Final Exam Study Set

1/337

Earn XP

Description and Tags

This is a final exam study set that are completely based on the information in all the slides from the semester.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

338 Terms

What does are the responsibilities of the manufacturer?

They must determine how best to distribute the product.

With certain products, the distribution functions require minimal resources, and the manufacturer can manage the entire supply chain.

In most supply chains though, the service is better fulfilled by a company focusing on distribution functions.

The distributor fills the role!

Where do you want to be in the business model?

Core customers.

What are cost to serve indicators (CTS)?

Each indicator is weighted according to importance to distributors and suppliers.

What is disintermediation?

Direct to consumer.

What are disadvantages of buying groups?

Less control of product specifications, inflexible shipping schedules, and cost of membership fees.

What does the manufacturer’s agent do?

Usually represent companies whose sales in a territory do not support a full salaried employee

May call on distributors, end users, specifiers, and manufacturers

Complimentary products

Do not typically stock inventory

May also be referred to as a manufacturer rep or manufacturer rep agent (agency)

What skills and expertise does a manufacturer’s agent require?

Product knowledge

Market knowledge

Negotiation skills

Teaching skills

Interpersonal skills

What are some examples of specifiers?

Architects

Engineers

Designers

What are advantages of buying groups?

Lower cost of goods, lower shipping costs, centralized ordering and support.

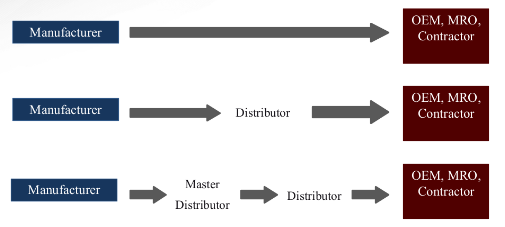

What do master distributors do?

Common in industries with heavy logistical requirements

Stocks products of represented manufacturers

Only sells to distributors, not to end users

Typically, complimentary products

May also be referred to as a wholesaler

May also function as a manufacturer’s agent

What are some distribution key performance indicators (KPI)?

Order Lead Time

Perfect Order Rate

Back Order rate

Lost Sales

Order Cycle Time

Health and Safety Incident Rate

Employee Turnover

Vendor Performance

Labor and Equipment Utilization

Put Away Cycle Time

What are distribution strategies?

Intensive

Selective

Exclusive

The intensive distribution strategy…

Penetrate the market

As many outlets as possible

No cap on stores or locations

The selective distribution strategy…

Specific locations

Limited number of stores

Target consumer

The exclusive distribution strategy…

High-end and exclusive brands

Limited outlets

Particular locations

What are distribution competitive advantages?

Order Lead Time

Perfect Order Rate

Back Order rate

Lost Sales

Order Cycle Time

Health and Safety Incident Rate

Employee Turnover

Vendor Performance

Labor and Equipment Utilization

Put Away Cycle Time

What is the difference of a manufacturer vs a distributor?

Prefer Stability “Play it Safe”

Research & Development

Salesperson becomes expert

Design, Create and Build

Combination of standardized, catalogued product and custom equipment

Demand Creation at distributor & end user

Sell through multiple channels – direct to end customer, through distribution, or through manufacturer’s rep agency

Responsible for one portion of the project, example for electrical is “the gear”

What is the difference of a distributor vs manufacturer?

Higher Risk, Higher Reward

Hundreds of lines authorized to sell – salesperson knows a little about a lot

Demand Creation with contractors and end users

Transactional & Solution Selling

The “bank” for manufacturers

Must innovate constantly, and find creative approaches

Responsible for all items on the BOM

RELATIONSHIPS are the utmost of importance to succeed (with both vendors & customers)

What are the manufacturer’s expectation of the distributor?

Participate in true partnership

Engage and encourage joint sales calls and social activities

Keep high levels of standard inventory

Be an extension of manufacturer’s sales force

Bridge the gap on end customer credit worthiness, terms and conditions

Provide feedback on pricing, performance, and ways to improve as a vendor

Reach growth goals year over year

Use our e-commerce tools for self sufficiency

What are the distributor’s expectation of the manufacturer?

Participate in a true partnership

Engage and encourage joint sales call and social activities

Provide accurate information for lead times and ship dates

Get their products specified

Support the distributor salespeople and end customers from a technical perspective

Train their salespeople on products and processes

Make it easy for them to do business with – dealing with hundreds of vendors’ e-commerce platforms, billing & invoicing, thousands of shipments a year

What does the industrial supply chain include?

Manufacturers

Master Distributor

Manufacturer’s Agent

Distributor

3PL

Assembler and Processor

End User (Customer)

What does the manufacturers do?

Developing new products

Sourcing components and materials

Manufacturing products

Quality

Efficiencies

Cost Control

Distribution of products

What are the manufacturer’s responsibilities?

Sourcing components and materials

Manufacturing products

Quality

Efficiencies

Cost Control

Distribution of products

What does TQM stand for?

Total

Involving the entire department of the company.

Quality

Achieving customer satisfaction all the time.

Management

Maintaining a high-level quality in every sector.

What are the manufacturer’s priorities?

The primary driver for manufacturing is market share resulting in efficient use of resources.

Due to high fixed costs (facilities, equipment, and labor), higher market share creates higher volume which reduces cost per item to manufacture.

The selected distributors and channel should offer the greatest market access.

The relationship should provide for a solid information exchange and mutually supportive deployment of resources.

What are the roles in the industrial supply chain?

Manufacturer

Master Distributor

Manufacturer’s Agent

Distributor

3PL

Assembler/Processor

End User (Customer)

What is a master distributor?

A master distributor is a wholesale distributor who sells product to resellers (wholesalers). They have direct relationships with brand owners who recognize them as exclusive distributors of their product.

What do manufacturer’s agents do?

Manufacturers' agents or representatives are independent contractors.

They work on commission to sell products for more than one manufacturer.

They are not under the immediate supervision of the manufacturers (principals) for whom they sell.

The relationship generally falls into client-customer patterns.

Manufacturers' agent firms range from businesses operated by a sole entrepreneur to considerably more extensive organizations armed with numerous salespeople covering specific territories.

Key value add is that they are generally paid on commission, thus if there are not sales, there are no costs.

There are no fixed costs to bring them on board.

They generally offer compatible—but not competing—products to the same industry.

What are the risks of a wholesaler?

Competition

Reputation

Property damage

Inability to obtain supply

Legal penalties

Product liability

Theft

Equipment breakdown

Incident tracking

What is a 3PL?

A third-party logistics warehouse, or 3PL for short, is an outsourced business that takes care of a company’s supply chain and logistics operations.

What are 3PLs used for?

Outsourcing third-party warehouse and distribution needs for their customer’s inventory and fulfillment services.

Managing 3PL stock

Holding, and shipping the inventory of multiple businesses or other businesses in addition to their own inventory.

What is a hybrid 3PL?

A 3PL fulfills and stores orders for both their own business as well as their clients.

What does an assembler or processor do?

Every manufacturer assembles goods.

An assembler is determined based on how much of the content of your product is built in-house versus by a supplier.

Are there risks of an assembler or processor?

Risk varies substantially based on whether you are a manufacturer or supplier.

What are the risks of an end user (distributors or retailers)?

Property damage

Inability to obtain supply

Legal penalties

Product liability

Theft

Equipment breakdown

Incident tracking

What is industrial manufacturing?

Fabrication of products from raw materials destined for industrial use

Output from industrial manufacturing keeps other mass manufacturers in business

Produces

Massive industrial machines

Simpler household machines

Other industrial use products

Additionally manufacturer wide range of other industrial use products

Hardware

Paper and packaging materials

Glass

Fixtures

The industrial manufacturing plays?

A crucial role in producing the goods and services vital to the economy in a timely and cost-efficient manner and range of products is vast and shares a common function.

What are the broad classes of industrial equipment?

Standard equipment

Custom built equipment

Standard Equipment are?

Cheaper to build

Used in various industries

Cannot fulfill specific needs of new factories

Custom Built Equipment are?

More expensive

More profitable

Takes longer to build

Can be tailored to incorporate specific attributes, as needed

by the buyer

How many groups can industrial equipment be grouped in?

7 different segments

3 industrial equipment produce special purpose machinery for specific industry segments…

Agricultural, Construction and Mining

Industrial

Commercial and Service

What are the industrial equipment produce special purpose machinery for specific industry segments?

Ventilation equipment

Heating and cooling equipment

Engine and engine related equipment

Other general-purpose machinery

What is the future of manufacturing?

Assembly lines of the future will incorporate robotics, technology, AI, and people to be more consistent, efficient, quick, and more profitable.

As manufacturers innovate and improve how they manufacture products, the distributor must also innovate and improve to remain relevant.

Bullwhip Effect

The bullwhip effect describes the increasing fluctuations in inventory in response to changing consumer demand as one moves up the supply chain.

Observing, analyzing and understanding how the bullwhip effect influences the supply chain can provide us with important insights for improvement.

What causes the bullwhip effect?

Customer orders come in for the retailer, but this information is quickly lost upstream.

This situation is reflective of supply chains with low levels of trust.

Absent customer demand data, forecasts rely on the incoming orders at each successive stage.

The delay or pause in information using traditional forecasting methods and inventory strategies create the bullwhip effect.

What are the benefits of batch ordering?

The discount incentive works!

Typically discounts prompt partners to withhold small orders.

Yet, the tradeoff is that the practice further aggravates the bullwhip effect by:

Causing an added delay in information flow.

Muting the information associated with the order.

Upstream partner can’t be sure whether a bulk order reflects true demand, or a downstream partner’s need for cost savings.

How would we redesign the supply chain?

Implement efficient replenishment practices.

Efficiently manage inventory with Quick Response, Continuous replenishment, Vendor Managed Inventory (VMI).

Efficiently manage logistics through warehousing practices, Direct

Delivery, Cross-Docking.

Other practices such as JIT delivery (auto industry with Kanban system.

What is Gross Domestic Product (GDP) supposed to measure?

Annual spending in the economy by…

Consumer Spending: 67.1%

Government Spending: 16.5%

Business Spending (investment): 16.5%

What actually drives the economy?

Consumer spending does not drive the economy, instead the supply chain does.

Business spending (gross investment): 62%

Consumer spending: 31.5%

Government spending: 6.5%

What should the general model of economics include?

Gross Output (GO) complements Gross Domestic Product (GDP). GO is the missing piece in macroeconomics.

In quarterly financial statements, “Top Line” is?

Revenues or Sales

Total Income

Gross Output (GO) measures revenues at all stages of production

In quarterly financial statements, “Bottom Line” is?

Earnings or Net Income

Profits

GDP means “value added” or final product (similar to “gross profit” in financial statements)

General Model of the Economy

Expand beyond GDP to include GO-the whole production process.

Analyze not just the CPI, but the PPI and Commodity Price Index.

Look beyond "the" interest rate to the yield curve.

Examine more than "the" rate of unemployment, but the structure of employment and unemployment.

Go beyond the broad stock indexes (S&P 500) and look at various industries.

Commercial Firms

Manufacturers, Construction companies, Service firms, transportation companies, select professional groups, distributors, wholesalers, retailers

Institutions

Schools, health care orgs, libraries, foundations, non-profits, etc.

Governments

Federal government (defense & non-defense), state, local, municipalities, counties, townships

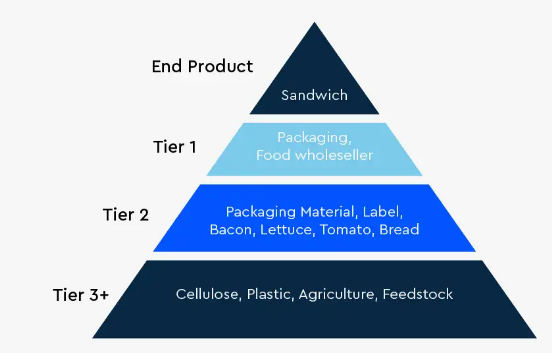

A channel is?

Composed of supply tiers

Supply Chain

Any activity needed to transfer goods from raw material extraction through consumption by the final consumer.

Supply Chain Management

Includes both the movement of products as well as critical service operations.

Supply Tiers

Tier 1 suppliers - Companies that provide materials to to a manufacturer

Tier 2 suppliers - Companies that provide products to Tier 1 suppliers

Tier 3 suppliers - Companies that provide products to Tier 2 suppliers

What does Manufacturer’s Agent do?

Usually represent companies whose sales in a territory do not support a full salaried employee

May call on distributors, end users, specifiers, and manufacturers

Complementary products

Do not typically stock inventory

May also be referred to as a manufacturer rep or manufacturer rep agent (agency)

Master Distributor

Common in industries with heavy logistical requirements

Stocks products of represented manufacturers

Only sells to distributors, not to end users

Typically, complementary products

May also be referred to as a wholesaler

May also function as a manufacturer’s agent

Structured Difference of a Manufacturer Compared to a Distributor

High value on brand recognition and perceived product quality

High fixed cost

Significant need for volume

High market share is an extreme predictor of profitability

Structured Difference of a Distributor Compared to a Manufacturer

Less value on brand and quality and more value to customer relationships

High variable cost

Less need for volume

Market share less of a predictor of profitability

What do distributor compensation Includes?

Extended payment terms

Cash discounts

Consignments

Stock rotations and return allowances

Cooperative and market development funds

Special pricing agreements

Volume incentives

Why does pricing matter?

The fastest and most effective way for a company to realize its maximum profit is to get its pricing right.

Getting the price right is one of the most fundamental and important management functions.

“3 C’s” of Pricing

Cost

Competition

Customer

What is the importance of distribution in the economy growth?

Distribution helps to satisfy the needs of consumers by supplying assortment of different products of different producers.

Why is growth important to manufacturers?

Larger market share

Reduce cost per item (recall large fixed costs)

Increased importance to distributor

What is growth to a distributor?

More customers

More sales or profit

More employees

More facility locations

More products and additional inventory

Primary Growth Options

Sell more to existing customers.

Find or build new customers.

Expand or broaden inventory, market, services, and capabilities including eCommerce.

Using business analytics to determine a strategy and implementation plan for growth.

What is an essential step in developing a customer-centric operations strategy?

A classification of customers into groups based on profitability, cost to serve, loyalty, and buying power.

What is the path to growth?

Increase sales to existing customers

New products and services to existing customers

New customers similar to existing customers

New markets

Product innovations

eCommerce

What is a distribution channel?

The paths products and services take on the way from the manufacturer or service provider to the end consumer.

The channel involves a set of interdependent organizations in the process of making a product or service available for use or consumption.

What is a distribution channel strategy?

Distribution strategy is the method used to bring products, goods and services to customers or end-users.

Ensuring an easy and effective way to get your goods and services to people, depending on the item, and its distribution needs.

Organizations consider which distribution strategy is best while being cost-effective and increasing overall profitability.

Can even use multiple or overlapping distribution strategies to reach target audiences and meet company goals or objectives.

Best Practices To Determine Channel Goals

Understand channel context

Set firm-level financial goals

Translate firm goals to channel goals

Identify channel success factors

Why a Better Supply Chain?

Better Supply Chain = Improved Profitability.

Invest in Technology and Talent.

Effective Supply Chain enables a Distributor to compete on Service, Sourcing, and Cost.

Invest in right Processes.

Turn ‘Cost Center’ into ‘Profit Center’.

Avoid Disruptions.

Be aware of ‘Amazonification’

Channel Conflict

Channel conflict can be explained as any dispute, difference, or discord arising between two or more channel partners (e.g. supplier and customer).

The conflict of interest causes channel members to work against each other rather than working together.

One or more members believe they are not being treated fairly.

Industrial Supply Chain

What are the manufacturer’s responsibilities?

Produce quality/competitive products

Create new markets

End-user and specifier calls

Advertising in magazines, trade journals, internet, trade shows, etc.

Provide up-to-date printed or electronic catalogs

Provide technical information and training

Understand value and compensate channel partners

What are manufacturer priorities?

The primary driver for manufacturing is market share resulting in efficient use of resources.

Due to high fixed costs (facilities, equipment, and labor), higher market share creates higher volume which reduces cost per item to manufacture.

The selected distributors and channel should offer the greatest market access.

The relationship should provide for a solid information exchange and mutually supportive deployment of resources.

Factors for Relationships

Trust

Communication

Commitment

How do you earn trust?

Demonstrated and earned over time

Willingness to honor commitments—integrity

Ability to honor commitments—track record, skill sets, authority, and resources

Believe the other person’s best interest is understood and will be pursued

Difficult to build

Easy to destroy

What is the definition of trust?

The firm belief in the reliability, truth, ability, or strength of someone or something

Mutual Trust

Trust is not between firms, but individuals

Trust is earned over time and is for a long-term relationship

Trust is lost very quickly

Trust is about performance, NOT intent

POSIWID

The purpose of a system is what it does.

Communication is…

Open, honest and a two-way street

Ask questions

LISTEN

Provide constructive performance feedback

Discuss opportunities

Develop mutual goals

What are the commitments demonstrated by the manufacturer?

Dedicated personnel and facilities

Efforts to learn about operation

Coordinated reporting systems

Coordinated planning efforts

Coordinated training efforts

Alignment in the mind of the end-user

What are the commitments demonstrated by the distributor?

Dedicated personnel and facilities

Build relationships with manufacturer’s organization

Investment in product training and support

Investment in compatible reporting system

Alignment in the mind of the end-user

Train customer to use manufacturer’s products

Commitment to Relationship

Reputation for treating partners fairly

Demonstration of fair treatment and understanding of supply chain partner

Don’t beat up the manufacturers

A distributor is a partner, not a customer

How you react when conflict exists is critical!

Why is the relationship piece critical?

Provides insight and knowledge into how the manufacturer operates.

Provides information on hot buttons and yields opportunities to secure incentives based on need.

Forms the bonds of trust and mutual understanding.

Builds communication.

Strategic Relationships are

Genuine long-term commitment and trust

Willingness to sacrifice and share

Alignment of goals

Risk of a Strategic Relationship

Becoming dependent on partners

What are the manufacturer’s motivations?

Better coverage at lower cost

Better presentation

Better coordination of marketing efforts

Greater access to information

Pool of potential partners drying up

Loss of distribution

Loss of power

What are manufacturers services?

Choose their customers based on a certain technological offering.

Make a substantial investment in production equipment that is highly inflexible.

Need a distribution channel that can reach and support their customers and help the manufacturer to efficiently control their production investments.

What are the distributor’s motivations?

Assured and dependable supply of desirable products

Enhance marketing efforts

Cut cost

Eliminate redundancy

Differentiate themselves from competition

Discourage competition

What are distribution responsibilities?

Choose a customer market to serve and built the resources needed to serve that market.

Choose a set of suppliers with the products, technology, brand name, and service to set market demand.

Determine and create a network of warehouses, transportation, equipment, and other service capabilities to excel in the chosen market.

Invest in and carry inventories matching the customers’ needs with manufacturers’ capabilities.

How does a distributor’s value add to the manufacturer?

Fabrication

Assembly

Volume Influence

Aftermarket Service

Marketing Support

Product Training

Distributor’s Value Add To the Customer

Customization

Value-added Services

Distributor Branding

Rapid Response Times

Order Tracking

Inventory Management

What do manufacturers bring to the table?

Branding

Expertise

National Accounts

Marketing Support

Minimal Inventory

Variable Delivery Schedule

Manufacturing Technology and Sourcing