Robotics

1/31

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced |

|---|

No study sessions yet.

32 Terms

Why robots

reduced production cost, increased productivity, improved product quality

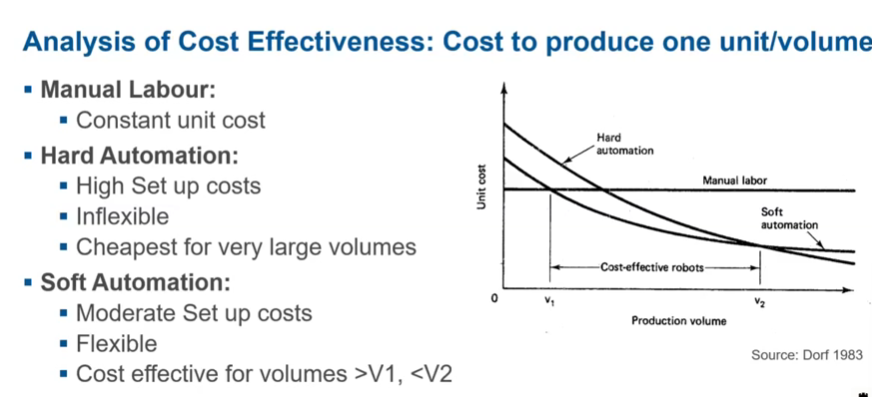

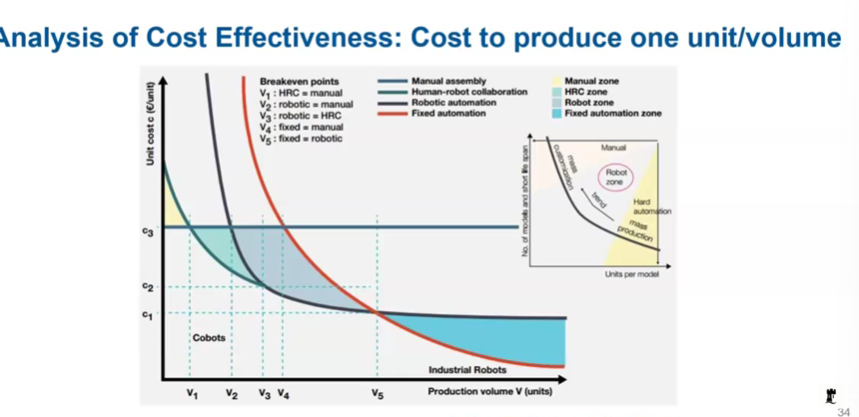

Manual labour/Hard/Soft Automation - cost effectivenes

Hard automation - automated to do one thing no intelligence, soft automation robot flexible can be reprogrammed.

Up to a point, manual labour cheapest, then soft automation, then hard automation. (As production volume increases)

Manual labour + soft automation = collaborative robots

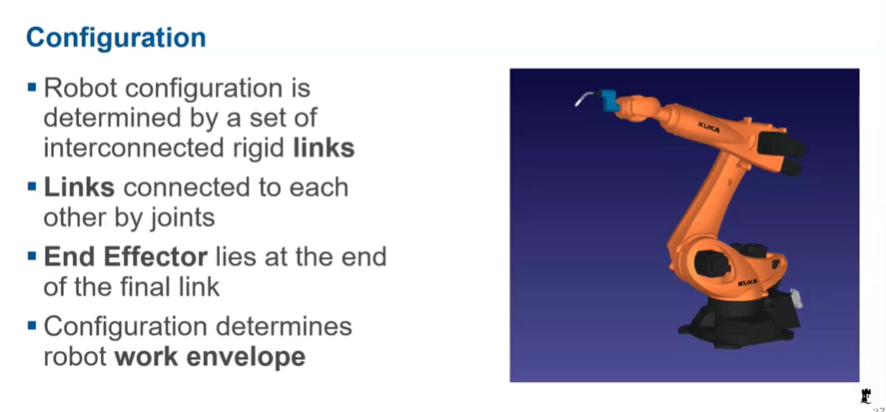

Main components and structure of industrial robot - links, actuators, joints, arm/manipulators, wrist, end effector

Arm/manipulator is everything from base to wrist.

Each joint has actuator.

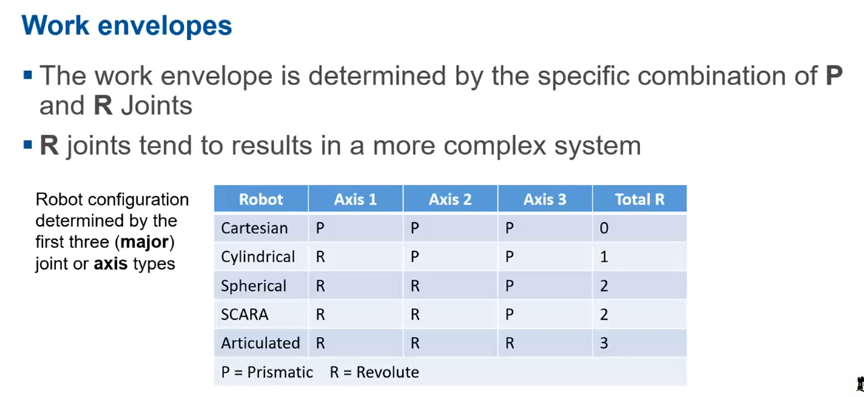

Work envelope - everywhere the robot can reach.

Configuration

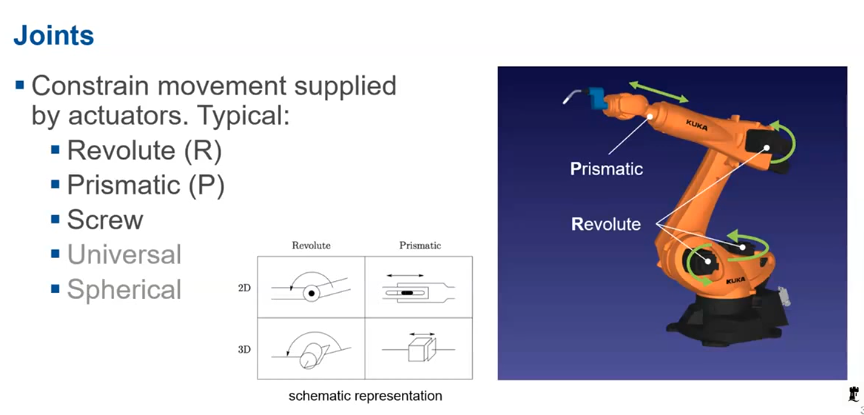

Types of joints - revolute and prismatic

revolute, prismatic, screw, universal, spherical

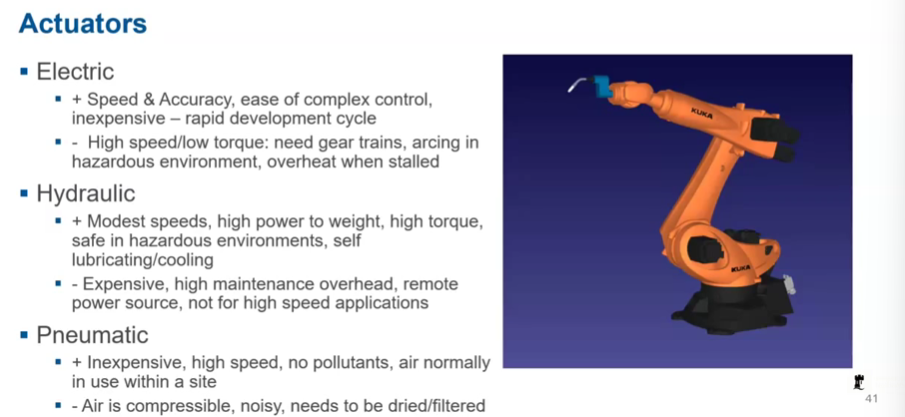

Actuators/ pros and cons of energy sources for actuators

End effectors

tool connected to the final link, connected by wrist joint

Sensor systems

Motion control method

point to point

continuous path

Work envelope is determined by configuration

robot specification

capacity and speed - how much you want to lift, how quickly you want to move it

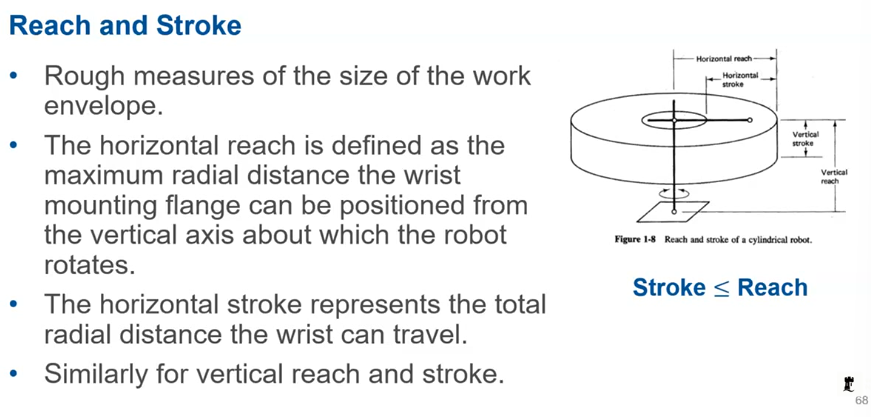

reach and stroke - how far robot has to reach

tool orientation - does the wrist need to be fully flexible or can it fixed in some way

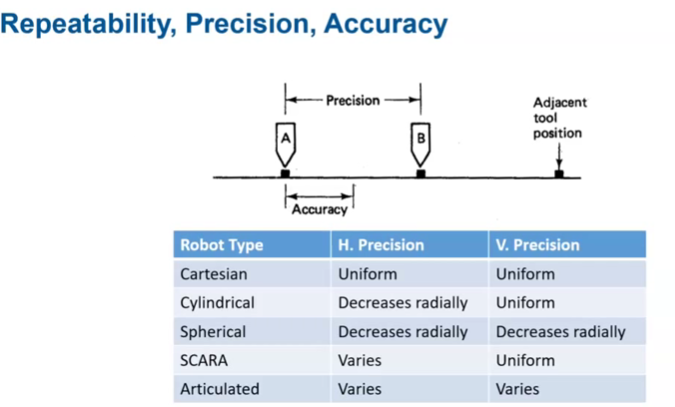

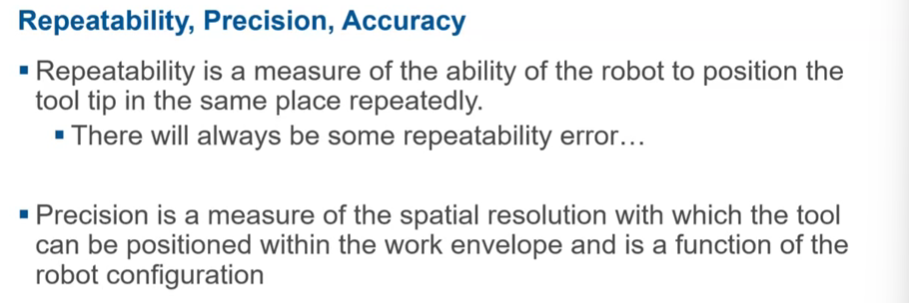

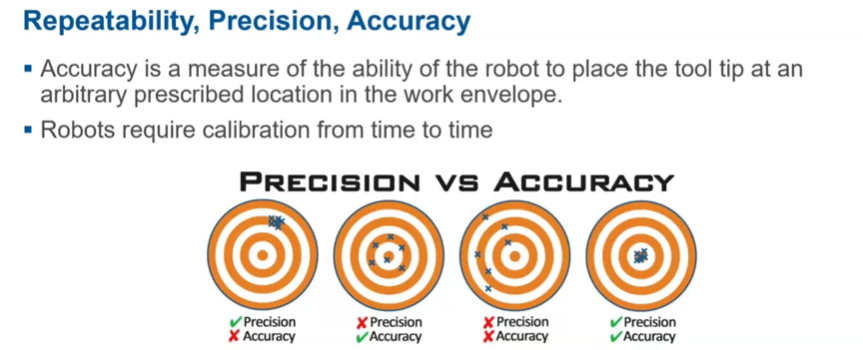

repeatability, precision, accuracy

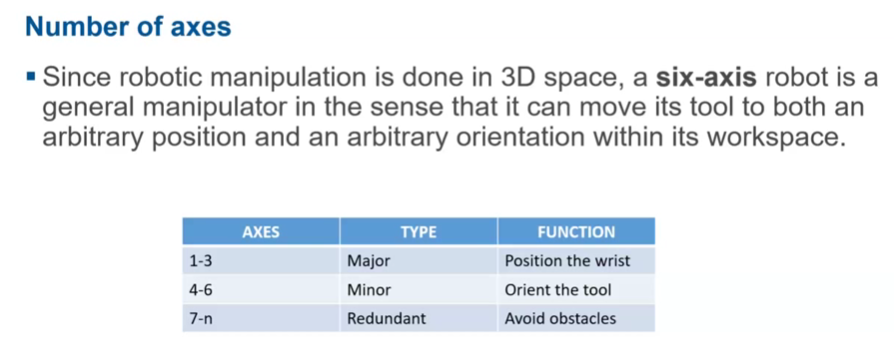

Number of axis-major/minor

major axis position the wrist, the next 3 orient the tool. Additional joints are introduced to move around obstacles

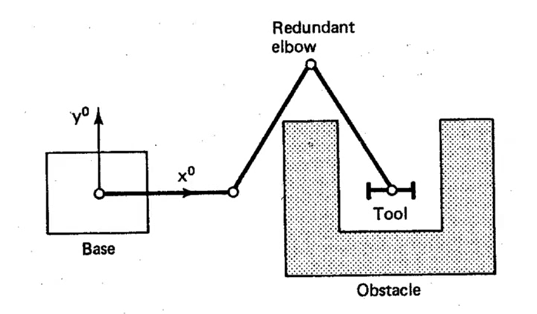

Redundant joint example

Used to move around obstacle

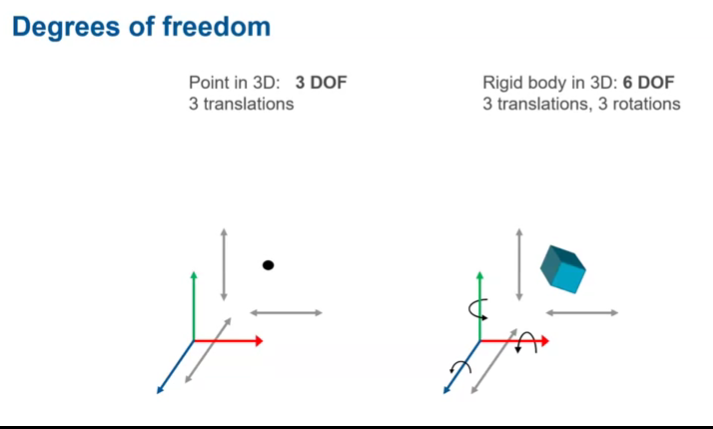

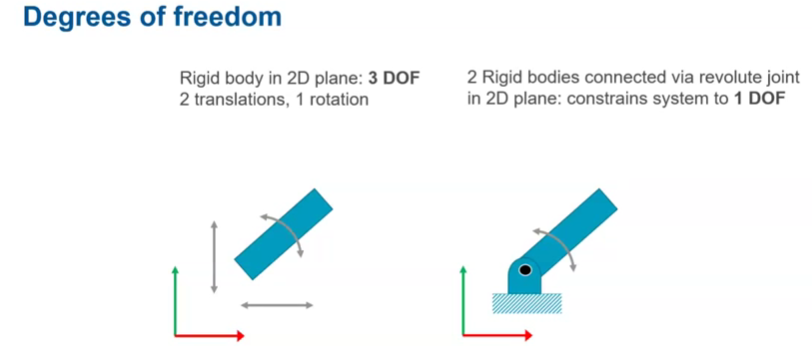

degrees of freedom

3 translation to position the end effector:

up/down, back/forward, left/right

3 rotational to

yaw - vertical axis

pitch - back and forward

roll - horizontal

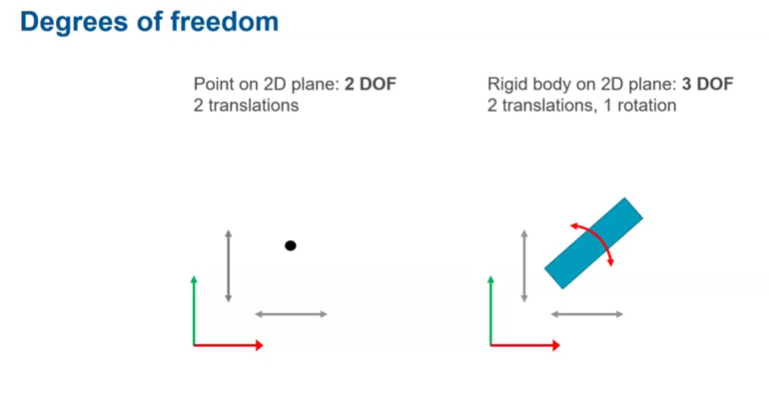

Degrees of freedom example: 2D space

Degrees of freedom example: 3D space

DOF - robots

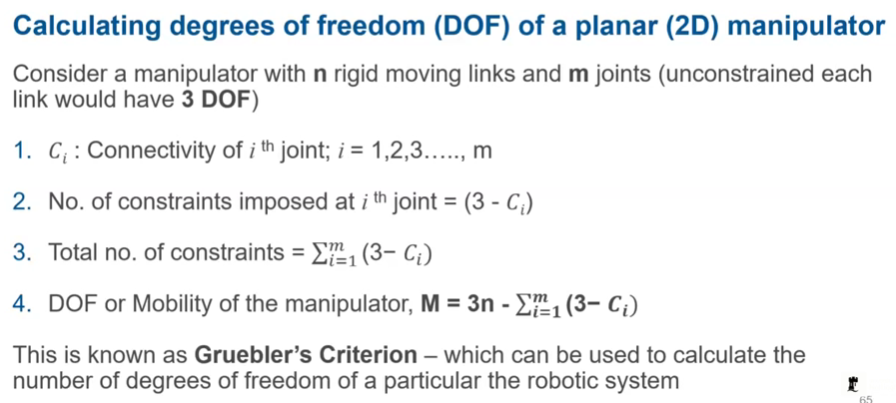

Calculating DOF -2D

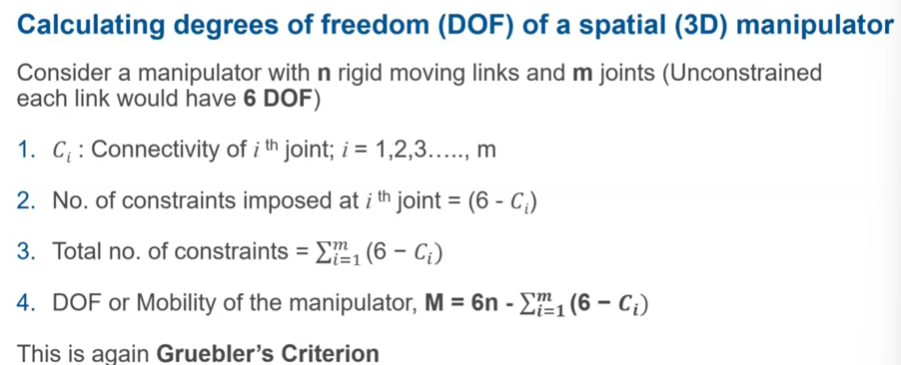

Calculating DOF -3D

Reach and stroke

horizontal/vertical

reach - maximum distance the end effector can be positioned from the vertical axis it rotates about

stroke - the total radial distance it can travel

Reapeatability, precision, accuracy

horizonal precision decreases when the radius is bigger (for rotary joint)

More on the precision/accuracy

robots need calibration from time to time

Capacity and speed

Motivation for coordination transformations

Find the formula that relates tool coordinates to the base coordinates

2D geometry

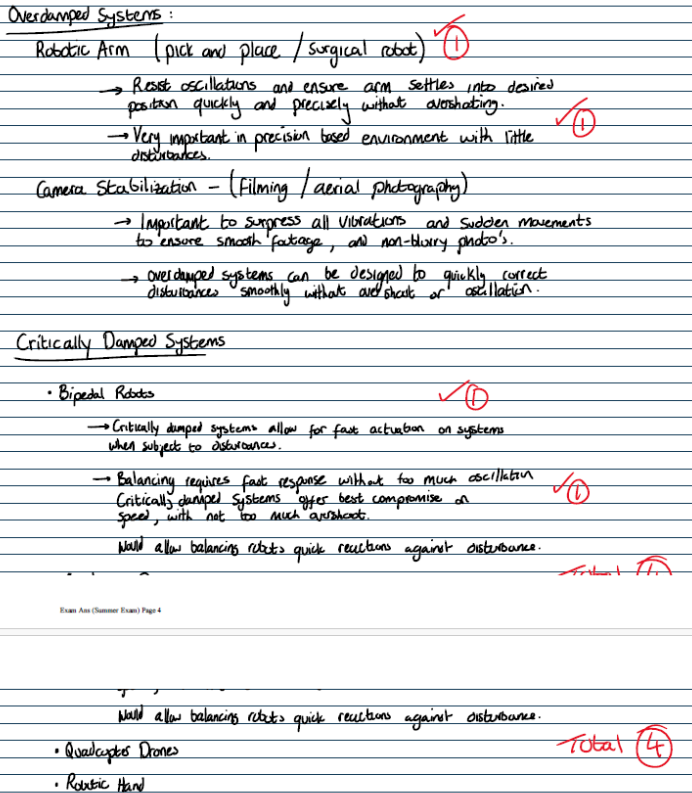

over damped and critically damped systems

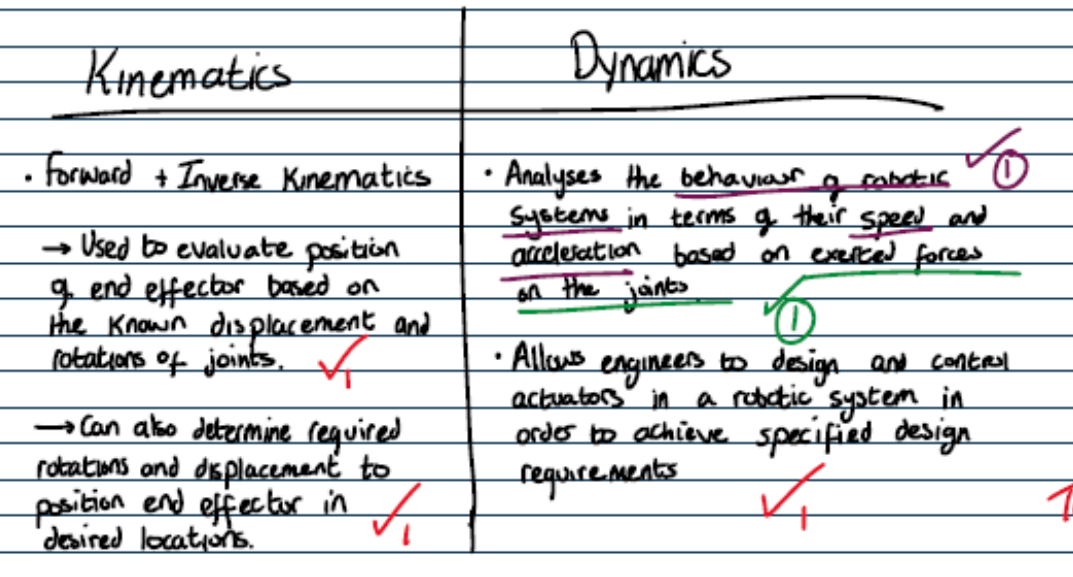

kinematics vs dynamics

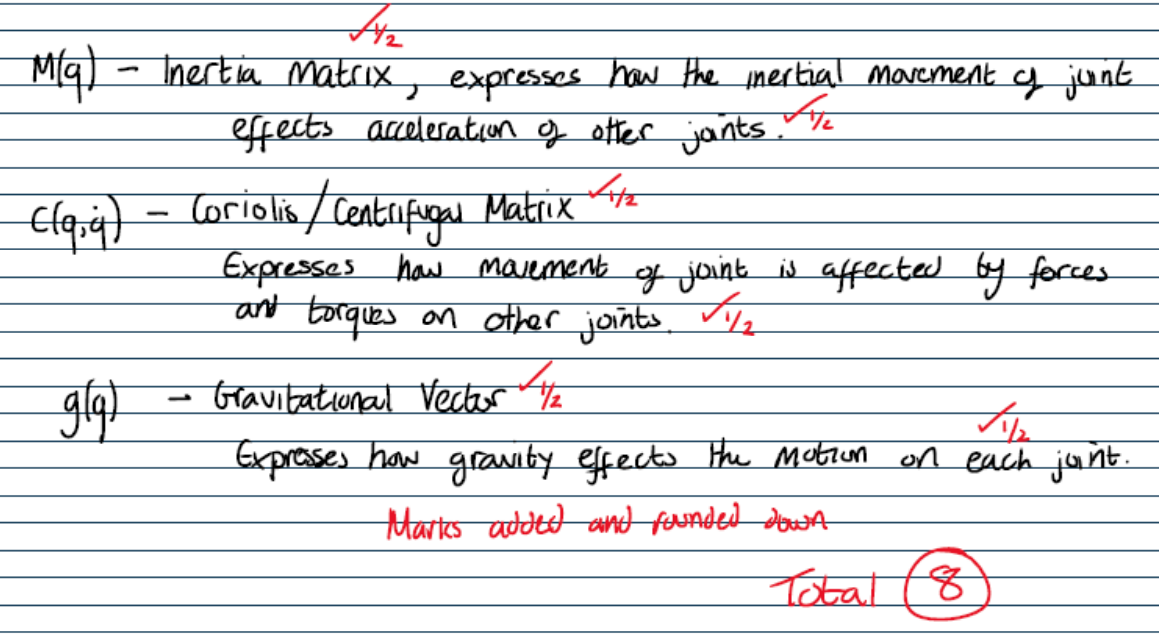

robot dynamic equation

scara robot