Surface Final

1/158

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

159 Terms

Name two of the largest natural gas plays in Western Canada.

Duverney

Montney

What are the top five countries in the world in terms of natural gas production?

Russia

United States

Canada

Qatar

Iran

What types of wells can natural gas be produced from?

Gas wells

Oil wells

Associated or solution gas

Non associated gas or gas cap

Coal bed methane wells

Shale gas wells

Tight gas wells

Give 4 reasons why natural gas is compressed

To boost pressure at the wellhead

To boost pressure within a facility

To meet sales pipeline specs

To boost pressure along transmission lines

Define the term ‘dew point’ in regard to natural gas

The temperature at which the first drop of water is formed when cooling the gas.

It is a measure of the relative humidity (ie. the water content) of the gas at STP.

Processed natural gas will typically contain what percentage of methane?

At wellhead: 75% to 95%

After processing: 95% to 99%

What contaminants are found in natural gas that must be removed by processing?

Carbon Dioxide

Nitrogen

Hydrogen Sulphide

Water

Mercury

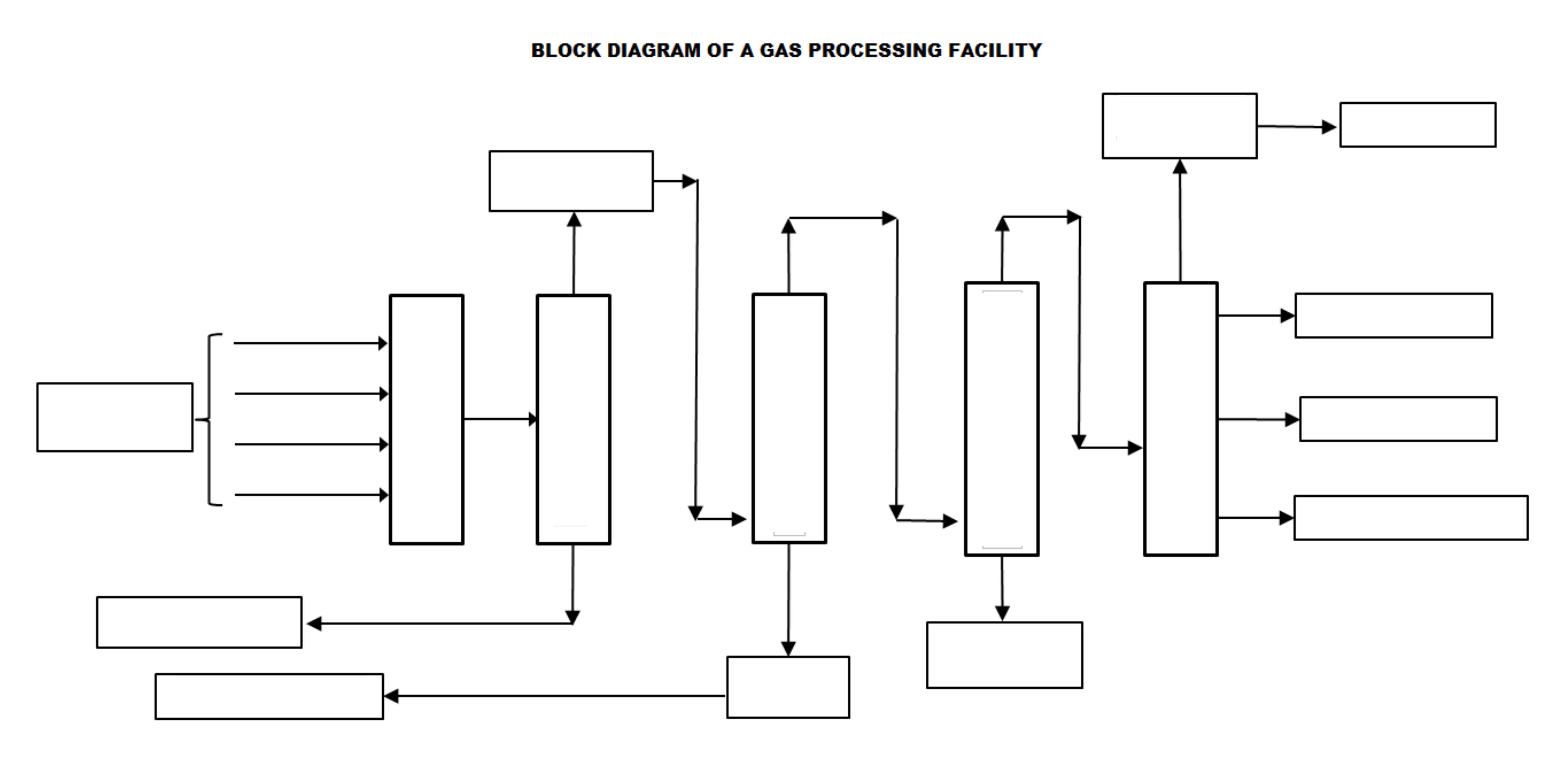

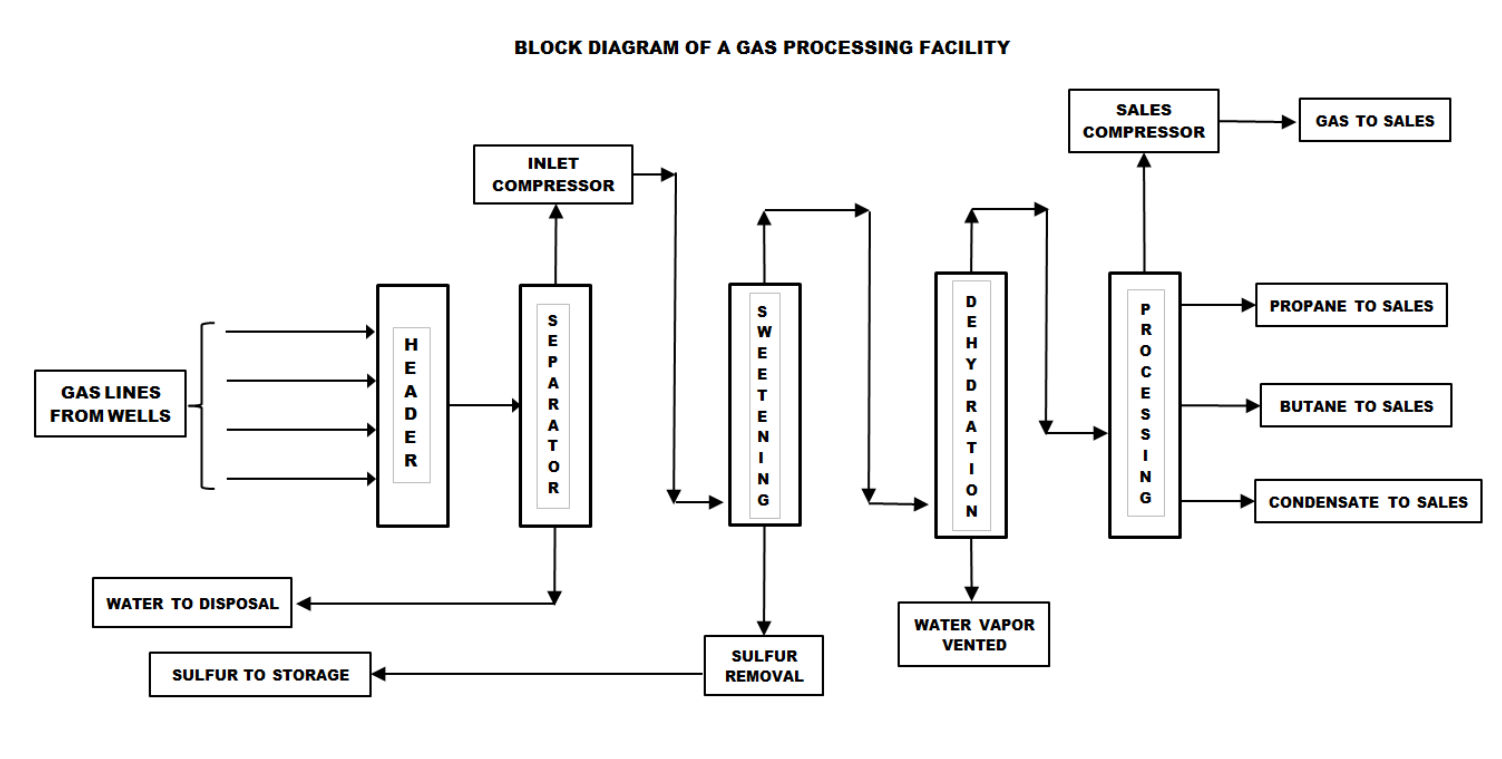

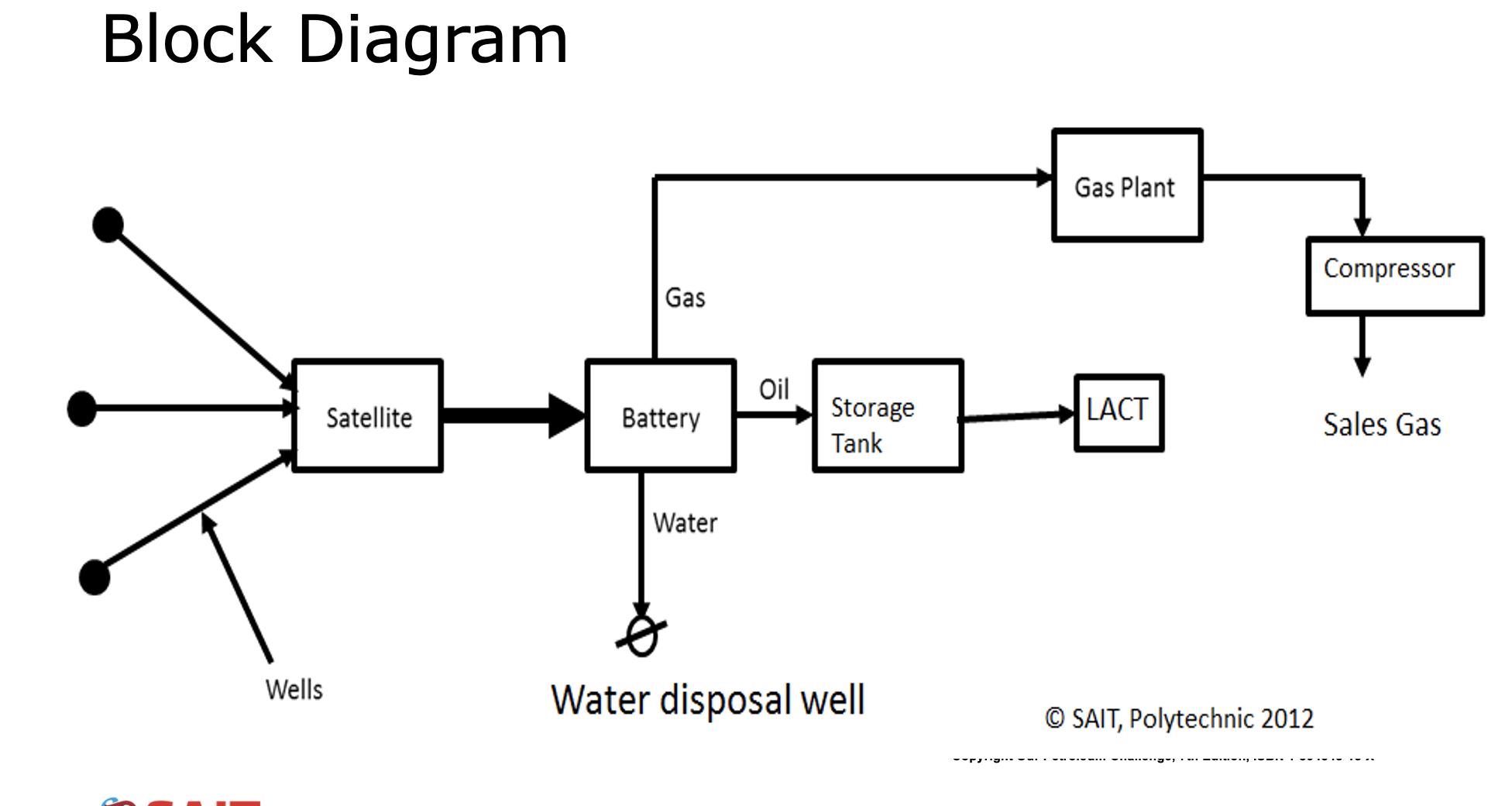

Label the block diagram of a gas processing facility

Define the ‘hydrocarbon dew point’ of natural gas.

The temperature at which the first drop of liquid hydrocarbon appears in a gas mixture.

It is a measure of the amount of liquid hydrocarbon in the gas

What is condensate?

C5+

pentane

hexane

etc.

Liquid at surface

What are the heating value line specs for sales natural gas?

A specific heating value greater than 36 MJ/m3 (966 BTU/ft3) at 20 °C.

When gas contains propane (C3) and butane (C4), the heating value, _________.

a) increases

b) decreases

a) increases

What is the temperature range for a typical refrigeration plant?

- 30 ̊C to - 40 ̊C

Give the recovery ranges for C3 and C4 in a typical refrigeration process (-30°C to -40°C)

C3 → 30% - 60%

C4 → 60% - 80%

Beyond refrigeration, name 2 alternative processes that are used to remove C3 and C4 from a gas stream

Absorption Process

Involves using lean oil in a contact tower with the gas. C3 and C4 molecules are attracted to the lean oil. The oil is then stripped of the C3 and C4 and cycled back through the tower.

Cryogenic Process

This is the same process as the refrigeration plant, however the gas temperature is dropped to below -100 ̊C. This results in higher C3 and C4 recovery as well as some recovery of C2 (ethane)

What are the sales line specs for H2S and CO2 content?

16 ppm H2S

20,000 ppm CO2

What is the most common method used to extract acid gas?

Amine contact tower

Where does the sour gas exit an amine contact tower? What about the sweet gas?

Sour → bottom

Sweet → top

What are the 4 factors that dictate what type of amine solution is used in the contact tower?

Gas composition

Gas flow rate

Processing pressure

Waste product disposal method

Which amine type is best suited for CO2 removal?

Monoethanolamine (MEA)

Which amine type is best suited for H2S removal?

Methyldiethanolamine (MDEA)

Beyond amine sweetening, what is an alternative method used to sweeten natural gas?

Claus Sulfur recovery method

What is the AER tolerance for acid gas flaring?

Zero

What is the most common method used to dispose of acid gases?

Disposal into very large water bearing horizons.

What is the maximum pressure allowed in an acid gas disposal well?

60% of the formation fracture pressure

What are NGLs?

Natural Gas Liquids

C2 - ethane

C3 - propane

C4 - butane

Recovered at surface through refrigeration

What is LNG?

Liquified Natural Gas

C1 to C4 (but mostly C1) at below -160 °C & Standard Pressure

LNG occupies 1/600 of the volume compared to atmospheric conditions

Allows for container shipping

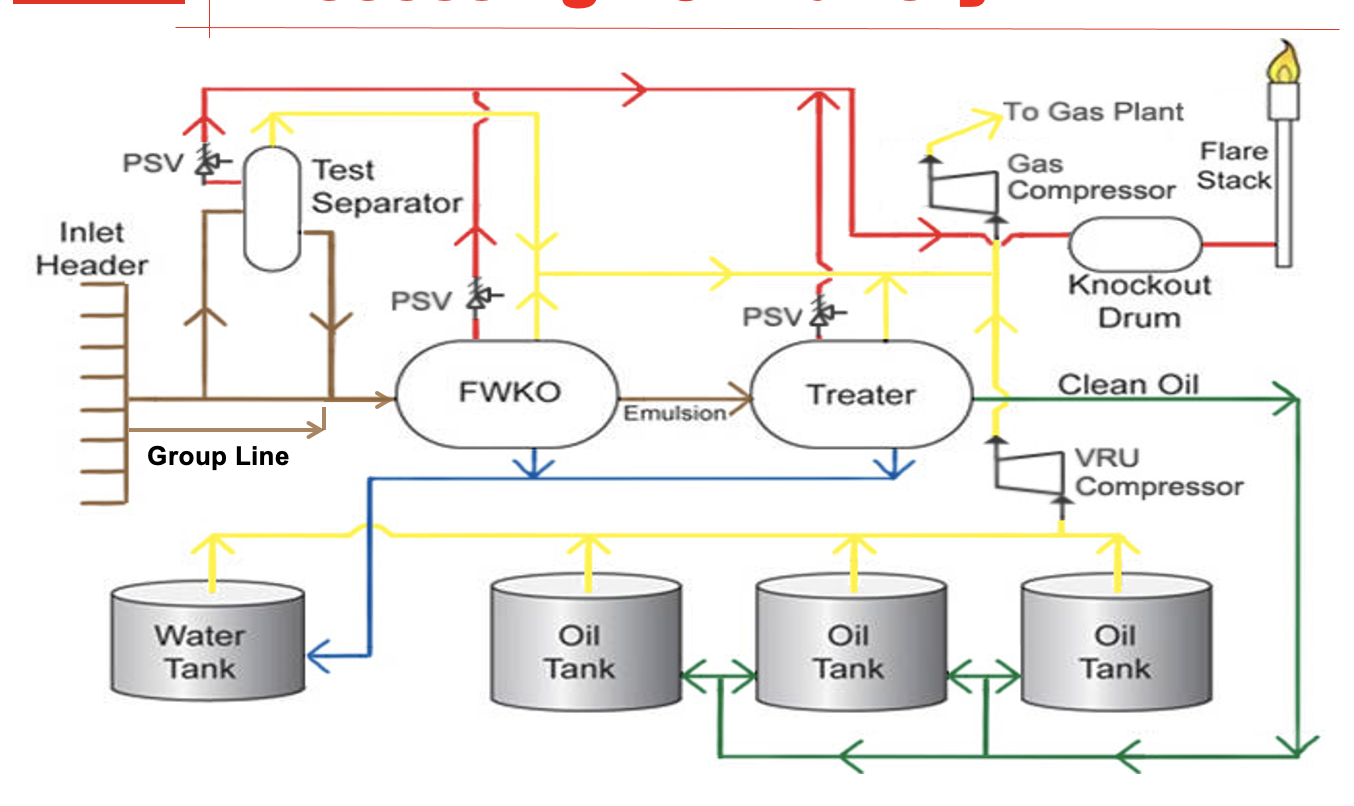

What equipment is used in a typical oil battery?

Oil Battery Equipment

Inlet header or manifold

Separator

Inlet side

Effluent (gas, oil and water)

Outlet side

Gas and emulsion (2 phase)

Gas, emulsion and water (3 phase)

Treater

Inlet side

Effluent (gas, oil and water)

Outlet side

Gas, sales quality oil and water

Flow meters – for oil and water volumes

Orifice meters – for gas volumes

Compressor

What does LACT stand for?

Lease Automated Custody Transfer

What type of devices are used to measure the volume of oil and water? For gas?

Flow meter → oil & water

Orifice meter → gas

What type of equipment is used in natural gas processing?

Natural Gas Processing Equipment

Inlet header or manifold

Separator

Gas and water (2 phase)

Condensate, gas and water (3 phase)

Amine Tower – H2S and CO2 removal (ie. sweetening)

Dehydrator – water removal

Orifice Meter – volume measurement

Compressor

What is the general formula for single chain hydrocarbons (alkanes)?

CnH2n+2

What is condensate?

Light liquid hydrocarbon: C5 to C8 (pentane to octane)

liquid at surface

What are API standard conditions for oil measurement?

Temperature: 15°C (60°F)

Pressure: 101.325 kPa (14.7 psi)

Draw an oil battery with FWKO

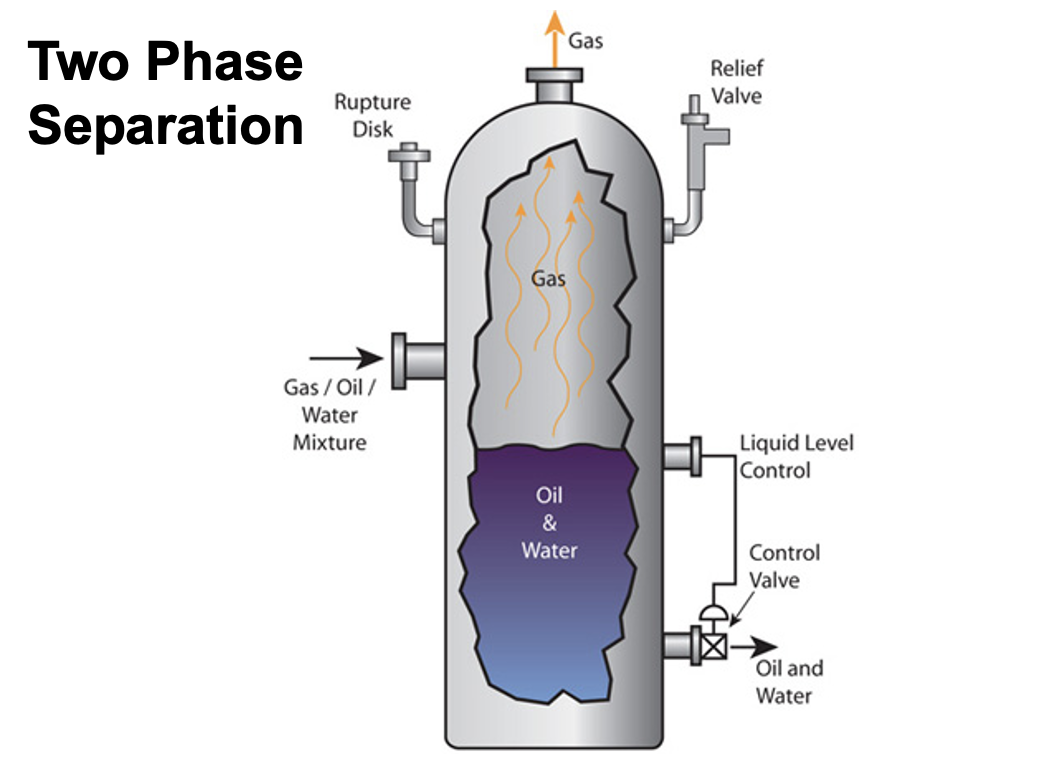

Draw a typical 2 phase separator

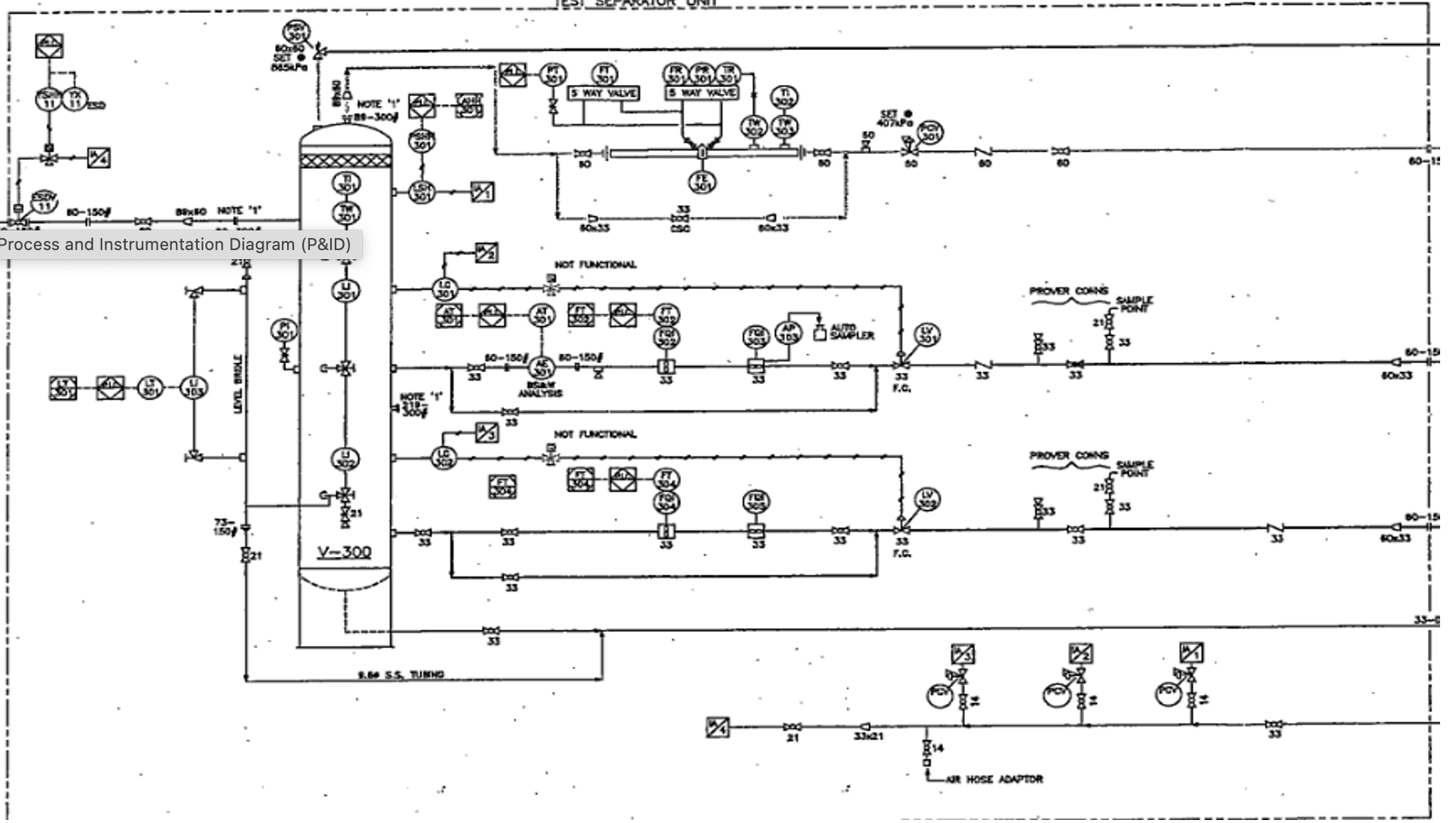

What does P&ID stand for?

Process and Instrumentation Diagram

A diagram that lays out the facility’s equipment and shows how each piece is connected to the next piece without any detail on size, dimensions, instrumentation or controls

Block Diagram

A diagram that includes basic piping, valves, controls, pumps, and meters for an individual process or an entire facility

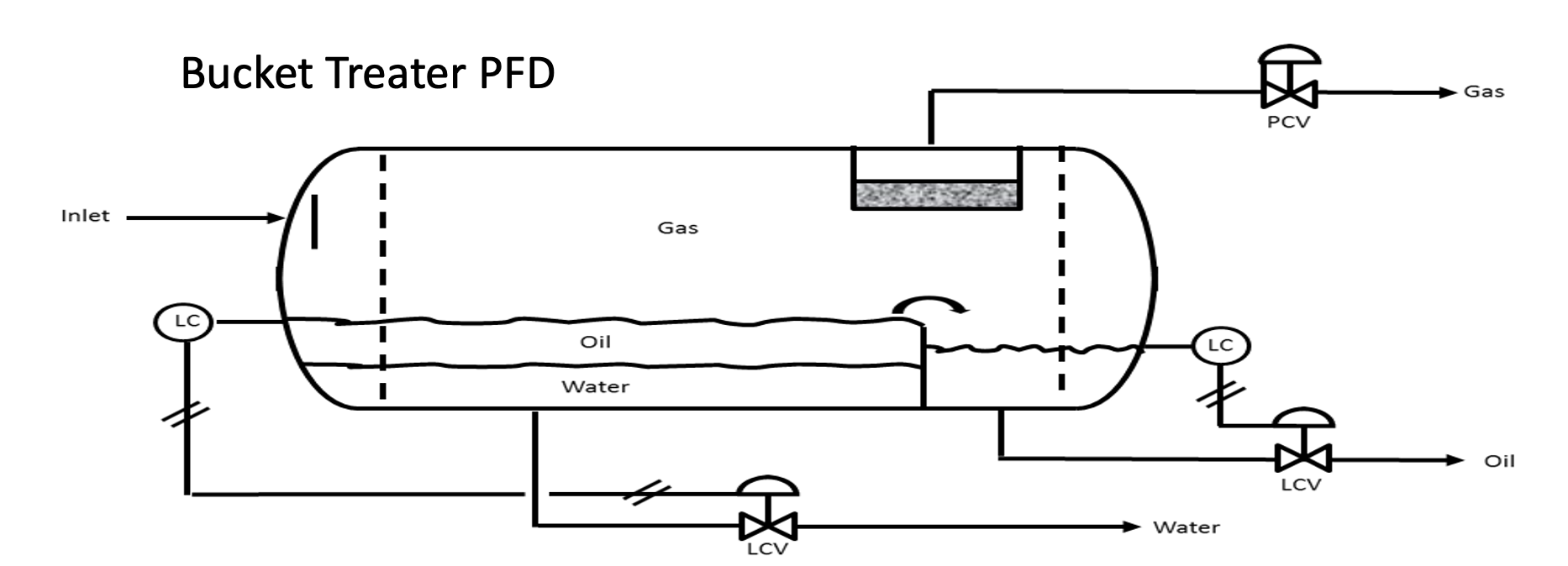

Process Flow Diagram (PFD)

A highly detailed diagram that includes all instrumentation and control, specifications, piping, sizes and dimensions.

Process and Instrumentation Diagram (P&ID)

Where would you typically find flow meters?

Installed on lines leaving:

separators

treaters

dehydrators

leases

What does ISA stand for?

International Society of Automation

What are ISA symbols?

A standard set of symbols used in PFD’s and P&ID’s.

used for valves, controllers, meters, pumps, compressors, vessels, tanks

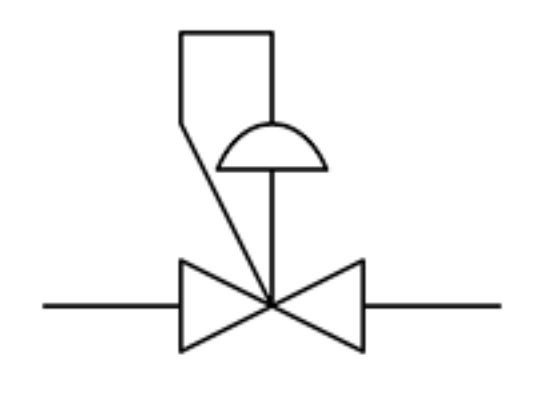

Ball valve

Needle valve

Gate valve

Check valve

Orifice meter

Back pressure control regulator

Relief PRV

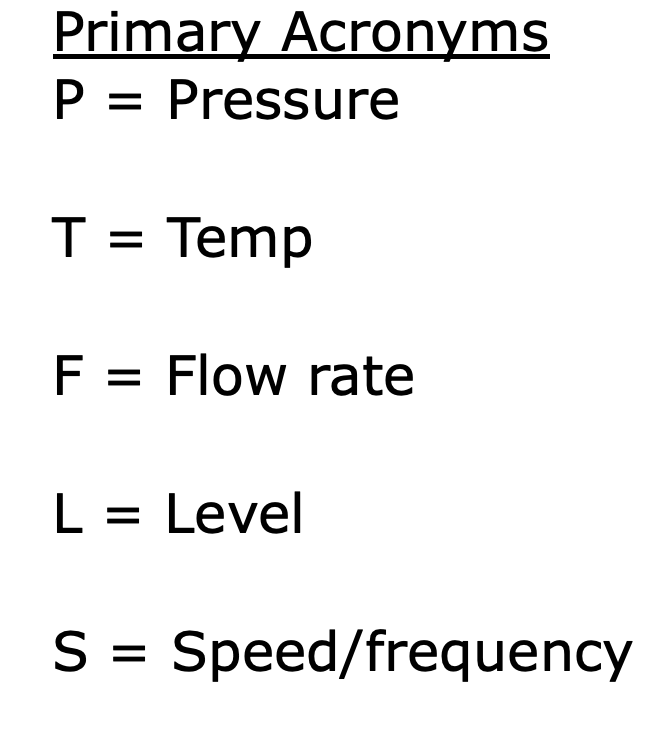

Name these ISA primary acronyms:

P

T

S

L

F

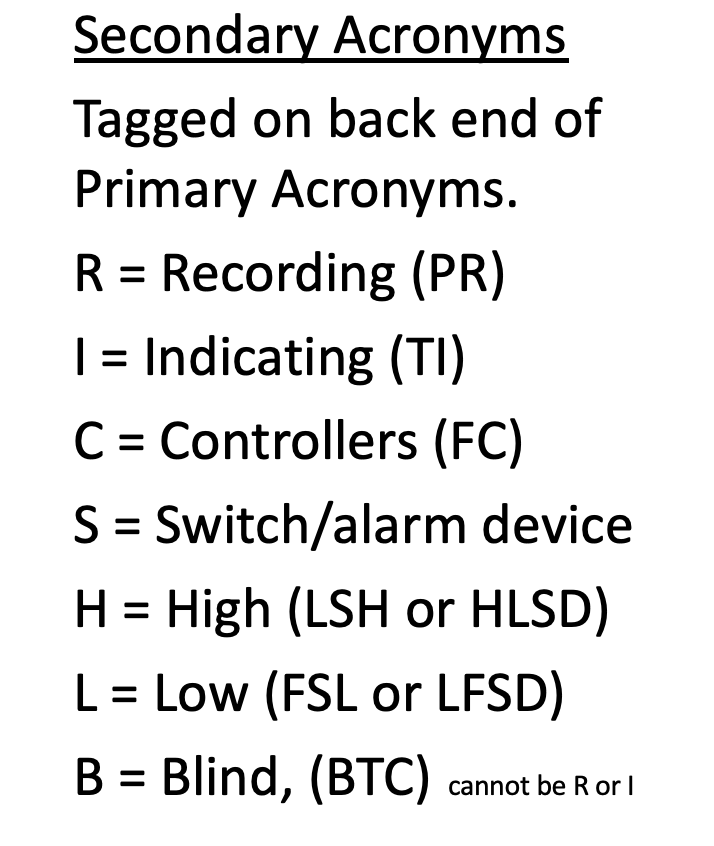

Name these ISA secondary acronyms:

R

I

C

S

H

L

B

What is a control loop? Give examples.

A control loop is designed to maintain a process variable (e.g., temperature, pressure, flow rate, or level) within a specified range, typically using continuous feedback.

Ex: High Level Shut Down; Temperature Control

These two pieces of processing equipment are used to split production streams so that liquid(s) and gas volumes can be independently determined.

Separators and Treaters

Most commonly a vertical cylindrical vessel that uses agitation and gravity to separate the components of a production stream

Separator

efficiency of a separator is not high enough to create sales quality oil

Most commonly a horizontal cylindrical vessel that uses agitation, gravity and heat to separate the components of a production stream to create sales quality oil.

Treater

What is the BS&W criteria for sales quality oil?

< 0.5% BS&W

A single well or multi-well facility that tests wells individually as per AER requirements

Satellite battery

Gas production rates can be determined directly utilizing this type of meter

Orifice plate meter

How is the total oil production determined from a given well?

Take a reading of the flow meter for the total emulsion (oil + water) coming out of the test separator.

Determine BS&W: Use a centrifuge to find the percentage of water and sediment in the oil.

Calculate Net Oil: Subtract the BS&W from the measured emulsion flow to determine the net oil production

Output of a 2 phase gas well separator

Gas and Water

Output of a 2 phase oil well separator

Gas and Emulsion

Output of a 3 phase gas well separator

Gas, Condensate, Water

Output of a 3 phase oil well separator

Gas, Emulsion, Water

This type of separator is most commonly used for portable testing of new wells

Spherical separator

Name 1 pro and 1 con of a vertical separator

pro → small footprint

con → difficult to transport

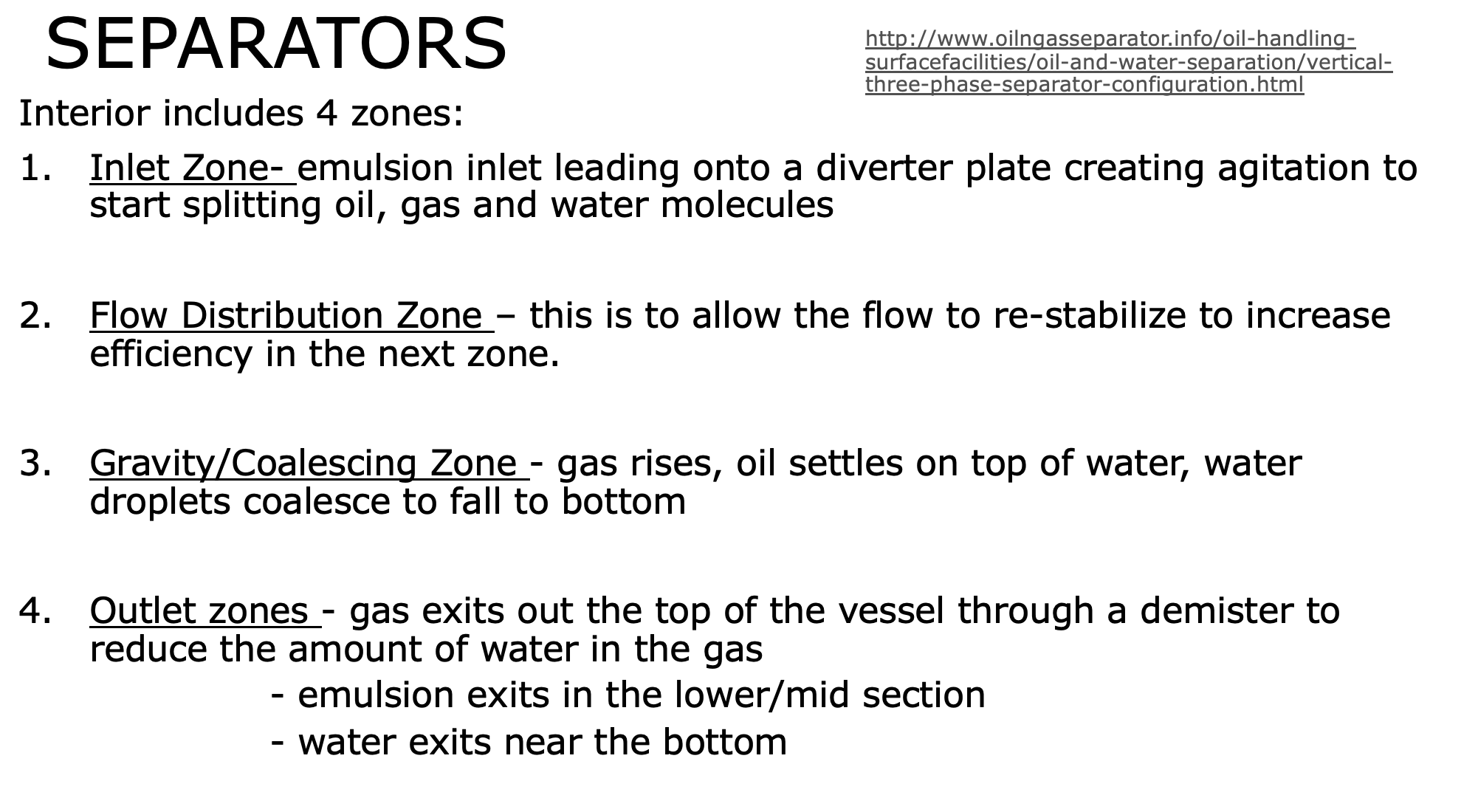

What are the 4 zones of the interior of a separator?

What are 3 methods of demulsification used in a treater?

Heat

Electro-static grids

Demulsifying chemicals

These all allow for a decrease in retention time.

What function does heat play in a treater?

Heat aids in demulsification and so reduces the retention time required to break the oil/water emulsion

Oil heats faster than water and rises → cooler denser water coalesces and sinks.

Heat increases the motion of the water droplets, increasing the chance of collision → water droplets coalesce and sink

Multi-phase mixture of two or more substances that appears to be a single phase.

Emulsion

What is a normal emulsion?

Water in oil

What is a reverse emulsion?

Oil in water

Will a tight emulsion (small droplet size) require more or less heat to separate?

More

Compare the retention times between separators and treaters

The retention time in a treater is typically 10-30 times that of a separator - or 10-30 mins.

(Darcy math)

Name some problems caused by using too much heat in a treater

More fuel gas used than necessary

Oil will vaporize

Fire tube can prematurely corrode

Precipitation of solids from water or oil onto firetube leading to hot spots and corrosion

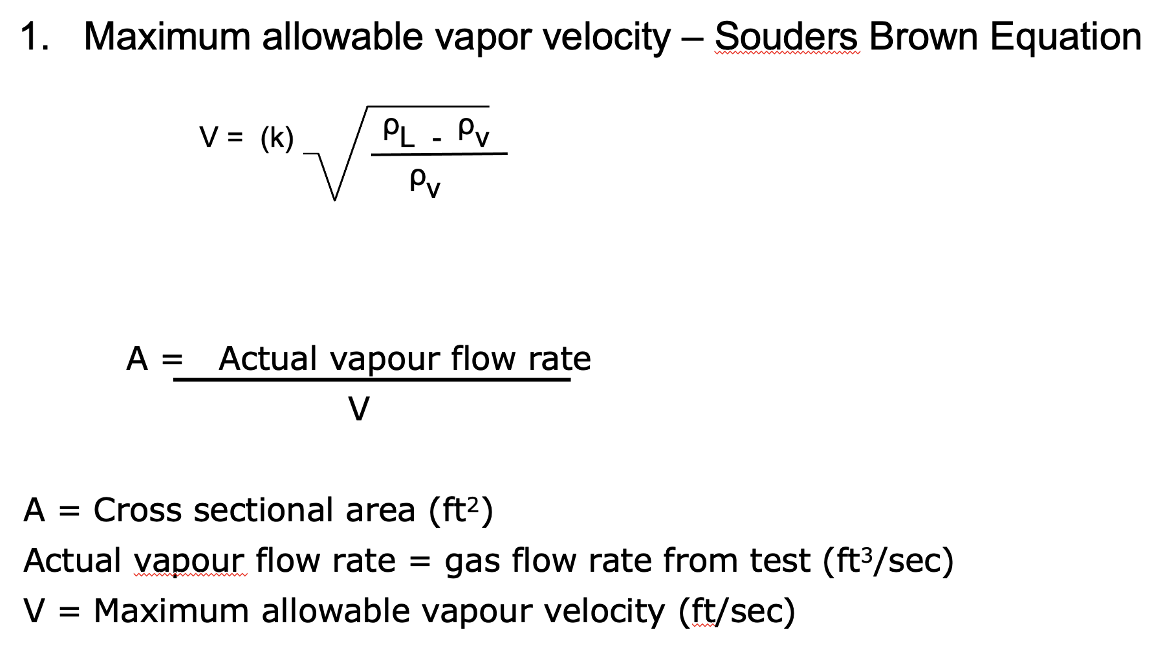

What does the Souders Brown Equation calculate?

Maximum allowable vapour velocity

This velocity is then used to calculate the cross sectional area requirement for a separator → then this area is used to calculate the minimum diameter

When sizing a separator, what is the initial estimate used for retention time?

What is the estimate used when sizing a treater?

Separator → 3 minutes

Treater → 20 minutes

What does Lss stand for?

seam-to-seam length

In separator sizing, the Lss is the height of the vertical separator.

ie. the total internal length of the vessel from one head (end cap) weld seam to the other

What retention time range for treaters has been observed to be sufficient in order to achieve sales quality oil?

10-30 minutes

The ratio of the height to the length of the treater

Slenderness ratio

Treater manufacturers generally build treaters to a slenderness ratio of 1:3 or 1:4 to minimize chances of buckling. (ie. 3 or 4 times as long as wide/high)

Give the suggested treater heating ranges for the various emulsion types (ie. loose, moderate, tight)

Loose Emulsions → 100oF to 120oF

Moderate Emulsions → 120oF to 140oF

Tight Emulsions → 140oF to 180oF

What are the 4 basic types of compressors?

Reciprocating → back and forth motion (piston/cylinder)

Centrifugal → spinning

Screw → rotary motion

Axial → rotating air foil (ex: turbine)

What is the most common type of compressor used in the oil and gas industry?

Reciprocating

What are the 5 main components of a reciprocating compressor?

Cylinder

Piston

Crankshaft (converts rotational to linear motion)

Suction valve

Discharge valve

A type of compressor in which compression only takes place on one side of the cylinder

Single-acting

A type of compressor in which compression takes place on both sides of the cylinder concurrently

Double-acting

more efficient and smooth running than single-acting

reduced volume on one side of the cylinder due to the rod

What process can improve efficiency in multi-stage compression?

Inter-cooling

What is the “swept volume” ?

The displacement capacity of a compressor

the total volume that a piston moves through (sweeps) as it compresses gas in each cycle.

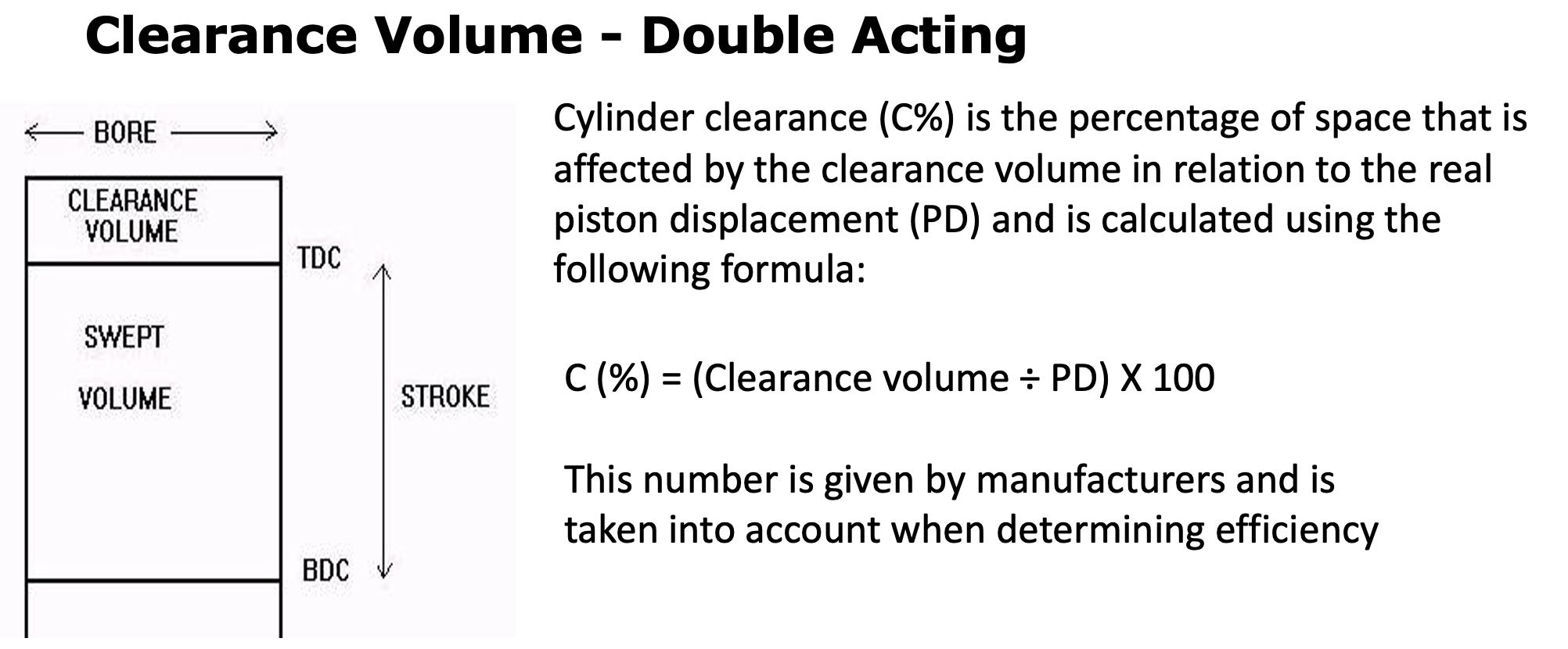

The ratio of the clearance volume to the swept volume (or displaced volume)

Cylinder clearance (C%)

where:

Clearance Volume → the small space left between the piston and the cylinder head when the piston is at the top of its stroke

Swept Volume (displaced volume) → the volume displaced by the piston moving through its entire stroke

Actual pumping capacity of the cylinder compared to the piston displacement.

Volumetric Efficiency (Ve)

Calculated using the mass of gas delivered compared to the mass of gas that could have been moved with full piston displacement.

What factor has the largest impact on volumetric efficiency?

The re-expansion of the gas trapped in the clearance volume

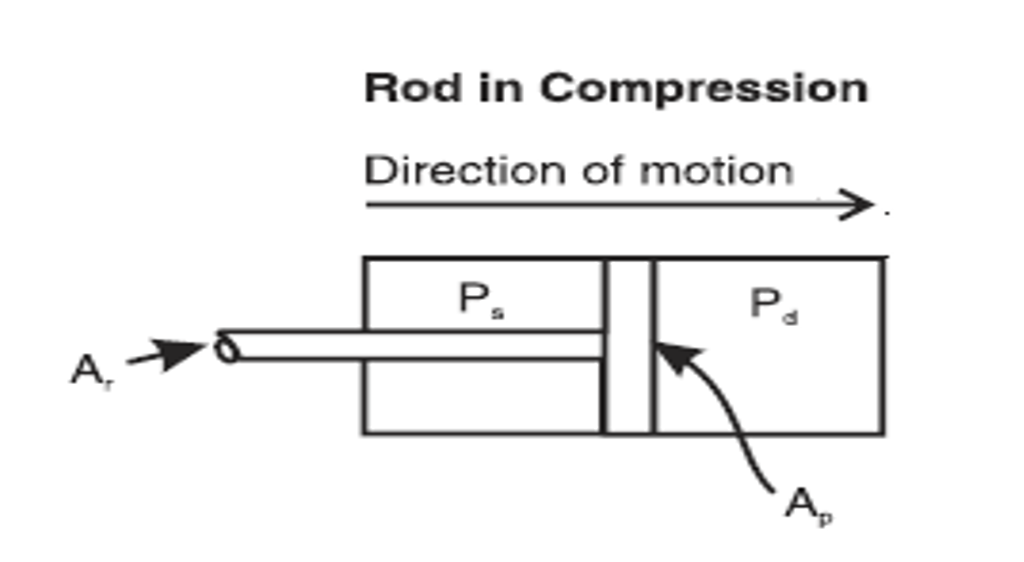

How are rod loads generated?

Gas forces → gas loads

Inertial forces → inertial loads

Gas loads cause most of the load on the rods and all of the other components connected to the rod

How:

As the piston moves forward to compress the gas, the differential pressure acting on the piston results in a gas force pushing against the piston, causing a compressional force on the piston rod

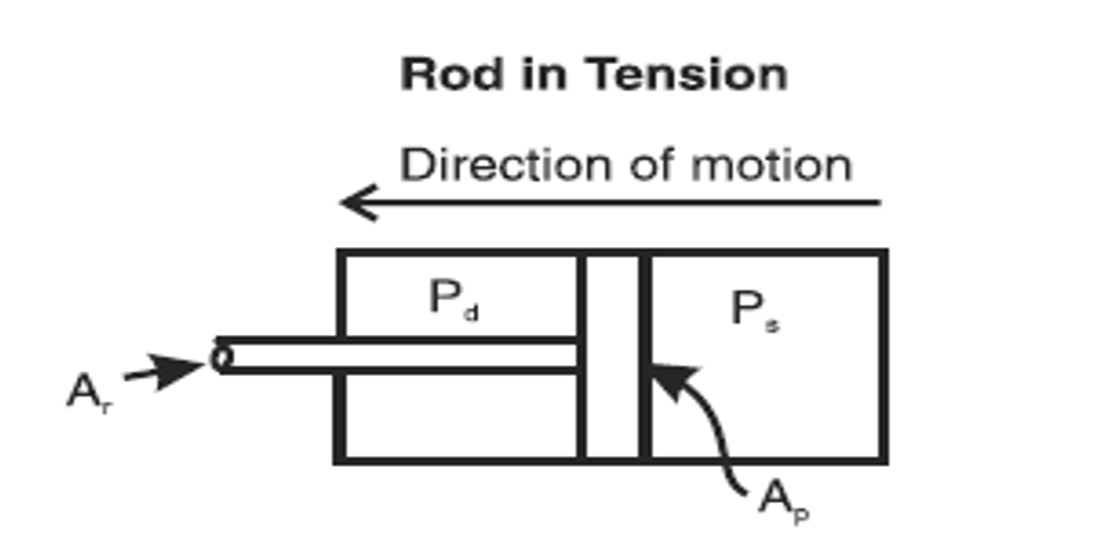

This type of load occurs when the piston is at the furthest point during the stroke moving away from the crankshaft.

Head End Load

This occurs when the piston is at the closest point during the stroke moving towards the crankshaft

Crank End Load

The Ideal Gas Law states that a reduction in volume of a given mass of gas must ___________ the temperature of the gas.

increase

Name 3 reasons why cooling is important when compressing gas

High temperatures can:

Decrease the efficiency of the compression process

Reduce the life span of the materials in the machinery

Present a significant safety hazard to the operators

What type of valves would you expect to find on the outlet lines of a treater or separator?

Oil/water lines → LCV

Gas lines → PCV

Flare line → PSV

A type of valve designed to protect equipment and personnel from dangerous overpressure by opening rapidly and fully when the pressure exceeds a set limit. Its primary role is safety.

Pressure Safety Valve (PSV)

A valve primarily designed to relieve pressure in a controlled manner to prevent overpressure in a system. It typically opens gradually as the pressure increases, allowing a controlled release of fluid (gas or liquid) to maintain system pressure within safe limits.

Pressure Relief Valve (PRV)

What is calculated using an orifice plate coefficient?

a. Oil flow rate

b. Gas flow rate

c. BS&W

d. None of the above

b. Gas flow rate