands of recharge cycles

Environmentally Friendly: Fewer harmful materials, no toxic cadmium

Safety: Stable, lower risk of thermal runaway or fire hazards

Cost-Effective: Long-term economic power solution with fewer replacements needed

Disadvantages of NiMH battery

Self-Discharge: Loses 1–5% charge per day when idle

Memory Effect: Potential issues if not fully discharged before recharging

Temperature Sensitivity: Performance affected by extreme temperatures

Charging: Slower charging rates, limited fast charging capability

Voltage Output: Lower compared to newer battery chemistries

Applications of NiMH battery

Consumer electronics

Power tools

Hybrid Vehicles

Emergency lighting and backup power

Flashlights and portable devices

Electric bicycles and scooters

Renewable energy storage

👉 ""Cats Play Violins Loudly For Big Rewards.""

Lithium Ion Batteries

Anode: Lithium-carbide type intercalate (LixC6)

Li (C) → Li+ + C + e-

Cathode: Transition metal oxide MO2 of variable oxidation state

Li+ + CoO2 + e- → LiCoO2

Overall Cell Reaction: Li (C) + CoO2 → LiCoO2 + C

The electrolyte is usually inert (polar) dry ether or carbonates(diethyl carbonate or propylene carbonate)

Applications of Lithium Ion Batteries

Used in applications where one or more of the advantages(size, weight or energy) outweigh the additional cost, such as mobile telephones and mobile computing devices.

Used when the battery design matters in a particular application, as different designs are possible (Cylindrical,jelly-roll design, flat rectangular).

Used in current-generation laptops, cellular phones, videorecorders, portable CD players, televisions and implantable medical devices.

Mobile telephones/cellular phones → (has a screen) → laptop, televisions → (video related) → videorecorders, portable CD players

Advantages of Lithium Ion Batteries

1. Designed to overcome the safety problems associated with the highly reactive properties of Lithium metal.

2. Long cycle life (400-1200 cycles).

3. Smaller, lighter and provide greater energy density than either nickel-cadmium or nickel-metal-hydride batteries

4. Can be operated in a wide temperature range and can be recharged before they are fully charged.

5. Typically designed to be recharged in the device rather than in an external charger.

6. The average voltage of a Li-ion battery is equivalent to three Ni-Cd cells.

7. A typical Li-ion battery can store 150 watt-hours of electricity in 1kilogram of battery, as compared to lead acid batteries, which can store only 25 watt-hours of electricity in one kilogram.

Disadvantages of Lithium Ion Batteries

Poor charge retention

Self-discharge rate is about 10% per month

High cost

Traditional Li-ion batteries rely on liquid electrolytes, which are flammable and can pose a fire risk if the battery ruptures or overheats

Safety Concerns with Lithium-Ion Batteries

Damage, puncture or malfunction can lead to dangerous heating, pressure buildup and thermal runaway

Over time, batteries degrade, becoming more prone to overheating and thermal runaway

Safety Measures and Environmental Impact of Battery Production

Battery Management System: Monitors and controls charging/discharging to prevent hazards.

Thermal Management Systems: Utilize heat sinks and fans to prevent thermal runaway.

Quality Control and Testing: Ensures detection and correction of cell flaws before market entry

Safety Standards and Regulations: Established by authorities to ensure safe battery use.

Sodium-Ion Batteries

Lithium (Li): Limited supply, energy-intensive extraction, costly and geographically restricted.

Sodium (Na): Abundant (6th most in Earth’s crust, seawater, salt), simpler extraction, cheaper and more stable supply → promising for large-scale storage.

Similarities

Both are alkali metals (Group 1), lose one valence electron to form Li⁺ / Na⁺, making them good for batteries.

Both work by ion flow between electrodes during charge/discharge.

Differences

Ionic size: Li⁺ (0.76 Å) < Na⁺ (1.00 Å).

Larger Na⁺ ions struggle to fit into electrode materials designed for Li⁺ → lower efficiency.

Challenges & Advances in Na-ion

Electrode design: Need new materials (e.g., Prussian blue analogues, layered sodium vanadates) to handle bigger Na⁺ ions.

Performance: Current Na-ion batteries have lower energy & power density than Li-ion.

Research: Focused on optimising electrodes & electrolytes to improve efficiency.

Emerging Battery Technologies

Solid State Batteries

Solid electrolyte

High energy density and enhanced safety

Ability to revolutionize EV sector

Lithium-Sulfur Batteries

Higher energy density than lithium ion

Sulfur is more abundant and affordable

Challenges: low electric conductivity of sulfur and polysulfide dissolution

Lithium-Air Batteries

Extremely high theoretical energy density

Lithium metal anode, oxygen from air cathode

Challenges: cycle life and lithium stability

Flow Batteries

Liquid electrolytes in external tanks

Electrolytes contain active materials that undergo oxidation and reduction reactions during charge and discharge cycles.

Scalable, flexible capacity

Research on better energy density and cost

Metal Air Batteries

Metal (Zn or Al) anode, atmospheric oxygen cathode

High theoretical energy densities, potentially low cost

Challenges: Reversibility, efficiency, and cycle life

Fuel Cells

A fuel cell is a galvanic cell of a special type in which chemical energy contained in a fuel–oxidant system is converted directly into electrical energy

The reactants (i.e. fuel + oxidant) are constantly supplied from outside and the products are removed at the same rate as they are formed.

Advantages of Fuel Cells

High efficiency: 70–75% vs. only 35–40% for coal-based thermal plants.

Eco-friendly: No noise, chemical, or thermal pollution.

Decentralized use: Can be installed near point of use , reducing ~30% transmission losses.

Continuous power: Provides steady electricity as long as fresh reactants is supplied.

Methanol Fuel Cell

Electrolyte: Sulphuric acid

Electrodes: Typical gas diffusion electrodes, made up of porous C coated with Pt catalyst

Fuel: Methanol Oxidant

Air Catalyst: Platinum

Anode reaction:

CH3OH + H2O → CO2 + 6H+ + 6e-

Cathode reaction:

3/2 O2 + 6H+ + 6e- → 3H2O

Net reaction:

CH3OH + 3/2 O2 → CO2 + 2H2O

Proton Exchange Membrane Fuel Cell

Electrolyte: Ion exchange polymeric membranes.

Electrodes: Typical gas diffusion electrodes, made up of porous C coated with Pt catalyst.

Fuel: Hydrogen

Oxidant: Air

Catalyst: Platinum

Operate at relatively low temperatures, around 80 °C → Quick start-up, less wear, better durability.

Efficiency of 60 % → Power output of 50-250kW

Anode Reaction:

H2 → 2H+ + 2e-

Cathode Reaction:

½ O2 + 2H+ + 2e- → H2O(l)

Overall Reaction:

H2 + ½ O2 → H2O

Challenges:

Require expensive platinum catalyst.

Platinum is highly sensitive to CO poisoning, so extra processing is needed to clean fuel → higher cost.

Role of Proton conducting membranes:

Functions: Acts as electrolyte (ionic conduction) and separator (keeps reactant gases apart).

Proper proton & water transport is critical.

Too dry → low proton conductivity.

Too wet → electrolyte flooding.

Advantages:

No liquid electrolyte → simpler flow control than alkaline/phosphoric acid cells.

CO₂ tolerant.

Breakthrough: DuPont’s Nafion (perfluorinated ionomer) membranes (since 1966).

Durable (>60,000 hours at 353 K).

Advantages and Disadvantages of PEMFC

Used in transportation: passenger vehicles such as cars and buses

Advantages:

Solid electrolyte provides excellent resistance to gas crossover.

Low operating temperature allows rapid start-up

Capable of high current densities

Disadvantages:

Dehydration of the membrane reduces proton conductivity, and excess water can lead to flooding of the electrolyte. Both the conditions leading to poor performance

High cost

Sensitive to poisoning by trace levels of contaminants, including CO, sulfur species and ammonia.

Environmental Impact of Battery Production

Resource Extraction: Mining for battery materials can lead to ecological damage.

Energy Intensity: High energy consumption in production; renewable energy can reduce impact.

Chemical Pollution: Handling and disposal of hazardous chemicals must be managed safely.

Water Usage: Significant water use in production; conservation and recycling are key

End-of-Life Management

Crucial Disposal Management: Essential to minimize environmental harm.

Recycling Infrastructure: Development needed to prevent pollution.

Material Reuse: Advocacy for reusing battery materials to reduce impact.

Remember as RRRReduce Environment Harm

Recycling Infrastructure

Reuse Material

Environmental Considerations

Vital Role of Batteries: Key in renewable energy and electrification transition.

Mitigation of Environmental Impact: Necessary at all life stages of batteries.

Sustainable Practices: Implementation critical for environmental protection.

Technical Advancements: Adoption can address manufacturing concerns.

Regulatory Frameworks: Establishment helps ensure environmental safety.