Unit 4.5 - Managing Inventory and Supply Chains

1/46

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

47 Terms

Mass customisation

Offering individually tailored goods or services to customers on a large scale

Factors required for mass customisation

Market which values variety and individuality

Quick responses to market changes

Ability to provide customisation

Scope for economies of scale

Benefits of mass customisation

Cost reductions

Higher revenue

Customer loyalty

Greater understanding of wants

Greater protection from market changes

Improved employee motivation

Drawbacks of mass customisation

Requires sophisticated systems

Expensive - equipment and training

Difficult to resell rejected products

Unsuitable supply chains - requires flexibility

Matching supply to demand - managing demand

- Widen product range to overcome issues of spare capacity

- Off peak special offers for periods of low demand

- Increasing prices to reduce overly high demand

Matching supply to demand p managing supply

- Producing to order

- Use of temporary and part time employees

- Outsourcing

Producing to order

Only ordering or manufacturing a product when an actual purchase has been made

- Ranges from small scale, tailor made products such as suits to large scale one off planes where the basic layout is modified

- Adopt a modular approach to manufacturing:

Basic element

Then an element which can be customised

Benefits of producing to order

Meets customers exact requirements

Reduced costs of holding inventory

Higher prices

Targeting markets becomes easier

Production planning is easier (no need to forecast demand)

Drawbacks of producing to order

Higher costs of production

Can't take advantage of sudden interest

Unpredictable fluctuations of demand

Factors to consider when producing to order

Value to the customer

Willingness of customers to wait

Nature of the product and relative costs

Cost of holding inventory i.e needs refrigeration

Impact of having no stock - loss of sale

Part-time workers

limited number of hours, such as 15 hours per week

Temporary workers

contract of employment has an end date. Can be full or part time

When temporary or part time are likely to be used

More flexible than full time staff

Seasonal demand - temporary workers to cover busy periods

Saves wage costs - no need to pay them all year round

Part time staff usually used for predictable variations in demand

Pubs employing more people on a weekend

Benefits of part time or temporary workers

Lower costs

More flexible - respond to changes in demand

Higher customer service

Employees may be motivated if part time suits them

Can retain valued employees i.e parents

Outsourcing

transfer of activities which were previously conducted by the business, to a third party. The business get another business to produce some or all of its product for it or perform part its operations

Benefits of outsourcing

React to changes in demand

Increased specialisation - higher quality

Less disruptive to production

Is sometime cheaper than having to get skilled workers or train own employees

Drawbacks of outsourcing

Loss of control - lower quality

Overall price could rise - everyone needs to make a profit

factors influencing decision to outsource

- Available capacity - high capacity utilisation = likely to outsource

- Expertise - lower skill level = likely to outsource

- Quality considerations - if USP isn't quality = likely to outsource

- Nature of demand - unpredictable = likely to outsource

- Cost - not benefiting from economies of scale = likely to outsource

Inventories/stock

Goods or stock a business holds to use in production or sell to customers

Inventory/stock control

management of levels of raw materials, work in progress and finished goods

3 forms of inventory

Raw materials - components or ingredients

Work in progress - part finished products

Finished goods - completed products that are owned by the business until the sale has been agreed

Inventory control key features

- Can be used to ensure production matches demand

- By holding high levels of inventory, can meet growing demand

- During low demand periods, business can produce to replenish inventory sold in high demand

- The ideal level of inventory depends on circumstances

Benefits of high inventory levels (JIC)

- Customer demands are met

- There is no loss of goodwill caused by running out of inventory

- Sudden increase in demand can be met

- Production lines not halted because of shortages of raw materials

- Companies can benefit from bulk buying

Benefits of low inventory levels (JIT)

- Reduced warehouse costs are possible

- Opportunity cost is low (cash)

- Security costs are lower

- Perishable products are less likely to deteriorate and less likely for products to become obsolete

- Less cash flow issues due to cash not being tied up in inventory

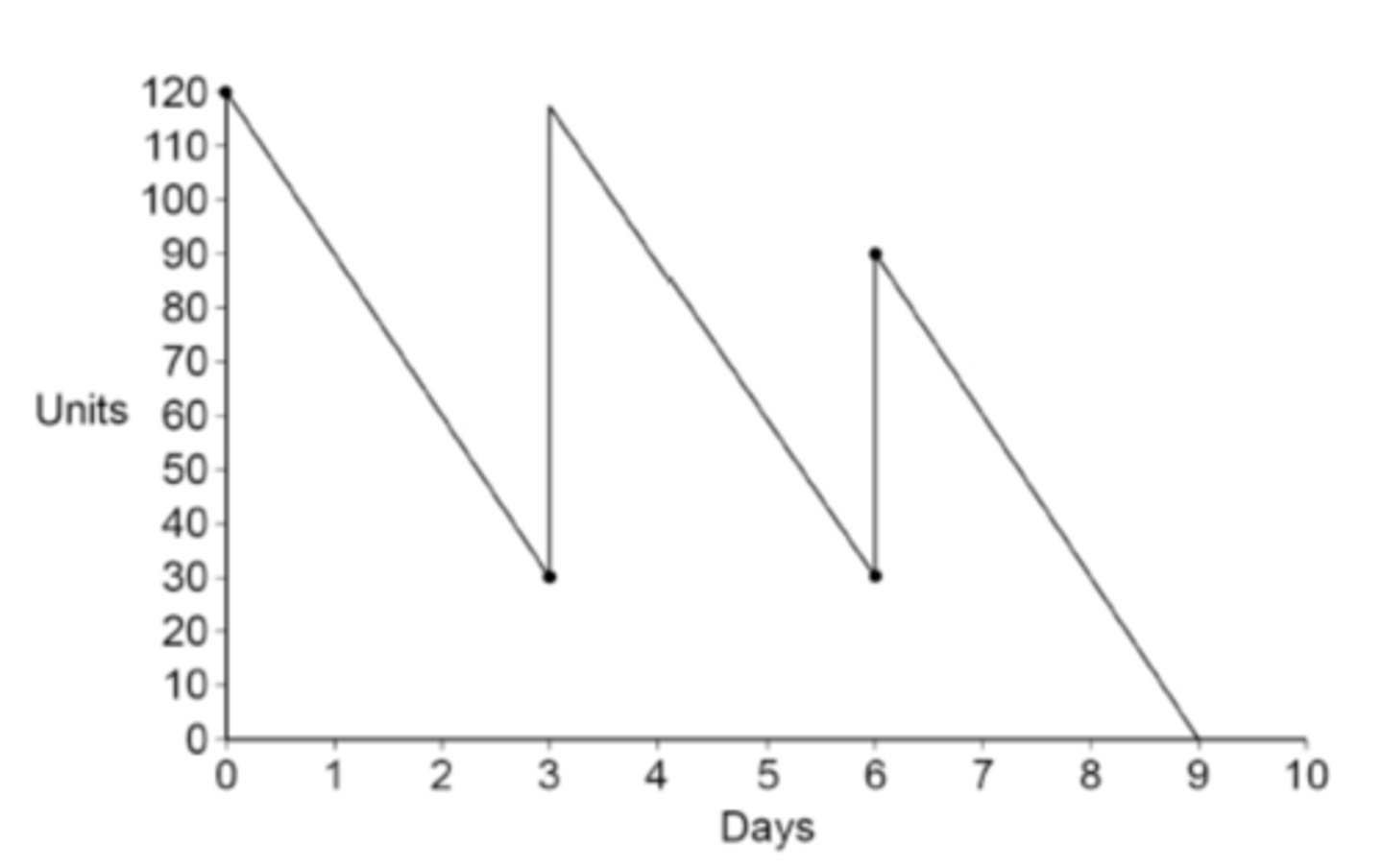

Inventory control chart

A diagram that is used to register levels of stock/inventory over a period of time.

Inventory control chart (diagram)

Buffer levels/inventory/stock

minimum amount of inventory held by a business

Re-order level

the inventory level at which an order is placed for new inventory

Re-order quantity

the actual number of products purchased from the supplier in a particular order

Lead time

how long the supplier takes to deliver an item once the order has been placed

What does re-order quantity and level depend on

Suppliers lead time

Demand for the product

Consequences of running out of inventory

Inventory wastage

Measure the loss of inventory within a business

Inventory rotation

using old inventory before new to make sure that wastage is kept to a minimum

Improving the efficiency of inventory control

- Traditionally, businesses kept high levels of inventory ‘just in case’ they were needed

- Led to businesses selling inventory at cheap prices to avoid complete wastage

- Japanese firms led the way in arguing that this was a waste of space and inventory

- This lead to the introduction of just in time inventory control

Just in time stock control (JIT)

An inventory-management approach in which supplies arrive just when needed for production or resale

Benefits of JIT

- Low inventory holding costs

- Less space needed to hold inventory

- Less cluttered environment - safer

- Less chance of inventory going out of date or going unsold

Drawbacks of JIT

- Cannot not benefit from purchasing economies of scale

-Relies on suppliers, may be unreliable

- May require more frequent deliveries

- May be less able to meet sudden increases in demand/fluctuating demand

- Will have to pay whatever the price is for materials when you need them as there is no buffer stock

Supplier

An organisation that provides a business with materials or finished goods needed to carry out activities

Factors influencing choice of suppliers

Prices

Payment terms

Quality

Capacity

Reliability

Flexibility

Price (choice of suppliers)

- Reduce the final selling price - gain competitive advantage

- Keep selling price the same but enjoy extra profit

But may be trade-off in other areas such as quality

Payment terms (choice of suppliers)

Arranged made about the timings of payments (and other conditions)

It is normal for credit to be offered (no need to pay for 28 or 30 days) for two reasons:

Helps improve cash flow cycle

Order supplies - make product - sell product - gain revenue - use revenue to pay suppliers

Helps suppliers to be competitive

Businesses will prefer to use them over other suppliers

Trade credit

Period of time given by suppliers where the business is proved with resources needed but does not have to pay until a later date

Quality (choice of suppliers)

Must match customer expectations

Price trade off

How important is quality?

Capacity (choice of suppliers)

Can the supplier provide the quantity needed?

Particularly relevant if the resource can't be obtained elsewhere

Reliability (choice of suppliers)

% of deliveries made on time

If the business is manufacturing, this could be detrimental to production

Important if the business uses just in time production

Flexibility (choice of suppliers)

Sudden changes in demand

Negative publicity around an ingredient / component

Transport difficulties preventing deliveries from other sources

Value of contingency plans: PLAN B can be used in an emergency

How to manage supply chain effectively

Different businesses will have different operational objectives:

Low costs

High quality

Speed of response

Flexibility

Dependability

Environmental objectives

Added value

But will likely all require

- getting the right suppliers, supplies arriving on time, getting a fair price, product being priced in a way that is acceptable to the business, good communication with suppliers, coordinating other functional areas