Introduction to Interior Design and Textiles

1/417

There's no tags or description

Looks like no tags are added yet.

Name | Mastery | Learn | Test | Matching | Spaced | Call with Kai |

|---|

No analytics yet

Send a link to your students to track their progress

418 Terms

Interior Design

Integration of the basic requirements for an efficient and aesthetically pleasing space.

Function and the human factor

Refers to the individual and group requirements in a space.

Aesthetics

The form and style of a space.

Economics

The cost and ecological considerations in design.

Image and character

The overall impression and identity of a space.

Interior spaces

Defined by architectural elements of structure and enclosure such as columns, walls, floors, and roofs.

Interior designer's palette

The design elements and choices that affect the function and expressive qualities of a space.

Soft furnishings

Resilient furnishings that include textiles, fabrics, and window treatments.

Hard furnishings

Non-resilient furnishings such as floors, walls, hardware, and lighting fixtures.

Textiles

An overall term used to describe a fiber, yarn, or fabric.

Fibers

Raw materials, either natural or synthetic, that produce yarns and fabrics.

Yarns

Fibers that are twisted or assembled together to form strands used for fabric construction.

Fabrics

Results from the weaving, knitting, twisting, felting, or lacing of fibers and yarns.

Natural fibers

Fibers that come from nature, classified into protein and cellulose fibers.

Protein fibers

Animal fibers such as wool and silk.

Wool

The fleece of sheep, known for its resilience, flame retardance, and ability to absorb moisture.

Silk

An ancient fiber produced from the larvae of silkworms, known for its luxurious texture.

Durability

The ability of materials to withstand wear, pressure, or damage.

Safety

Considerations to ensure the well-being of individuals in a space.

Acoustics

The properties or qualities of a room that determine how sound is transmitted.

Quality

The standard of something as measured against other things of a similar kind.

Cost

The amount that needs to be paid or spent to acquire a space or materials.

Ecology

The relationship of living organisms to one another and their physical environment.

Advantages of fiber

Beautiful, long fiber that is soft and luxurious, surpassed only in strength by nylon.

Disadvantages of fiber

The sun's rays break down the fiber, requiring it to be protected from direct sunlight; susceptible to deterioration by soil and moisture; also expensive.

Cellulose fibers

Fibers derived from stems, leaves, and seed hairs found in plants, with cotton and linen as the two most common.

Cotton

Believed to have been grown in India during the 4th century BCE; the most plentiful of the natural fibers.

Advantages of cotton

Takes and holds color well, washes easily, and can be woven to produce sheer or heavyweight fabrics.

Disadvantages of cotton

Not as durable as other fabrics, wrinkles, mildews, and fades.

Linen

Made from flax fibers; the most ancient of all fibers, used for weaving in Egypt as early as 4000 BCE.

Advantages of linen

Strong, pliable, lustrous, washable, and takes and holds color; also absorbent.

Disadvantages of linen

Wrinkles unless chemically treated, which reduces its wear potential; fades; stiff; and difficult to clean.

Mineral and metallic fibers

Created from naturally occurring minerals, including metals; metallic fibers include strips of gold, silver, or copper used chiefly as accents in decorative fabrics.

Advantages of metallic fibers

Glitter without tarnishing and are washable.

Manufactured fibers

Derived from synthetic chemicals or natural solutions chemically treated, designed to improve the quality, durability, and ease of care of natural fibers.

Cost of manufactured fibers

Tend to be less expensive than those made from natural fabrics.

Production of manufactured fibers

Made by creating a liquid or viscose out of the substance, then running the liquid through holes in a device called spinneret.

Regenerated cellulose fibers

Produced by altering the physical and chemical properties of cellulose; examples include rayon, acetate, and triacetate.

Synthetic fibers

Produced from chemical compounds such as acrylic, modacrylic, polyester, olefin, and glass.

Origin of the loom

Evidence suggests it was used in Mesopotamia before 5000 BCE.

Jacquard loom

Invented in France in 1801 by Joseph-Marie Jacquard, it can create multicolored fabrics with intricate patterns.

Woven textiles

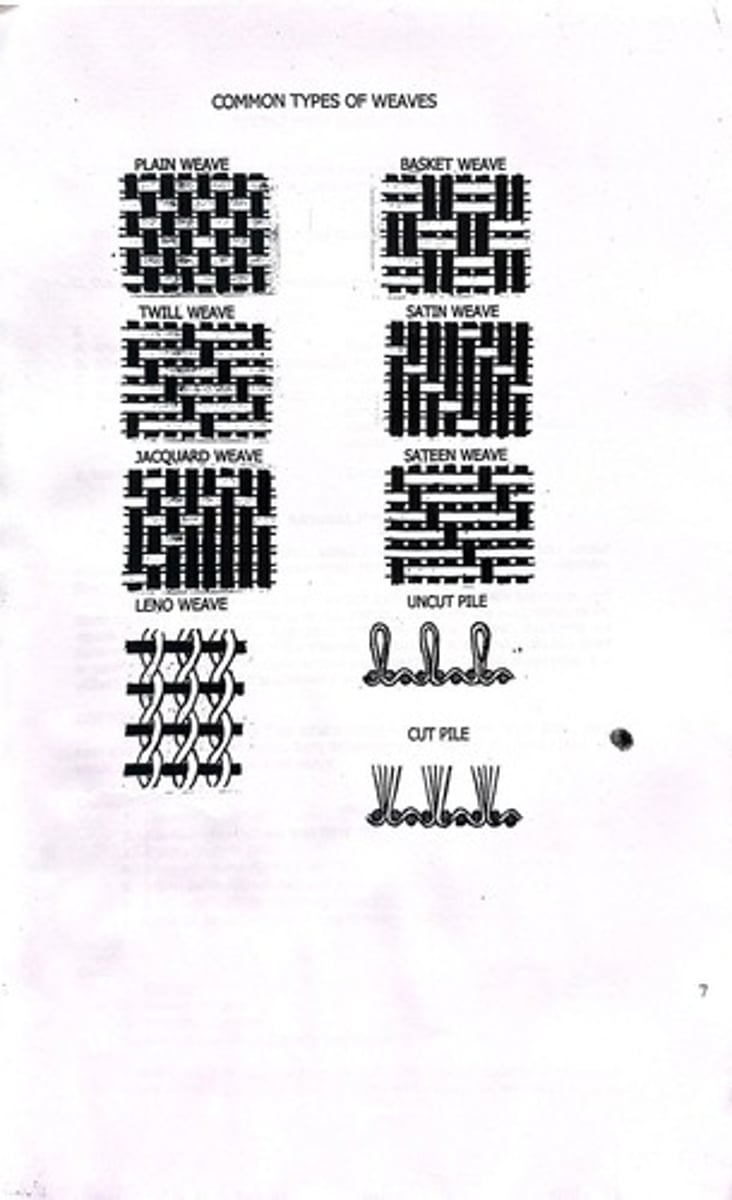

The most common weaves used in producing decorative fabrics.

Plain or tabby weave

Made by interweaving the warp (vertical) and weft (horizontal) threads; may be single or double, regular or irregular.

Plain single weave

One weft thread passes over each warp thread; when balanced in sequence of over and under, it is called regular.

Plain regular weave

Also called a tabby weave; when warp and weft differ due to different weights or textures, it is called irregular or unbalanced.

Plain double or basket weave

Two weft threads are interlaced into the warp threads; may be irregular due to variations of weight or textures.

Twill weaves

Weaves in which two or more threads pass over or under another set of threads, skipping at regular intervals to produce a diagonal effect.

Regular twill

A type of twill where the long threads, or floats, pass over or under the same number of yarns.

Irregular twill

A type of twill where the floats pass over and under a different number of threads, often used in decorative fabrics such as denim, gabardine, and herringbone.

Satin weave

A weave with a few interlacings and long floats, producing a fabric with luster, softness, and drapability, such as satin and sateen.

Jacquard weave

A weave that requires an intricate series of hole-punched cards to tell the machine which threads to drop, resulting in fabrics like damask, tapestries, and brocade.

Pile weaves

Weaves produced by loops of tufts of yarn that stand out from the surface of the fabric, which may be cut, uncut, or a combination of both.

Raised warp-pile

The basic weave of the carpet industry, originally used for plush and velvet fabrics, now often made in a double-cloth method.

Double-cloth weaves

Fabrics woven in two attached layers, often resulting in a quilted appearance, known to be durable and beautiful.

Leno weave

A loose, lacelike weave where the warp threads are wound in half twists around each other, alternating positions on each row.

Gauze weave

A weave similar to leno, but where the warp threads maintain the same position in relation to the weft.

Tension and texture-treated weaves

Weaves where uneven tension in either weft or warp yarns produces an uneven surface effect, accomplished through various methods.

Brocatelle

An example of a fabric produced using tension and texture-treated weaves.

Combination weaves

Fabrics produced by combining two or more weaves, often reflected in the name of the fabric, such as brocaded-satin and voided-velvets.

Knitting

A process of interlocking a series of yarn loops by means of blunt needles, forming patterns through variations of stitches.

Knitted fabrics

Fabrics that range from loose, open construction to a close, fine mesh, used for home furnishing needs due to their wrinkle resistance and ease of care.

Mesh construction

Types of construction such as nets, laces, and macramé, resulting from twisting, interlocking, and knotting of yarns.

Felting

A process of subjecting a mass of fibers to moisture, heat, and pressure to produce a compact sheet that does not fray and provides insulation.

Bonded fabric

A fabric that results when two fabrics are adhered together chemically or with heat.

Natural Cellulosic Fibers

Fibers derived from plant sources such as cotton, flax, ramie, and jute.

Natural Protein Fibers

Fibers derived from animal sources such as wool and silk.

Natural Mineral Fiber

Fibers derived from mineral sources, specifically asbestos.

Man-Made Fibers

Fibers that are manufactured through chemical processes.

Man-Made Cellulosic Fiber

Fibers made from regenerated cellulose, such as rayon.

Man-Made Modified Cellulosic

Fibers such as acetate that are chemically modified from natural cellulose.

Man-Made Protein Fiber

Fibers such as azlon that are derived from protein sources.

Man-Made Synthesized Fibers

Fibers such as nylon, polyester, and acrylic that are created from synthetic processes.

Man-Made Mineral Fibers

Fibers such as glass and metallic fibers that are manufactured from mineral sources.

Flax

A bast fiber obtained from the stalk of the flax plant, which grows up to one and a half meters.

Ramie

A fiber from the stalk of a stingless plant belonging to the nettle family, known for its strength and durability.

Characteristics of Cotton

Cotton is absorbent, stronger when wet, can withstand heat, has strong resistance to alkalis, is inelastic, wrinkles easily, and can be damaged by moth and mildew.

Uses of Cotton

Used in clothing, home furnishing, industrial purposes, and medical supplies such as gauze and bandages.

Characteristics of Flax

Flax is lustrous, absorbent, stronger when wet, inelastic, creases easily, and does not lint.

Uses of Flax

Used in wearing apparel, household linens, kitchen towels, upholstery, thread, and handkerchiefs.

Characteristics of Ramie

Ramie is the strongest and most durable natural fiber, absorbs moisture readily, dries rapidly, is stiff, and wrinkles easily.

Pina

Pina fibers are obtained from the leaves of the edible pineapple plant. The production of the fiber and the weaving of the pina cloth are both done in the Western Visayan province as Cruz, Aklan and Ilo-ilo.

Characteristics of Pina

Pina is very fine and durable.

Abaca

Abaca is also known as 'Manila Hemp' in the commercial world and strictly a Philippine product. The fiber is derived from the stalk of the abaca plant, which looks like a banana plant.

Methods of extracting Abaca fibers

The fibers are separated from the stalks in any of these three methods: hand stripping, decortication, and machine stripping.

Characteristics of Abaca

Abaca is light, strong, durable, has high abrasion resistance, is very washable, and will not be harmed by exposure to sun and rain.

Uses of Abaca

Cordage, ropes and twine, clothing, sinamay and pinukpok fabrics, hats, hammocks, pulp for high grade paper, and non-woven fabric.

Jute

Jute fibers are derived from the stems of a plant called saluyot in the Philippines. The jute fibers are extracted from the stem from retting or machine decortication.

Characteristics of Jute

Jute tends to disintegrate in water and has poor elasticity.

Uses of Jute

Sacks and bags, carpet backings, home furnishing, rope and twine, tape reinforcement, electrical insulator, and decorative fabric.

Kenaf

Kenaf fibers come from the stem of a plant belonging to the Gumamela family. The kenaf plant has been found to thrive well in Mindanao.

Characteristics of Kenaf

Kenaf fibers are strong and inelastic.

Uses of Kenaf

Burlap and other coarser textiles, twine, carpet backing, fishing nets, stuffing material for pillows and mattresses, and paper manufacture for its pulp content.

Maguey

Maguey is a fiber derived from a plant Agave cantala that is raised chiefly in the Philippines particularly in the coastline of Bohol, Cebu, Pangasinan and the Ilocos region.

Extraction of Maguey fibers

Maguey fibers are extracted from the leaves of the plant by retting in streams or rivers along the seashore or machine decorticated.

Maguey Fibers

Fibers that are yellowish white to brownish white, fine, soft, and strong, used in the manufacture of rugs, carpets, sacks, ropes, and paper.

Sisal Fibers

Fibers obtained from the Agave sisalana plant, grown in Mexico and cultivated in Africa, Java, and some areas of Central and South America, used in mats, rugs, carpets, rough totes, bags, ropes, cordage, and native style hats.

Saguran

A native textile made from the leaves of the talipot palm (Corypha umbraculifera), used specially for packing.

Buntal

Fibers derived from the stout petioles of the buri palm (Corypha elata), used for the manufacture of hats, cigarette cases, glass covers, and baskets.

Kapok Fibers

Seed fibers known as 'silk cotton', light and buoyant, used for stuffing cushions, pillows, mattresses, life belts, and surgical dressing.

Coir Fibers

Fibers obtained from the husk of coconut, coarse, uneven, and straggly, used for life belts, buoys, stuffing materials, and upholstery.