Materials and MFG Process Exam 1 Notes

1/134

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

135 Terms

metals are?

high stiffness, low elasticity, high strength, ductility, good conductive of heat and electricity.

example of metal?

Steel, Casting irons, alloys

Polymers are?

low strength, low density, low melting point, low conductive of heat and electricity.

example of polymers?

PE,PP,PET, nylons, polyesters, expoxies

Ceramics are?

Low elasticity, high strength, high hardness, brittle, high melting point, low conductive of heat and electricity.

example of ceramics?

Aluminas, silicon carbides, silicon nitrides, zirconias

Glasses are?

Low tensile strength, brittle, transparent and corrosion resistant.

example of glasses?

soda glass, silica glass, glass ceramics

Elastomers are?

highly amorphous materials, high randomly orientated structure.

example of elasomers?

Isoprene, butyl rubber, natural rubber, silicones, EVA

Hybrids?

Composites sandwiches, segmented structures lattices and forams.

Density

mass divided volume

Ductility

the amount a material can change length/shape before fracture (how "stretchy" it is)

Strength

the ability to withstand loads without fracture (how high of stress it can withstand)• A material property (e.g., yield stress, ultimate tensile stress)

Stiffness

how much a material/structure deflects under a given load•

Based on both the intrinsic material properties (stress vs. strain behavior) and the geometric features

Example of Stiffness

an I-beam is several times stiffer than a square beam made of the same type/amount of material

Hardness

resistance to indentation, scratching, abrasion, and wear

Toughness

ability to absorb energy and deform without fracturing (does not consider cracks)

Fatigue resistance

ability to resist crack growth and fracture when subjected to repeated cyclic loading

Corrosion resistance

a material's ability to withstand deteriorating/chemical breakdown in corrosive environments

Creep resistance

a material's ability to resist creep deformation

Creep deformation

very slow (almost imperceptible) deformation when material is subjected to a load for a longperiod of time (usually at elevated temperatures)

Elastic deformation

reversable deformation

elastic modulus and hooks law

Plastic deformation

irreversible post yield hardening law

Yield strength (𝝈𝒀)

the onset of plastic deformation• Defined as 0.2% offset stress: amount of stress required to create plastic strain of 0.002

Ultimate Strength (𝝈𝑼)

the highest engineering stress the material can withstand

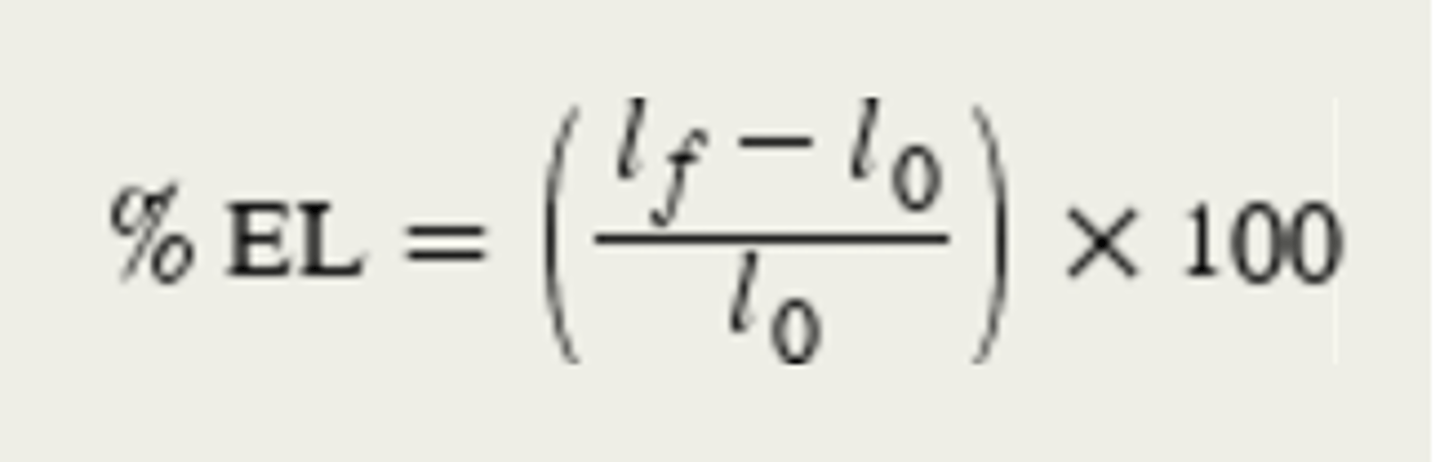

Percent elongation

amount material lengthens before fracture

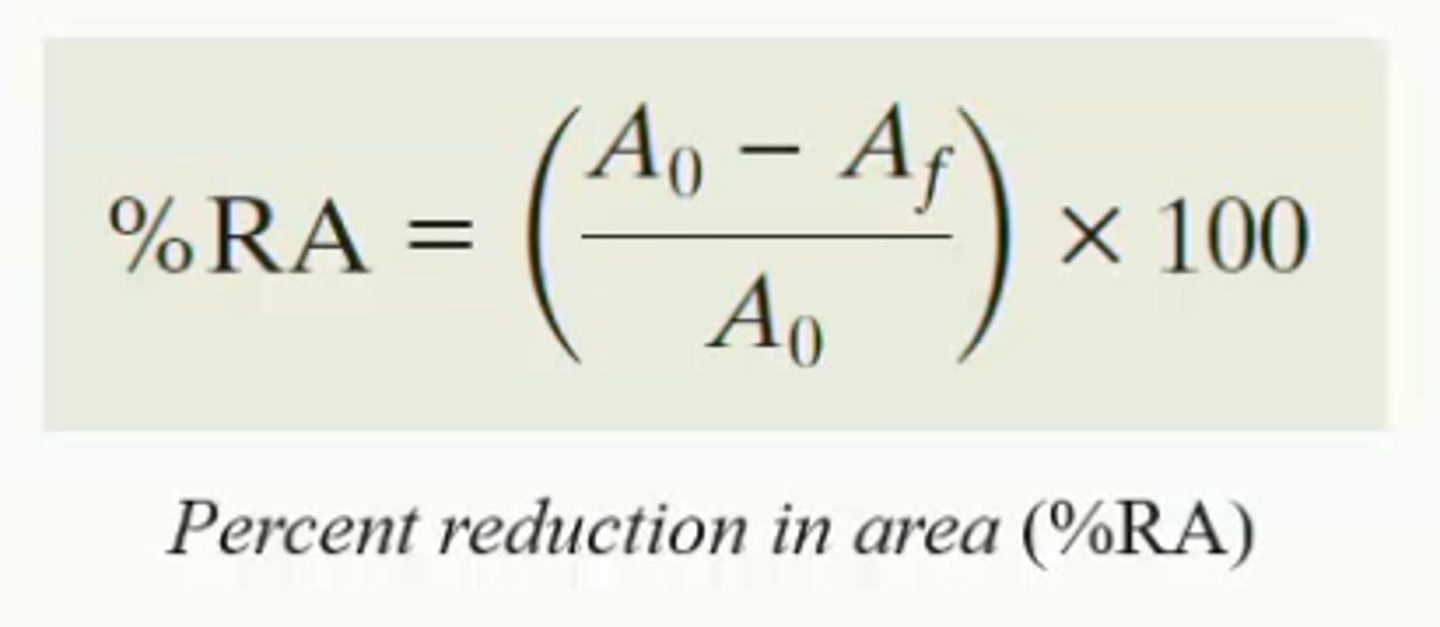

Percent reduction in area

amount the area is reduced before fracture

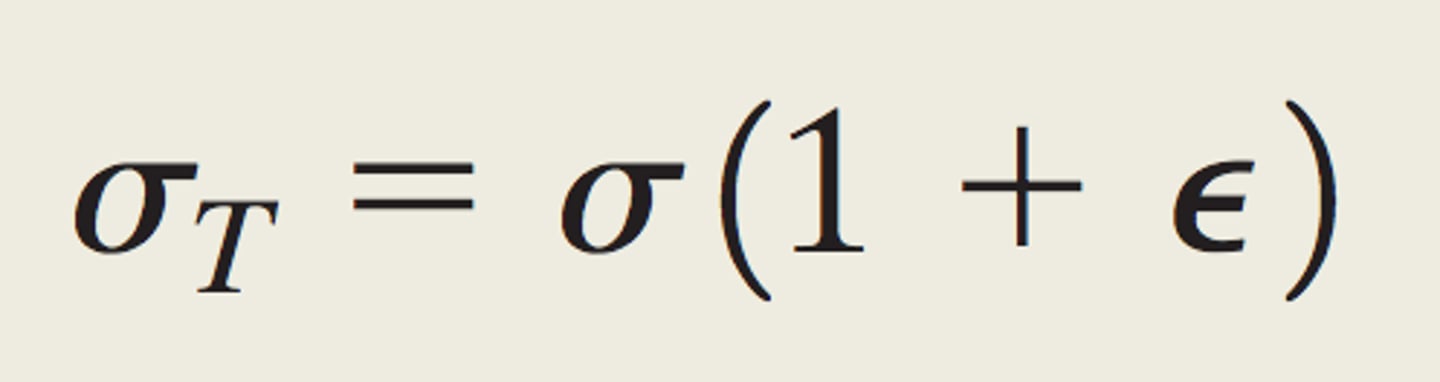

True stress

stress measure based on current cross-sectional area

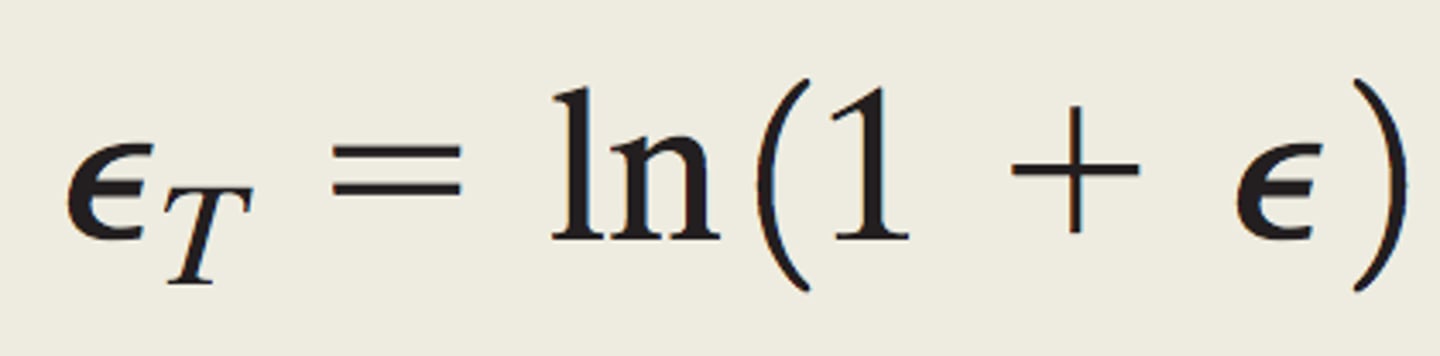

True strain

the elongation of the specimen in increments of instantaneous change in length

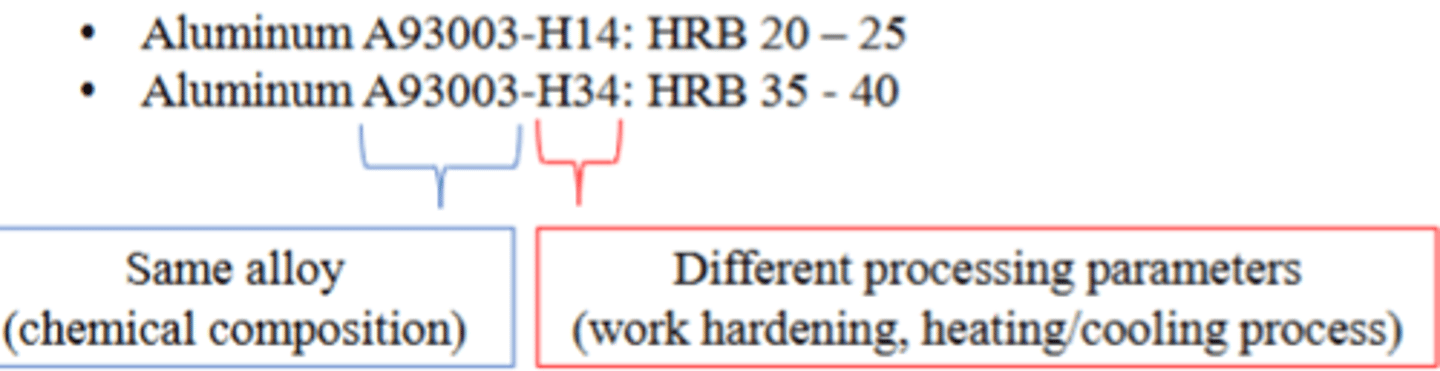

Work Hardening (Strain Hardening)

he increased yield/flow stress and strengthening of a material that occurs after plastic deformation

After each manufacturing step that plastically deforms material, increases the material strength and decreases the ductility

Flow Stress, 𝝈𝒇

amount of stress to continue deformingthe material (aka, "keep it flowing")

𝜎𝑓 will typically____?

increases as 𝜀 increases due to work hardening

Means that manufacturing operations require higher and higher forces to continue deforming the material

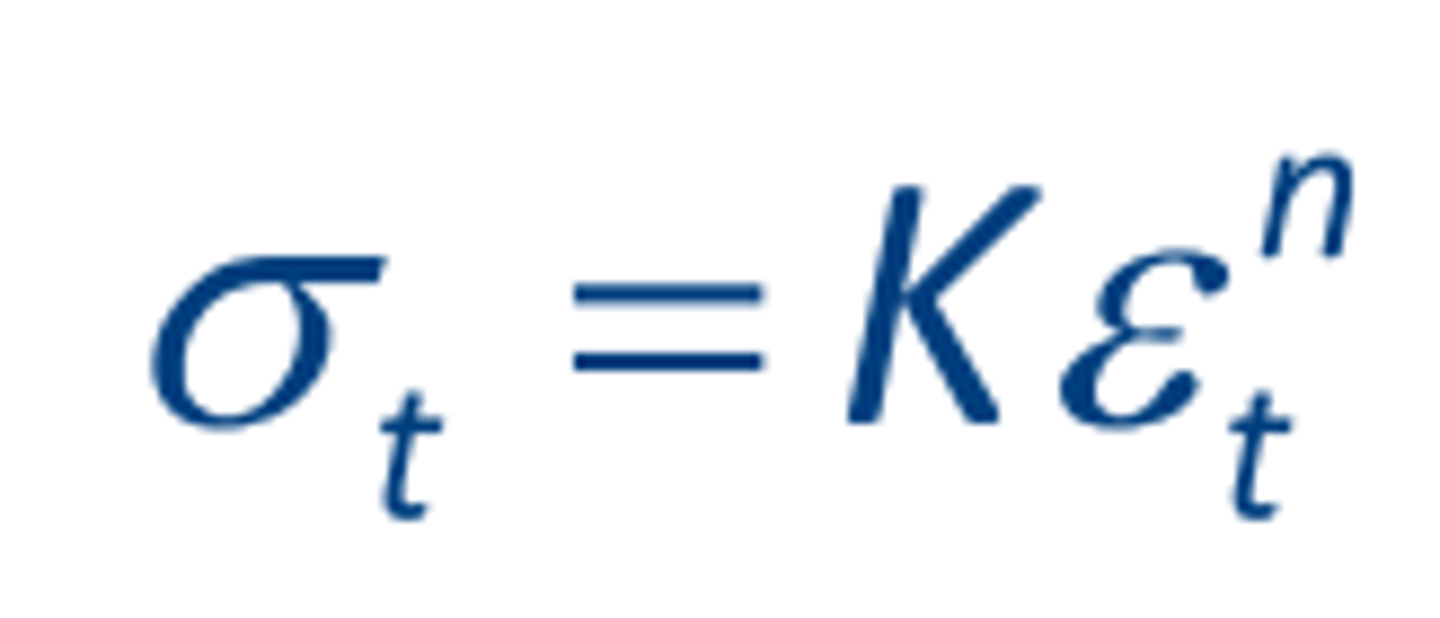

Power Law Hardening

K: strength coefficient

𝑛: strain hardening exponent

The true stress v. true strain post-yield hardening behavior often described

What is Hardness?

Hardness is associated with increased 𝐸 and 𝜎𝑌, which in harder materials cause increased abrasion and wear resistance of the material, and decreased ductility

Hardness testing?

is a two step process: load an indenter with known load,then measure the size of the indentation

Hardness testing is a quick___?

convenient, and non-destructive method of testing general material properties

hardness values

based on the difference in depths of indentation produced by a minor and major load

Toughness units

kJ/m^3

Toughness ?

Can be calculated by integrating stress-strain curve

•Often measured using a Charpy impact test

•Toughness is a function of both the material strength and ductility

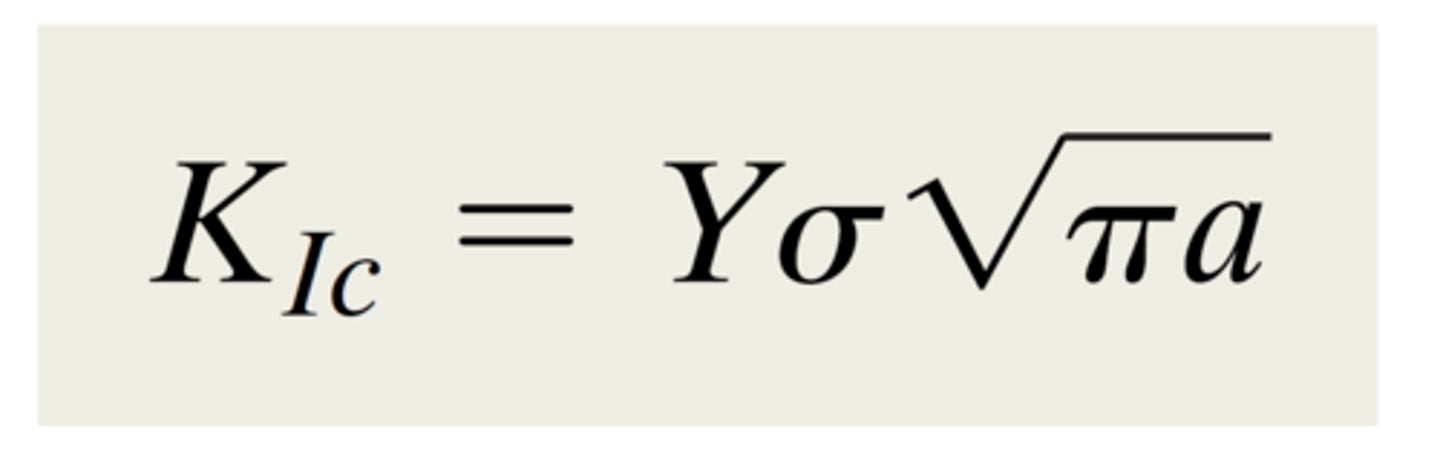

fracture toughness (Kc)

ability of a material with a pre-existing crack to resist further crack growth and catastrophic fracture

fracture toughness (Kc) formula

𝑌: geometric scaling factor (assume 𝑌 = 1 for this class)

𝜎: applied stress

𝑎: crack length

• Edge cracks: physical crack length = a

• Internal cracks: physical crack length = 2a

Fatigue

crack growth and material fracture caused by cyclic loading

Applied stresses are much lower than 𝜎𝑌 and 𝜎U

Yet fracture still eventually occurs due to gradual growth of cracks

Fatigue Lifetime

how many loadings cycles the material/structure can withstand before fracture occurs

∆𝜎 (Delta Sigma)

𝜎max−𝜎min

𝜎mean

(𝜎max+𝜎min)/2

S =?

𝜎a = (𝜎max-𝜎mean)/2

R

-(𝜎min/𝜎max)

Endurance Limit

the maximum cyclic stress amplitude (fully reversed loading) the material can withstand and never experience fatigue failure • Not all materials have one • Design to operate under this stress level to ensure durability over time.

S-N Curve

-plot of stress amplitude (S) vs. corresponding number of cycles to failure (N) for a material

-Allows for estimation and design decisions of the number of cycles until component failure at a given loading condition

S-N Curve formula

∆𝜎*(NF)^a = C

increasing the temperature will?

-Decrease strength

-Decrease elastic modulus

-Decrease endurance limit and fatigue strength

-Increase the ductility

What happens to metals at a high temperature?

They become softer more ductile

Lower temperature

Stiffer more brittle

Creep

permanent deformation under a static load that is below the typical 𝜎y if load is maintained for long periods at elevated temperatures

Creep in metal occurs

high-temperature

Creep occurs in polymers at more

moderate temperatures

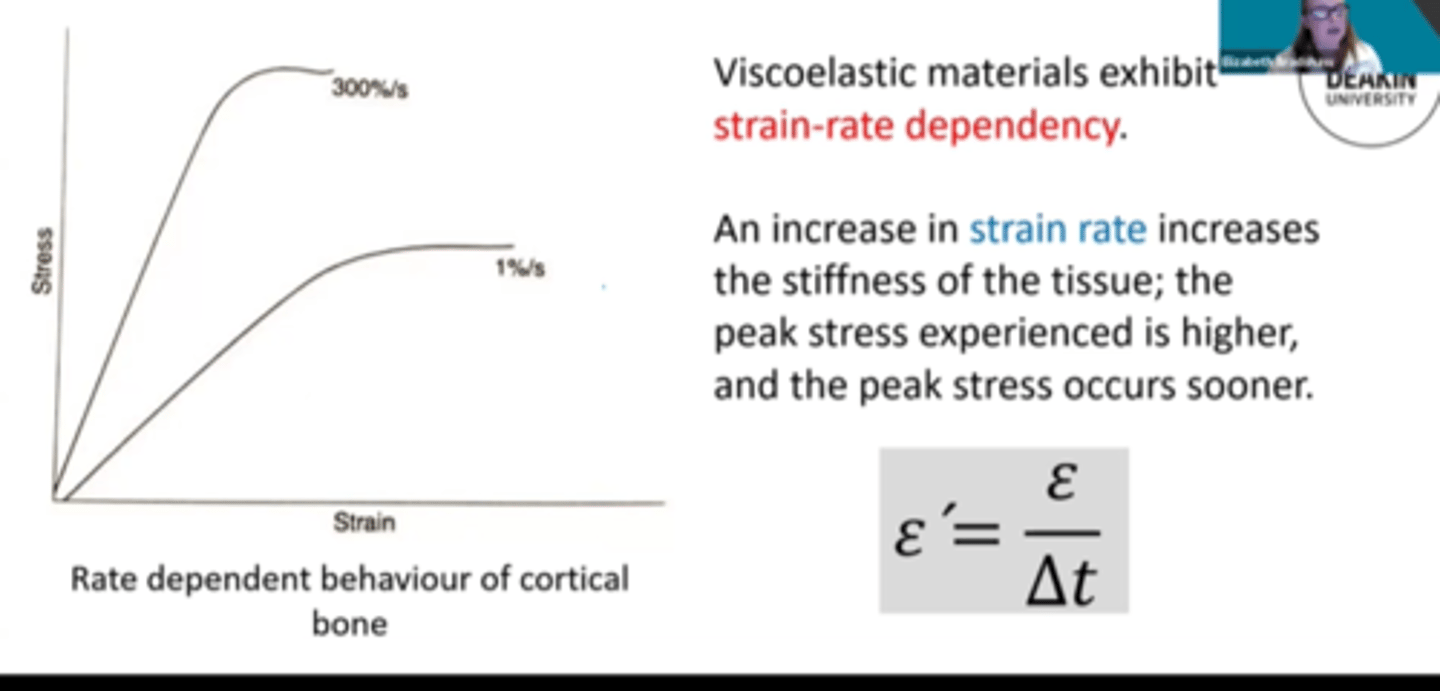

Strain Rate

the amount of deformation induced per unit time

Hertz is a measure of frequency?

not strain per unit time.

Increased strain rate generally causes

-Increase strength

-Decrease ductility

percent elongation

-No effect elastic modulus

Elevated temperatures generally cause

-decreased strength, increased ductility

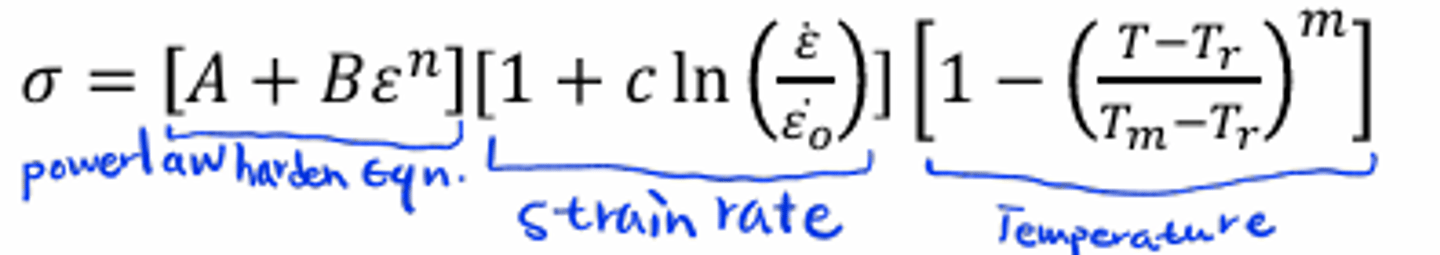

Johnson-cook model?

𝐴,𝐵,𝑛,𝑐,𝑚: constants fitted to material behavior

𝜀: reference strain rate 𝑇𝑟: reference temperature

𝑇𝑚: melting temperature

Ionic bonding

Electrons transferred

Metallic and non-metallic elements

Ionic bonding

Characteristics of this bonding type are,

Moderate to high strength

High hardness

Brittle

high melting point

Low conducive

Covalent bonding

Electrons are shared

non-metal to non-metal

covalent bonding characteristics

High strength

high melting point

brittle

Generally insulate

metalic bonding

Sharing a "sea" of electrons that are loosely held together and can travel through the metal

metallic bonding characteristics

Moderate to high strength

moderate to high melting point

high ductility

conductive

Difference between ceramics and polymers

Crystalline or amorphous arrangement difficult to deform

Polymers stretch and untangle because of the polymer chain

Allotropy

Of an element, having more than one form

carbon : diamond, graphite

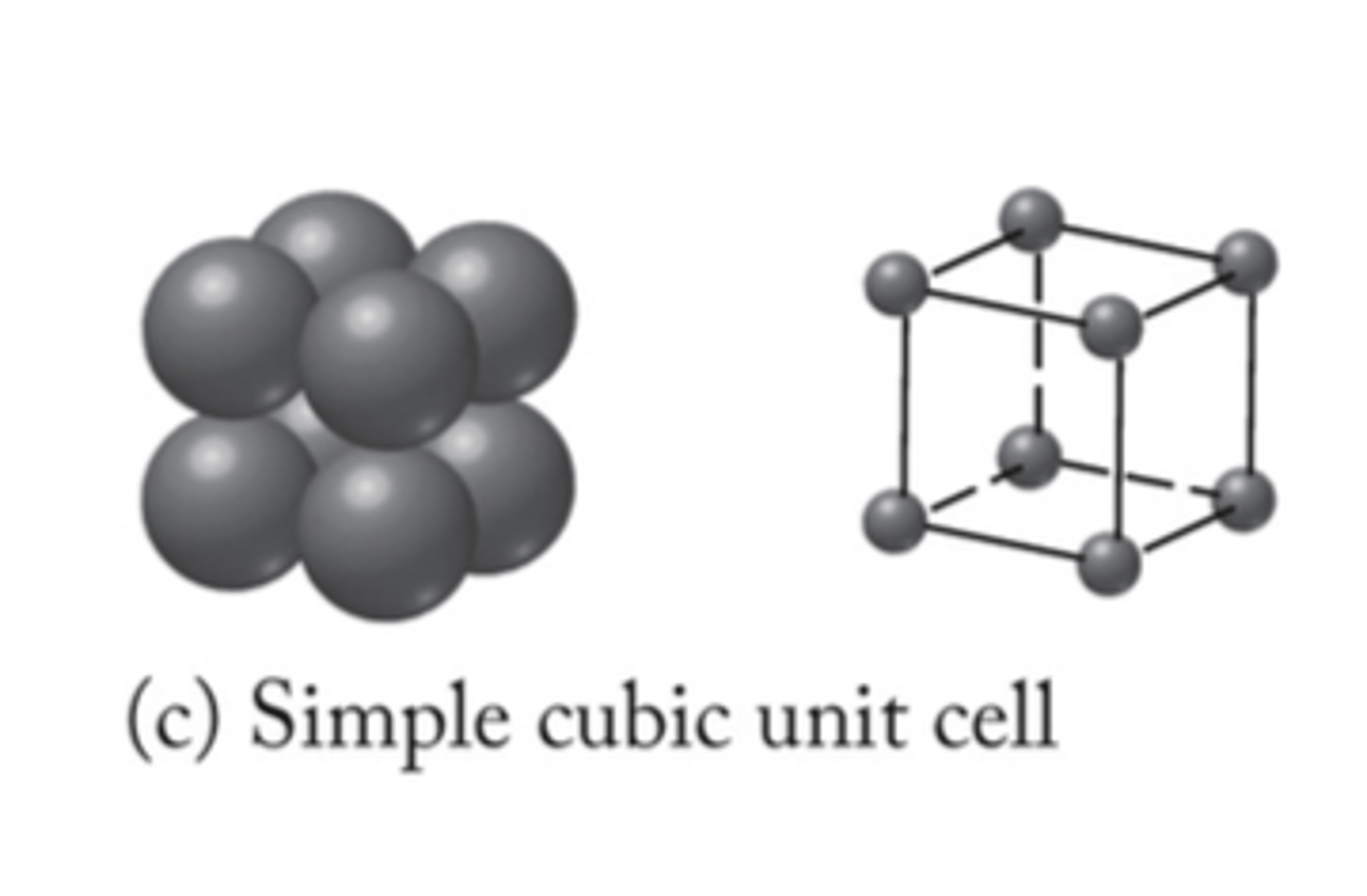

simple cubic unit cell

None in typical metals

lowest packing factor

52%

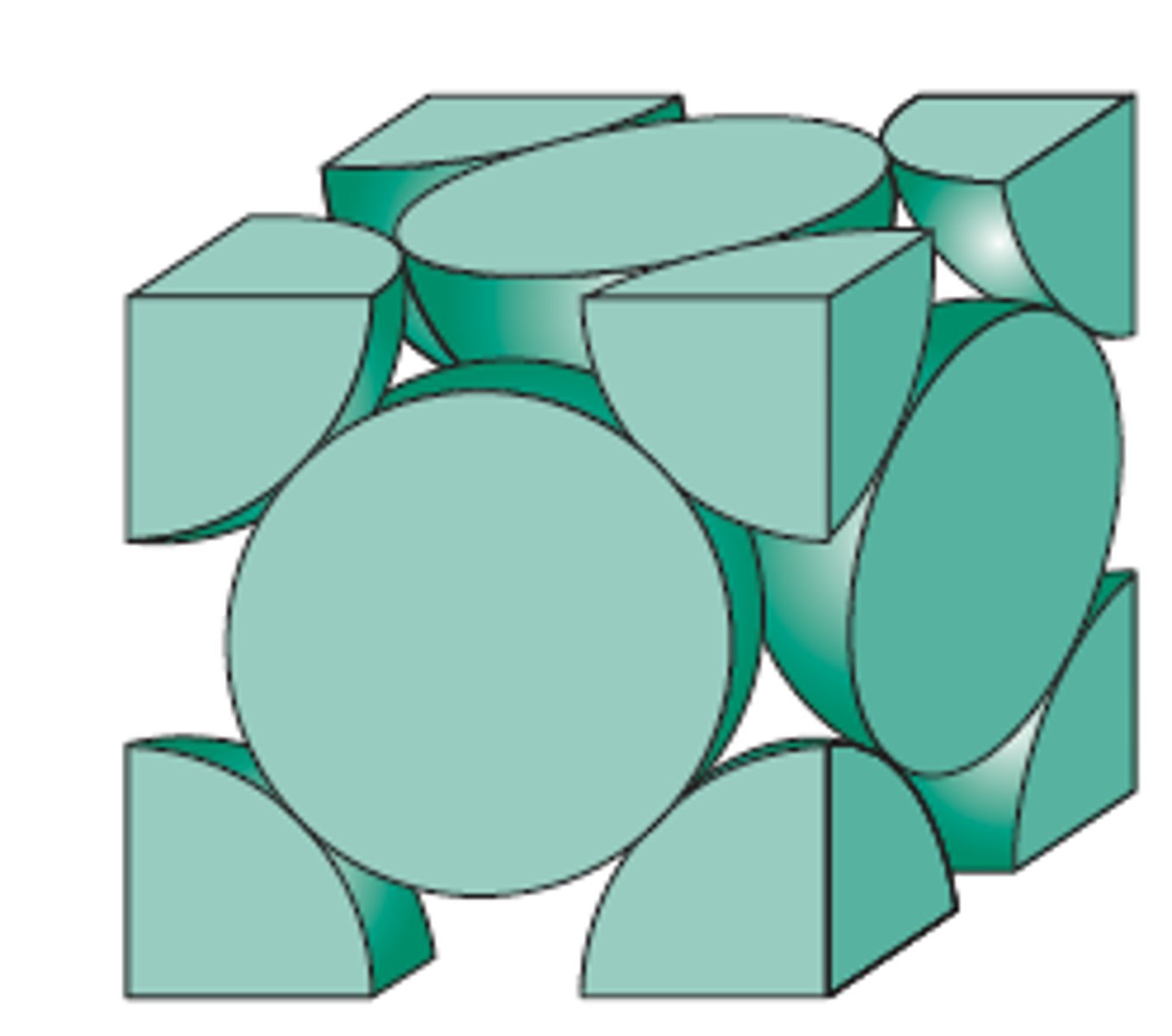

Body Centered Cubic (BCC)

Fe, Cr, Mn, W, Nb, V

68% packing factor

Face Centered Cubic (FCC)

Fe, Al, Cu, NI, Au

74% par=cking factor

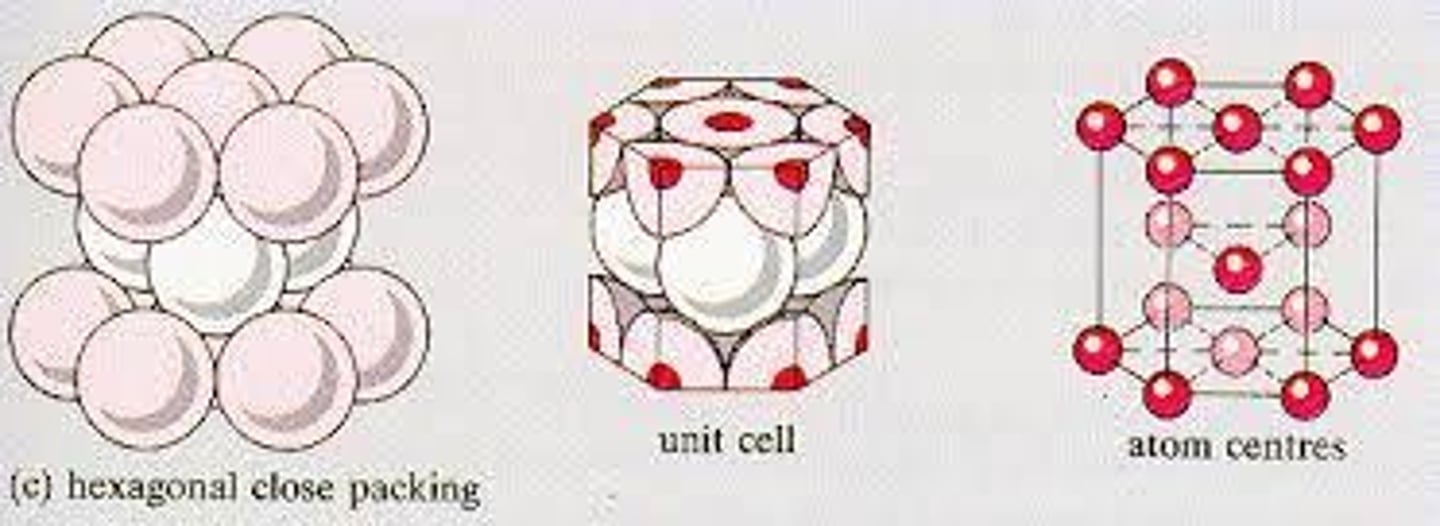

hexagonal close-packed (HCP)

Ti, Mg, An, Ar

74% packing factor

Single Crystals

crystalline materials consisting of a single crystal

only possible in small scale

Polycrystalline materials:

Have many grains, separated by grain boundaries

most material

Grain Nucleation

Particle form as metal cools

Grain Growth

More particles attach to the initial one, different orientations

As grains grow large enough, they encounter other _________ which obstructs the__________ growth

grain,

Upon complete solidification, grains with___________formed

irregular shapes and multiple orientations

grain boundaries

Surfaces that divide the grains and form boundaries between them

Defects in Crystal Structure

Grain boundaries

Point defects

dislocations

intrinsic defects

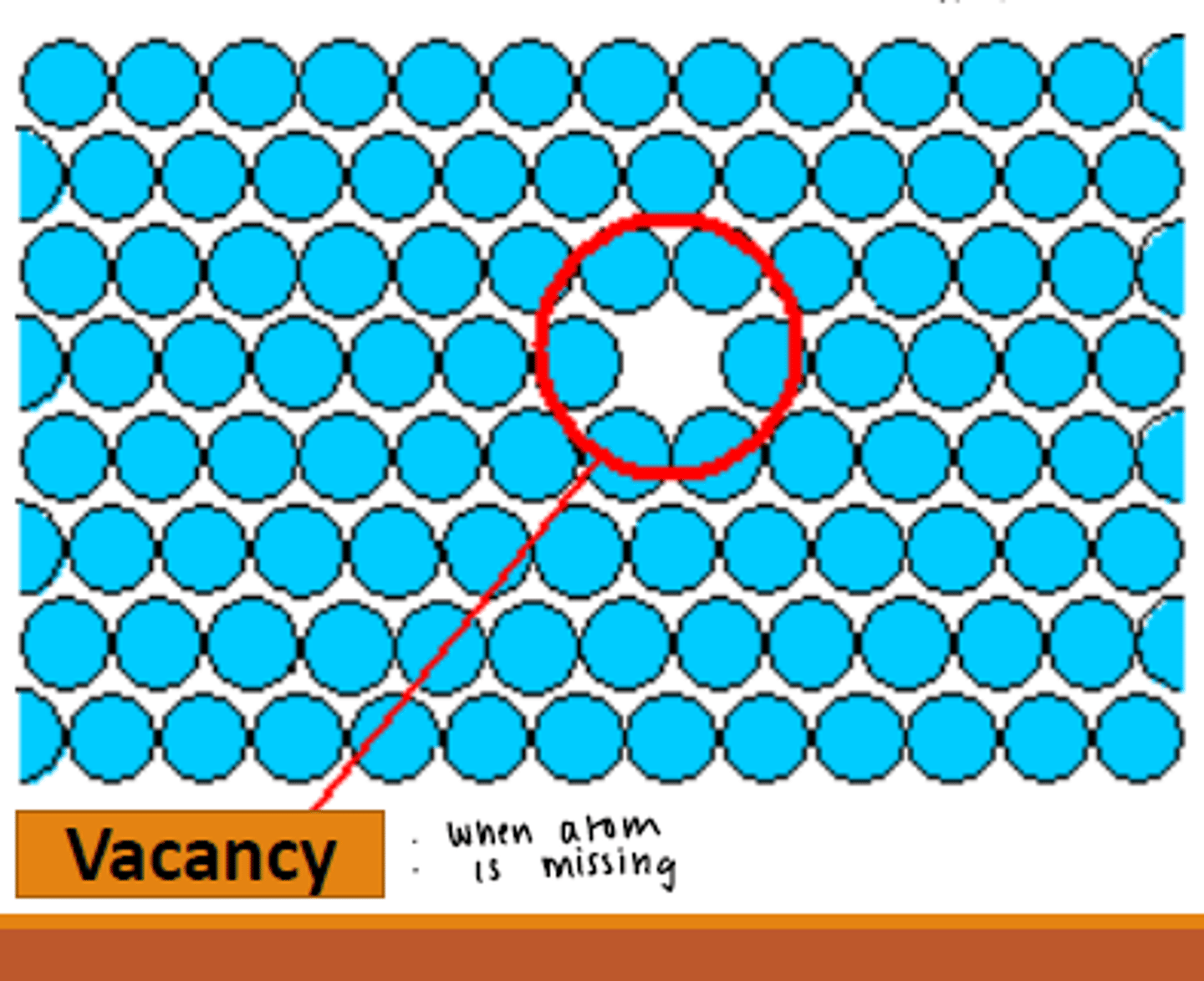

Vacancy atoms

interstitial atoms

vacancy

Suppose be an atom there but no

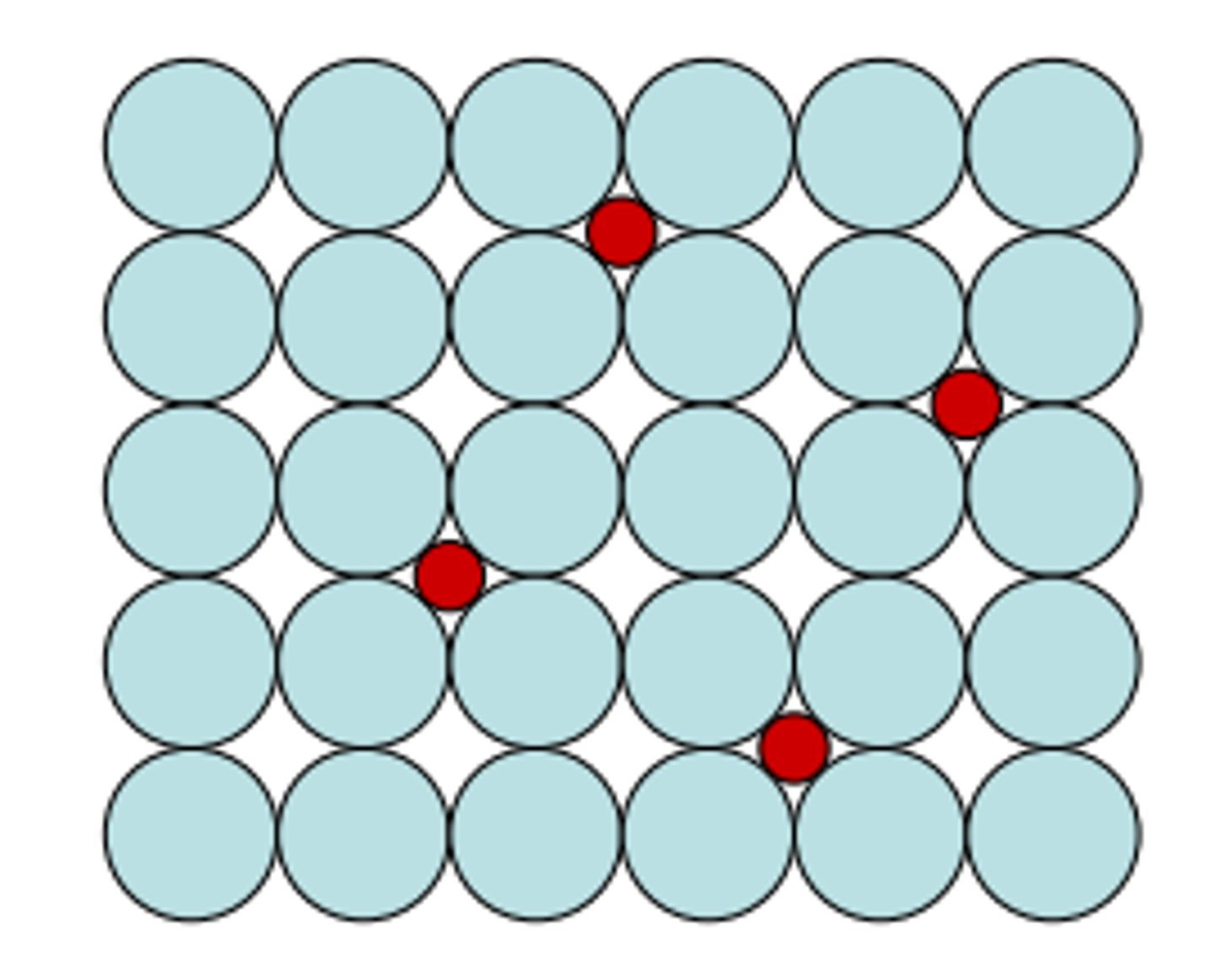

Interstitial atom

extra atom in the lattice

Solutes atoms

Intentionally added

Solid Solution Strengthening

Adding atom to make metal strong

Impurities

Unintentionally have

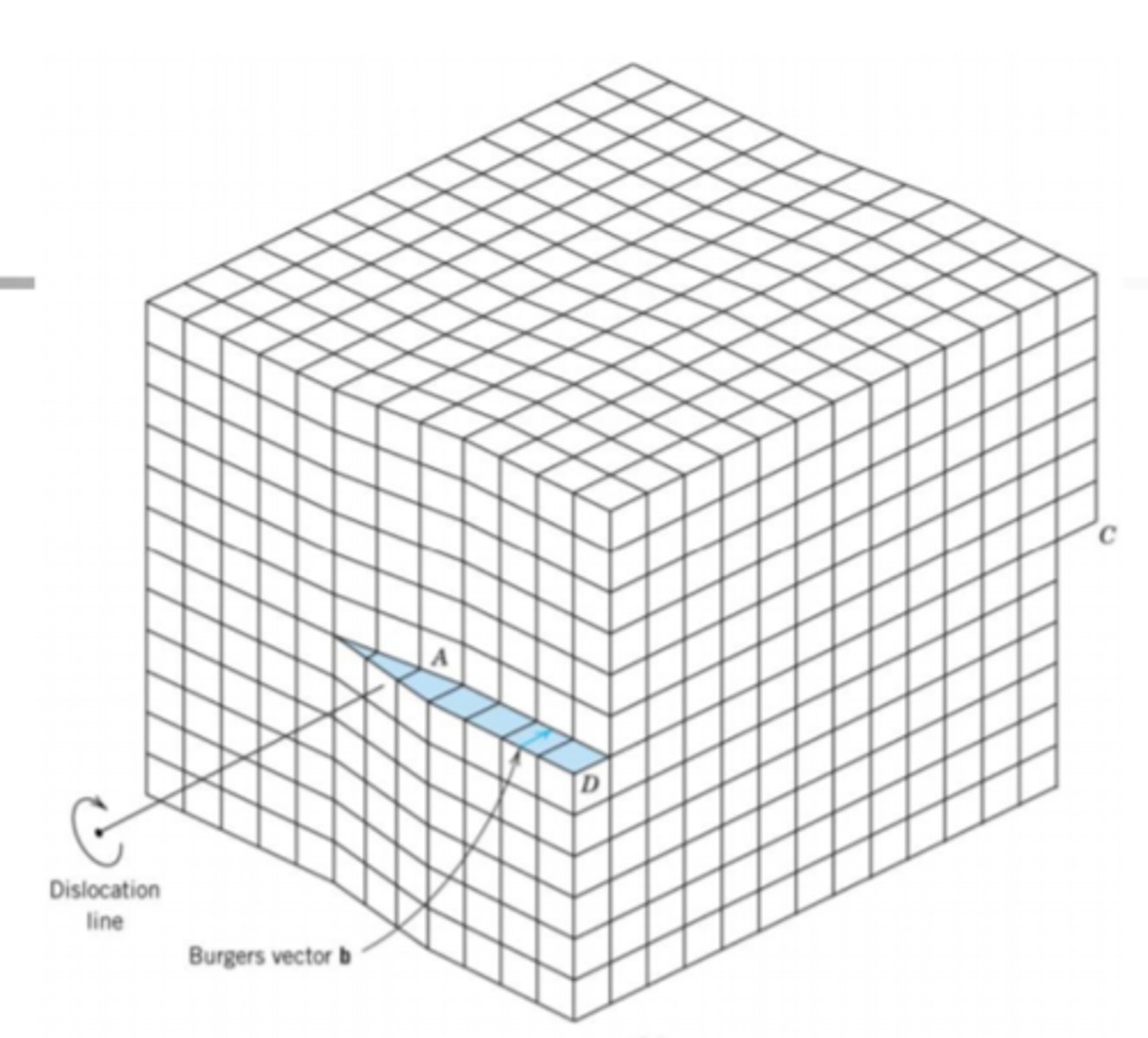

Dislocations

Half of row of atoms are missing

Dislocations effects on materials

Make metals weaker

Increase ductility

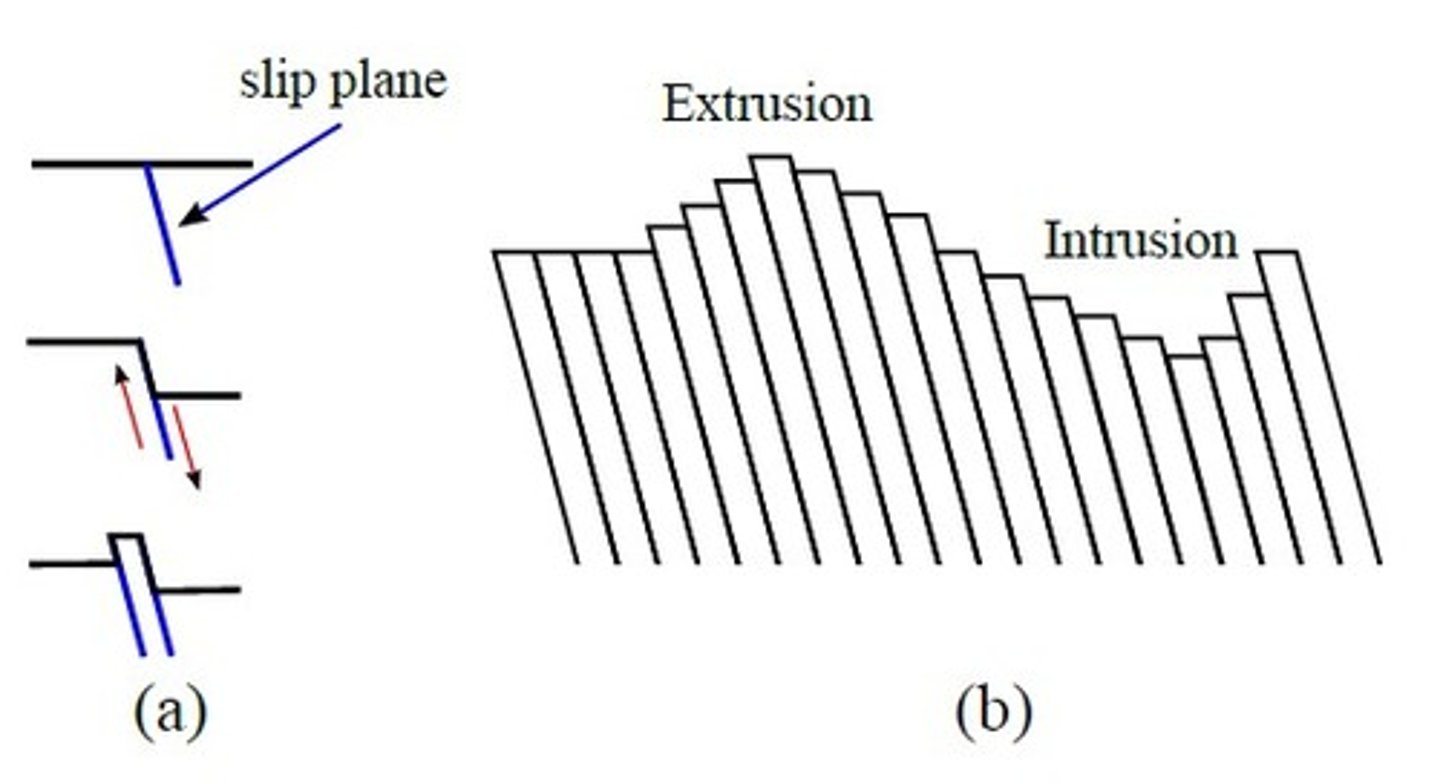

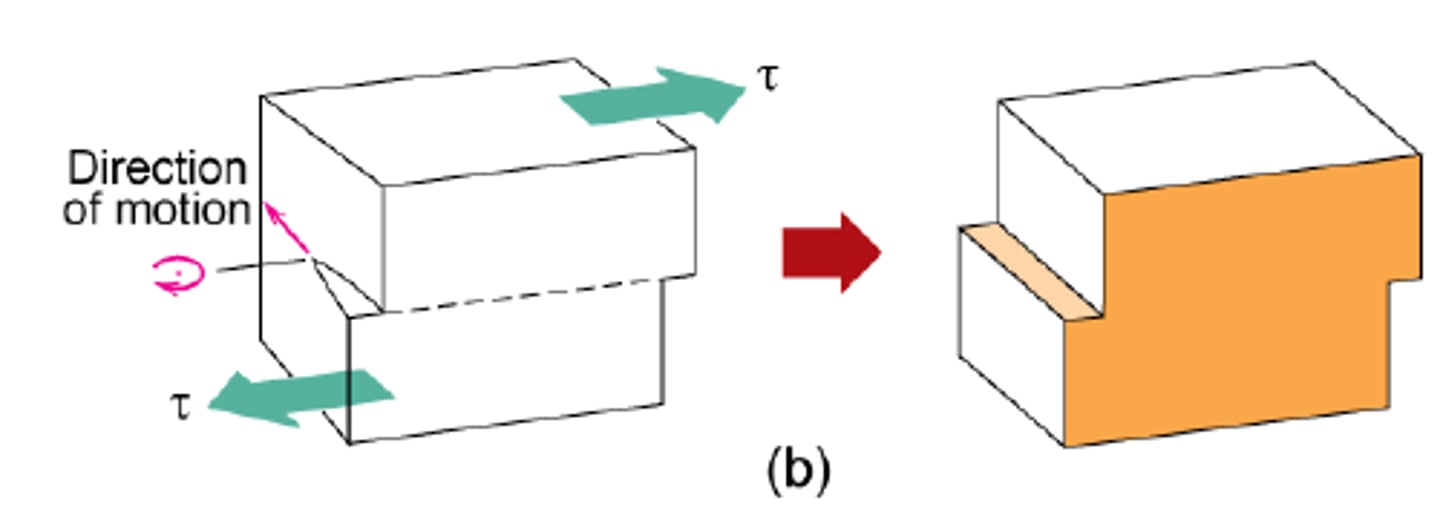

Slip

dislocations move under stress

plastic deformation

Slip direction

direction of dislocation movement

most densely packed line with atoms

Slip plane

plane which dislocation motion occurs

most densely packed plane with atoms

slip systems

the possible ways a dislocation can move

combination of slip plane and slip direction

Dislocation motion and slip

controls the plastic deformation of crystalline solids

Slip bands

slip occur in slip systems makes bands

Edge dislocation

line moves parallel to the allied shear direction

Screw dislocation

perpendicular to the applied shear direction

Dislocations in Metals

easy breaking/re-forming of bonds to move dislocation

easy to deform and have high ductility

Dislocations in ceramics

do not allow easy dislocation movement

brittle hard