Engineering Graphics Flashcards

1/52

Earn XP

Description and Tags

Vocabulary flashcards for engineering graphics.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

53 Terms

Tolerance

The allowable amount of variation in a dimension to ensure proper function and interchangeability.

Nominal Size

The general size of a part, usually expressed in fractions.

Basic Size

The theoretical size from which limits are determined.

Actual Size

The measured size of a finished part.

Limits

The maximum and minimum sizes a part can be and still function.

Allowance

The minimum clearance or maximum interference between mating parts.

Maximum Material Condition (MMC)

The state when a part contains the most material-largest shaft or smallest hole.

Least Material Condition (LMC)

The state when a part contains the least material-smallest shaft or largest hole.

Clearance Fit

Always allows clearance between parts; hole is bigger than shaft.

Interference Fit

Always results in interference; shaft is bigger than hole.

Transition Fit

May result in either clearance or interference depending on actual sizes.

Bolt

Used with a nut.

Screw

Used in a threaded hole.

Internal Threads

Inside holes.

External Threads

On the outside of shafts.

Major Diameter

The largest diameter of a thread.

Minor Diameter

The smallest diameter of a thread.

Thread Pitch

The distance between threads; in English units, expressed as threads per inch

have a longer, gradual taper, making them suitable for starting threads in a new hole.

Taper tap

Cuts full threads to the bottom of blind holes.

Bottoming Tap

$$have a shorter taper and are used for cutting threads after a taper tap has been use

Plug tap

Class 1 Thread Fit

Loose fit for easy assembly.

Class 2 Thread Fit

Standard fit for general use (most common).

Class 3 Thread Fit

Tight fit for high precision and load applications.

Surface Finish

The texture or smoothness of a part's surface.

English Unit System

Inch-Pound-Second (IPS) system.

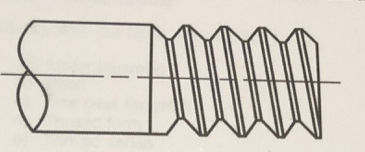

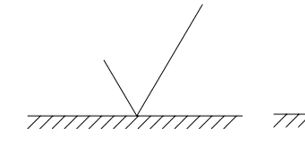

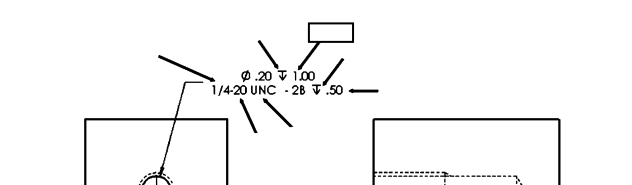

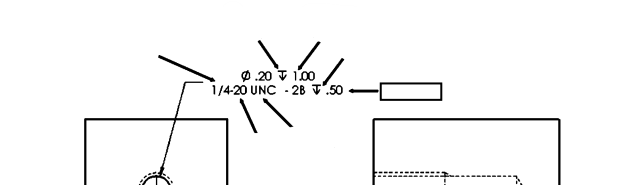

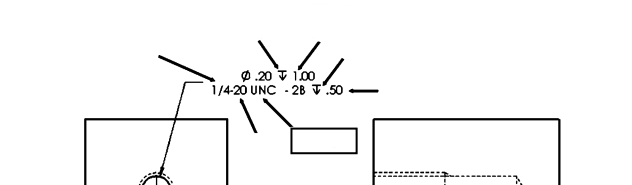

Detailed Representation

Is this a Detailed, Schematic, or Simplified representation of a thread

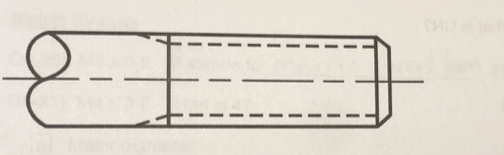

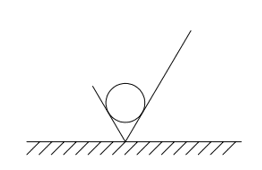

Simplified Representation

Is this a Detailed, Schematic, or Simplified representation of a thread

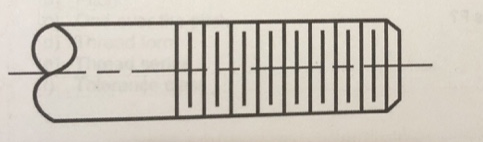

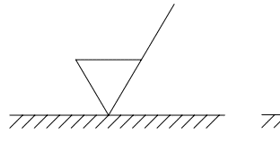

Schematic Representation

Is this a Detailed, Schematic, or Simplified representation of a thread

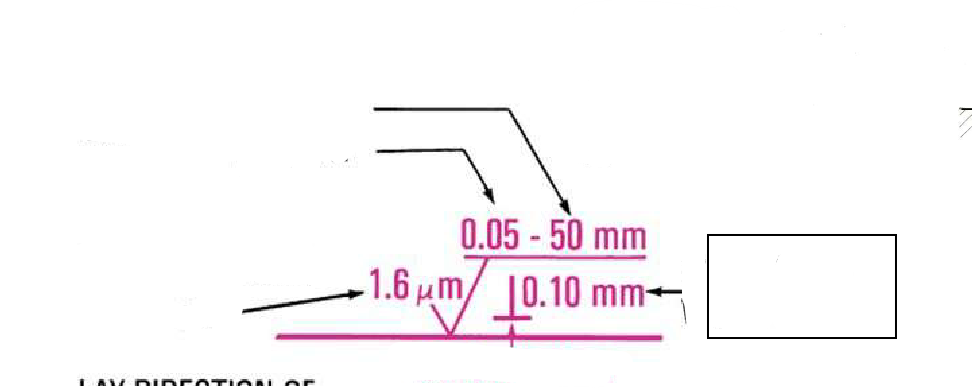

Any Method Surface Finish

What is this Symbol for

Machining Only Surface Finish

What is this Symbol for

Machining Prohibited Surface finish

What is this Symbol for

3rd

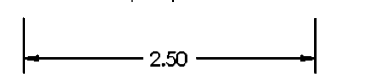

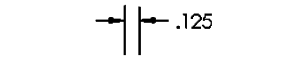

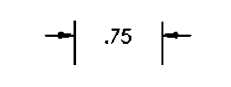

Where in the order would this dimensioning style fall?

1st

Where in the order would this dimensioning style fall?

4th

Where in the order would this dimensioning style fall?

2nd

Where in the order would this dimensioning style fall?

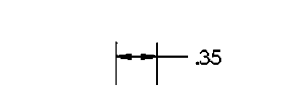

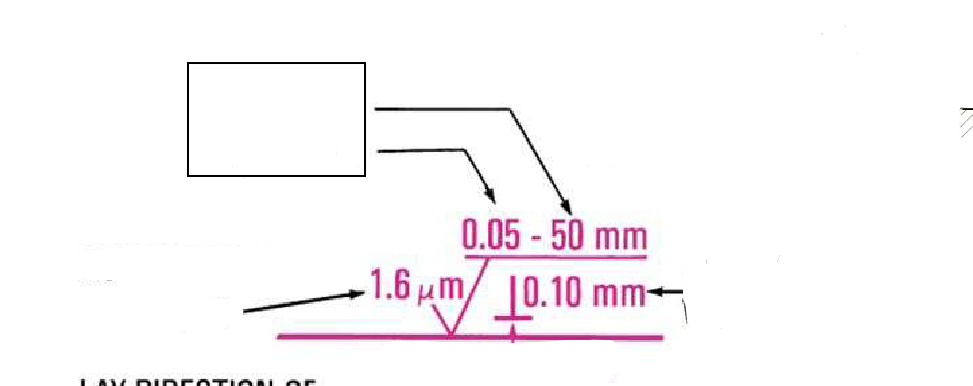

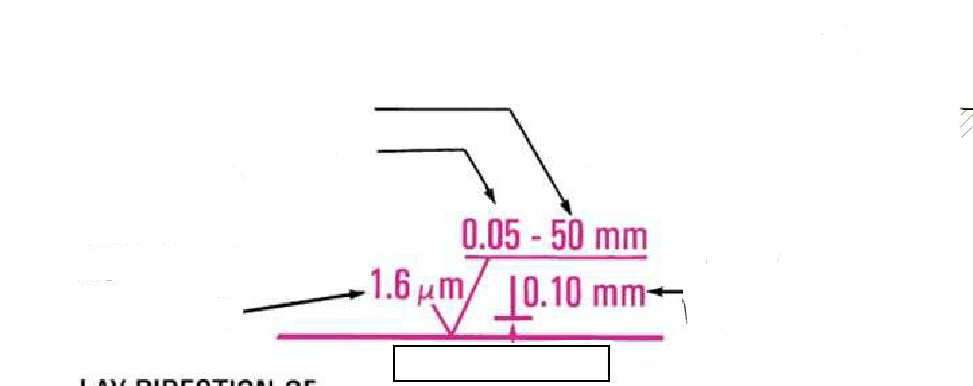

Roughness Width

refers to the width of the surface texture that affects the roughness of a material. It is a critical measurement in engineering graphics for specifying surface finishes.

Width

Height (waiveness)

Refers to the amplitude of the surface irregularities, quantifying the peak-to-valley distance of the waviness.

Lay Direction

The orientation of the surface texture relative to a specified reference direction, affecting the functional performance and appearance of a component.

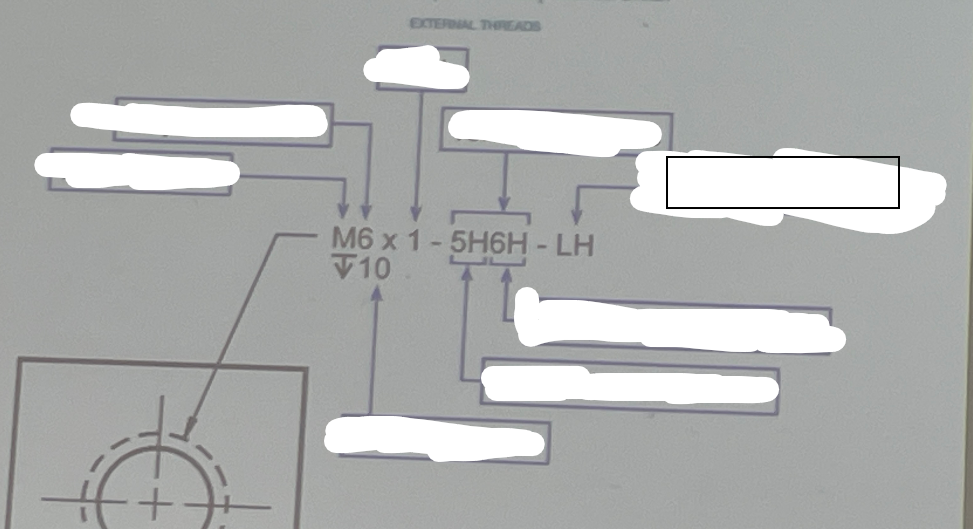

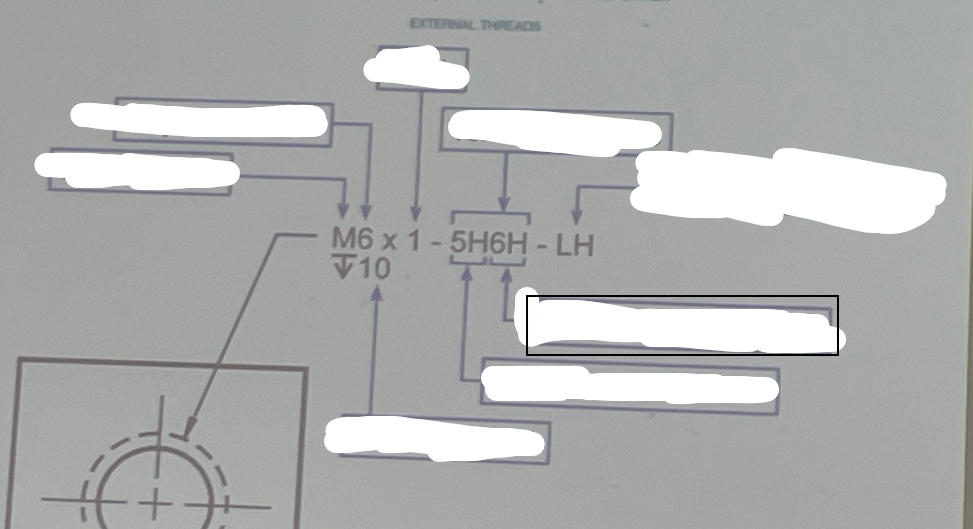

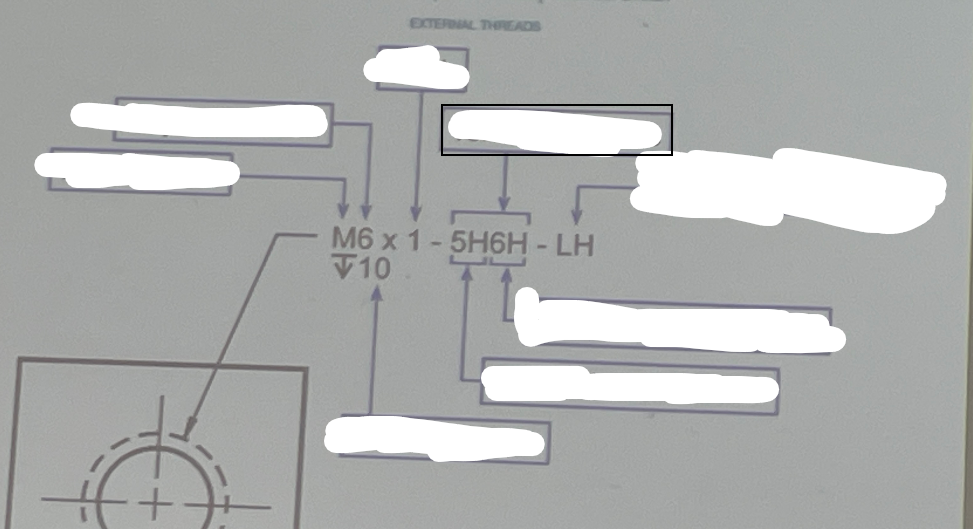

Right/Left Handed

Refers to the orientation in which a part or feature is designed or used, indicating its operational direction based on the user's perspective.

Minor Diameter Tolerance

The permissible variation in the minimum diameter of a cylindrical feature, such as a hole or shaft, ensuring proper fit and function.

Pitch Diameter Tolerance

Refers to the allowable variance in the pitch diameter measurement of a screw thread. This tolerance ensures that threads will fit together correctly and function as designed.

Thread Depth

The perpendicular distance from the crest to the root of a thread, which determines the thread's height.

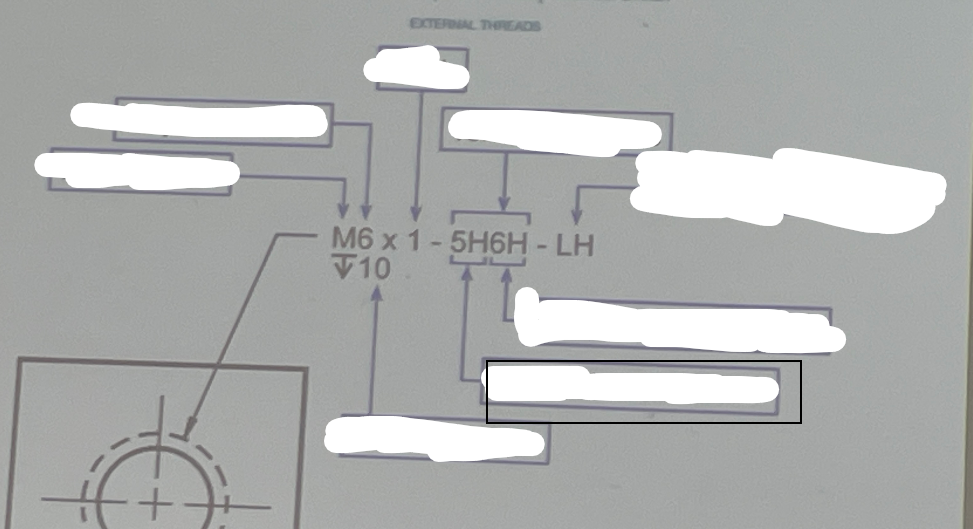

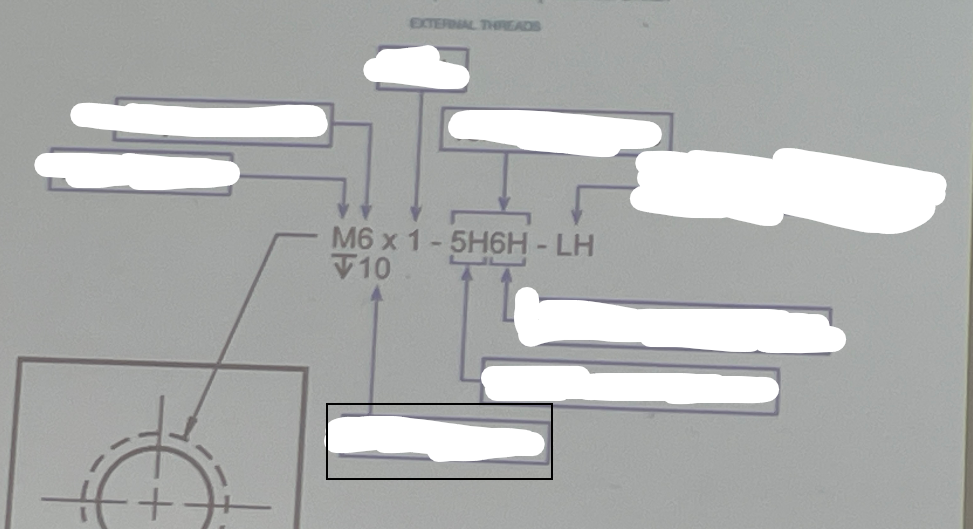

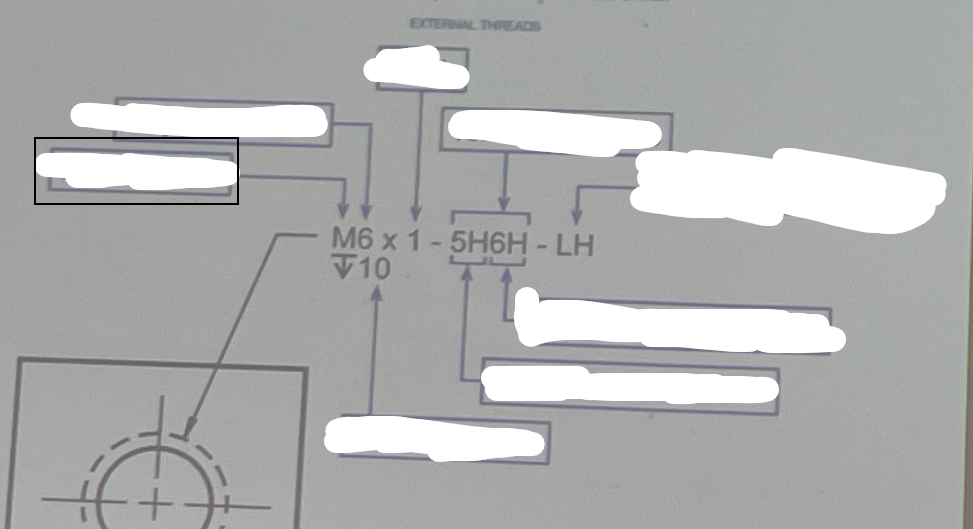

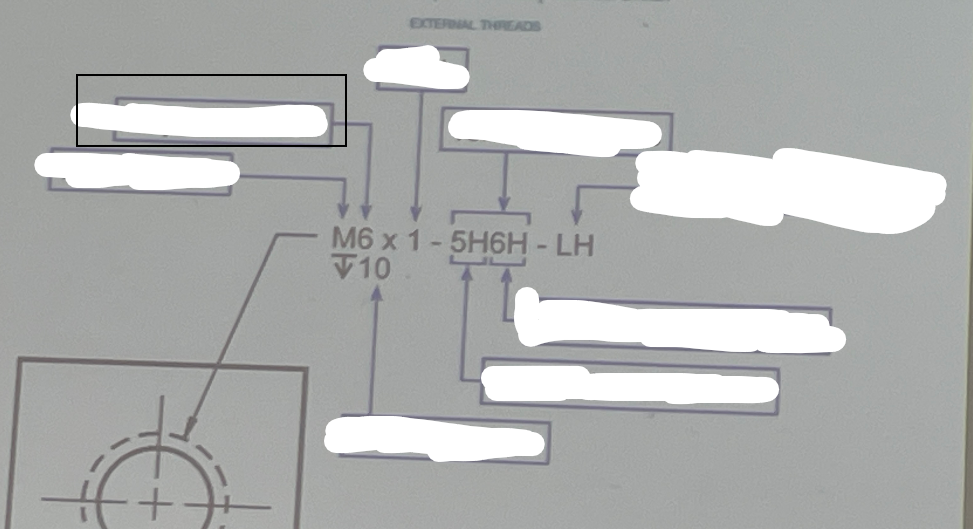

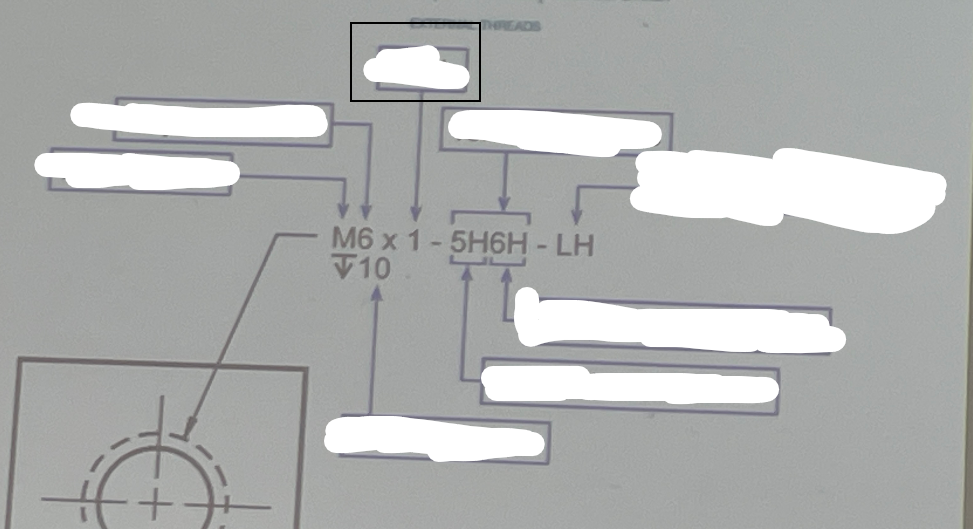

Metric Form

In engineering graphics, metric form refers to a system of measurement where dimensions and tolerances are specified in millimeters and are often applicable to ISO standards, ensuring consistency and precision in technical drawings.

Major Diameter

The largest diameter of a screw thread, measured from crest to crest.

Pitch

The distance between corresponding points on adjacent threads, measured parallel to the axis.

Tolerance Class

A classification that specifies the permissible limits of variation in a dimension or physical property during the manufacturing process.

Major Diameter

The largest diameter of a cylindrical screw or shaft, measured from the outer edges of the threads.

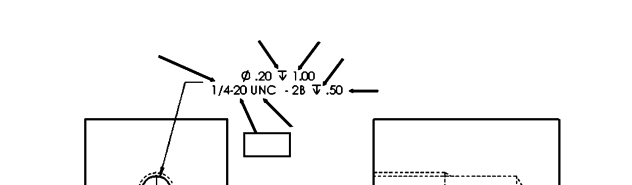

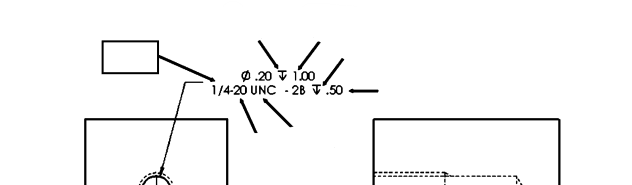

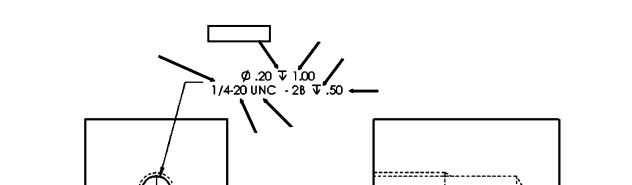

Depth Symbol

A symbol used in engineering drawings to indicate the depth of a hole or feature.

Depth of Hole

The specified measurement from the top of the workpiece to the bottom of a hole, often indicated by the depth symbol on drawings.

Depth of Thread

The measurement from the crest to the root of a thread, which determines how deep the thread engages with the mating part.

Thread form and series

refers to the specific shape of the thread profile and its corresponding series, such as Unified, Metric, or Acme, which define the thread's size and characteristics.

Threads per inch

A measurement indicating the number of threads within one inch of a given length, commonly used for imperial thread specifications.